19 20

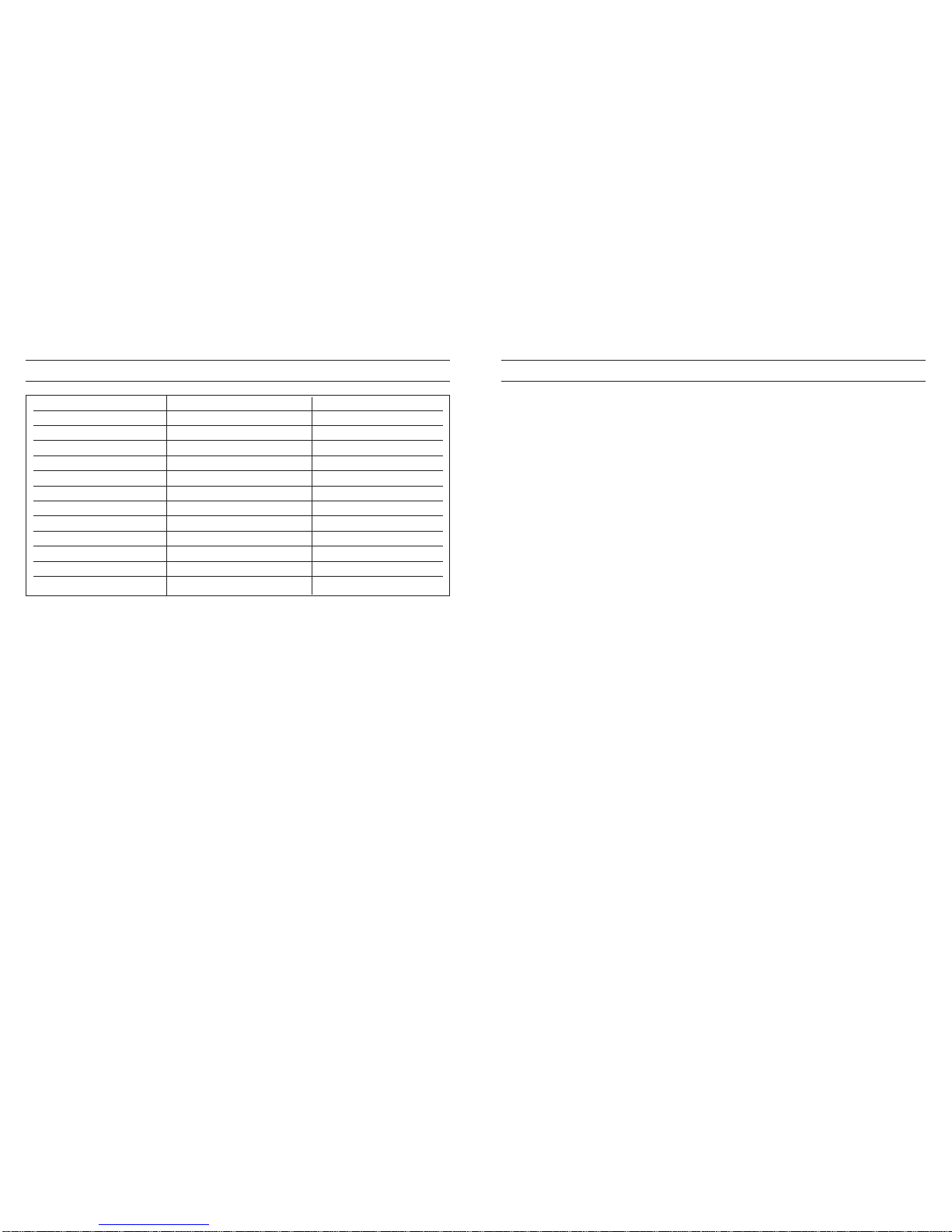

Model BASIC 1600-35 EXTRA 1800-40

Motor 230 V, 1600 watt 230 V, 1800 watt

No Load Speed 6.000 - 7.000 / min 6.000 - 7.000 / min

Oil Capacity 200 ml 200 ml

Cutting Speed 12 m/sec 12 m/sec

Net Weight 4,3 kg 4,4 kg

Cutting Length 14”/35cm 16”/40cm

Barking Time 0.1s 0.1s

Vibration < 12.1 m/s2< 12.1 m/s2

Sound Power Level 107.0 dB(A) 107.0 dB(A)

18. Check damaged parts

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to deter-

mine that it will operate properly and perform its

intended function. Check for alignment of moving

parts, free running of moving parts, breakage of

parts, mounting and any other conditions that may

affect its operation. A guard or other part that is dam-

aged should be properly repaired or replaced by an

authorized service centre unless otherwise indicated

in this instruction manual. Have defective switches

replaced by an authorized service facility. Do not use

the tool if the switch does not turn it on and off.

19. Warning!

The use of any accessory or attachment, other than

those recommended in this instruction manual, may

present a risk of personal injury.

20. Have your tool repaired by a qualified person

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts,

otherwise this may result in considerable danger to

the user.

21. Guard against KICKBACK

A. GRIP SAW FIRMLY: Hold the chain saw firmly

with both hands when the motor is running.

Keep a good firm grip on the saw with both

hands, the right hand on the rear handle, and the

left hand on the front handle.

B. Do not over reach.

C. Keep proper footing and balance at all times.

D. Do not let the nose of the guide bar contact a

log, branch, ground or other obstruction.

E. Do not cut above shoulder height.

F. Use devices, such as low-kickback chain, guide

bar nose guards, chain brakes and special guide

bars, which reduce the risks associated with

kickback.

G. Use only replacement bars and chains

specified by the manufacturer or the equivalent.

H. There are no other replacement components for

achieving kickback protection in accordance

with CSA Z62.3.

22. Power supply

Connect the chain saw to correct voltage; be sure

that the voltage supplied is the same as that specified

on the nameplate of the tool.

23. DO NOT operate a chain saw that is damaged,

improperly adjusted, or not completely and securely

assembled. Be sure that the saw chain stops moving

when the trigger is released.

24. DO NOT attempt operations beyond your capacity or

experience.

25. DO NOT operate a chain saw with one hand! Serious

injury to the operator, helpers, or bystanders may

result from one-handed operation. A chain saw is

intended for two-handed use.

26. TO REDUCE potential for electric shock, do not

operate the saw on wet or slippery surfaces, or dur-

ing snow storms, rain storms, and other adverse

weather conditions.

27. Keep the handles dry, clean, and free of oil or grease.

28. DO NOT allow dirt, debris or sawdust to build up on

the motor or outside air vents.

29. Follow the manufacturer’s sharpening and mainte-

nance instructions for the saw chain.

30. Cut at high motor speeds.

31. Operation of a chain saw should be restricted to

mature, properly instructed individuals.

32. Your chain saw is intended for occasional

homeowner use. It is not made for heavy continuous

use.

33. DO NOT FORCE a small saw to do a job requiring a

heavier duty unit.

34. Examine the electrical switches. Do not use the

chain saw if the switches do not properly turn on and

off. Do not attempt to make any repairs to the electric

switches. Take your saw to a Texas Authorized

Service Center.

35. Maintain extension cords Inspect the extension

cords periodically and replace if damaged. Only use

power cords that are suitably marked for outdoor use.

36. DO NOT operate your chain saw near or around

flammable liquids or gases, whether in or out of

doors. An explosion and/or fire may result.

37. All chain saw service, other than the items listed in

the user manual safety and maintenance

instructions, should be performed by competent

chain saw personnel. Do not attempt to repair it your-

self; there are no user serviceable parts inside.

38. NEVER REMOVE, modify or make inoperative any

safety device furnished with your unit. The CHAIN

BRAKE®/Hand Guard is a major safety feature. The

saw will not run when the CHAIN BRAKE®is tripped.

39. It is intended for infrequent use by homeowner’s, cot-

tagers and campers, and for such general applica-

tions such as clearing, pruning, cutting firewood, etc.

It is not intended for prolonged use. If the intended

use involves prolonged periods of operation, this may

cause circulatory problems in the user’s hands due to

vibration. It may be appropriate to use a saw having

an anti-vibration feature.

40. Safety clothing required by your safety organizations,

government regulations, or your employer should be

used; otherwise, snug fitting clothing, safety footwear,

and hand and ear protection should be worn.

41. When felling, keep at least 2 tree lengths between

yourself and your fellow workers.

42. Keep everyone, especially children and pets, away

from the area of operation. Never allow children to

operate the appliance. Turn off unit immediately if you

are approached.

WARNING: Kickback may occur when the

nose or tip of the guide bar touches an

object, or when the wood closes in and

pinches the saw chain in the cut. Tip contact

in some cases may cause a lightning-fast

reverse action, kicking the guide bar rapidly

back towards the operator. Pinching the saw

chain along the top of the guide bar may

push the guide bar rapidly back towards the

operator. Either of these reactions may cause

you to lose control of the saw, which could

result in serious injury to the user. The fol-

lowing precautions should be followed to

minimize kickback.

SPECIFICATIONS

IMPORTANT SAFETY

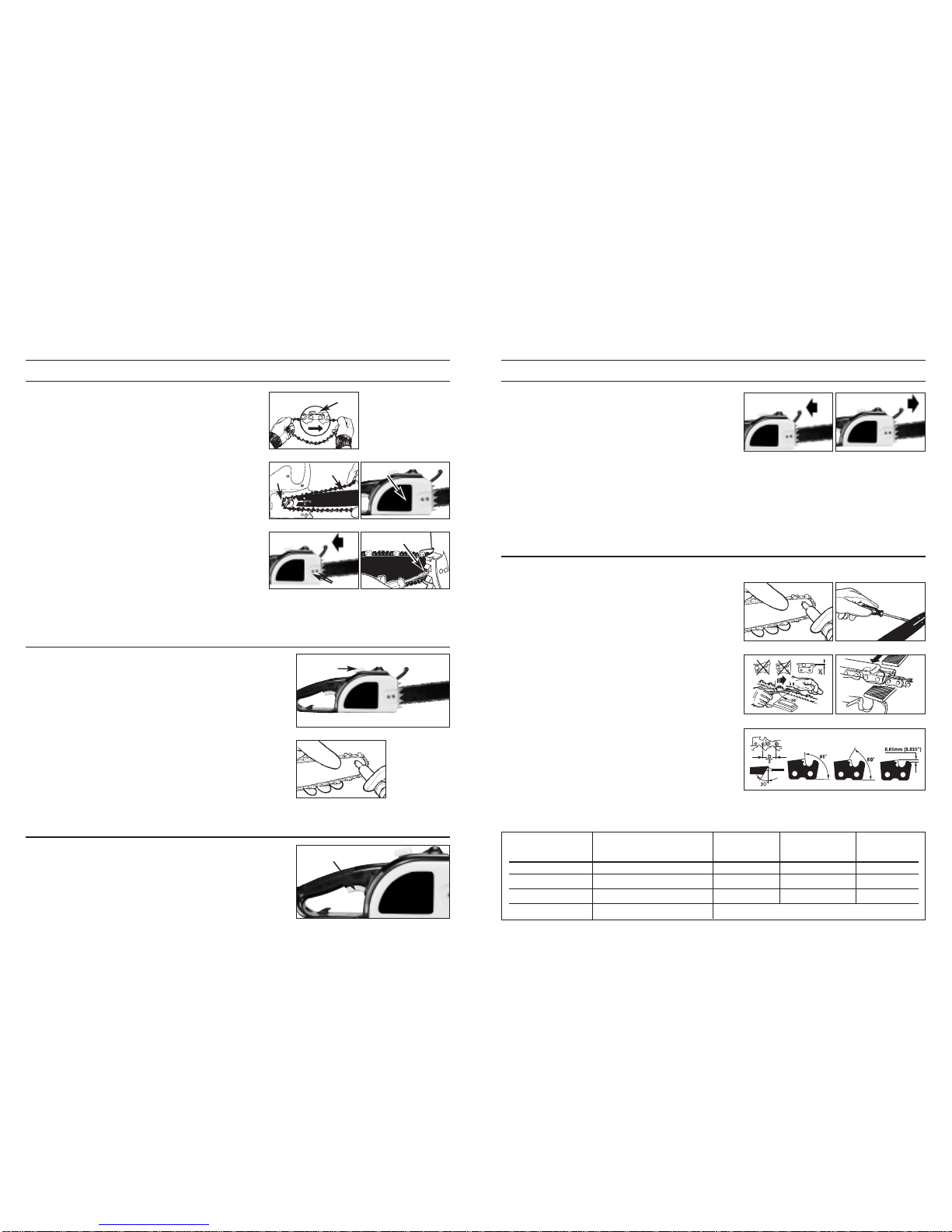

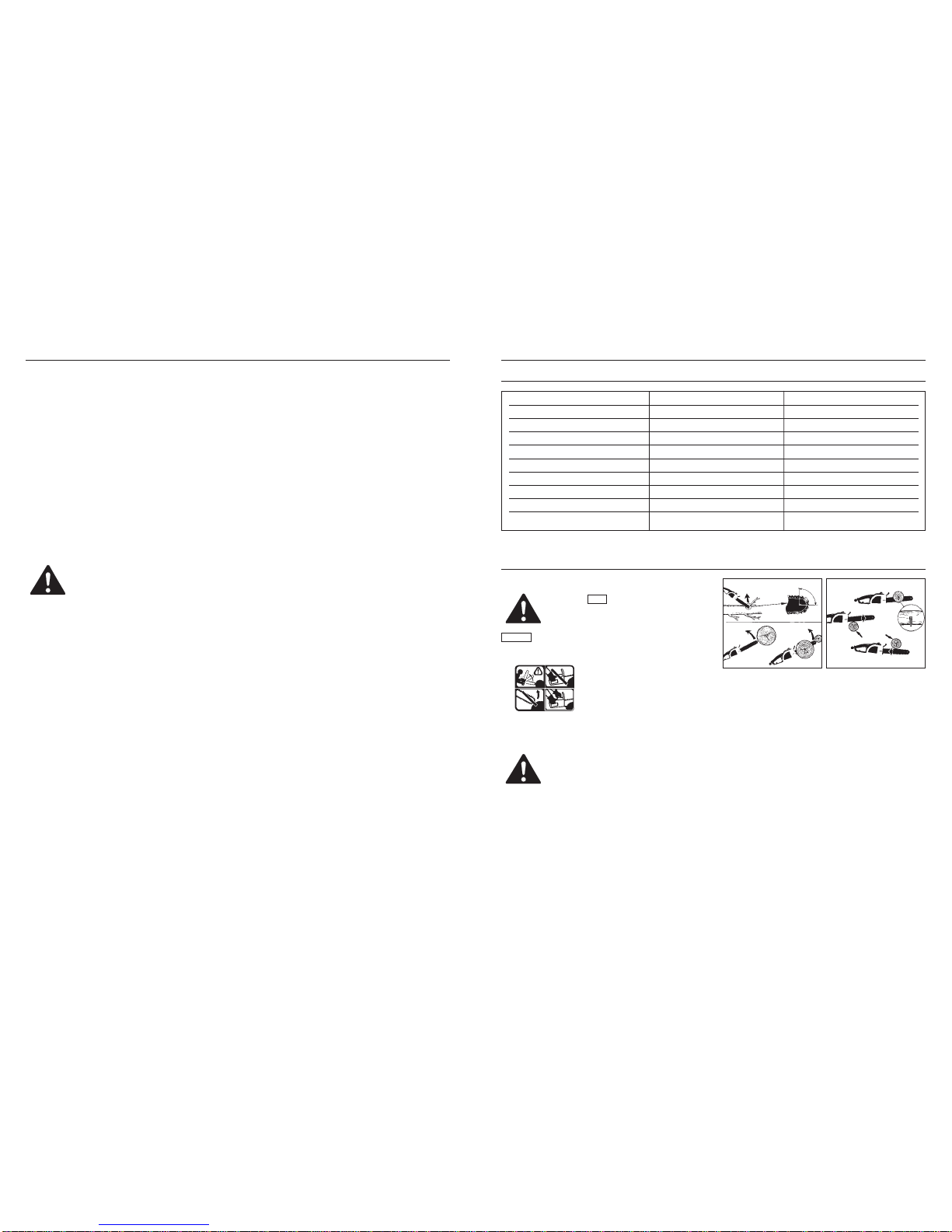

•How to read symbols and colors (Fig. 1)

GREEN RECOMMENDED

Recommended cutting procedure.

WARNING

1. Beware of kick back.

2. Do not attempt to hold saw

with one hand.

3. Avoid bar nose contact.

RECOMMENDED

4. Hold Saw properly with both

hands.

•DANGER! BEWARE OF KICKBACK!

BEWARE OF: ROTATIONAL KICKBACK

(Fig. 2A)

A=Kickback path

B = Kickback reaction zone

THE PUSH (PINCH KICKBACK) AND PULL REAC-

TIONS (Fig. 2B)

A=Pull

B = Solid objects

C = Push

KICKBACK may occur when the NOSE or TIP of the guide

bar touches an object, or when wood closes in and pinch-

es the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast

reverse reaction, kicking the guide bar up and back

toward the operator.

PINCHING the saw chain along the BOTTOM of the guide

bar may PULL the saw forward, away from the operator.

PINCHING the saw chain along the TOP of the guide bar

may PUSH the guide bar rapidly back toward the opera-

tor.

Any of these reactions may cause you to lose control of

the saw, which could result in serious personal injury.

WARNING: RED Used to warn that an

unsafe procedure should not be performed.

1

3

2

4

Fig. 1

WARNING: Kickback can lead to dangerous

loss of control of the chain saw and result in

serious or fatal injury to the saw operator or

to anyone standing close by. Always be alert

because rotational kickback and pinch kick-

back are major chain saw operational dan-

gers and the leading cause of most acci-

dents.

Fig. 2A Fig. 2B

A

A

B

A

A

B

B

C