- 2 -

1. Things to be confirmed

upon arrival

Upon arrival of the pump, please check and

confirm followings:

(1) The specifications on the nameplate of the pump

match the order specifications.

(2) All accessories are in place.

(3) All bolts and screws are securely fastened.

Looseness may occur during transportation, so be

sure to check the casing and drain bolts for looseness

before trial operation.

(4) The pump has no visible damage during the

transportation.

(5) Remove the motor fan cover and check that the motor

fan can be turned easily by hand. If the rotation seems

heavy or the fan does not turn, there may be some

internal damage. Contact the vendor or supplier

immediately.

2. Safety precautions

Like other high-speed or high-pressure machinery, a

magnetic drive pump can be very dangerous if it is not used

properly. Special attention is required if a corrosive or

hazardous chemical is used.

Instructions listed as "Warning" must be followed to avoid

property damages or fatal accidents.

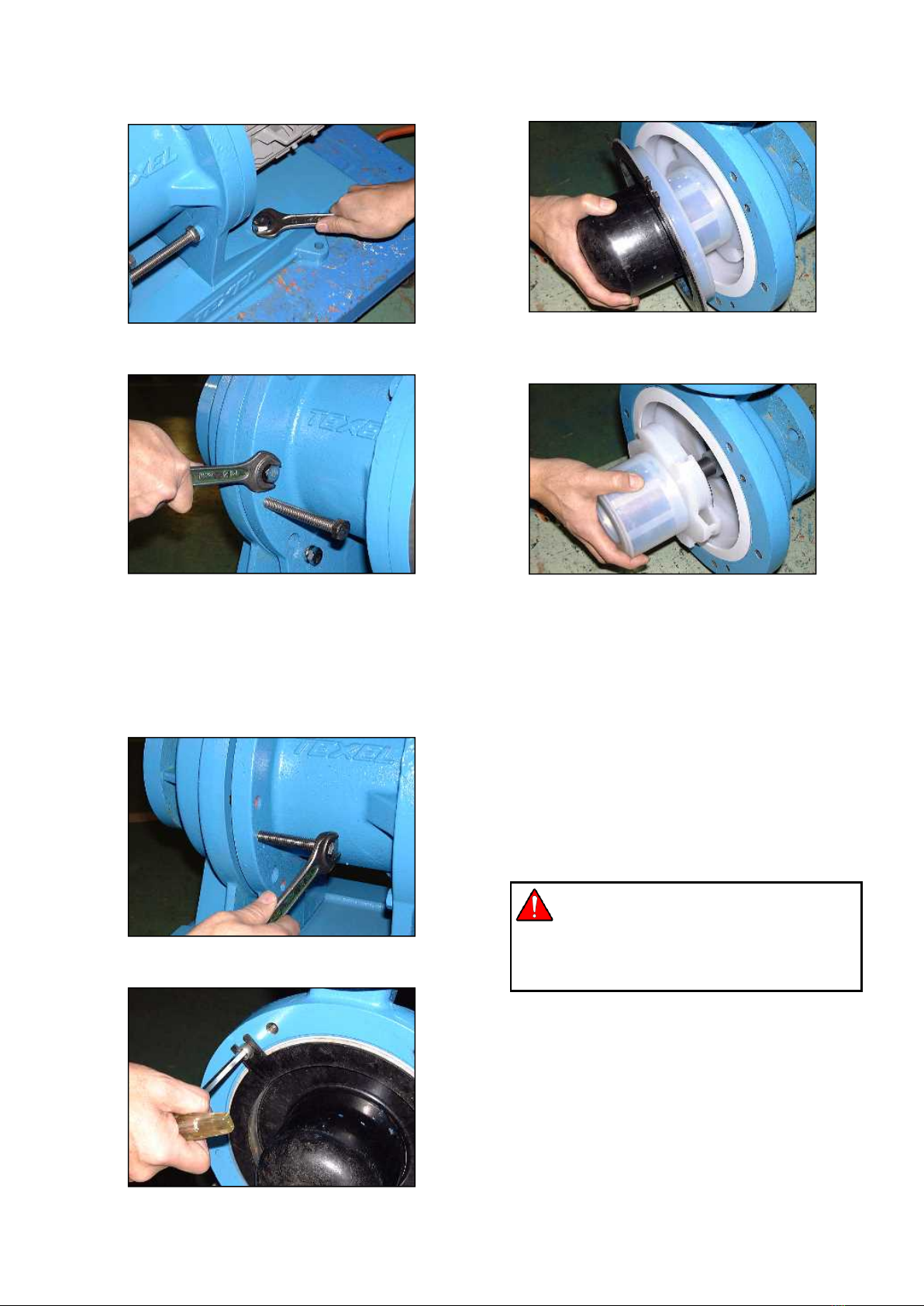

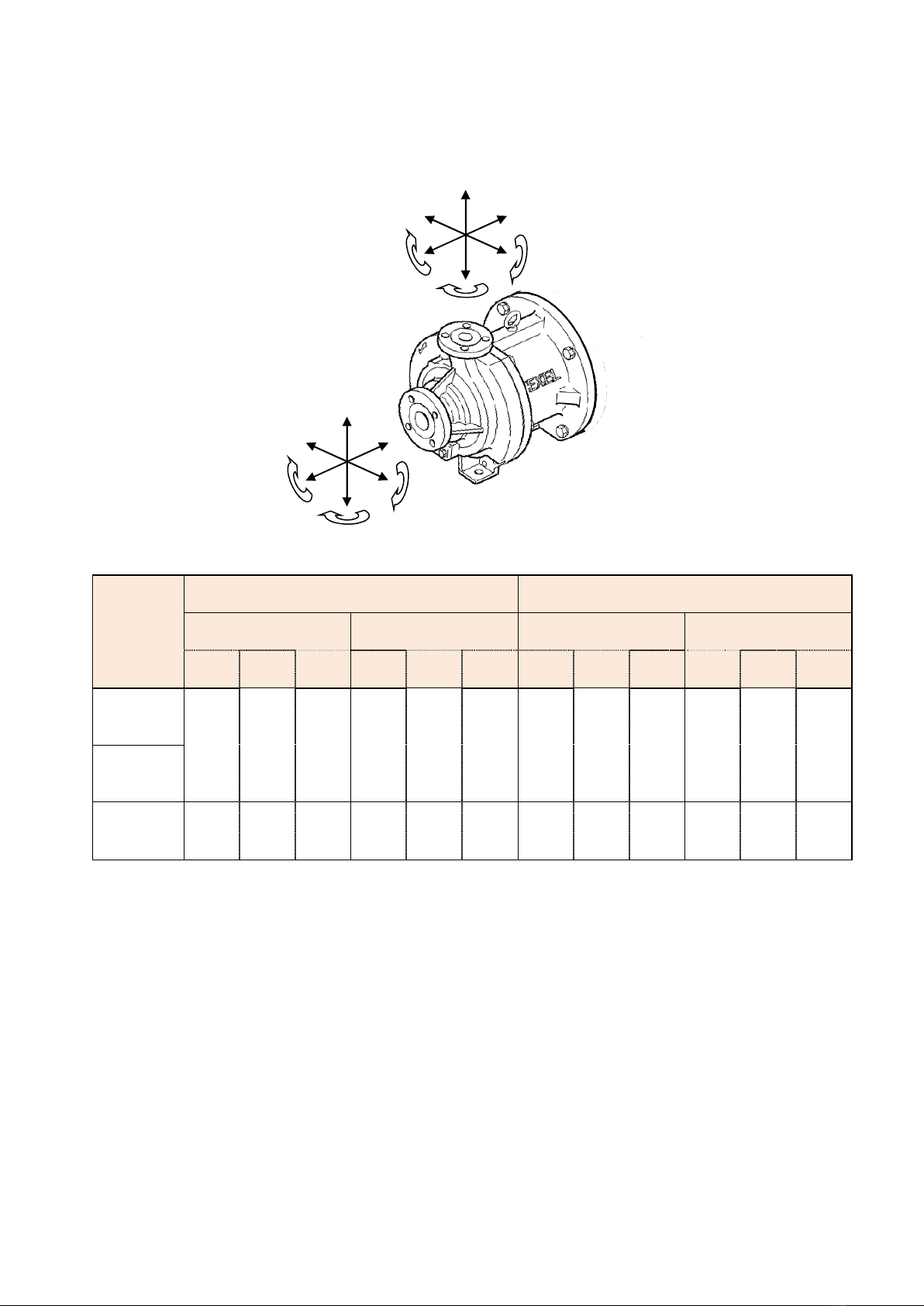

2.1. Transportation

The entire pump can be lifted using the eye-bolt provided on

the pump. However, ensure to secure the motor part with a

suspension rope (nylon sling) prior to the operation for

safety.

Warning

(1) An eye-bolt or a hooking hole provided on the motor

is rated only for the motor weight. Avoid suspending

the entire pump using the hooking hole on the motor.

(2) If a special base (not specified in the contract or listed

as standard) is set on the pump, do not suspend the

pump using the eye-bolt.

2.2. Confirmation

Before a test run after pump installation or a maintenance

work, make sure that all bolts including drain bolts and

casing bolts are securely fastened.

2.3. Application

The pump is designed and manufactured for the specific

application and specifications designated in the contract. If

the pump needs to be used for any other application, please

consult with the vendor or supplier prior to such use.

2.4. Alteration

Alterations to the pump carry a high degree of risk. It is not

the manufacturer’s responsibility for any failure or injury

resulting from alterations to the pump.

2.5. Ventilation

When handling chemical liquids that may generate harmful

gases, install safety equipment such as a ventilation system

in case of liquid leakage from the pump.

2.6. Qualified personnel only

The pump should be handled or operated by qualified

personnel with a full understanding of the pump. Any person

who is not familiar with the product should not take part in

the operation or management of the pump.

3. Storage

While in storage, perform maintenance and inspections by

following the instructions shown below until pump startup.

3.1.

Short-term storage (less than 3 months)

(1) Do not remove the bore seal.

(2) Store the pump in a well ventilated location without

humidity. Also ensure to avoid.

wind-blown rainwater, leak from the roof, pool of water, etc.

(3) Protect the cable holes on the motor terminal box with

a duct tape to close the gap and prevent dusts from

entering the box.

(4) Avoid a location where there is a potential risk of pump

damage due to surrounding equipments falling on the

pump or due to a contact with other devices being

transported. If it is not possible to avoid such locations,

provide sufficient protections for the pump.

(5) Do not place heavy objects on the pump.

(6) In winter, there is a possibility of dew condensation

and the dew being frozen inside the pump. Drain the

liquid to avoid this.

(7) In case a pump that had been used needs to be stored,

do the followings:

Clean the interior of the pump with fresh water.

Provide protections to the pump inlet and outlet to

prevent infiltration of foreign materials.

If the sum of initial operation period and the

storage period becomes longer than one year,

replace the gasket inspect the interior of the pump

before running it again.

3.2.

Long-term storage (more than 3 months)

(1) Follow instructions (1) through (7) for the short-term

storage stated above.

(2) Measure and record the insulation resistance at the

time of delivery and check it regularly as the insulator

of the motor may absorb moisture and the insulation

resistance may drop. If the insulation resistance is

dropped, dry the insulator following instructions from

the manufacturer and provide protection against

moisture. (Refer to the motor instruction manual.)

Warning

If the pump is run with poor insulation of the motor, a

leak of electricity or other accident may occur. Ensure

to check the insulation resistance regularly.

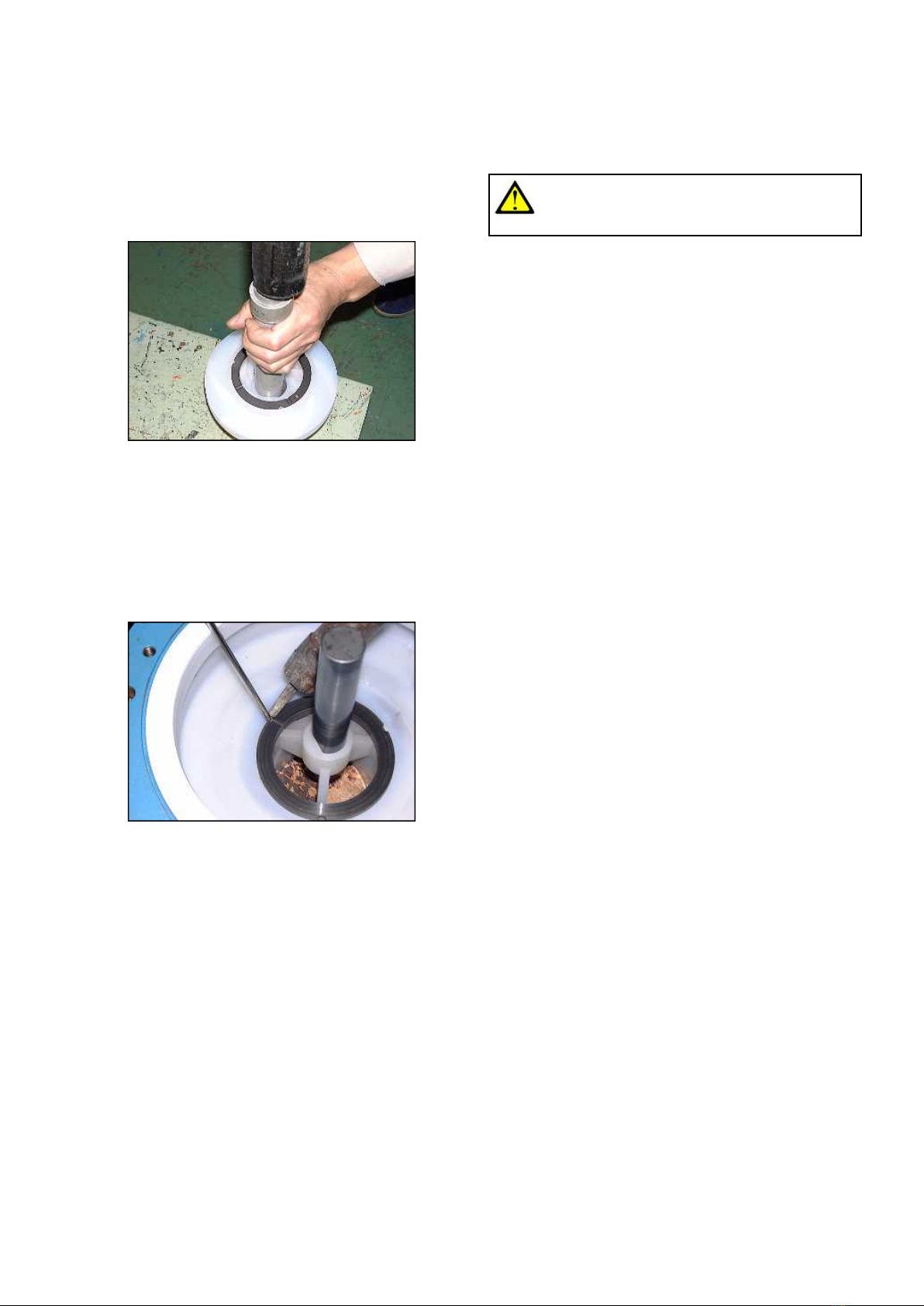

(3) Remove the motor fan cover once a month and turn

the motor fan manually.

(4) If the pump is run after a period of one year or longer,

ensure to replace the gasket with a new one.