TGW NBS 90 SP Instruction manual

NBS90-SP IOM

1

NBS90-SP Rev010512

Installation, Operation, Maintenance Manual

NBS®90SP

Narrow Belt Sorter

NBS90-SP IOM

2

NBS90-SP Rev010512

Contents

Purpose..................................................................................................................................... 3

Equipment Warranty.................................................................................................................. 4

Warnings & Safety Instructions.................................................................................................. 5

Definition of Terms .................................................................................................................... 8

NBS SP Application................................................................................................................. 10

Receiving & Site Preparation................................................................................................... 12

General Procedures ................................................................................................................ 14

Supporting Arrangements........................................................................................................ 16

Belt Installation........................................................................................................................ 18

Air Supply Requirements......................................................................................................... 21

Air Line Connections ............................................................................................................... 24

Electrical.................................................................................................................................. 26

Electrical Control Enclosure for NBS90-SP............................................................................. 29

Commissioning of Equipment.................................................................................................. 30

Preventive Maintenance.......................................................................................................... 32

NBS Maintenance Checklist.................................................................................................... 35

Maintenance Schedule............................................................................................................ 36

Repair Procedures................................................................................................................... 38

General NBS90-SP Sorter Layout........................................................................................... 42

Parts Identification................................................................................................................... 43

NBS SP Transfer Assembly Replacement Parts Diagram....................................................... 44

NBS SP End Pulley Assembly Replacement Parts Diagram................................................... 45

NBS SP Encoder Assembly..................................................................................................... 46

MISSION.................................................................................................................................... 47

NBS90-SP IOM

3

NBS90-SP Rev010512

Purpose

It is the intent of TGW Systems, through this manual, to provide information that acts as a guide in the

installation, operation and maintenance of TGW Systems NBS sorter NBS 90SP.

This manual describes basic installation practices, assembly arrangements, preventive maintenance

and assists in replacement parts identification.

This service manual is intended for use by personnel who are knowledgeable of installation and safe

working practices on conveyor systems.

Not all applications and conditions can be covered; therefore, this manual is to be used ONLY as a

guide.

If additional copies of this manual are needed or if you have any question concerning the conveyor

please contact your Business Partner or TGW Systems Customer Support at 231-798-4547 or Fax

231-798-4146.

NBS90-SP IOM

4

NBS90-SP Rev010512

Equipment Warranty

TGW warrants that the material and workmanship entering into its equipment is merchantable and will

be furnished in accordance with the specifications stated.

TGW agrees to furnish the purchaser without charge any part proved defective within 2 years from date

of shipment or before the equipment has forty-one hundred (4100) hours of running use, whichever

period is shorter, provided the purchaser gives TGW immediate notice in writing and examination

proves the claim that such materials or parts were defective when furnished. For drive components

specific to XenoROL® (i.e. Xeno belts, slave Xeno belts, drive spools, standard and speed-up, and

spacers), this warranty shall be extended to five years or ten thousand (10,000) hours of running use,

whichever period is shorter, provided the conveyors are applied, installed and maintained in

accordance with TGW published standards. Other than the above, there are no warranties which

extend beyond the description on the face hereof. Consequential damages of any sort are wholly

excluded.

The liability of TGW will be limited to the replacement cost of any defective part. All freight and

installation costs relative to any warranted part will be at the expense of the purchaser. Any liability of

TGW under the warranties specified above is conditioned upon the equipment being installed, handled,

operated, and maintained in accordance with the written instructions provided or approved in writing by

TGW.

The warranties specified above do not cover, and TGW makes no warranties which extend to, damage

to the equipment due to deterioration or wear occasioned by chemicals, abrasion, corrosion or erosion;

Purchaser's misapplication, abuse, alteration, operation or maintenance; abnormal conditions of

temperature or dirt; or operation of the equipment above rated capacities or in an otherwise improper

manner.

All equipment and components not manufactured by TGW carry only such warranty as given by

the manufacturer thereof, which warranty TGW will assign or otherwise make available to

Purchaser without recourse to TGW, provided that such warranty is assignable or may be made

available.

IMPORTANT

For service on motors, reduction units, electrical components, controls, air or hydraulic cylinders,

contact the local authorized sales and service representative of respective manufacturer. If none is

available in your locality, contact the TGW representative. TGW will not be responsible for units that

have been tampered with or disassembled by anyone other than the authorized representative of the

respective manufacturer.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EXTENDING

BEYOND THOSE SET FORTH IN THIS STATEMENT OF WARRANTY.

Rev 04/08/2009

NBS90-SP IOM

5

NBS90-SP Rev010512

Warnings & Safety Instructions

Failure to follow the instructions, warnings, cautions (throughout this booklet) and warning

labels (on the conveyor) may result in injury to personnel or damage to the equipment.

Your TGW Systems NBS Narrow Belt Sorter is powered by a motor and can be stopped only by turning

off electrical power to the motor. As with all powered machinery, the drive and driven sprockets,

chains, and pneumatically actuated devices present a danger. We have installed or provided guards to

prevent inadvertent contact with these components along with warning labels to identify the hazards.

After maintenance, REPLACE guards immediately. Keep ALL warning labels clean and clear of

any obstructions.

Be sure to read and heed all Warnings. Warnings and Cautions are included throughout this manual

and are defined as follows:

Warning ---- A notice which, if not followed, could

result in serious injury to personnel.

Caution ---- A notice which, if not followed, could

result in damage to equipment.

A thorough understanding and compliance with these Warnings and Cautions will greatly reduce the

possibility of personnel injury or equipment damage.

Never remove, deface or paint over any labels. Any damaged label will be replaced by TGW Systems

Inc. at no cost by contacting the Distributor Services Department.

WARNING

Do not perform maintenance on the conveyor until the start-up controls are locked out and cannot be

turned on by any person other than the one performing the maintenance. If more than one member of

a crew is working on the conveyor, EACH CREW MEMBER MUST HAVE A LOCK ON THE POWER

LOCK OUT. The air pressure must be turned off to the work area. All pneumatic devices must be de-

energized to prevent accidental cycling of the device.

Make sure personnel are clear of all conveyor equipment before restarting the system.

It is very important to instruct personnel in proper conveyor use including the location and function of all

controls. It is important to establish work procedures and access areas which do not require any part of

a person to be under the conveyor. It should be required that long hair is covered by caps or hair nets

and the wearing of loose clothing or jewelry when working at or near the conveyor be prohibited.

Maintain enough clearance on each side of the unit for safe adjustment and maintenance of

components. Provide crossovers at sufficient intervals to eliminate the temptation to climb over or

under any conveyor. Prohibit riding or walking on conveyor by anyone.

NBS90-SP IOM

6

NBS90-SP Rev010512

WARNING

Before servicing or performing any work in the motor control panel, disconnect and lockout the main

incoming service. If only the panel disconnect is off, the incoming side will still be hot.

Warning examples on conveyor frames.

NBS90-SP IOM

7

NBS90-SP Rev010512

NBS90-SP IOM

8

NBS90-SP Rev010512

Definition of Terms

KEY WORD ABBREVATION DESCRIPTION

AIRBAG Inflatable lifting device used in NBS30

BEARING

“BRG”Low friction rotating or sliding device

BELT

“BLT”Flexible load carrying surface or O-ring

BETWEEN-FRAME

“BF”The distance between conveyor side frames

BRACKET

“BRKT”

Attachment between a main and another part

CHANNEL

“CH”Structural side member of conveyor equipment

CONNECTOR

“CONN”Adapts and holds two other parts together

CROSSMEMBER

“XM”Holds channels apart in NBS bed sections

DIVERTER NBS30 module

DRIVE

“DR”Power unit at the discharge end of NBS sorter

ELEVATION

“EL”Top-of belt height above base surface

ENCODER Electrical distaqnce counter used to track package locatio

ENDPULLEY

"E-PULL" 6” diameter roller at charge end of NBS sorter

EXTRUSION Aluminum base that holds UHMW belt strips

FEET PER MINUTE

“FPM”Speed sorter belts are traveling

FILTER / REGULATOR Combination air pressure regulator / air filter

FLOOR STAND

“FS”Name for conveyor bed support

FLOW CONTROL Needle valve used to control airflow

FOOTPAD Part used to distribute load from a jackscrew

GEARMOTOR

"GEARMTR" One piece gear-reducer motor assembly

GUARD RAIL

“GR”Angle or channel used to keep product on NBS

GUARD

“GRD”Any part used to protect area for safety reasons

IDLER Un-driven pulley used as a tensioning device

ITEM NUMBER

“IT #”TGW-ERMANCO part identification number

JOB NUMBER

"C010_ _ _ _ _" Original factory tracking order number

KEY Square locking device used on rotating shafts

KIT Group of several parts with a single item number

LACED

“LCD”The condition of a correctly installed lacing

LACING Type or method of joining belts together (splice)

LIFT FRAME The lifting structure of a NBS90 transfer

LIFT TABLE Assembly that guides the NBS30 wheels upward

LOCKNUT Self-locking fastener that resists vibration

LOCTITE A thread-locking adhesive that resists vibration

LOOSE PARTS

“LP”Individual parts that must be installed in the field

MULTI-BELT

“MBLT”Another name that describes NBS equipment

MODULE

“MOD”A self contained mechanical assembly

MOUNT

“MNT” Part used to hold another, similar to a bracket

MOUNTING

“MTG”Location and fasteners to attach a mount

MOTOR

“MTR”Rotational power source usually using electricity

MUFFLER Device used to reduce the noise of exhausted air

NATIONAL PIPE THREAD

“NPT”Standard identifier for USA tapered pipe sizes

PHOTOEYE

“PE”Optical sensing device used for product control

PLATE

“PL”Flat piece of metal usually bolted on for strength

NBS90-SP IOM

9

NBS90-SP Rev010512

KEY WORD ABBREVATION DESCRIPTION

PROGRAMMABLE Self-contained programmable control unit that

LOGIC CONTROLLER

“PLC” Can control several input and output devices

O-RING Polyurethane cord belts of differing lengths

PULLEY

Roller described by diameter and body length

REDUCER

“RED” A C-face motor mount right-angle worm gearbox

REFLECTOR Target used to reflect a light back to a photo eye

REGULATOR

“REG” Air device that reduces pressure to usable level

RETAINER

Part used to mechanically lock a part in place

ROLLER Described by axle size and BF dimension

ROLLER CHAIN

“RC” Roller link chain used for power transmission

SCANNER A device that recognizes products by bar codes

SCHEMATIC Line drawing of a electrical or pneumatic circuit

SCREW A threaded fastener also called a bolt

SEAL Sealing device on a rotating shaft or cylinder rod

SMART DISTRIBUTED The name for a proprietary software / hardware

SYSTEM

“SDS” Network control system marketed by Honeywell Inc.

SHAFT Round steel rod described by diameter and length

SHEAVE A grooved disc that guides a V-belt or O-ring

SHIM Thin piece of metal, used to fill up a space

SKATEWHEEL

“SW” 2” diameter X 5/8” wide X ¼” axle hole roller

SMILEY

“J” (See standhead)

SOCKET

“SOC” Hex shaped hole in an Allen screw

SOLENOID

“SOL” An electrically operated multi-position air valve

SPACER Thick washer or tube that a fastener passes thru

SPLICE Area where similar materials are joined together

SPRING

“SPR” Coiled wire device used for un-powered return

SPROCKET

“SPKT” Wheel with shaped teeth that engage roller chain

SPUR Transition bed between a diverter and exit lane

STANDHEAD Pivoting bracket that attaches support to the bed

STARTER

Electrical relay that energizes the drive motor

TAG Number that identifies unit in system lay-out

TAKEUP Assembly used to remove slack from a belt / belts

TEE A part with three connections locations

TENSIONER A pneumatic, spring, or static take-up device

THREADED FULL LENGTH

“TFL” Adjusting bolt used in take-up/tracking applications

TRANSFER

“TRNS” NBS90 and NBS-SP module

ULTRA HIGH Industry standard term for the hard milky white

MOLECULAR WEIGHT

“UHMW” polyethylene used in wear strip applications

VALVE An air shut-off or switching device

VENT Small hole in gearbox to allow hot air expansion

WEARSTRIP Low-friction material used to reduce rubbing wear

WELDMENT

“WLDMT” Any part that requires welding in its manufacture

VFD Variable Frequency Drive for motor speed control

NBS90-SP IOM

10

NBS90-SP Rev010512

NBS SP Application

NBS SP SELECTION GUIDELINES

Use NBS SP When:

•Higher speed sortation then NBS is required

•Product may be same size and weight, or mixed

•Product weight: 1-20 lbs, 1000 lbs. total load

•Product size: 4" X 4" Min. -- 13" X 24" Max.

•Ambient temperature is +35° to 100°F

APPLICATION NOTES

1. Matching conveyor rates before and after NBS sortation are vital to proper application decisions.

2. The transfer exit lanes from NBS SP can be gravity roller (used as a deceleration area), chutes or

powered conveyor run at a speed which allows the lane to receive products as fast as they are

transferred.

3. The maximum divert rate for a NBS SP single-direction is 120 CPM. The bidirectional rate is 120

CPM. (Contact the Customer Support group for application consideration above these rates)

4. Induction to NBS-SP sortation must be able to singulate individual products with a minimum gap of 6"+

conveyor width at 250 FPM 10"+ conveyor with at 300 FPM.

5. Justify all products along the exit lane side of the NBS SP sortation for single direction transfers.

6. When NBS-SP over-all-length is over 50' and up to 100' in length, an addition auxiliary air take-up is

required.

7. The maximum length of a NBS SP sortation conveyor, including two air take-up units, is 100'.

8. The gearmotors used for NBS SP drives are all VFD (variable frequency drive) rated.

CAUTION

The use of a VFD or at least a "soft start" motor drive is recommended for NBS SP drive motor control.

Ignoring this point may void the motor warranty.

GENERAL CONSIDERATIONS

ELEVATION (TOB)

The minimum elevation at the discharge end of an NBS SP sortation line is 23". The end drive unit is

located at the discharge end and requires a space 23" high by 33" long.

Extra room alongside the drive should be provided to allow maintenance personnel access to either

side of the drive assembly.

TRANSFER LOCATIONS

•The leading edge of the first transfer module must be a minimum of 28" from the charge end of the

sorter.

•The trailing edge of the last divert module must be at least 42" from the discharge end.

•The center line of a transfer exit lane is centered on the center line of the transfer rollers in an NBS

SP.

•Standard available coated transfer rollers widths are: 9", 12", 15", 18", & 21"

•One NBS SP transfer can transfer to up to four separate lanes of 1/2 the width of the roller length.

•Single direction transfer to two lanes is called a "Dual Transfer"

NBS90-SP IOM

11

NBS90-SP Rev010512

•Bi-directional transfer to two lanes each side is called a "Quad Transfer"

STANDARD AVAILABLE DRIVE SELECTIONS

.5, .75, 1, 1.5 HP @ the following speeds

120, 150, 180, 200, 220, 250, 300 FPM

Additionally: 2 HP @ 200, 220, 250, 300 FPM

SORTER NOMINAL WIDTHS & NUMBER OF BELTS

11.5NBS-SP with 3 Belts on 2-1/2" Centers

14NBS-SP with 4 Belts on 2-1/2" Centers

NBS90-SP IOM

12

NBS90-SP Rev010512

Receiving & Site Preparation

GENERAL

TGW Systems NBS Narrow Belt Sorters are shipped in subassemblies. These subassemblies are

packaged to guard against damage in shipment, when handled properly.

Examination immediately following unloading will show if any damage was caused during shipment. If

damage is evident, claims for recovery of expenses to repair damage or replace components must be

made against the carrier immediately. While unloading, a check must be made against the Bill of

Lading, or other packing lists provided, to confirm full receipt of listed items.

CAUTION

TAKE CARE DURING THE REMOVAL OF EQUIPMENT FROM THE CARRIER. Remove small items

and boxes first. Pull and lift only on the skid, not on the frame, crossmember or any part of the

equipment. Be sure the skid is free of other materials which may be on top of or against the side of the

skid to be removed.

PREPARATION OF SITE

After the conveyor is received, move it to the

installation site or designated dry storage area as soon

as possible. Clean up all packing material immediately

before parts get lost in it. Loose parts should remain

in the shipping boxes until needed.

Prior to starting assembly of the conveyor, carefully

check the installation path to be sure there are no

obstructions that will cause interference. Check for access along the path needed to bring in bed

sections and components closest to the point where they are needed. It is often necessary to give the

area along the system path a general cleanup to improve installation efficiency, access and accuracy.

PARTS INVENTORY & IDENTIFICATION

Each subassembly is shipped completely assembled except the bed joint splice plate/nuts which are

shipped with other loose parts. Identify and separate the sorter subassemblies by type or tag number,

for inventory and ease of locating during installation.

An identification label is attached to the inside of one side channel or on a crossmember, close to one

end of each conveyor bed. This label contains: job number, part number, order number, tag number (if

specified), assembler's initials and date of manufacture. On supports, the tag is located on the bottom

side of the foot. On special devices it is located on a convenient flat surface that is not offensive to the

appearance of the equipment but is still accessible for

viewing. These numbers can be cross-referenced against

the packing list. The illustrations in this manual and the part

number stickers will assist you with your inventory.

Identification Label

NBS90-SP IOM

13

NBS90-SP Rev010512

Loose parts are boxed and shipped separately. You should have all conveyor sections and supports

for a particular conveyor prior to installation. It is cost-effective to identify and procure any missing

parts before they are needed for assembly. Small items like nuts and bolts are weigh-counted and

packaged by size and type.

CAUTION

Do not remove finishing nails from rail ends. They keep the UHMW guides from sliding down to the

discharge end.

NBS90-SP IOM

14

NBS90-SP Rev010512

General Procedures

The following procedures are to be used as guidelines only. Specific installation methods will vary

somewhat depending on available equipment on site and each installer's preferences based on past

experience.

WARNING

The Installation Supervisor must be experienced with conveyor and qualified in the mechanics of the

equipment and enforce safe working procedures for the protection of the crew, customer, and

customer's property.

DIMENSIONAL REFERENCE POINTS

The path of each conveyor in the system is determined by establishing a reference point at each end.

The center line of the conveyor is established and a chalk line is snapped between these points.

Conveyors should be installed with the center line of the bed matching the center line of the conveyor

path. Locate and mark the center of the crossmembers at each end of the conveyor. Use a plumb line

or other acceptable means to ensure accuracy to the chalk line.

Always carry out a thorough check for any obstructions such as building columns, manholes, etc. It

may be necessary to reroute the conveyor to avoid the obstruction. In this case it would be advisable

to begin installation at this point, using the obstruction as a reference point (Datum), and install the

sections in either direction as required.

All conveyor sections must be checked for squareness prior to installation as "racking" or being

knocked out of square may have occurred during shipping and handling.

ELEVATIONS

All top-of-belt (TOB) heights should be installed in accordance with the elevations shown on the

drawings. In addition, all sortation devices must be level across both the frame width and length.

Leveling of the frames is best done using a rotating laser level along the length of the conveyor and a

builder's level across the width.

After the first elevation is established at a critical point, the elevation of all other points shall be relative

to this first point. Normal practice is to dimension the layout and measure elevations from the floor at

each point of support.

As the conveyor system proceeds onto another floor or into another building or room, a new elevation

will be measured from the floor at that point. This new elevation will then become the reference for

subsequent elevations.

When installing an overhead system, the first elevation is measured from the floor and becomes the

reference elevation point until a change in elevation is shown on the layout. Any new elevation is also

measured from the floor and becomes the new reference point. The process is repeated each time an

elevation change occurs.

CAUTION

NBS90-SP IOM

15

NBS90-SP Rev010512

Consult the building architect or a structural engineer regarding ceiling loading or structural limitations of the

building if any conveyor is ceiling hung.

COMPONENT ORIENTATION

Using your conveyor system layout drawing and the numbers on the I.D. tags on each component,

position and orient the conveyor sections. You must know:

•The direction of product flow

•The elevation height

•The drive is positioned at the discharge end

•The end pulley is positioned at the charge end

IMPORTANT! Do not make alterations to the equipment without consulting with user's representative

and TGW Systems. Unauthorized modifications to the equipment may impair its function, create a

hazardous condition, affect its useful life and/or void the warranty.

NBS90-SP IOM

16

NBS90-SP Rev010512

Supporting Arrangements

FLOOR SUPPORTS

Install bolts used to attach the standhead to the frame

so the nut is on the bottom. Standhead bolts should be

left finger tight while the conveyor is being assembled

and aligned.

Floor supports are ordered by nominal height range,

which is the dimension from the floor to top of the

support. Conveyor elevations are shown on the layout

by top-of-belt elevations. The difference between top of

belt (TOB) and top of support is 7-5/8". This dimension

must be subtracted from the TOB height to set support height.

It is important that conveyor frames be installed level. Floor supports will accommodate normal

irregularities in the floor surface. Adjustment for elevation in floor supports is accomplished with metal-

on-metal bolt clamping force. To achieve the support's stated load rating, it is necessary to tighten the

elevation adjustment bolts (3/8" diameter) to 23 ft./lbs. of torque.

Supports should always be installed in the vertical position, and any variations due to conveyor pitch or

floor slope will be compensated for in the pivoting standhead of the support.

ANCHORING

Anchoring in concrete floors is accomplished by drilling into the floor and inserting the suitable anchor

bolt. The hole diameter and depth must be in accordance with the anchor bolt manufacturer's

instructions.

Anchor intermediate floor supports with two anchor bolts, one through each support foot plate using at

a minimum 3/8" diameter anchor bolts. For floor supports over 5' high or when supporting drives, use

1/2" diameter anchor bolts.

Stagger anchors from front hole on one side of the support, to rear hole on opposite side. Anchor bolts

for equipment subject to impact loads should be a minimum of 1/2" in diameter.

WARNING

Place a bolt through the frame and support immediately with finger tight nut. This will prevent the frame

from falling off the support, if bumped, and causing injury.

NBS90-SP IOM

17

NBS90-SP Rev010512

BED/SUPPORT CONNECTORS

NBS can only be supported at bed joins. Adjoining beds are connected using 3/8” thick by 10” nut

plate, 3/16” thick by 10” clamping plate and 3/8” hardware. These parts are shipped with other loose

parts. Insert 10” nut plate halfway into the formed channel end of each bed. Then mount standhead

support with two 3/8-16 X 1” hex head bolts with flat and lock washers. After that mount 10” clamp plate

to channel ends with four 3/8-16 X 1” hex head bolts with nut, flat and lock washers (see picture below).

It can be seen that a crossmember could be moved into the recessed area of the standhead support

bracket if needed.

Maintaining the rigidity and flatness of the conveying surface is the end result of proper support

installation.

ALUMINUM EXTRUSION T-NUT CONNECTORS

The aluminum extrusions that hold the UHMW belt guides are installed at the factory with tee bolts up

through their mounting crossmembers. The placement of these extrusions is gauged precisely (2-5/16"

center-to center) so that the triple T-nut connectors between the extrusions line up at installation. The

triple T-nut connectors are mounted, at the factory, flush with the ends of the aluminum extrusions on

the discharge side of all NBS bed assemblies. These triple nut connectors should be extended half-

way out of the extrusions before "plugging in" the next bed downstream during installation. After all bed

components are installed, leveled and straightened the 5/16-18 hex head bolts used in the triple T-nut

connectors should all be loosened, to straighten the aluminum extrusion joints and re-tightened.

10” nut plate

10” clamping plate

standhead

NBS90-SP IOM

18

NBS90-SP Rev010512

Belt Installation

PRE-INSTALLATION

Belts, as shipped from TGW Systems, are cut to length

with lacing installed. Rolls of belting should be stored on

edge on a pallet (see belt below). Never leave a belt

where it may absorb moisture. Remove any tight shipping

banding immediately upon arrival. Lacing pins are taped

inside the lacing on each belt.

The NBS90-SP conveyor should be completely installed

and aligned before belt installation.

Remove the plexiglass side covers from the sides of the

auxiliary belt take-up frame, exposing the take-up pulleys.

Switch the take-up air switch to the un-tensioned position,

raising the take-up pulleys to the minimum take-up position. Then remove or slide covers between the

aluminum belt track extrusions so that the belt guide wheels are exposed. Do the same for each NBS

30 diverter and the charge end pulley.

Remove the o-ring from the o-ring driven gap roller.

BELT THREADING

Because NBS uses multiple narrow belts of long length, it

will be most efficient to have two people working together

during the threading process.

The belting must be uncoiled and laid out flat on the

sorter, with the smooth black carrying surface up. The

belts must not be allowed to twist along their length as

they are installed. Start at the charge end (farthest from the drive) and feed all of the belts through

together at the same time. Start the belts down between the gap roller and the end pulley. Guide the

belts under the 5" diameter end pulley and up and over the 4" diameter snub pulley, before passing

through the belt guide wheels.

All belts must pass over any return rollers positioned to minimize belt sag and through holes in crossmembers.

NBS90-SP divert rollers fit up between the narrow belts.

The black PVC surface of the belt should be up and the rough surface rides in the UHMW tracks.

Mesh the loops of the lacing on one end of the belt with the loops on the other, so the sides of the belt are even,

and install the lacing pin.

Because the different width sorters have different numbers of belts, the air pressure to properly tension the belts

is different for each width.

NBS90-SP IOM

19

NBS90-SP Rev010512

BELT TRACKING

With the belts tensioned, "bump" the motor to be sure rotation is correct, the belts are running smoothly

and maintaining their position. Most NBS90-SP conveyors do not require belt tracking. However,

each conveyor should be checked at the charge and discharge ends to be sure the belts are floating in

a neutral position not crowding the sides of the UHMW guide tracks. If the belts are out of their grooves

or riding hard to one side adjustment can be made on the driven pulley jackscrew, at the discharge end,

or the snubber roller in the end pulley assembly at the charge end, to realign them.

Reinstall the bottom pan on the end pulley assembly and access covers on the auxiliary belt take-up.

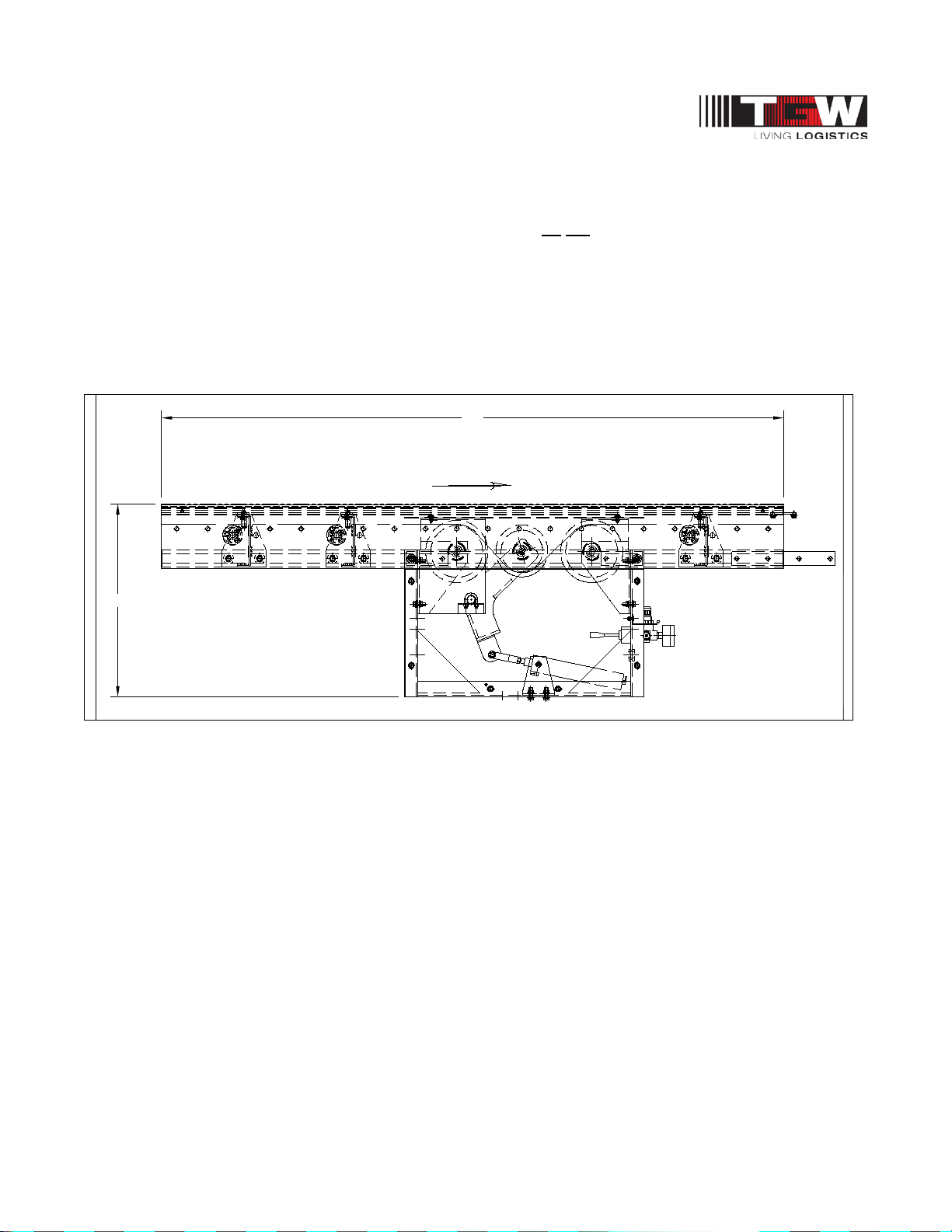

NBS-SP67A004

BELT LENGTH REQUIRED PER UNIT = 10' 4" AIR PRESSURE SET AT

50-55 PSI

TAKE UP IS CAPABLE OF 12 3/4" PER BELT

18 9/16

5'0"

FLOW

NBS-SP BELT TAKE-UP

NBS90-SP IOM

20

NBS90-SP Rev010512

BELT SPECIFICATIONS AND LACING

•PVC 200 belt

•Width: 15/16" + /- 1/32"

•Thickness: .203" +/- .015 thick, with a recessed

•Thickness at recess: .125" to .156"

•Lace: Clipper P/N 05265 U2S12 (tote); minimum

number of hooks = 5 on one end, 6 on other end.

•Lacing Pin: Nylostainless

.093 dia. x 7/8” +/- 1/32” long (316 stainless steel

w/nylon coating); clipper P/N 02670

CAUTION

Only use the specified lacing and pin. Any substitution will result in premature belt failure.

For field repair chamfer belt corners, no more than 1/8”.

BELT REPLACEMENT

Replacement belts may be ordered by the original "P" part number marked on the belt or belt length

can be determined by the following information.

1. The 2’-9’ drive bed requires 5’-11.25” (71.25”)

2. The 18" end pulley bed 3'-0" (36")

4. NBS90-SP transfers require 0" each

5. Auxiliary take-up with 5’ bed requires 10’-4” (124”)

6. All other beds require 2 times their length.

NOMINAL WIDTHS (# OF BELTS)

11.5" with 3 Belts on 2-1/2" Centers

14.0" with 4 Belts on 2-1/2" Centers

Other manuals for NBS 90 SP

1

Table of contents

Other TGW Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

HappyJapan

HappyJapan HCR3 Instruction book

ADCA

ADCA FLT80 Installation and maintenance instructions

SAMCHULLY

SAMCHULLY SD-E instruction manual

BUSCH

BUSCH R5 RA 1000-1600 B Installation and instructions

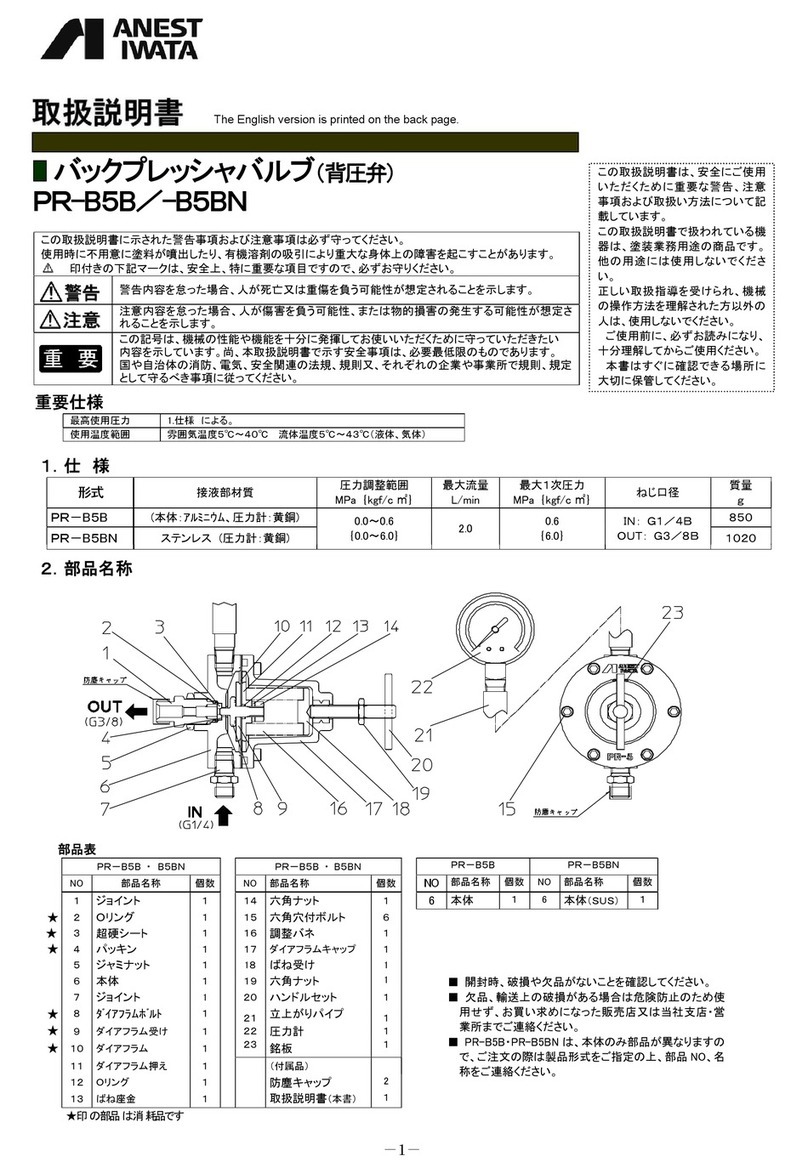

Anest Iwata

Anest Iwata PR-B5B instruction manual

Edge Technologies

Edge Technologies V-65 Series Operation manual