Edge Technologies V-65 Series User manual

V-65 Series

SHORT BAR FEEDER

REBEL-V-65E/LE-A

MANUAL FOR USE AND MAINTENANCE

REV. 08 DATE:

::

:2016/06/01 COD:

::

:BRV104032

S/H

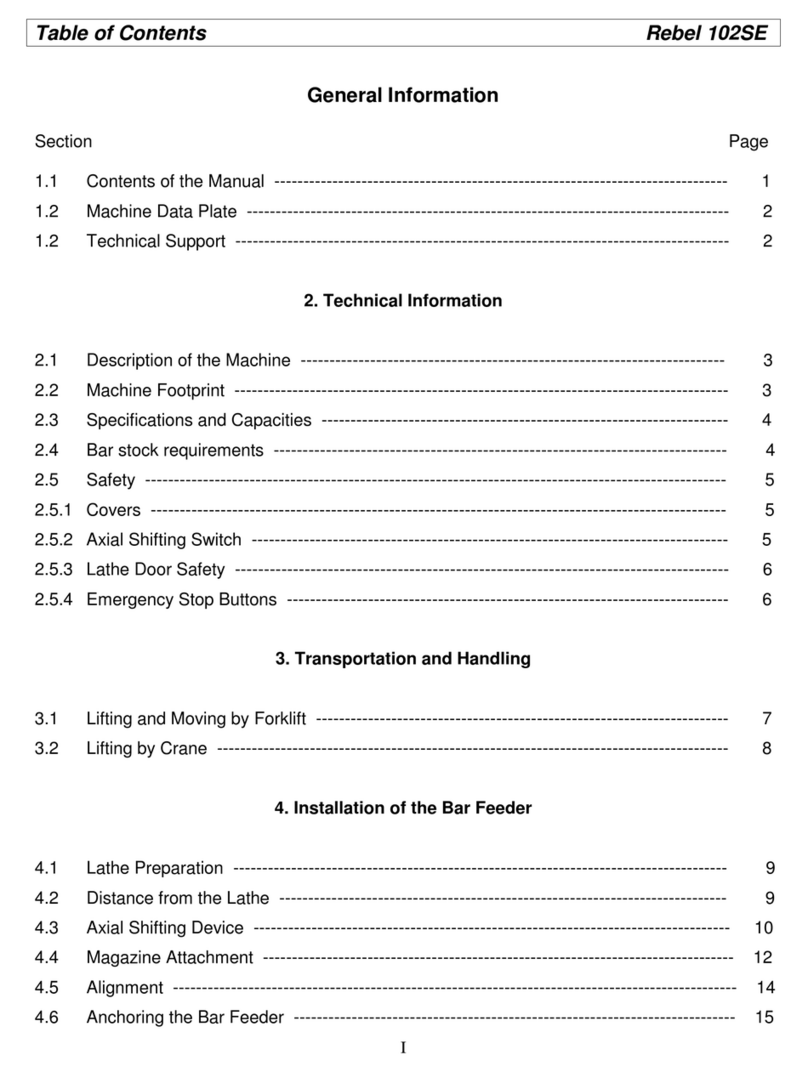

INDEX V-65E-A

Ⅰ

CONTENT(

((

(INDEX)

))

)

1 GENERAL INFORMATION

1.1 Contents of the manual -----------------------------------------------------------------

1-1

1.2 The label of manufacturer and bar feeder -----------------------------------------

1-2

1.3 Support of technique --------------------------------------------------------------------

1-2

2 DATA OF TECHNIQUE

2.1 Introduction of the bar feeder ---------------------------------------------------------

2-1

2.2 Machine size ------------------------------------------------------------------------------

2-2

2.3 Description --------------------------------------------------------------------------------

2-2

2.4 Compressed air supply and power supply -----------------------------------------

2-3

3 TRANSPORTATION

3.1 Packing the Feeder ----------------------------------------------------------------------

3-1

3.2 Transportation and hoist ---------------------------------------------------------------

3-2

3.3 Forklift transportation -------------------------------------------------------------------

3-3

3.4 Installation area --------------------------------------------------------------------------

3-5

4 INSTALLATION

4.1 Bar feeder ---------------------------------------------------------------------------------

4-1

4.2 Adjustment of height --------------------------------------------------------------------

4-1

4.3 Initial position -----------------------------------------------------------------------------

4-2

4.4 Directional adjusting --------------------------------------------------------------------

4-3

4.5 Mounting of the feeder frame ---------------------------------------------------------

4-4

4.6 Securing and fastening of the bar feeder ------------------------------------------

4-4

4.7 Accessories installation ----------------------------------------------------------------

4-5

INDEX V-65E-A

Ⅱ

CONTENT(

((

(INDEX)

))

)

5 ADJUSTMENTS AND SETTING

5.1 Structure of the bar feeder -------------------------------------------------------------

5-1

5.2 Adjustment and selection of the bar feeder ---------------------------------------

5-2

5.3 Adjustment of bar stop -----------------------------------------------------------------

5-2

5.4 Adjustment of bar diameter -----------------------------------------------------------

5-3

5.5 Adjustment of push bar pressure ----------------------------------------------------

5-3

5.6 Selection of push bar -------------------------------------------------------------------

5-4

5.7 Optimizing remnant ---------------------------------------------------------------------

5-5

5.8 Maintain notice-key switch ------------------------------------------------------------

5-6

6 OPERATIONS AND ILLUSTRATIONS

6.1 Material preparation --------------------------------------------------------------------

6-1

6.2 Operation description ------------------------------------------------------------------

6-2

6.3 Description of settings and parameter ---------------------------------------------

6-7

6.4 Refer alarm message ------------------------------------------------------------------

6-23

7 ELECTRICAL CIRCUIT DIAGRAM

8 PARTS LIST

1. GENERAL INFORMATION V-65E-A

1-1

1. GENERAL INFORMATION

Please read the Manual carefully before operating bar feeder.

1.1 Contents of the manual

The feeder manufacturer provides this manual, which is an essential part of the

integrated products. Please act according to the indication of the manual in order

to assure operators’ safety as well as the machines’, and greatly achieve

economic efficiency and to get the best output of the machine’s capability. The

important part is printed in boldface, and included the following marks:

Warning:

::

:

Hazard! It is possible to hurt you seriously, please be careful.

Watch out-Precautions:

::

:

For preventing the accident or the loss of property, you should take precautions.

Important information:

::

:

Special important know-how information

Please take use of the table of contents, you will quickly find the information you

need.

The mark shown in the manual means that the machine should be operated by a

qualified and expert operator. As to the other operation shall be handled by a

qualified personnel or professional operator of bar feeder.

1. GENERAL INFORMATION V-65E-A

1-2

1.2 The label of manufacturer and bar feeder

A. Name of manufacturer

B. Model(Type)

C. Serial Number

D. Manufacture Date

E. Weight of Machine

F. Pneumatic Pressure

G. Rated Voltage

H. Control Voltage

I. Full Load Current

J. Power

K. Short Circuit Rating

L. Wiring Drawing Number

1.3 Support of technique

If you need any support of technique, you can inquire the service center in the

appendix at anytime.

INFORMATION:

::

:

When you need the support of technique, please refer to the label on the bar

feeder. Tell us the data of the bar feeder.

2. DATA OF TECHNIQUE V-65E-A

2-1

2. DATA OF TECHNIQUE

2.1 Introduction of the bar feeder

The V-65E/LE-A is designed for full automatic lathe to auto feeds material, the bar

feeder is suitable for digital control sliding headstock lathe and fixed headstock

lathe. The program of the P.L.C system can control the bar feeder running with the

lathe at the same time. Operator can set parameters by the interface of man

machine directly.

The remote control box is easily to be operated.

The bar feeder can feed circular material and any other forms of material. While

the lathe is running, the guide channel is closed completely; meanwhile, the

lubricating oil is poured into the guide channel. Therefore, noise and shake can be

reduced while the material is rotated in high speed.

Furthermore, the lubricating oil also can reduce the temperature resulted from

friction so the surface of material can't be damaged. The remnant material will be

pushed out off the guide channel by the push bar or the next material.

The instructions and legends of the manual are edited according to the operator

stands at the left side of the lathe.

2. DATA OF TECHNIQUE V-65E-A

2-2

2.2 Machine size

2.3 Description

V-65E-A V-65LE-A

Diameter of bar

∅

5 mm ~

∅

65 mm

Length of bar max.1250 mm

Bar length depends on

spindle length.

max. 1550 mm

Bar length depends on

spindle length.

Spindle height 850 mm ~ 1250 mm

Extend spindle height 1095 mm ~ 1500 mm

Weight 250 kg 280 kg

Air supply 5 ~ 7 kg / cm2

Power supply 220 / 380V 0.4A 50 / 60Hz

2. DATA OF TECHNIQUE V-65E-A

2-3

2.4 Compressed air supply and power supply

2.4.1 Compressed air pipe minimum Ø 8mm. Minimum pressure 6 kg/cm2. Compressed

air consumption about 50L/H.

2.4.2 Put the air supply tube into (A). Then pull and turn around the knob (B) and set the

pressure at 6kg/cm2.

2.4.3 Power supply 220V/380V,50/60Hz.

3. TRANSPORTATION V-65E-A

3-1

3. TRANSPORTATION

Hazard-

--

-warning:

::

:

Transportation and hoist (please refer to the item 3.2.1 of following weight table)

You have to sure the crane; forklift or other related tools could take the weight.

Using the proper equipment to move and hoist the machine should be led by the

expert personnel.

3.1 Packing the Feeder

There are three kinds of packing Feeder:

A. Unpacking.

B. On the pallet: Put the feeder on the pallet and wrap PE membrane around the

feeder.

C. Packing with wooden box: The Feeder was packed with wooden box and wrap

PE membrane around the box.

3. TRANSPORTATION V-65E-A

3-2

3.2 Transportation and hoist

3.2.1 Unpacking hoist

Putting two steel bars (Diameter:

30mm, Length: 1M) under the bar

feeder, using suitable steel ropes

which are able to bear the weight to

hoist the bar feeder.

3.2.2 On the pallet

Using suitable steel ropes which are

able to bear the weight to hoist the

bar feeder.

3.2.3 Packing with wooden box

Using suitable steel ropes which are

able to bear the weight to hoist the

bar feeder.

V-65E-A 250kg(NET) 300kg

V-65LE-A

280kg(NET) 370kg

3. TRANSPORTATION V-65E-A

3-3

3.3 Forklift transportation

3.3.1 Safety regulation moved by forklift

1. The operator of forklift should have been trained.

2. Select the suitable forklift.

3. Make sure the weight and the center of gravity of the machine.

4. The forks should extend under the full length of the machine body during

transportation.

5. Be sure the balance and don’t lift too high.

6. Be careful when climbing or descending down a slope.

7. Be sure all wire connections have been removed before moving.

8. Someone should to guide the operator of the forklift.

9. Forklift truck must be a minimum of 7 tons capacity.

10.Make sure that forks do not touch any delicate part of the machine.

11.Make sure machine is in balance.

(Note) Machine weight approx.:V-65E-A------ 250kg (506lbs)

V-65LE-A---- 280kg (594lbs)

(1) Unpacking hoist

3. TRANSPORTATION V-65E-A

3-4

(2) On board transportation

(3) Wooden transportation

Machine weight approx.:V-65E-A------ 300kg (660lbs)

V-65LE-A---- 370kg (814lbs)

A. Moved by crane B. Moved by forklift

3. TRANSPORTATION V-65E-A

3-5

3.4 Installation area

In order to fix the feeder securely, the floor must be flat and firm.

According to the operation of the feeder to reserve a suitable area in advance.

Area:(D-operator area),(E-supply area),The space must be enough to avoid the

feeder caused crashed by the operator.

The area of installation needs to have suitable lighting, outlet and compressed air

joint.

The feeder can’t adapt to explosive surrounding.

4. INSTALLATION V-65E-A

4-1

4. INSTALLATION

4.1 Bar feeder -

--

-Installation

Before installing the bar feeder, the spindle of the lathe must be horizontal and the

Lathe is fixed on the ground strongly.

4.2 Adjustment of height

4.2.1 Disengage the screw(1).

4.2.2 Adjust the screw(2)and shift from up to down.Adjust the height to a straight line

between the center of the bar feeder and the center of the lathe.

4. INSTALLATION V-65E-A

4-2

4.3 Initial position

4.3.1 Distance between V-65E/LE-A and CNC-lathe

In order to use the automatic bar feeder in the best possible way you should see to

it that the distance between the CNC-lathe and the bar feeder is not too short!!

You may; however, load only bars whose length equals the spindle length of the

CNC- lathe. The bar stock has to be fed completely into the lathe spindle.

The bar feeder, however, must not be too far from the CNC-lathe.

The Max distance between CNC-lathe and bar feeder can be seen from the

following drawing.

If 1250mm should not be enough, you have to install a V-65LE-A to replace

V-65E-A.

! IMPORTANT ! Be careful that – if several chucking devices are available-the max.

Distance will never be exceeded.

L A

V-65E-A 1600mm Max.1250mm

V-65LE-A 1900mm Max.1550mm

4. INSTALLATION V-65E-A

4-3

4.4 Directional adjusting

! IMPORTANT !

During directional adjusting the push bar must not touch the lathe spindle!!

The height must have been adjusted roughly beforehand and has to be readjusted if

necessary.

The direction has to be adjusted rather exactly as the adjusting range for precision

adjusting is limited.

Adjusting: You should be able to see through the spindle from the chuck and move the

push bar forwards.

If the push bar does not go through the middle of the spindle, go back to final position “ –Z ”

and adjust the bar feeder afterwards. Then check the direction of the push bar and repeat

checking until the push bar is adjusted exactly.

4. INSTALLATION V-65E-A

4-4

4.5 Mounting of the feeder frame

4.5.1 First, put the lever into support tube(1).

4.5.2 The support profile fixed with the extension(2)and fastened in the suitable height

with screw(3).

4.5.3 Then the middle support profile fixed with the extension(4).

4.5.4 Finally securing with the screw(5).

4.6 Securing and fastening of the bar feeder

4.6.1 Rotate 4 ground-screws(1)to touch the ground, and fix the nuts.

4.6.2 Drill ground(2)with drill bit Ø19mm(¾”), and fix the spindle-screw.

5

1

3

4

2

2

4. INSTALLATION V-65E-A

4-5

4.7 Accessories installation

4.7.1 Axial displacement (optional)

4.7.1.1 Place two woods (height: about 10cm) under the bar feeder.

4.7.1.2 Place axial displacement by each side under stands of the bar feeder

(axial displacement has two parts: right part and left part)

4.7.1.3 Push the stands to the end of axial displacement and fix. And then take woods

away.

4.7.1.4 Drill ground with drill bit Ø 19mm(¾”)of bit, and fix the spindle-screw.

4.7.2 Auxiliary support stand (optional)

4.7.2.1 Place a bar on V-type holder and spindle of the lathe.

4.7.2.2 Place Auxiliary support stand in front of the bar

feeder and then lift Auxiliary support stand to touch

the bar and fix the screws.

4.7.3 Auxiliary support stand (optional)

4.7.3.1 Place Auxiliary support stand between bar feeder and lathe.

4.7.3.2 Loose screws(1)and(2), adjust screws(3)to suitable height so that the push

bar into the center of the guide tube is accurately.

4.7.3.3 Tighten screws(1)and(2).

4. INSTALLATION V-65E-A

4-6

4.7.4 Spindle liners

4.7.4.1 How to select correct spindle liners:

The inner diameter of the spindle has to be adjusted to the outer diameter of the

bar stock. According to our experience, the diameter of spindle of blank bar stock

should be bigger by 3mm to 5mm than the diameter of bar stock.

Even black bar stock can be machined by spindle liners.

4.7.4.2 How to make two kinds of spindle liners:

1 Iron tube:

::

:Choose tubes which internal diameter is bigger by 3mm to 5mm

than the material to make.

2 PE:Choose PE or Teflon to make according to the following method.

1. Tube:The thickness of the tube is 2mm to 3mm

2. Liners:Internal diameter of the lines should be bigger by 3mm to 5mm than the

material.

3. Stop ring:In order to fasten the liners, the stop ring would be accorded with the

inter diameter of the spindle to can make in the form of ladder.

4. When feeding different sizes of material, exchange the liners and stop ring.

※ The tube and the diameter of the liners must be smaller by 3mm to 5mm than

the inter diameter of the spindle which prevent the tube was expanded.

This manual suits for next models

2

Table of contents

Other Edge Technologies Industrial Equipment manuals