Thaler KE-SP 60100 GM User manual

Operation Manual

Cable pulling winch

KE-SP 60100 GM

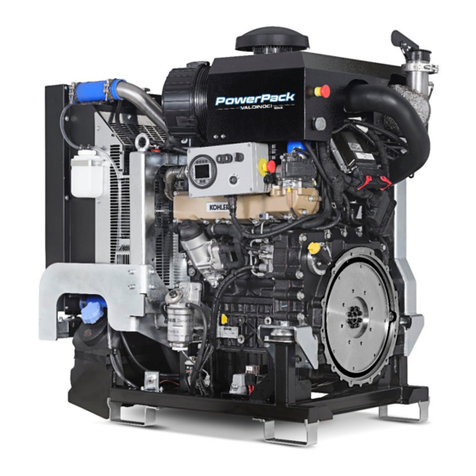

Diesel motor (Kohler)

Electronic Measuring System TM 3000

Indicate Serial Number W09SP5103EET06517

!"#

$%&"''(###%

)!"#

$%&"''(###(

*+,-.

/+000-.

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Jakob Thaler GmbH

25335 Elmshorn GERMANY

This symbol calls attention to important safety instructions which, if not

followed, could result in serious personal injury or death.

Read, understand and observe all safety information and instructions in this manual,

and on safety decals on the KE-SP 60100 GM before using it. For safety reasons, read

the operators manual carefully and exercise caution while using the winch.

Please note specific safety requirements as explained by procedures called out in this

manual. Failure to follow these instructions could result in serious personal injury

or death.

All tools, materials and equipment manufactured and supplied by Jakob Thaler GmbH

are designed to be used by qualified and trained personnel only. Jakob Thaler GmbH

will not be held liable for any injury or damage to either people or property resulting from

the misuse of Thaler equipment.

Please save this user's guide for future reference and have it available to all

operating personnel. Personnel should thoroughly read this operating manual.

Warning:

Do not start, operate or service

machine until you read and

understand operator’s manual.

Failure to do so result in serious injury.

Warning:

Moving cable can crush and cut.

Do not operate with panel open. Shut off machine

before servicing, cleaning and inspection.

Warning:

Battery explosion can blind.

Acid can blind and burn.

Read manual before servicing

Warning:

Fuel and fume can explode and burn

No smoking - No fire - Stop engine

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Warning:

Stay clear of front and rear while pulling cable

Equipment may move in either direction suddenly when under tension.

Warning:

Warning:

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Follow all safety instructions concerning safety and possible danger.

Do not modify or remove the safety devices or warning labels of this machine. Keep all labels

regarding safety and possible danger on the machine in good, readable condition. Special care is

required before and during the safety check.

Every crew member should fully understand the safety measures required for the operation and

should be capable of following these regulations individually.

The KE-SP 60100 GM is manufactured to the current technical safety-relevant regulations.

Nevertheless, the use of the machine may represent a danger to the health and life of users or third

parties. Always ensure that you pay particular attention to warnings, safety labels and instructions.

Read Operators Manual

Before starting the machine, fulfil

l all safety related requirements. All

personnel should thoroughly read this operating manual.

Follow all safety instructions concerning safety and possible danger. Do not

modify or remove the safety devices or warning labels of this machine.

Keep all labe

ls regarding safety and possible danger on the machine in

good, readable condition. Special care is required before and during the

safety check.

Every crew member should fully understand the safety measures required

for the operation and should be capable

of following these regulations

individually.

Call Before You Dig

Check the existence and exact position of buried pipe and cables by

contacting the respective utilities or owners of networks. The exact and

definite existence and position of buried cabl

es and pipes should be defined

by trial pits or using cable and pipe detection equipment or other means.

Cable Strike

Should you accidentally hit an electrical cable, immediately leave the site,

ensure no one enters and contact the electrical company t

o turn off the

supply.

In case of a cable strike, the danger resulting from that damaged electric

cable can only be evaluated following detailed information by the respective

electrical company. Never rely on your own knowledge as to types of

cables, safet

y measures and protective measures that may not be correct

for the type of cable encountered. Always consider cables to be “live” and a

potential danger to life. Do not re-enter the site until authorized by the

electrical company.

No Loose Clothes

Do not wear loose clothes or long hair. Danger of body injury by loose

clothes or hair being caught in the moving parts of the machine.

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Personal Protective Equipment

The operating crew should always wear the appropriate safety

equipment, safety shoes

/boots, hard hat, safety glasses, gloves, ear

protection etc.

Operation by Qualified Personnel Only

Operation of the winch should be carried out by suitably trained,

qualified, and certified personnel only. New operators or operators in

training should be working under the constant supervision of a qualified

person. Personnel operating the winch should have sufficiently

studied the operating manual.

Skin Burning Caution

This item can be hot or cold. Do not touch as burns may result.

Winch Maintenance

Use the machine only if it is in perfect working order and after studying

the operating manual, particularly the safety-

related sections. Always

check the machine and its accessories for unwanted movements. To

guarantee long life, regular maintenance is essential. Inadequate or

infrequent repair and maintenance operations may lead to accidents,

downtime and costly repairs of the machine.

During repair and maintenance operations always follow the respective

safety recommendations. Repair and maint

enance operations are

restricted to trained and certified staff only.

Transporting the KE SP 60100

Danger of accidents. Do not overload the transportation vehicle.

Starting & Exit Pit Excavation

Make sure that start and exit pits are excavated and sh

ored as

necessary to comply with the regulations and guard against collapse.

Jakob Thaler GmbH

25335 Elmshorn GERMANY

The KE-

SP 60100 GM constant tension, variable speed winch is a trailer mounted twin capstan mobile

hydraulic winch used for a variety of ap

plications including cable placing. The winch is comprised of three

major components including the twin capstan assembly, rope storage drum and the engine/hydraulic power

pack

The winch is mounted on a heavy-duty tandem axle trailer fitted with overrun bra

kes for towing safety. The

machine is normally fitted with a ring eye and wired for stop and turn signals and night running lights.

2.

A. Product Identification

Record Identification Numbers.

If you need to contact your service station or Jakob Thaler f

or information on servicing, always provide the

model and serial numbers.

You will need to locate the Identification numbers for the machine. Record the information in the spaces

provided below.

Machine Identification Numbers

Model #__________________

Serial # __________________

Engine Identification Numbers

Model #__________________

Serial # __________________

Jakob Thaler GmbH

25335 Elmshorn GERMANY

B. Control Identification dependent to Model

1 Electronic Recorder TM 3000

2 Engine Control Box

3 Winching Lever

4 Dead Man’s Control

5 Engine Accelerator

6 USB Port

7 Beacon Light

8 Emergency Stop

9 Fuel Gauge

10 Printer

11 TM 3000 On/Off

12 Red Control Lamp Winch Function Off

13 Green Control Lamp Winch Function On

14 Air filter control

15 Ignition Key

16 Set Button

17 Display

When Pressing the set button the display shows:

Engine speed, working hours, service hours, oil

pressure, coolant temperature and engine torque

1

2

3

4

5

6 7

8

7

10

9

11 12 13 14

15

16

17

Jakob Thaler GmbH

25335 Elmshorn GERMANY

B. Control Identification dependent to Model

Rope Payout 0 Pulling in

Winch control lever

As more the lever is pushed in one direction than

higher the line speed increases.

For pulling higher loads it is essential to set the

lever into lower line speed mode.

The operator must maintain a balance between

required pulling force and line speed.

Please note:

High loads = low speed

Low load = higher speed

Dead man’s control

For winching the dead man’s control must be

pressed. Place the control in the holder as

shown in picture.

For leaving the winch for observing the line pull

in the pit take the control and keep the red lever

pressed. As soon as the lever is released

winching function stops automatically.

Diesel engine’s throttle lever.

Pulling the lever increase the engine speed.

Please note:

In most winching application it is sufficient

when the engine runs in medium speed. The

engine generates the highest performance at

1500 rpm.

Only for quick rope pay out the engine

should run with maximum speed of 2700

rpm.

Jakob Thaler GmbH

25335 Elmshorn GERMANY

A. Pulling Force

Winch type

Pulling force

KE-SP 60100 GM

22046 lbs (10 000 kg)

B. Winch Line Specifications

Line diameter

Line length

5/8 in. (16 mm)

3182 ft. (970 m)

C. Engine Specifications

Engine

Power

3-cylinder Kohler diesel engine

56 HP (42 kW)

D. Chassis

Type

Hitch

Weight capacity

Tires

Tandem

Pintle eye

8818 lbs (4000kg)

215/75 R 17,5

E. Winch Specifications

Length

Height

Width

Weight

F. Twin Capstan Assembly

The capstans are of equal diameter and are driven by one or two hydraulic motors. Unlike winches that pull

off the drum, the hydraulic system of the KE-

SP 60100 GM ensures full power output regardless of storage

drum back tension. The line pull is

regulated automatically, giving very smooth operation without jerking or

slack. The capstan and associated parts are machined from low wear, case hardened steel and include

roller bearings.

G. Winch Line Storage Drum

The winch line storage drum is indep

endent of the winch and is driven by a separate hydraulic motor. A

cross groove spindle-

layering device ensures precision rope layering on the drum during operations,

preventing winch line damage.

H. Hydraulic System

The hydraulic power system is comprise

d of a combustion engine, hydraulic pump and motors to operate

capstan and rope storage drum. A separate hydraulic reservoir and, if required an oil cooler allow for

continuous operation with no overheating. The system provides fully automatic winching control.

Hydraulic power is generated by an axial piston pump that is driven by a diesel or petrol engine. The

hydraulic flow from the pump determines the line speed that is infinitely variable by a winching lever. The

hydraulic system is close center circuit ( hydro-static drive).

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Safe Operating Procedures

A. Safety Instructions

For your protection and the protection of others, practice the following safety rules.

1. Read operators manual and safety decals before operating this winch.

2. Only authorized personnel familiar with this winch and its functions to operate.

3. Do not use to lift, support or transport personnel.

4. ONLY pull load in horizontal direction. Do not use to lower or pull equipment vertically.

5. Do not operate until all safety shields are in place and controls function properly.

6. Turn off engine and secure against accidental movement and/or unauthorized start-up if leaving winch

unattended.

7. Keep winch clear of motor vehicle traffic or provide barriers, signs and/or

warning lights.

8. Verify all safety shields are refitted after maintenance.

9. Provide a quality inspection by a qualified specialist at least once a year.

10. Shut off winch and wait for movement to stop before,

servicing, cleaning or inspecting.

11. Only authorized operations personnel to remain near

equipment while cable is pulled under load.

12. NEVER enter manhole or excavation pit while winch is

pulling cable under load.

13. Personal protective equipment is required while operating

this machine. Keep hands, feet

B. Hydraulic Equipment

1. Tighten all connections before applying pressure. Relieve pressure when service unit.

2. Check for leaks with a piece of cardboard. Do not use hands.

3. Do not exceed working pressure of hydraulic hoses.

4. Visually inspect hydraulic system and connections regularly. Service if needed

C. Rope Inspection, Maintenance

(See Appendix A, B)

Transporting The Winch

A. Towing the Winch

In Standard version the KE_SP 60100 GM has an adjustable ring eye to allow the winch to be towed by

vehicles with various height rear bumpers. By turning the lever on the tow bar , the tires will support the load

at a level attitude at most vehicle hitch levels.

1. To change the winch attitude, lower the front jack stand to support the front oft the winch and provide a

level winch attitude. Turn the lever on the towing bar.

2. Raise or lower the hitch to the proper tow vehicle hitch height.

3. Tighten all bolts of the pintle hitch firmly.

IMPORTANT: Winch must be level for safe highway towing.

4. Fit the emergency brake cable to a rigid part of the towing vehicle!

5. Connect winch lights/electrical system to towing vehicle. Check that lights are functioning correctly.

6. Check all accessories on winch that they are properly placed and secured.

7. After winch is properly secured to tow vehicle check that the manual brake is released before

towing. (See Appendix C)

CAUTION: The KE-SP 60100 weighs in excess of 4000 kg. The tow vehicle must be rated for

this load.

A trailer connection light cable is provided to transfer lighting and signals to the winch. Check all

lights for proper operation prior to towing. Due to the weight of the winch, limit operations to normal

highway speeds and be aware of increased stopping distances with the winch attached. Rain, ice

and snow will

Jakob Thaler GmbH

25335 Elmshorn GERMANY

have a detrimental effect on safe highway operations.

B. Parking the Winch

On level ground simply apply the parking brake of the

winch before uncoupling it from the towing vehicle.

Only winches having overrun brake

chassis!

With electric brake place the chocks in front of

both wheels

In down-

hill position apply the parking brake of the

winch and put the chocks (held on the side of the

winch) in front of both wheels.

Only winches having overrun brake

chassis!

With electric brakes never park the winch down-

hill!

In up-

hill position allow the towing vehicle to roll back

far enough to let the brake system engage into

reverse mode, apply parking brake and put the

chocks behind both wheels.

Only winches having overrun brake

chassis!

With electric brakes never park the winch up-hill!

Jakob Thaler GmbH

25335 Elmshorn GERMANY

The majority of winch operations using the winch involve either a manhole or trench box

(excavation). The following setup will describe a typical underground cable laying situation.

2 A. Winch Placement and Manhole Selection

A pre-survey of the site conditions will help the operator determine which manhole to set the winch,

what position around the manhole to set the winch; and depth of manhole will determine the length of

the boom.

An ideal winch placement includes adequate space for cable and equipment staging, minimal

disruption to the surrounding area and a properly sized manhole in good condition (see Fig.).

In a pipe bursting application the receiving manhole or winch manhole selection is based on several

factors including the following.

1. CABLE STAGING

Adequate space is needed to safely and properly stage the fused length of cable laying.

Avoiding public inconvenience or disruption such as blocked driveways or business entrances may

require switching manhole choice.

2. OBSTACLES

Any obstacles adjacent to the selected manhole such as street lights, trees, damaged walls,

landscaping, etc. and ground conditions such as mud, water, decorative stone, peripheral utilities, etc.

will affect where and how the winch can be set up.

3. MANHOLE CONSTRUCTION OR CONDITION

Offset inverts and chimneys, damaged walls and loose bricks may make the manhole unusable.

NOTE: Cones, barricades, etc., should be placed around the winch in a traffic situation. A minimum

10-ft. (3 m) working radius around the winch is desired to prevent traffic problems.

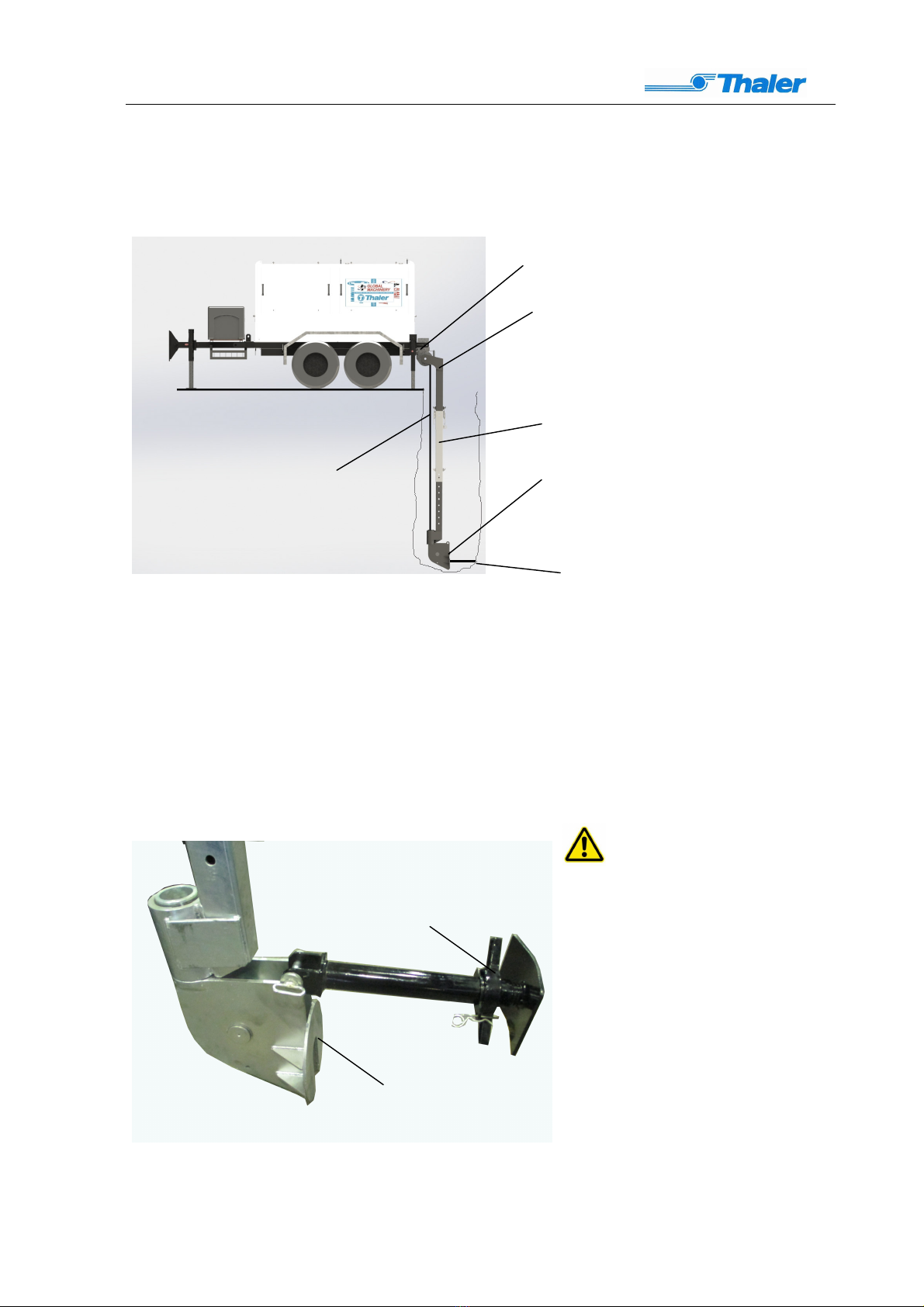

Boom

Cable

Exit pit

Support leg

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Stabilizing the Winch

The KE-SP 60100 GM has two rear jacks in addition to the front jack stand. This allows leveling

both laterally and side to side. In most situations, this is done after the winch boom is in position (if

required).

1. Turn the rear jack down.

2. Turn the front jack down to ensure proper stand of the winch.

Use proper lashing equipments as chains or

belts and connect them with the eyes of the

winch and a rigid point.

Rear Jack

Front Jack

Lashing points

Only for lifting the winch

Lashing eyes

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Boom Assembly

Warning:

The assembled boom is too heavy for manual installation! The use of a backhoe is

recommended to avoid injury

Top section

Intermediate section

Swivel bottom section

Support leg

bolt

bolt

bolt

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Boom Installation

Place the top section of the boom to the swivel pulley of the winch. Secure it with the appropriate

bolt. Dependent of required working depth use the intermediate sections. Fit them the top section.

Mount the swivel bottom section and adjust it to the required working depth.

Pull out the rope and insert the thimble of the rope through the swivel bottom section and guide the

rope over the pulley.

Note:

The face plate of the bottom section must placed against a rigid part in the pit or the support

leg must be mounted to the face plate and andjusted with the spindle to match a solid part!

When working with the

complete boom unit (maximum 16

ft.) it may be required to use

additional support legs at the

inter mediate sections! The

sections are fitted with

appropriate eys.

Swivel pulley

Top section

Intermediate section

Swivel bottom section

Winch rope

Winch rope

Face plate

Adjustable spindle

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Boom Application

When using the top and the swivel bottom section only the minimum working depth is 4 ft. and the

Maximum working depth 6 ft.

With one intermediate section the maximum working depth is 9 ft. With two intermediate sections

the maximum working depth is 13 ft. and with three sections 16 ft.

The bottom part of the boom is depth-adjustable in 3.94 inches steps. The supporting leg is

adjustable from 22 inches up to 34 inches

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Starting the Winch Before

Check to see if it is safe around the winch before starting.

Check low fuel indicator (only Diesel engines) when ignition

switch is on, if necessary fill with diesel fuel as required.

Check motor oil and hydraulic oil levels and fill as needed. (For

type of oils to be used check Technical Specifications.)

Make sure all covers and shields are closed and secured,

before start-up. (Except for winch controls cover.)

Make sure the dead man’s control is switched on.

Make sure the emergency-stop button is not pressed.

Caution: Do not run the winch in closed or poorly vented

areas.

Starting Procedure

Turn the winching lever to the neutral position

Set the engine throttle lever to a middle position.

Turn the ignition switch to the start position.

Do not start for longer than 20 sec. If winch did not start allow

starter to cool before attempting to start again.

Cold Starting Procedure

In cold weather the engine and hydraulic oil need a longer warm up time, allow at least 5-10 minutes

at half throttle before operating any functions.

NOTICE: Never use any spray starting additives, damage to the engine

could occur.

Winch Payout Procedure

With engine running using the throttle lever

increase engine speed to a 3/4 throttle.

Turn the winching lever completely into “pay-out”

position

Pull winch line out as needed.

Set the winching lever in 0 position

when the rope has been pulled out. Never

keep the capstan sheaves turning over a

longer period without pulling! Otherwise the

steel wire rope cause excessive wear to the

sheaves!

Jakob Thaler GmbH

25335 Elmshorn GERMANY

Winching In

After the rope has been pulled out to the

required length and the cable is connected

shift the lever carefully into “pull-in” position.

Observe winch’s movement. Stop winching

immediately if the winch is not proper

anchored!

During pull keep a balance between

generated pulling force and line speed. As

higher the reqired pulling force than lower

the line speed.

When pulling in the rope it must be sure that the rope is not pulled over sharp edges. Use

only swivel joints and tools which are declassified from winch’s manufacturer suitable for

use.

Make sure that no person enter the manhole during pull!

Stop winching

Shift the

winching lever in neutral position to stop

process.

Remove the cable from the rope’s thimble.

When pulling in the rope for transport make sure

that the thicker end is not pulled into the swivel

pulley to avoid damages to the layering arm and

measuring system!

For transport fix the end to a lashing eye with a

shackle.

Table of contents