FIGURE 4. Parts Code Numbers

Parts List continued

3

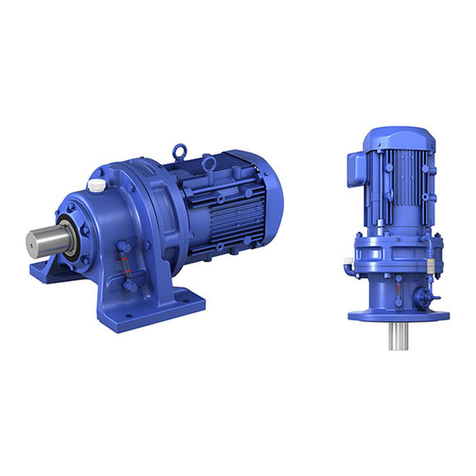

Cyclo®BBB

Item No. Description QTY A B C D E

1 Gear Housing 1 AE693LG AE774LG AE695LG AE696LG AE697LG

2 Output Cover 1 BL520LG BL531LG BL542LG BL550LG BL554LG

3 O-Ring 1 540NG1701-A-G 540NG2101-A-G 540NG2601-A-G 541N5.7-3258G 541N5.7-3757G

4 Oil Seal 2 531N8511013-G 531N10012513G 531N12015014G 531N14017014G 531N16019016G

5 Hex Head Bolt 8 001M010R030NG 001M012R030NG 001M016R040NG 001M020R050NG 001M020R050NG

6[2] Shim Varies As required As required As required As required As required

7 Plug 8 343C008R- - -NG 343C008R- - -NG 343C012R- - -NG 343C012R- - -NG 343C012R- - -NG

8 Bushing 1 332F008R004NG 332F008R004NG 332F012R004NG 332F012R004NG 332F012R004NG

9 Air Vent 1 DT206LG DT206LG DT206LG DT206LG DT206LG

10 Hex Head Bolt 4 001M010R030NG 001M010R030NG 001M012R040NG 001M016R050NG 001M016R050NG

11 Spring Washer 4 062W010- - - -NG 062W010- - - -NG 062W012- - - -NG 062W016- - - -NG 062W016- - - -NG

12 Eye Bolt 1 006C016R- - -NG 006C016R- - -NG 006C020R- - -NG 006C020R- - -NG 006C024R- - -NG

13 Key 1 233M2214021NG 233M2514028NG 233M2816040NG 233M3218050NG 233M3620060NG

14 Bevel Gear 1 AP0646G AP0647G AP0648G AP0649G AP0650G

15 Nilos Ring 2 50532017XAV-G 50532020XAV-G 50532024XAV-G 50532028XAV-G 50532032XAV-G

16 Tapered Roller Bearing 2 503T32017XU-G 503T32020XU-G 503T32024XU-G 503T32028XU-G 503T32032XU-G

17 Taper-Grip®Output Hub 1 BL937LG BL938LG BL939LG BL940LG BL941LG

18[3] Thrust Plate 1 — — — — —

19 Taper-Grip®Bushing 1 As required As required As required As required As required

20[3] Taper-Grip®Bushing Screws Varies — — — — —

21[4] Flanged Casing 1 As required As required As required As required As required

22 Hex Socket Plug Varies As required 343C008R- - -NG 343C008R- - -NG 343C008R- - -NG 343C008R- - -NG

23 Oil Seal 2 530N50689- - -G 530N60759- - -G 530N709513- -G 530N9011513-G 530N9011513-G

24[2] Shim Varies As required As required As required As required As required

25[2] Shim Varies As required As required As required As required As required

26 End Plate 1 AW7028G AW7030G AW7032G As required AW7036G

27 Lock Washer 4 EU593WW-05 EU593WW-05 EU593WW-07 As required EU593WW-09

28 Hex. Soc. Hd. Cap Screw 4 009M008R030NG 009M010R035NG 009M012R040NG As required 009M016R055NG

29 O-Ring 1 540NG1101-A-G 540NG1301-A-G 540NG1501-A-G 540NG1751-A-G 540NG1851-A-G

30[5] Pin Carrier 1 As required As required As required As required As required

31 Tapered Roller Bearing 1 As required As required As required As required As required

33 Bevel Pinion Shaft 1 BL513LG BL525LG BL536LG As required BL553LG

34 Nilos Ring 1 50532308AV- -G 50532310AV- -G 50532312AV- -G 50532314AV- -G 50532315AV- -G

35 Tapered Roller Bearing 1 503T32308U- -G 503T32310U- -G 503T32312U- -G 503T32314U- -G 503T32315U- -G

36 Collar 1 AW7027G AW7029G AW7031G As required AW7034G

Notes: [1] When ordering replacement parts, please indicate the complete unit model number, ratio and serial number.

[2] Shims are not available individually. They may be ordered as a complete set only.

[3] Item Numbers 18 and 20 are not available as individual parts. They come complete with the Taper-Grip® Bushing.

[4] The Flange Casing is determined based on the associated input Cyclo size.

[5] Item Number 30 is available as a complete subassembly only.

Unit Size