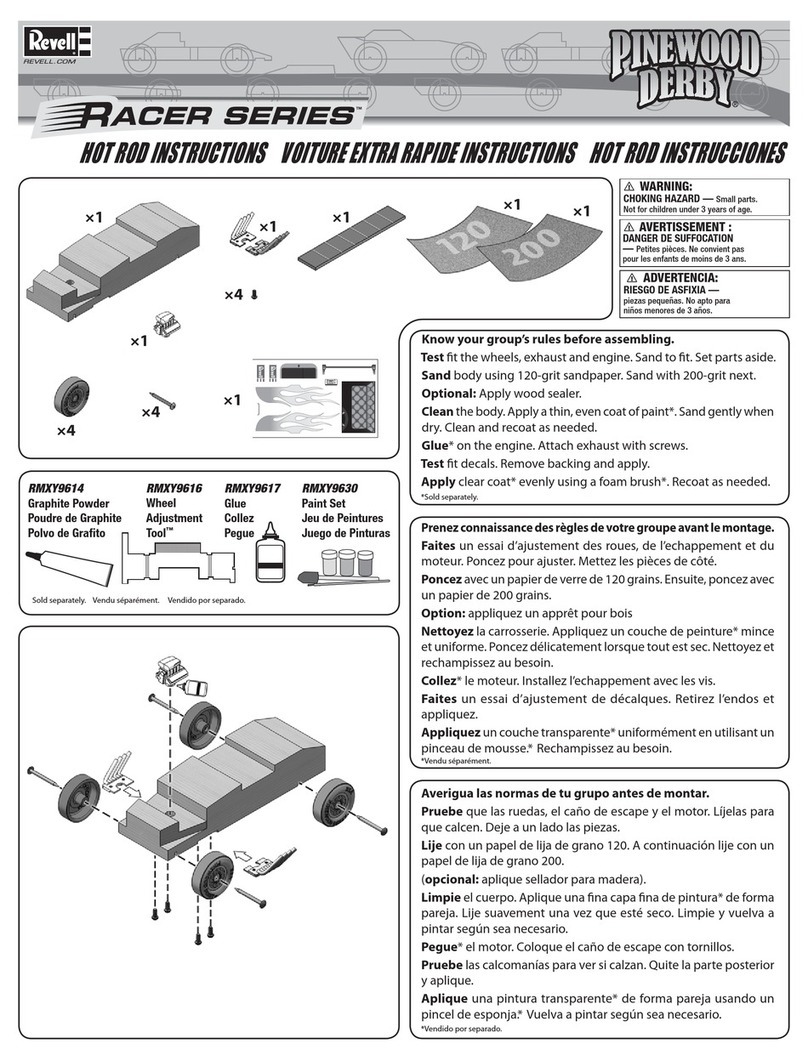

Introduction

General Safety Information

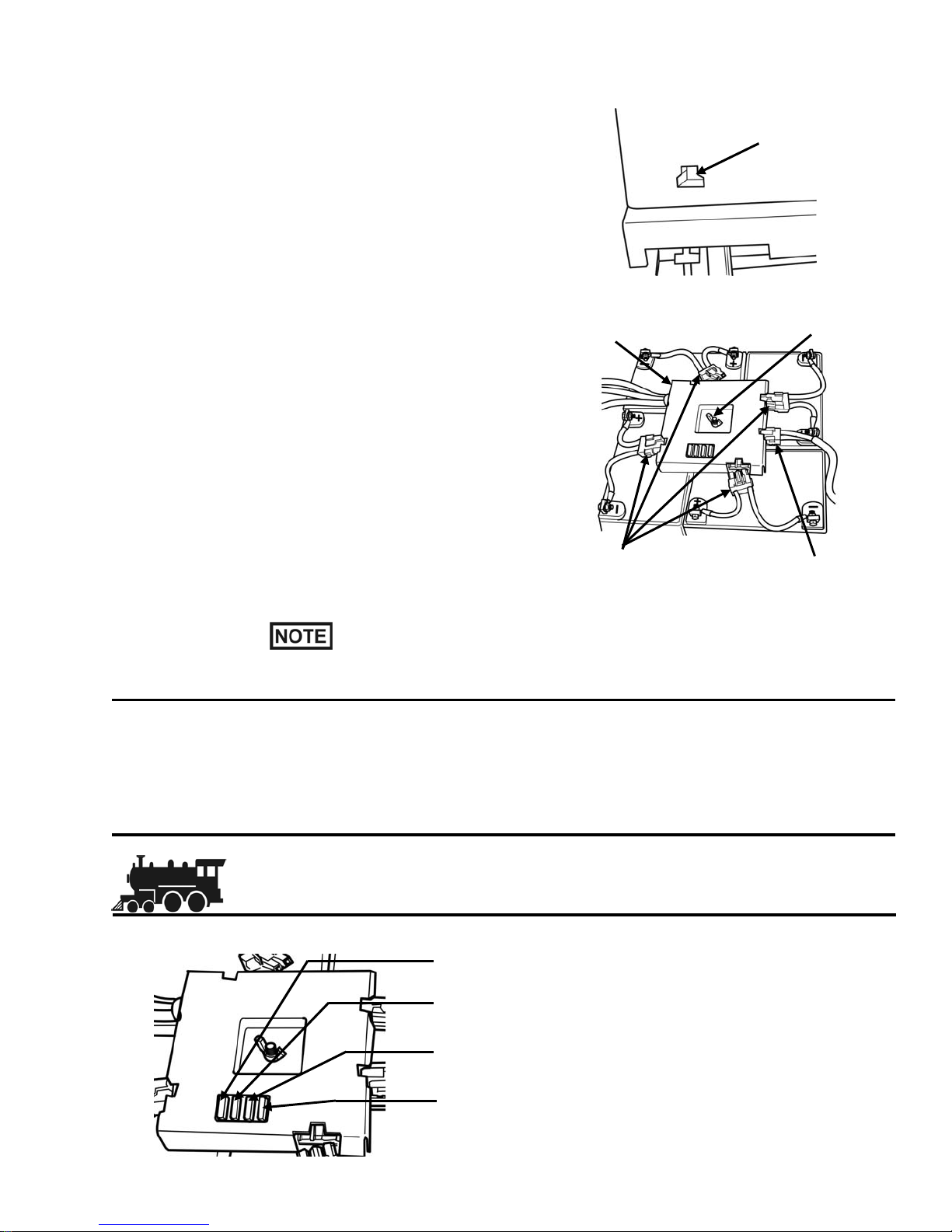

Notes are used to notify of installation,

operation, or maintenance information that is

important but not safety related.

Caution without the Safety Alert Symbol is used

to indicate the presence of a hazard, which if

ignored may result in property damage.

Caution with the Safety Alert Symbol is used to

indicate the presence of a hazard, which if

ignored may result in property damage and or

minor personal injury.

Warning denotes that a potential hazard exists

and indicates procedures that must be followed

exactly to either eliminate or reduce the hazard,

and to avoid serious personal injury, or prevent

future safety problems with the product.

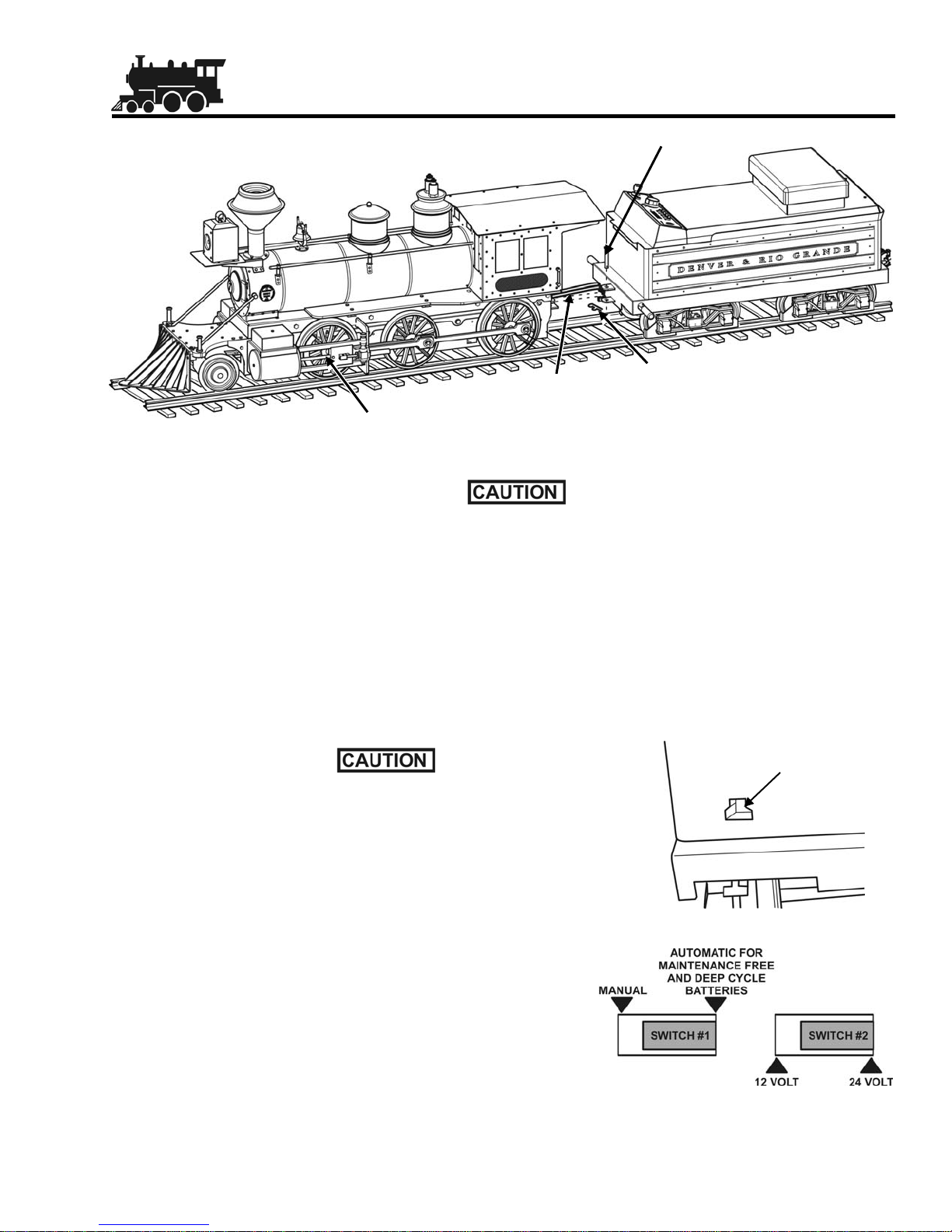

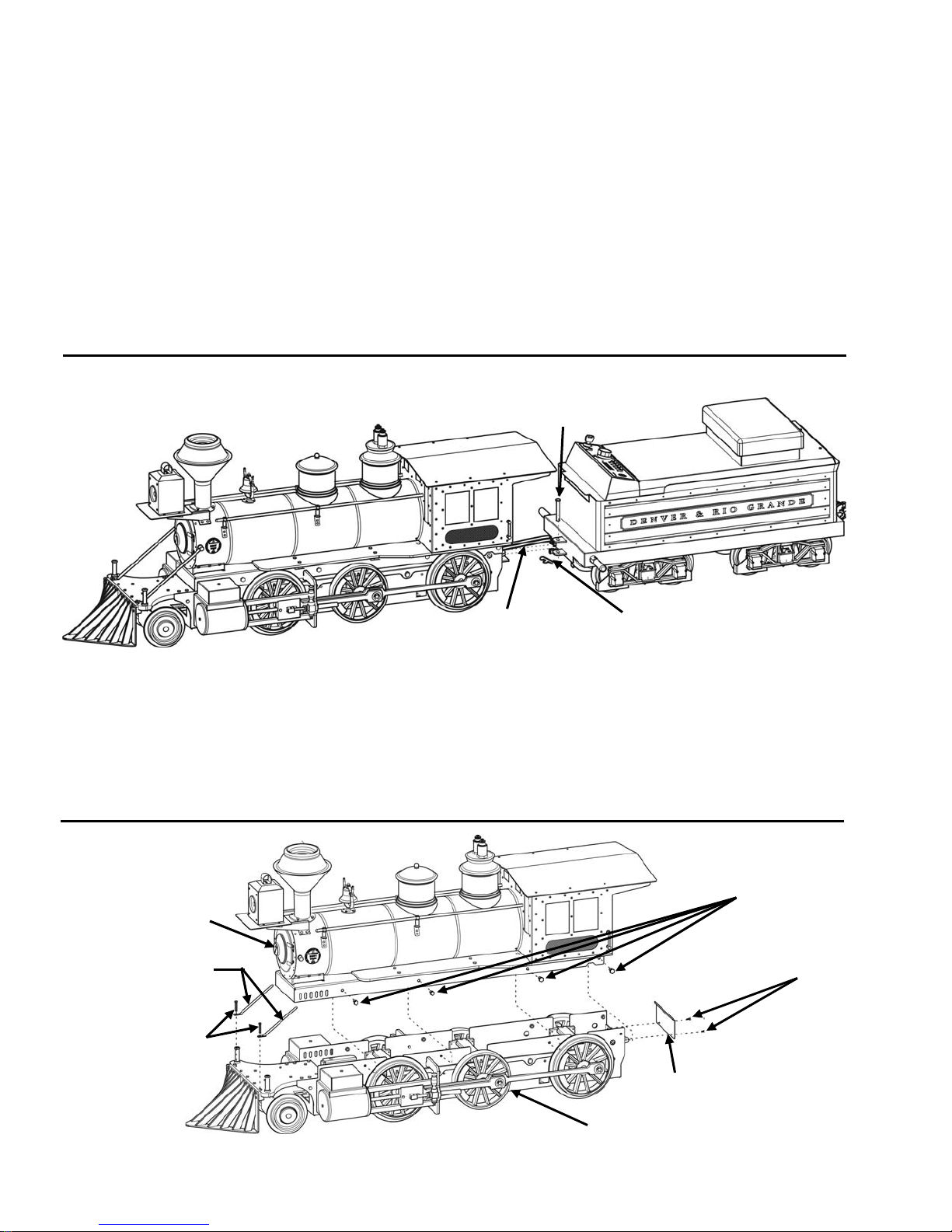

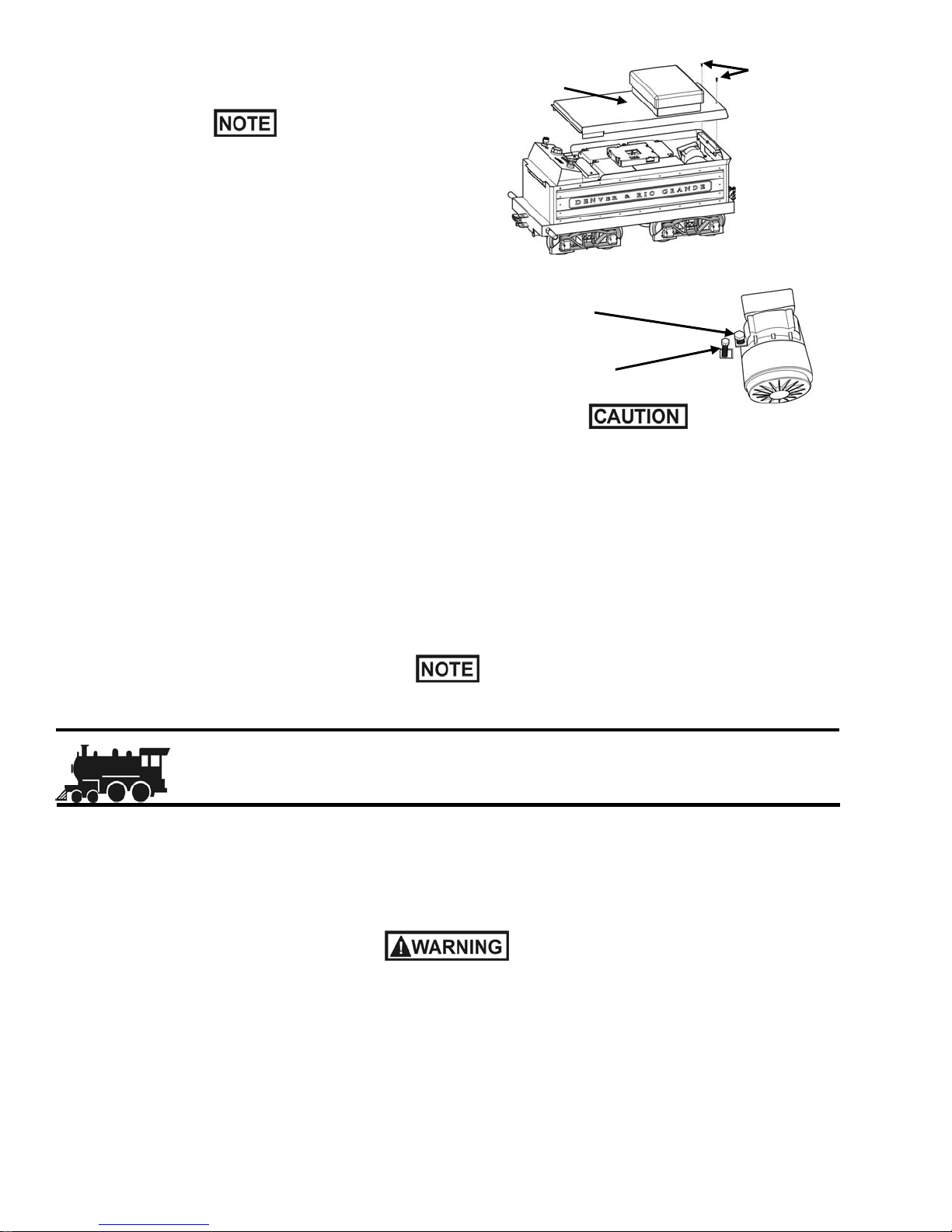

Congratulations on the purchase of your Great American Train Company (GATC), Mogul (2-6-0)

Steam Profile Locomotive. This model’s authentic styling is based upon the famous Baldwin Mogul

built by the Baldwin Locomotive Works of Philadelphia, Pennsylvania, U.S.A. during the late 1800s

and early 1900s. Baldwin Moguls were used extensively in the narrow-gauge railroads of the Old West

and particularly on the Denver and Rio Grande.

All Great American Train Company Locomotives are 24 VDC battery powered for safe, efficient and

reliable operation. Rated pulling power is awesome with its 1kW total motor power – about 1600 lbs.

of load on a 3% grade.

If you have any questions concerning the assembly and use, or if you feel your product is not working

properly, contact The Great American Train Company at 763-476-5140, or visit our website at

www.greatamericantrain.com.

Read these Instructions carefully, making full use of all explanations and instructions. The “Know

How” of trouble free operation of your railroad depends on the degree of your understanding of the

system and willingness to keep all components in proper operating condition. Pay particular attention

to all NOTES, CAUTIONS, and WARNINGS to avoid the risk of personal injury or property damage. It

is important to understand that these NOTES, CAUTIONS, and WARNINGS are not exhaustive. The

Great American Train Company cannot possibly know or evaluate all conceivable methods in which

procedures may be performed, or the possible hazardous consequences of each method.

Accordingly, anyone who uses a procedure that is not recommended by GATC assumes the risk of

personal injury or property damage.

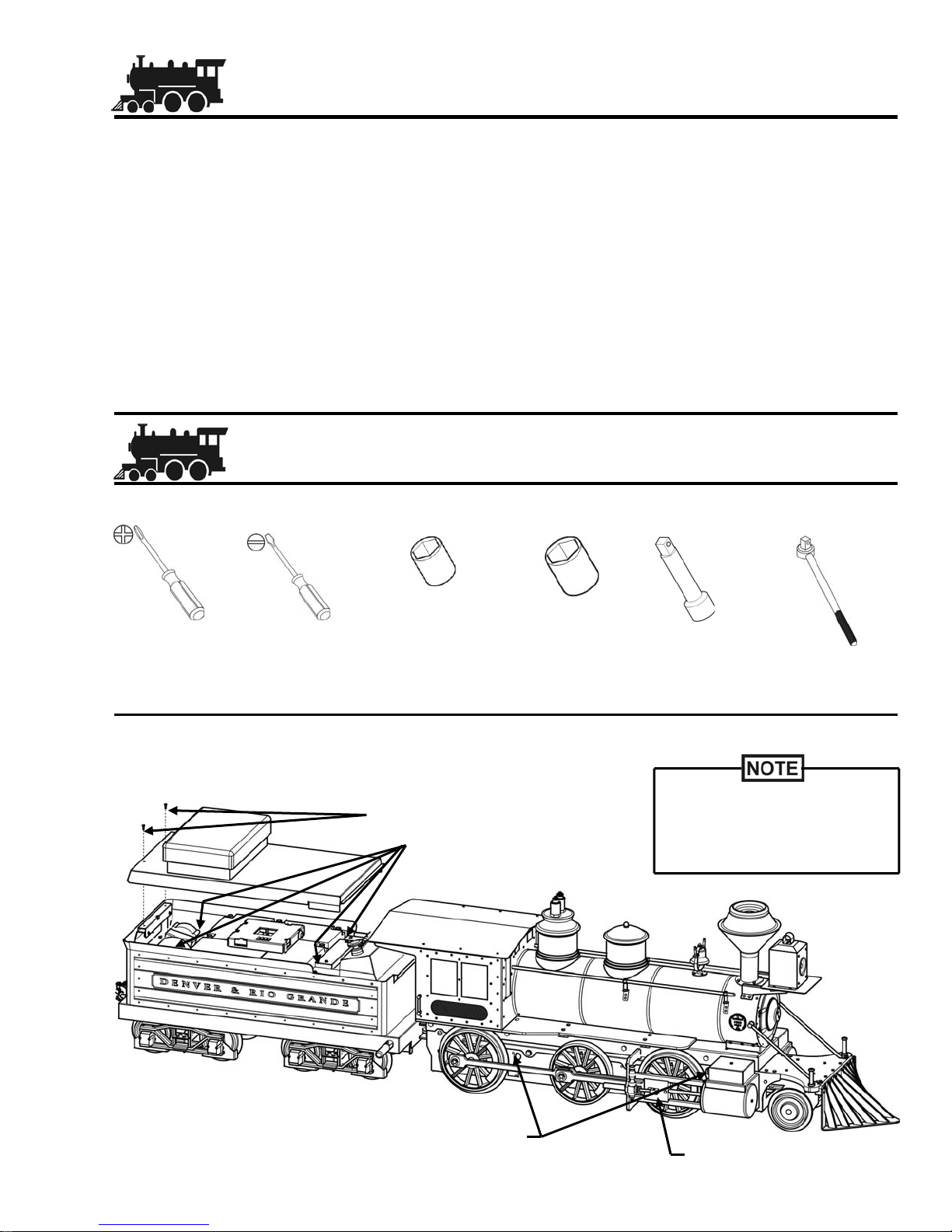

When unpacking your product, inspect each crate to ensure that no damage occurred during shipping.

If damage has occurred during shipping, contact the shipper immediately. Remove all components

from the shipping crates and inspect them. If any components are missing or damaged, contact The

Great American Train Company immediately at 763-476-5140. Do not use or assemble the product if

any components are damaged or missing. Do not use substitute components not manufactured by

The Great American Train Company.

2