The Handy THTD User manual

www.thehandy.co.uk

23/03/2022 v4

40” (101CM)

TOWED DETHATCHER

MODEL NO: THTD -- PRODUCT NO: 1938118001

EN - ORIGINAL INSTRUCTIONS

ASSEMBLY REQUIRED

SAVE THESE INSTRUCTIONS

SPARES & SUPPORT: 01793 333212

FOR YOUR SAFETY

Please read & understand this manual, paying attention to the safety instructions, before use.

Incorrect use of the product could put the operator or machine in danger.

Whilst every effort has been made to ensure the accuracy of information contained in this manual, our

policy of continuous improvement determines the right to make modifications without prior warning.

Images used are for illustration purposes only

INSTRUCTION MANUAL

Copyright Notice

Copyright © Handy Distribution

Permission is granted to reproduce this publication for personal & educational use only.

Commercial copying, redistribution, hiring or lending is prohibited.

No part of this publication may be stored in a retrieval system or transmitted in any other form or means without

written permission from Handy Distribution.

In all cases this copyright notice must remain intact.

CONTENTS

SPECIFICATIONS

IMPORTANT INFORMATION

GENERAL SAFETY INSTRUCTIONS

SET UP & PREPARATION FOR OPERATION

ASSEMBLY

OPERATION & ADJUSTMENT

MAINTENANCE

PARTS DIAGRAM & LIST

WARRANTY

NOTES

WARNING

Read this instruction manual carefully before operating this machine. Make sure that you are familiar

with the controls and properly operate the machine. Following these instructions can reduce the risk

of personal injury.

ASSEMBLY IS REQUIRED

This product requires assembly before use. See the “Assembly” section for instructions.

Please check that all parts required for the assembly of this dethatcher are included. If for any reason

you believe a part for the assembly is missing or damaged, please contact us.

Tools Required:

2x 1/2" Wrenches

1x 9/16" Wrench

1x 3/4" Wrench or Adjustable Wrench

1x Pliers

SPECIFICATIONS

The manufacturer reserves the right to change the product specification and livery according to continued

product improvements.

Model

THTD

Product Number

1938118001

Weight

14kg

Working Width

40” (101cm)

Recommended Tow Hitch Height

14 - 17cm

Spring Loaded Steel Tines

10 x 100mm

Consistent with our policy of continuous improvement, The Handy reserves the right to change the design and

configuration of any of its products without notice or obligation. Therefore, please treat the text and images in

this manual for illustrative purposes only. They may in no case serve as a basis for any legal claim.

If you require any assistance with regards to the contents or operation of your machine, please contact us:

Tel: 01793 333212, option 2

Opening Hours Weekdays: (CLOSED WEEKENDS & BANK HOLIDAYS)

February to October 8:00am - 5:00pm - November to January 8:30am - 5:00pm

IMPORTANT INFORMATION

IF NOT USED PROPERLY THIS MACHINE CAN BE DANGEROUS!

This machine can cause serious injury to the operator and others, the warning and safety instructions must be

followed to ensure reasonable safety and efficiency in using this product. The operator is responsible for

following the warning and safety instructions in this manual and on the machine. Never use the product unless

the fixing screws or guards are correctly positioned.

DESIGNED FOR DOMESTIC USE ONLY.

The Towed Dethatcher is designed for use in private gardens, whose annual use does not generally exceed 50

hours and is to be primarily used on LAWNS, but not in public facilities, parks, or sports grounds and not for

agricultural or forestry use.

Compliance with this manual supplied by the manufacturer is a prerequisite for the proper usage of the

machine. The operating manual contains servicing and maintenance instructions as well as directions for use.

TRAINING

Read the instructions carefully: Be familiar with the controls and the proper use of the equipment.

Never allow children or people unfamiliar with these instructions to use the product. Local regulations can

restrict the age of the operator.

Never operate while people, especially children, or pets are nearby.

Keep in mind that the operator or user is responsible for accidents or hazards involving the machine that occur

to other people or their property.

GENERAL SAFETY INSTRUCTIONS

It is important that you read and understand the owner’s manual and labels affixed to the machine. Learn its

application and limitations as well as the specific potential hazards. Retain these instructions for future

reference. The operator is responsible for following the warnings & instructions in this manual and on the

product.

Read & understand operator’s

manual before using the machine.

Failure to follow instructions could

result in death or serious injury.

Wear foot protection

Wear protective gloves to protect

your hands

Keep bystanders away

Keep guards in place and in working

order. Replace damaged, missing,

or failed parts before using it.

Risk of slicing. Keep hands

out of the way of all

moving parts.

Safety alert symbol. Used to alert

you to potential personal injury

hazards. Obey all safety messages

that follow this symbol to avoid

possible injury.

DANGER

Indicates an imminently

hazardous situation which,

if not avoided, will result

in serious injury.

WARNING

Indicates a potentially hazardous

situation which, if not avoided,

could result in serious injury

CAUTION

Indicates a potentially

hazardous situation which,

if not avoided, may result

in minor or moderate

injury.

CAUTION

Used without the safety alert

symbol indicates a potentially

hazardous situation which, if not

avoided, may result in property

damage.

IMPORTANT SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions!

Failure to follow the warnings and instructions may result in serious injury. Save all warnings and

instructions for future reference.

WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

PERSONAL SAFETY

a) Read the tow vehicle owner’s manual and vehicle safety rules to know how to operate the vehicle before

using this equipment.

b) Stay alert, watch what you are doing and use common sense when operating. Do not use whilst you are

tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating

may result in serious personal injury.

c) Use personal protective equipment. Always wear hard wearing gardening gloves and foot protection.

Protective equipment such as dust mask, nonskid stout shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

d) Prevent unintentional starting. Ensure the towing vehicle is switched off, when undertaking, cleaning,

servicing, or repairs.

e) Do not overreach. Always keep proper footing and balance. This enables better control in unexpected

situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing, and gloves away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

TOOL USE AND CARE

a) Do not force the tool. Use the correct tool for your application. The correct tool will do the job better and

safer at the rate for which it was designed.

b) Store idle tools out of the reach of children and do not allow persons unfamiliar with the tool or these

instructions to operate. It can be dangerous in the hands of untrained users.

c) Maintain tools. Check for misalignment or binding of moving parts, breakage of parts and any other

condition that may affect the tool’s operation. If damaged, have the tool repaired before use.

d) Many accidents are caused by poorly maintained power tools.

e) Use the power tool, accessories, and tool bits etc. in accordance with these instructions, considering the

working conditions and the work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

SAFE OPERATION PRACTICES

TRAINING

a) Read the instructions carefully. Be familiar with the controls and the correct use of the machine.

b) Never allow children or people unfamiliar with these instructions to use the machine. Local regulations

can restrict the age of the operator.

c) Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or

their property.

PREPARATION

d) Read the tow vehicle owner’s manual and vehicle safety rules to know how to operate the vehicle before

using this equipment.

e) Before use, always visually inspect the machine for damaged, missing, or misplaced guards or shields.

f) Never operate the machine while people, especially children, or pets are nearby.

g) Do not allow anyone to ride or sit on the dethatcher frame or on the towing vehicle.

OPERATION

f) Wear hard wearing gloves and stout shoes at all times while operating the machine.

g) Avoid using the machine in bad weather conditions.

h) Use the machine only in daylight or good artificial light.

i) Never operate the machine with damaged guards or shields or without guards or shields in place.

j) Switch on the tow vehicle engine only when hands and feet are away from a tow vehicle cutting means.

k) Take care against injury to feet and hands from the tow vehicles cutting means.

l) For ride on mowers, go up and down (NOT side to side). This gives maximum traction to the drive wheels

and lessens the risk of rolling. It also avoids the ‘crabbing’ that tends to happen when mowing crossways

on any slope, where the heavy end of the machine keeps trying to slide downhill making slope use

difficult. This equipment should be operated at reduced speed on rough terrain, along creeks and ditches

and on hillsides, to prevent tipping and loss of control. Do not drive too close to a creek or a ditch. Do not

tow this equipment on a highway or any other public thoroughfare. Always begin with the transmission in

first (low) gear & the engine at low speed. Gradually increase the speed as conditions permit. The vehicle

braking and stability may be affected with the dethatcher attached. Be aware of changing conditions on

slopes. Refer to safety rules in the vehicle owner's manual, concerning safe operation on slopes.

MAINTENANCE AND STORAGE

m) Disconnect the machine from the tow vehicle before carrying out maintenance or cleaning work.

n) Clean the machine immediately after use. Keep the machine clean to ensure it operates to its full & safest

performance.

o) Use only the manufacturer’s recommended replacement parts and accessories.

p) Inspect and maintain the machine regularly. Have the machine repaired only by an authorised repairer.

q) When not in use, the machine should be stored in a dry location, out of direct sunlight. Keep the machine

away from children & others not qualified.

ADDITIONAL SAFETY WARNINGS

PERSONAL SAFETY

DANGER

RISK OF SUFFOCATION

Small parts can be easily swallowed. There is also a risk that a polybag can suffocate toddlers. Keep toddlers

away when you assemble the product. Dispose of all polybags responsibly.

Know how to stop the product quickly in an emergency. Only work in the daylight or when visibility is good.

Check your product before each use. Always visually inspect your grass shear before each use. Check that the

ventilation slots are not obstructed in any way.

Do not overload the product.

WARNING

When wearing hearing protection, the operator may not notice persons approaching.

Always wear suitable clothing, protective gloves, and stout shoes. Always ensure that you have a secure

foothold whilst working. Do not work on slippery surfaces.

DISPOSAL

The garden product, accessories and packaging should be sorted for environmental-friendly recycling. Do not

dispose of garden products, into household waste!

SET UP & PREPARATION FOR OPERATION

This product must be assembled correctly before use. Carefully remove the product and any accessories from

the carton. Inspect the product carefully to make sure there are no breakages or missing items during shipping.

Do not discard the packing material and carton until you have carefully inspected and satisfactorily operated

the product.

WARNING

If any parts are damaged or missing do not operate this product until the parts are replaced. Failure to heed

this warning could result in serious personal injury.

Do not attempt to modify this product or create accessories not recommended for use with this product. Any

such alteration or modification is misuse and could result in a hazardous condition leading to possible

serious personal injury.

Read and follow all instructions for assembly and operation. Failure to properly assemble this equipment

could result in serious injury to the user or bystanders, or cause equipment damage.

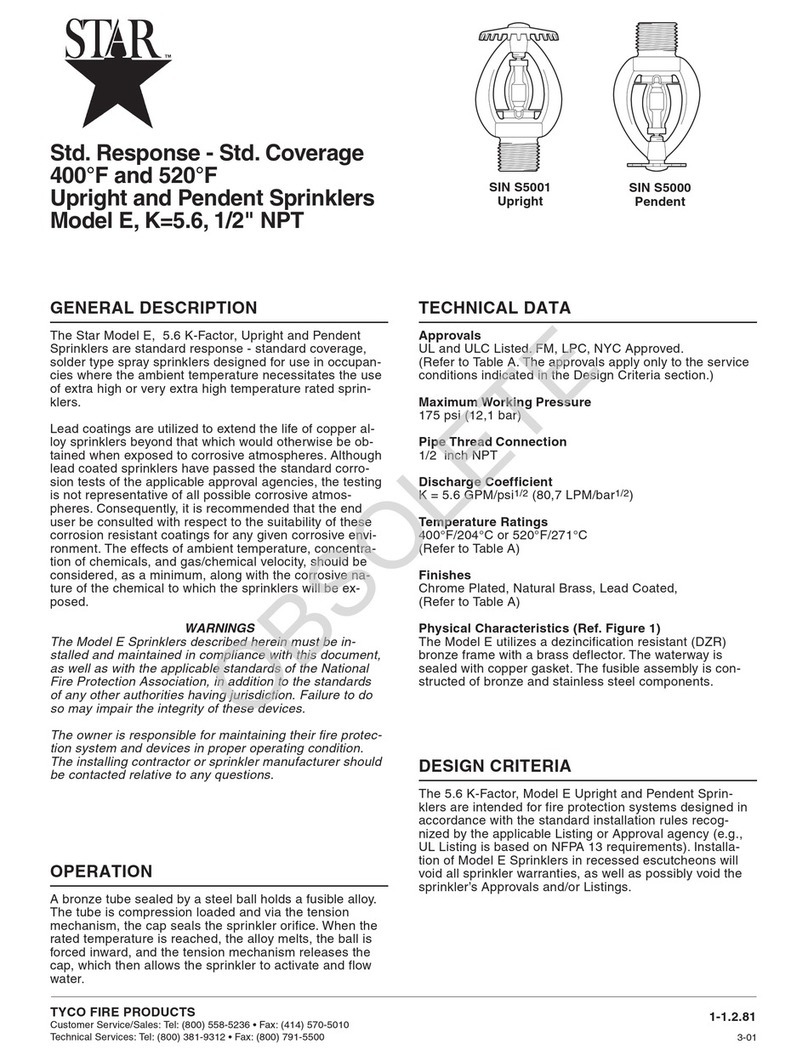

1. Tine Shield (40’’)

1

4. Axle Bracket

1

7. Hitch Brackets

2

2. Spring Tines x10

10

5. Wheels

2

8. Hitch Mount Arms

2

3. Lift Handle

1

6. Lift Plate

1

9. Spring Alignment Wires

2

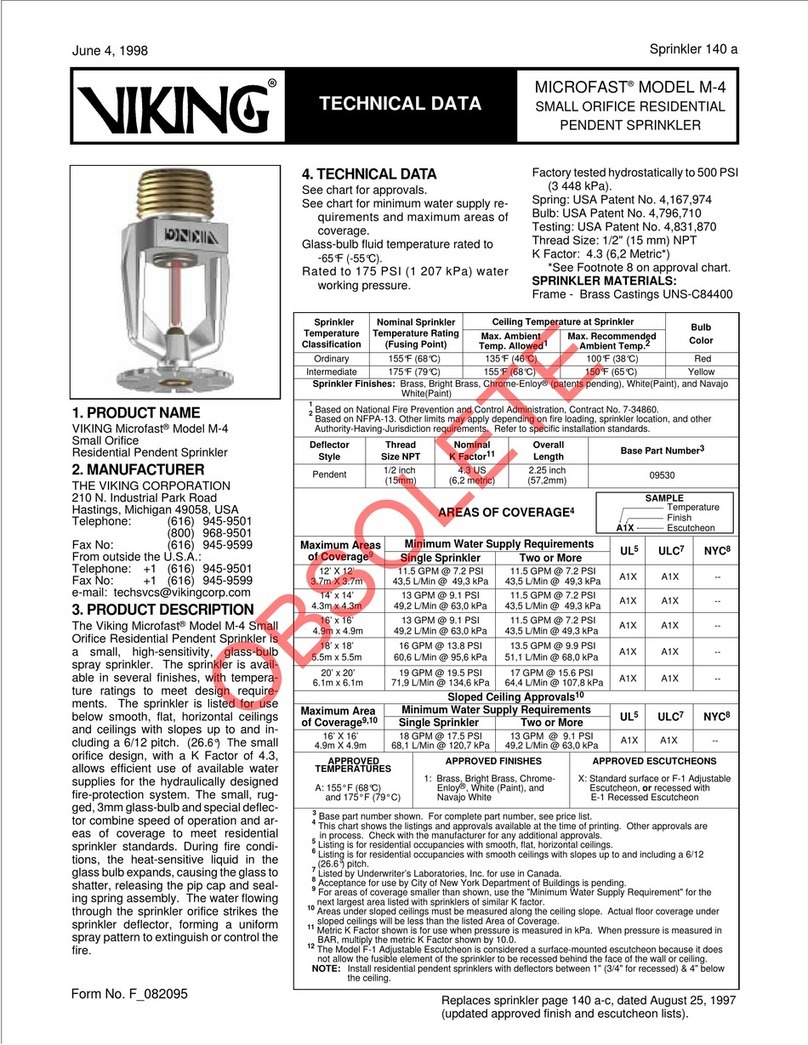

A. Shoulder Bolt

2

F. Hitch Pin φ10

1

K. Lock Washer φ8

14

B. Hex Bolt M8x50

2

G. Hair Cotter Pin φ3

1

L. Big Flat Washer φ8

10

C. Hex Bolt M8x30

2

H. Hex Nut M8

14

M. Angle Bracket

4

D. Hex Bolt M8x20

15

I. Hex Lock Nut M8

19

N. Hitch Arm Mount Brackets

3

E. Carriage Bolt M8x25

14

J. Hex Lock Nut M10

2

.

ASSEMBLY

Remove the machine and contents from the carton. Be sure the carton is empty before discarding. If you

require any assistance with regards to the contents or operation of your machine, please contact us:

Tel: 01793 333212, option 2

Opening Hours Weekdays: (CLOSED WEEKENDS & BANK HOLIDAYS)

February to October 8:00am - 5:00pm - November to January 8:30am - 5:00pm

STEP 1

Assemble the lift plate to the top of the tine shield using four M8x20 hex bolts and M8 hex lock nuts as shown

in Figure 1. Tighten.

STEP 2

Turn the tine shield upside down. See Figure 2.

STEP 3

Assemble two (tall) hitch arm mount brackets and two (short) angle brackets to the bottom of the tine shield.

Fasten the brackets to the four round holes at the rear of the tine shield using four M8x20 hex bolts and M8

hex lock nuts. Do not tighten yet. See Figure 2.

STEP 4

Insert two angle brackets into the round holes in the bottom of the tine shield at the front. Use two M8x20 hex

bolts and M8 hex lock nuts. Do not tighten yet. See Figure 2.

LIFT PLATE

M8X20

HEX BOLT

M8 HEX

LOCK NUT

HITCH ARM MOUNT

BRACKET

M8 HEX LOCK

NUT

ANGLE

BRACKET

ANGLE

BRACKET

M8X20 HEX

BOLT

FIGURE 1

FIGURE 2

STEP 5

Fasten the hitch mount arms to the outside of the angle brackets at the front of the tine shield. Use two

M8x20 hex bolts and M8 hex lock nuts. Tighten and then loosen the nuts slightly. See Figure 3.

STEP 6

Fasten the hitch mount arms to the outside of the hitch arm mount brackets at the rear of the tine shield. Use

two M8x25 carriage bolts, Ø8 lock washers and M8 hex nuts. Do not tighten yet. See Figure 3.

STEP 7

Connect the front ends of the hitch mount arms using two M8x30 hex bolts and M8 hex lock nuts. Do not

tighten yet. See Figure 4.

STEP 8

Attach the hitch brackets to the top and bottom of the hitch mount arms using two M8x50 hex bolts and M8

hex lock nuts. Do not tighten yet. See Figure 4.

STEP 9

Assemble the Ф10 hitch pin through the hitch brackets and secure it with a Ф3 hair cotter pin. See Figure 4.

FIGURE 3

FIGURE 4

STEP 10

Tighten the bolts and nuts assembled in step 8.

Tighten the bolts and nuts assembled in step 7.

Tighten the bolts and nuts assembled in step 3.

Tighten the bolts and nuts assembled in step 4.

Tighten and then loosen slightly the bolts and nuts assembled in step 5.

Tighten the bolts and nuts assembled in step 6.

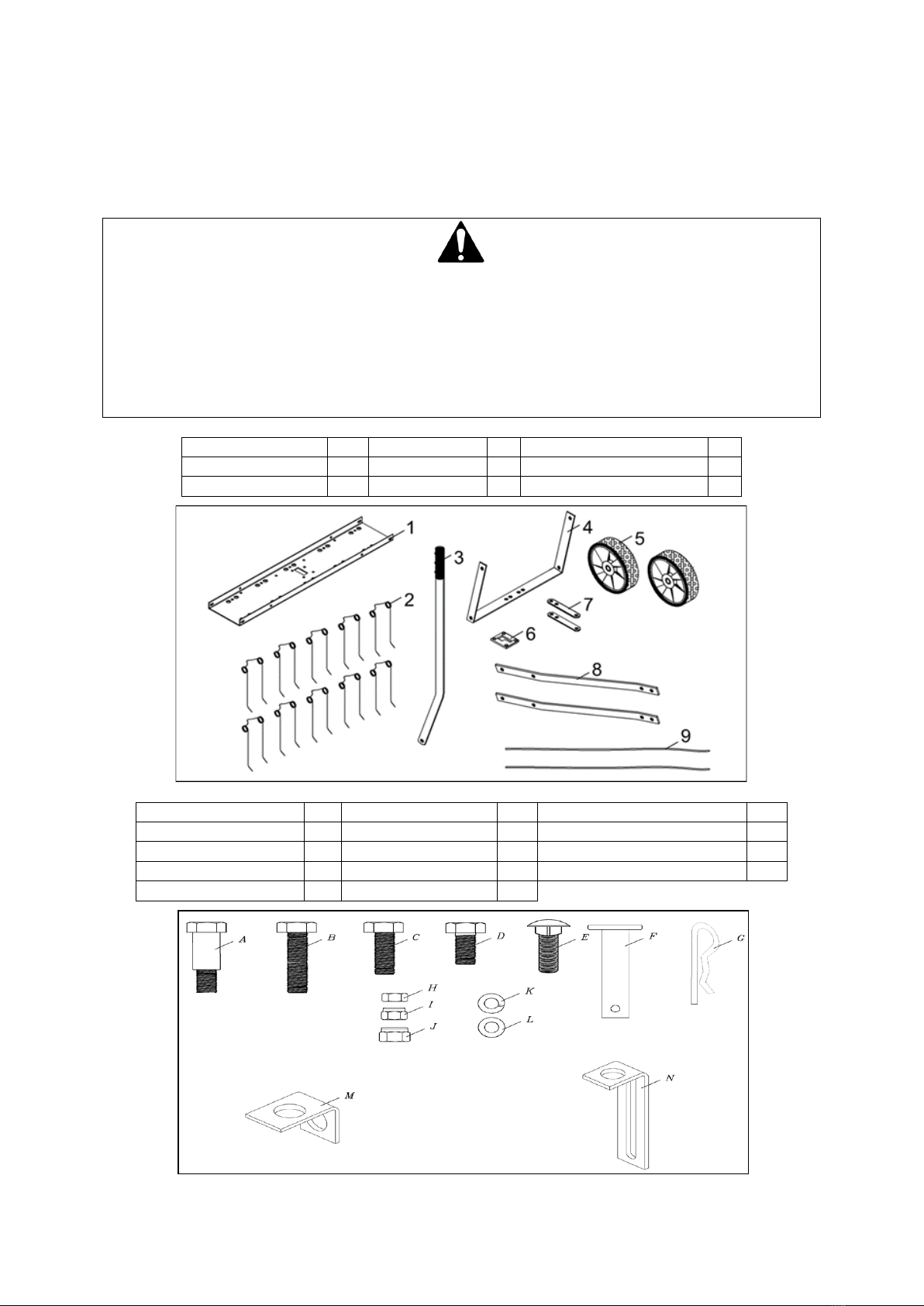

STEP 11

Attach the axle bracket onto the outside of the angle brackets using two M8x20 hex bolts and M8 hex lock

nuts. The ends of the axle bracket must point as shown in Figure 5. Tighten and then loosen the bolts and nuts

slightly.

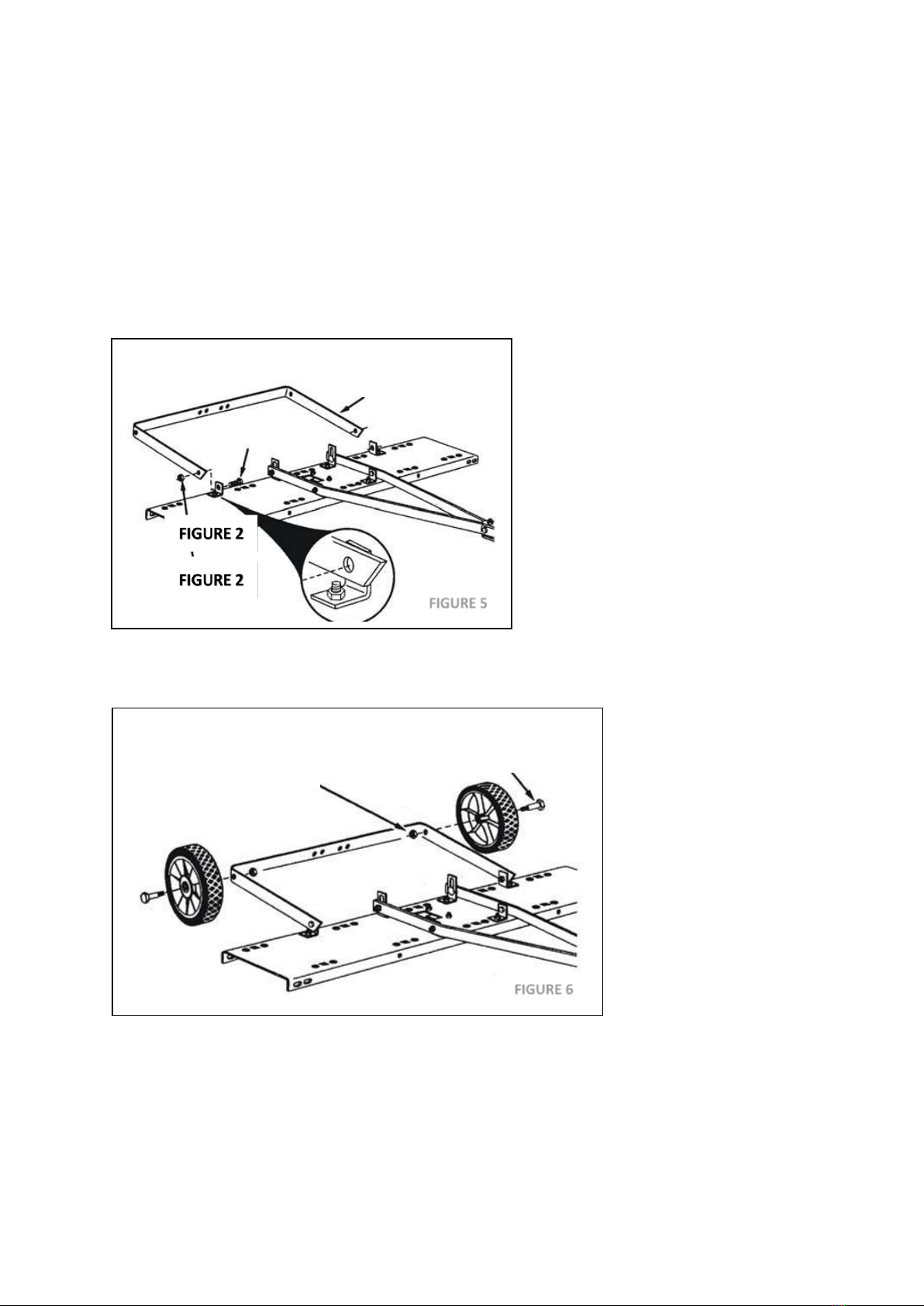

STEP 12

Assemble the wheels to the axle bracket using two shoulder bolts and two M10 hex lock nuts. Tighten. See

Figure 6.

AXLE BRACKET

M8X20 HEX BOLT

M8 HEX LOCK NUT

M10 HEX

LOCK NUT

SHOULDER BOLT

FIGURE 5

FIGURE 6

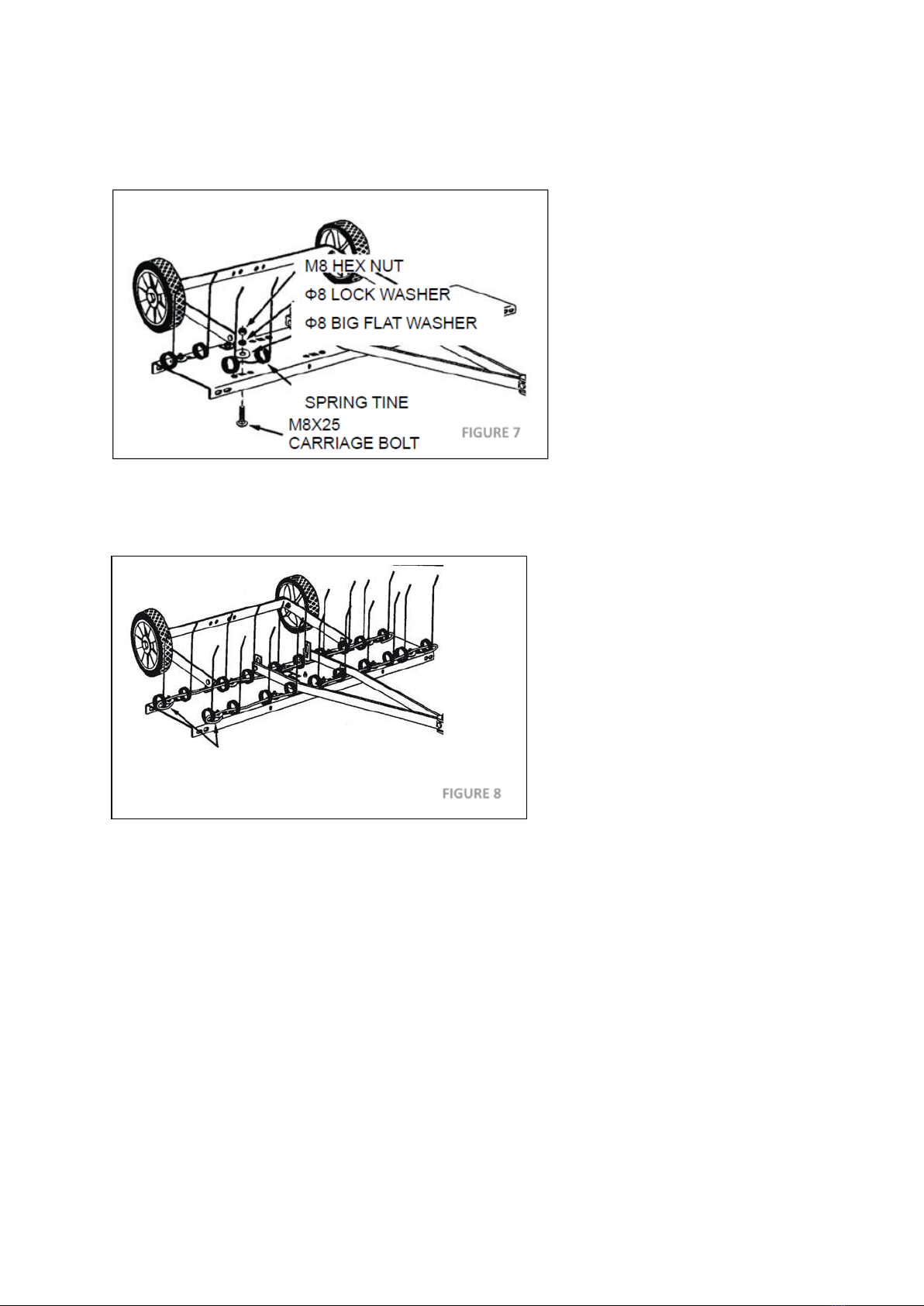

STEP 13

Fasten the ten spring tines to the square holes in the bottom of the tine shield. Use a M8x25 carriage bolt, Ф8

big flat washer, Ø8 lock washer and M8 hex nut for each spring tine. Tighten. See Figure 7. NOTE: Spring tines

must sit between dimples.

STEP 14

Thread the spring align wires through the front and rear rows of spring tines, passing the wires in between the

hitch mount arms and the tine shield. Bend the ends of the wires to secure them.

See Figure 8.

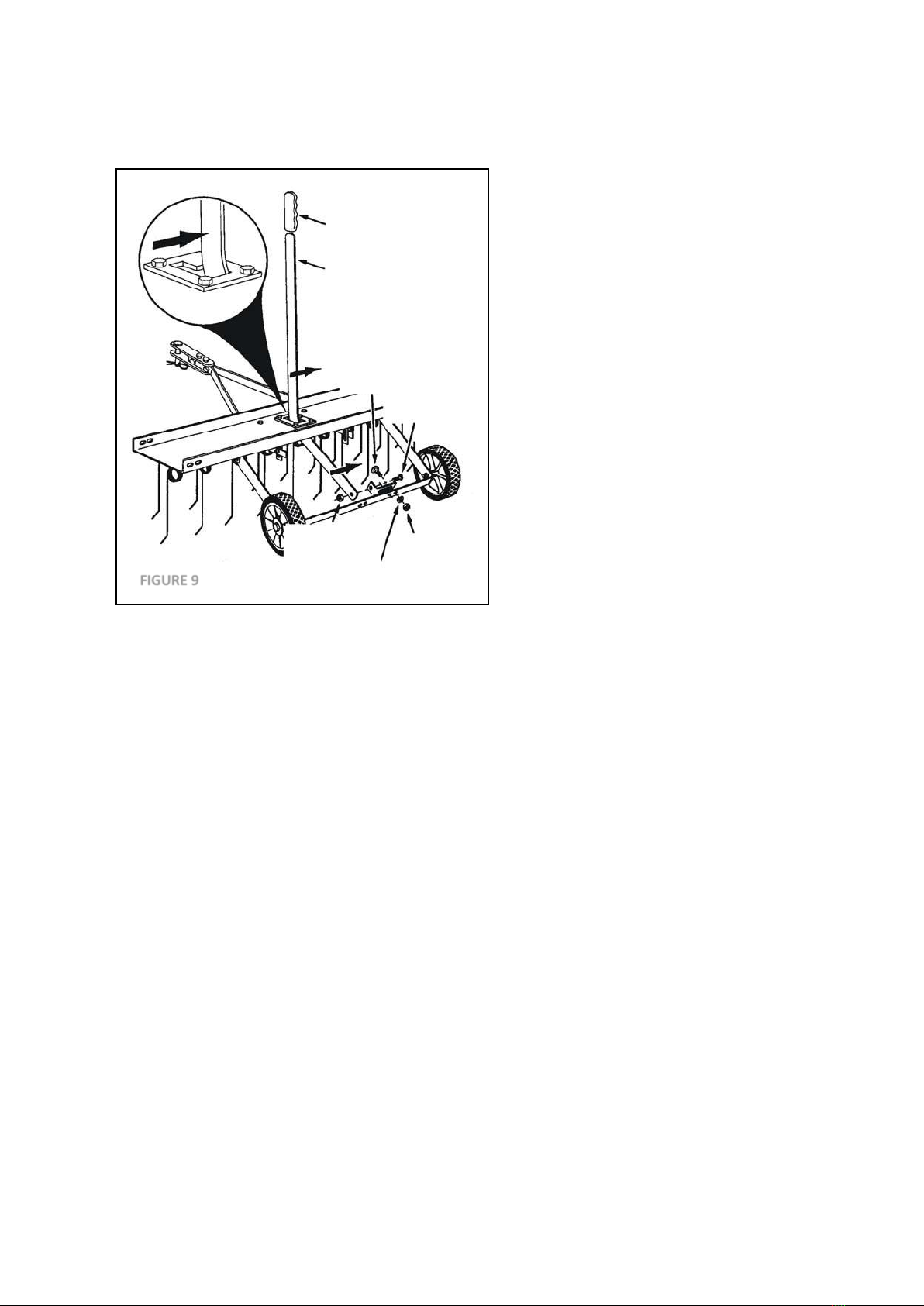

STEP 15

Attach a hitch arm mount bracket to the axle bracket using two M8x25 carriage bolts, Ø 8 lock washers and M8

hex nuts. Do not tighten yet. See Figure 9.

STEP 16

Insert the lift handle through the tine shield. Attach it to the just assembled hitch arm mount bracket using

M8x20 hex bolt and a M8 hex lock nut. Tighten. See Figure 9.

SPRING ALIGN WIRE

FIGURE 7

FIGURE 8

STEP 17

Position the hitch arm mount bracket so that some resistance is felt through the lift handle when it is locked in

the up position. Tighten the nuts. See Figure 9.

GRIP

LIFT HANDLE

M8X25

CARRIAGE BOLT

M8X20 HEX

BOLT

M8 HEX

LOCK NUT

Ø 8 LOCK

WASHER

M8

HEX

NUT

FIGURE 9

OPERATION / ADJUSTMENT

DANGER

The product must only be put into operation if no defects are found. It is crucial that defective parts are

replaced before the product is used again. Check the safety equipment and the safe condition of the

product: Check all parts to make sure that they fit tightly. Check whether there are any visible defects:

broken parts, cracks, etc.

Regular removal of thatch is critical to the maintenance of a healthy lawn. Thatch is a layer of stems, clippings,

runners, roots and leaves that have not decayed. Excessive thatch prevents air, water and fertilizer from

reaching the roots. The dethatcher effectively dislodges excessive thatch from your lawn. Read these

instructions to help avoid improper adjustment and operation.

Correct adjustment of the tine shield and spring tines is important for effective performance. Refer to the

following steps for the proper adjustment before operating the dethatcher.

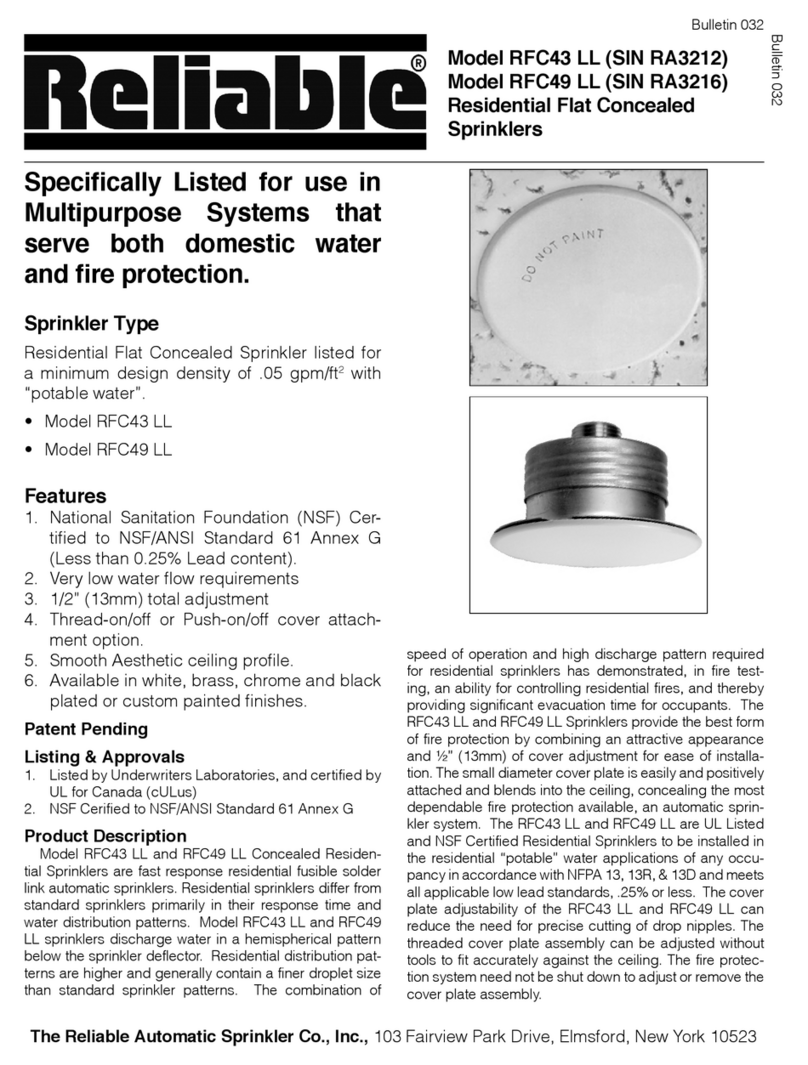

•Move the towing vehicle onto a level surface, such as a driveway or garage floor and attach the tine de-

thatcher to the vehicle hitch. See Figure 10. Recommend towing vehicle hitch height is 14-17cm.

•To adjust the spring tine shield, lower the de-thatcher into the operating position using the lift handle.

Loosen the two hex nuts and carriage bolts which fasten the rear of the hitch mount arm to the hitch arm

mount brackets. Adjust the tin shield until it is level and both the front and rear spring tines are in contact

with the ground. Re-tighten the hex nuts. See Figure 10.

•The wheels of the dethatcher will remain in contact with the ground at all times.

•Vary the vehicle's forward speed until the best dethatching action is achieved.

•For best results, use a crisscross pattern on your lawn.

ADDING EXTRA WEIGHT

If the dethatcher appears to be jumping during use, extra weight (max 70lbs/31.75kg) should be added to the

tine shield. Attach and secure weights (Concrete blocks are recommended) to each side of the tine shield using

rubber tie down straps.

DANGER

Vehicle braking and stability may be affected with the attachment of this machine to your garden vehicle.

Always operate up and down a slope, never across the face of a slope.

Do not work on slopes greater than 10°.

Drive slowly & carefully, especially when turning and on uneven ground.

Do not tow this equipment on a highway or any other public thoroughfare.

CARRIAGE BOLT & HEX NUT

HITCH

MOUNT

ARMS

FIGURE 10

MAINTENANCE

LUBRICATE

Maintenance spray or multi-purpose grease can be applied to the wheel axle prior to long-term storage.

CLEANING

After each use thoroughly wash the machine with a stiff brush.

STORING

Before storing, ensure that the machine is clean and dry.

Store in a dry or protected area and coat exposed metal with light oil when not in use.

CHECK ALL NUTS, BOLTS AND FASTENING

Before each use check all fastenings are tight & secure.

APPEARANCE

If rust appears on the shield or spring tines, sand lightly and coat with enamel paint.

NEVER EXCEED LOAD CAPACITY

To avoid damaging the dethatcher, never exceed the rated load capacity of max 70lbs/31.75kg

ONLY USE MANUFACTURER APPROVED PARTS

If a part needs replacing, only use the manufacturer’s original parts. Non-original replacement parts will

invalidate your warranty and may result in a safety hazard or poor operation.

PARTS DIAGRAM & LIST

No.

Part No.

Description

QTY

No.

Part No.

Description

QTY

1

TH153-1

Hitch Arm Mount Bracket

3

13

TH153-13

Hex Lock Nut M10

2

2

TH153-2GM

Hitch Bracket

2

14

TH153-14

Flat Washer

10

3

TH153-3

Spring Tine

10

15

TH153-15

Hex Bolt M8x20

15

4

TH153-4

Spring Alignment Wire

2

16

TH153-16

Lock Washer

14

5

TH153-5

Wheel

2

17

TH153-17

Hex Nut M8

14

6

TH153-6GM

Tine Shield

1

18

TH153-18

Hex Lock Nut M8

19

7

TH153-7GM

Hitch Mount Arm

2

19

TH153-19

Carriage Bolt M8x25

14

8

TH153-8

Gate Plate

1

20

TH153-20

Handle Grip

1

9

TH153-9GM

Axle Bracket

1

21

TH153-21

Hex Bolt M8x50

2

10

TH153-10GM

Lift Handle

1

22

TH153-22

Hex Bolt M8x30

2

11

TH153-11

Shoulder Bolt

2

23

TH153-23

Hitch Pin M8

1

12

TH153-12

Angle Bracket

4

24

TH153-24

R Clip

1

NOTE: Parts Lists are supplied for information purposes only, not all parts are stocked individually & we recommend

you contact our Spares Team on 01793 333212 for expert advice.

GJ HANDY (TRADING) LTD USER WARRANTY POLICY

Users Statement of Warranty

Each new machine is warranted against defective material or assembly of material under normal usage. The

warranty applies to the original purchaser and covers faulty parts and the labour involved in replacing and

repairing those parts, which are of original manufacture.

Period of Warranty

The Handy (Petrol & Electric only), Webb (excludes Dynamic, Heritage, Legacy),

a) 2 years from the original date of sale to the first domestic user.

b) 90 days from the original date of sale to the professional/commercial user.

c) 90 days from the original date of sale when used for hire.

d) A reduced warranty period of 90 days applies to those items which are subject to normal wear and tear

(e.g., but not limited to wheels, tyres, cutter bars, cylinders, cutting blades, blade boss, belts, cables, nylon

line & spool, collection bags, spark plugs).

e) Engines are supplied with a separate warranty to the machine. The engine manufacturers warranty

statement which will be supplied within the engine instruction manual. All enquiries and warranty repairs

should be discussed with the engine manufacturer or approved warranty repair dealer.

f) 90 days from the original date of purchase for Replacement Spare Parts (unless normal wear & tear

component, which are covered for 30 days).

g) All machines’ must be serviced within the first 12 months from the original date of purchase to comply

with the warranty (if applicable), failure to do so will invalidate the 2nd year of the warranty.

Webb Dynamic, Heritage & Legacy, Handy (All non-Petrol & Electric), Mowerland, Q-Garden

a) 1 year from the original date of sale to the first domestic user.

b) 90 days from the original date of sale to the professional/commercial user.

c) 90 days from the original date of sale when used for hire.

d) A reduced warranty period of 90 days applies to those items which are subject to normal wear and tear

(e.g., but not limited to wheels, tyres, cutter bars, cylinders, cutting blades, blade boss, belts, cables, nylon

line & spool, collection bags, spark plugs).

e) Engines are supplied with a separate warranty to the machine. The engine manufacturers warranty

statement which will be supplied within the engine instruction manual. All enquiries and warranty repairs

should be discussed with the engine manufacturer or approved warranty repair dealer.

f) 90 days from the original date of purchase for Replacement Spare Parts (unless normal wear & tear

component, which are covered for 30 days).

All warranty repairs must be undertaken by an authorised service dealer. These dealers have been accredited

by GJ Handy (Trading) Ltd and agree to only use genuine parts and follow our repair procedures.

Not covered by this warranty

a) The warranty policy does not cover any depreciation or damages caused by ordinary wear, rusting or

corrosion, lack of correct maintenance or operation, misuse, abuse, lack of transportation or accident.

b) The warranty policy does not cover any costs necessary for the standard periodic maintenance services

instructed by the operator’s manual, or service parts replacement which would include oil, filters, tyres,

belts, brake linings, fuses, blades, seals, and other service parts unless it can be proven that the item has

evidence of faulty manufacture.

c) The warranty policy will not cover failure or damage caused as a result of parts or accessories being

modified without the written approval of GJ Handy (Trading) Ltd.

d) The warranty policy will not cover the unit if non-genuine parts have been fitted and as a result damage

has occurred to the unit.

e) The warranty policy is non-transferable and is only applicable to the original purchaser.

Disclaimer

a) This warranty is only a remedy for defect of products. GJ Handy (Trading) Ltd will never warranty in terms

of the merchantability or the fitness for a particular purpose.

b) No person is authorised to make any warranties, representations or promises, expressed or implied, on

behalf of GJ Handy (Trading) Ltd, or to modify the terms conditions or limitation of this warranty policy in

any way.

c) Neither GJ Handy (Trading) Ltd nor any company affiliated with GJ Handy (Trading) Ltd shall be liable in any

event or manner whatsoever for incidental or consequential damages or injuries, including, but not limited

to, loss of crops, loss of profit, out of pocket expenses or profits, rental of substitute equipment or other

commercial losses.

General

a) Most warrantable failures show up within the first few weeks of use. These failures are usually

straightforward and warranty assessment is relatively easy.

b) Failures relating to cutter decks and belts need careful investigation, as the cause may not always be

straightforward. Look for damage to blades and pulleys especially when the cutter belt or blade boss have

snapped or cracked as this could be due to impact damage.

c) Customers should always refer to the operator/instruction manual when any disputed problem arises, you

will find most areas covered within the manual.

For spares or support of your handy product,

please contact us:

Tel: 01793 333212

Opening Hours Weekdays:

February to October 8:30am - 5:30pm

November to January 8:30am - 5:00pm

(CLOSED WEEKENDS & BANK HOLIDAYS)

To see our range of garden machinery & equipment visit:

www.thehandy.co.uk

Making gardening easier & affordable since 1938

Distributed by Handy, Murdock Road, Dorcan, Swindon, SN3 5HY

This manual suits for next models

1

Table of contents

Popular Irrigation System manuals by other brands

Johnson Controls

Johnson Controls tyco ESFR-34 manual

Duramaxx

Duramaxx Sprizzz manual

Reliable

Reliable RFC43 LL Application and Installation

CENTRAL

CENTRAL ESFR-1 quick start guide

Hunter

Hunter X-CORE Owners manual and programming instructions

Tyco Fire Product

Tyco Fire Product Star Galaxy SGQR instruction manual

Rain Bird

Rain Bird LG3HE Installation & operating guide

Tyco

Tyco TY-FRB Series Operation

Reliable

Reliable RFC43 quick start guide

Tyco Fire Product

Tyco Fire Product CENTRAL DS-1 instruction manual

Tyco

Tyco Rapidresponse LFII Series General description

Bocciolone Anticendio

Bocciolone Anticendio 920/A Technical bulletin