Std. Response - Std. Coverage

400°F and 520°F

Upright and Pendent Sprinklers

Model E, K=5.6, 1/2" NPT

GENERAL DESCRIPTION

The Star Model E, 5.6 K-Factor, Upright and Pendent

Sprinklers are standard response - standard coverage,

solder type spray sprinklers designed for use in occupan-

cies where the ambient temperature necessitates the use

of extra high or very extra high temperature rated sprin-

klers.

Lead coatings are utilized to extend the life of copper al-

loy sprinklers beyond that which would otherwise be ob-

tained when exposed to corrosive atmospheres. Although

lead coated sprinklers have passed the standard corro-

sion tests of the applicable approval agencies, the testing

is not representative of all possible corrosive atmos-

pheres. Consequently, it is recommended that the end

user be consulted with respect to the suitability of these

corrosion resistant coatings for any given corrosive envi-

ronment. The effects of ambient temperature, concentra-

tion of chemicals, and gas/chemical velocity, should be

considered, as a minimum, along with the corrosive na-

ture of the chemical to which the sprinklers will be ex-

posed.

WARNINGS

The Model E Sprinklers described herein must be in-

stalled and maintained in compliance with this document,

as well as with the applicable standards of the National

Fire Protection Association, in addition to the standards

of any other authorities having jurisdiction. Failure to do

so may impair the integrity of these devices.

The owner is responsible for maintaining their fire protec-

tion system and devices in proper operating condition.

The installing contractor or sprinkler manufacturer should

be contacted relative to any questions.

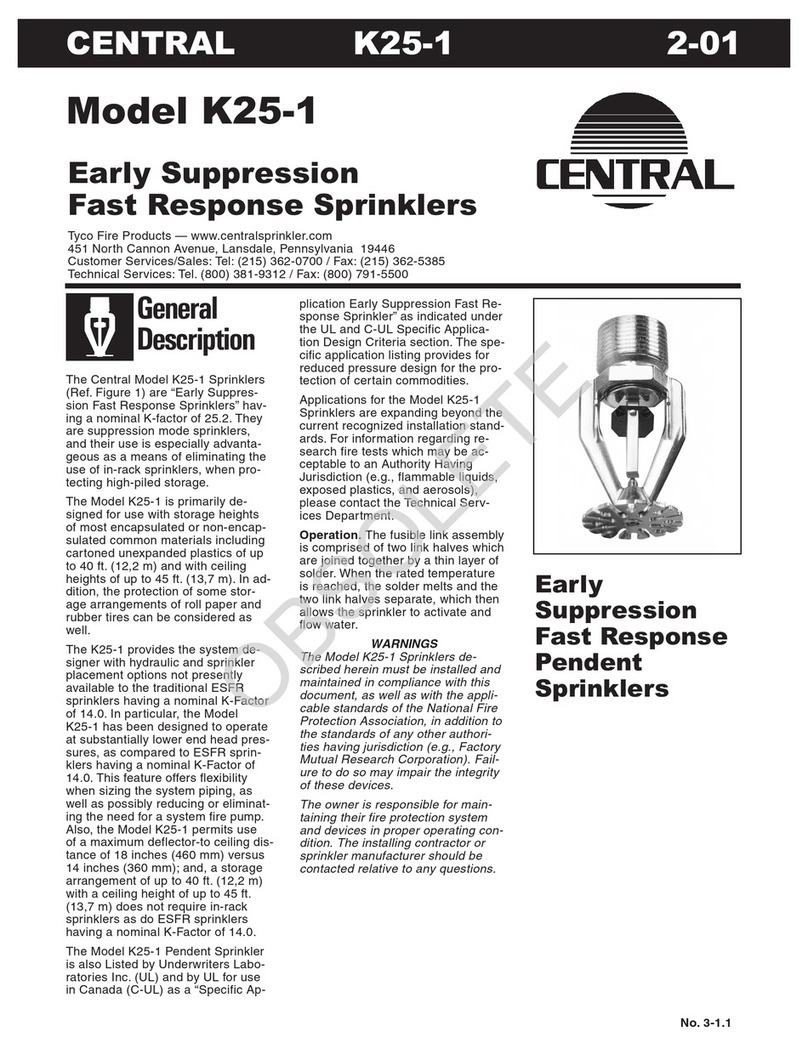

OPERATION

A bronze tube sealed by a steel ball holds a fusible alloy.

The tube is compression loaded and via the tension

mechanism, the cap seals the sprinkler orifice. When the

rated temperature is reached, the alloy melts, the ball is

forced inward, and the tension mechanism releases the

cap, which then allows the sprinkler to activate and flow

water.

TECHNICAL DATA

Approvals

UL and ULC Listed. FM, LPC, NYC Approved.

(Refer to Table A. The approvals apply only to the service

conditions indicated in the Design Criteria section.)

Maximum Working Pressure

175 psi (12,1 bar)

Pipe Thread Connection

1/2 inch NPT

Discharge Coefficient

K=5.6GPM/psi

1/2 (80,7 LPM/bar1/2)

Temperature Ratings

400°F/204°C or 520°F/271°C

(Refer to Table A)

Finishes

Chrome Plated, Natural Brass, Lead Coated,

(Refer to Table A)

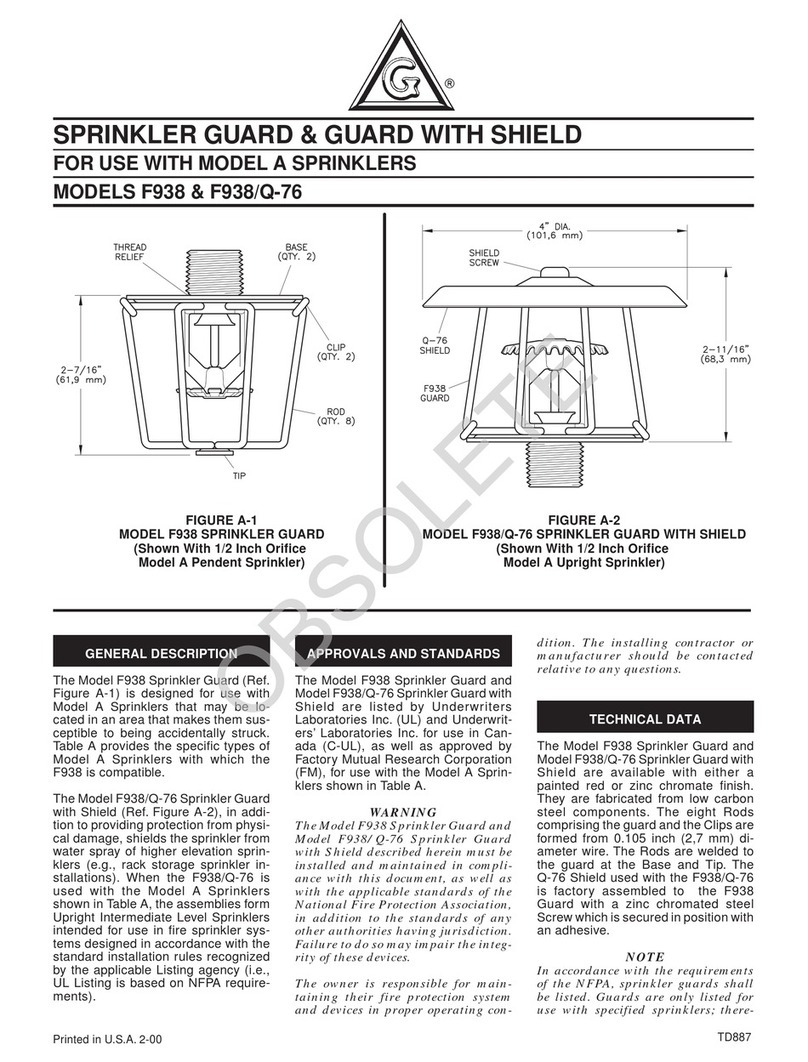

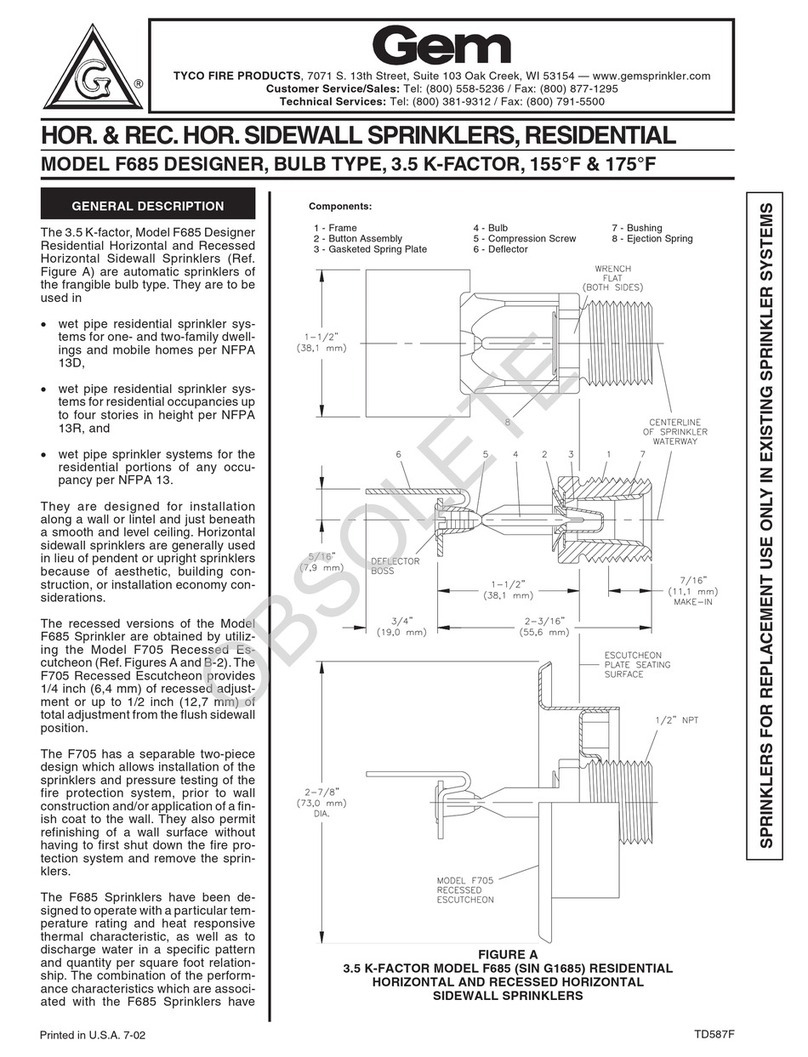

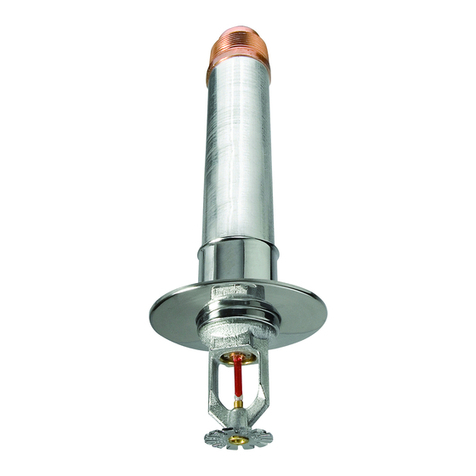

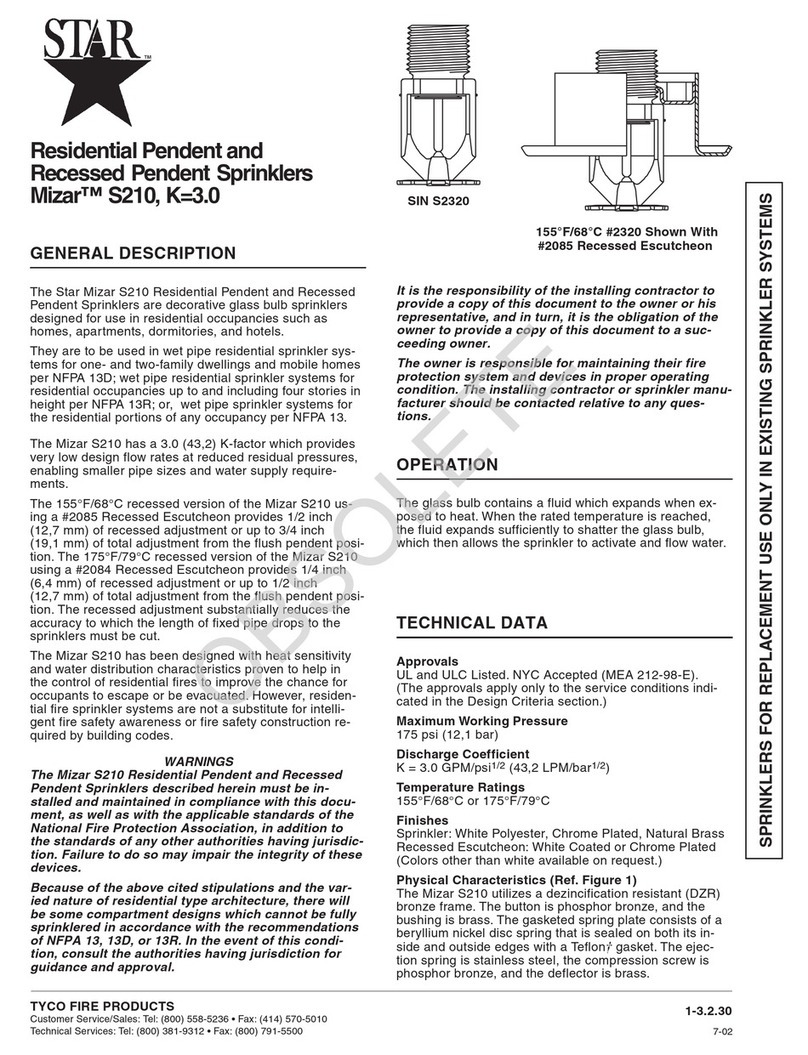

Physical Characteristics (Ref. Figure 1)

The Model E utilizes a dezincification resistant (DZR)

bronze frame with a brass deflector. The waterway is

sealed with copper gasket. The fusible assembly is con-

structed of bronze and stainless steel components.

DESIGN CRITERIA

The 5.6 K-Factor, Model E Upright and Pendent Sprin-

klers are intended for fire protection systems designed in

accordance with the standard installation rules recog-

nized by the applicable Listing or Approval agency (e.g.,

UL Listing is based on NFPA 13 requirements). Installa-

tion of Model E Sprinklers in recessed escutcheons will

void all sprinkler warranties, as well as possibly void the

sprinkler’s Approvals and/or Listings.

SIN S5001

Upright

SIN S5000

Pendent

Customer Service/Sales: Tel: (800) 558-5236 • Fax: (414) 570-5010

Technical Services: Tel: (800) 381-9312 • Fax: (800) 791-5500 3-01

1-1.2.81

TYCO FIRE PRODUCTS