Thermal Instrument Co. 9500P User manual

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 1

Rev: 9/2019

CUSTOMER NAME:

CUSTOMER PO#:

SERIAL NUMBER:

MODEL DESCRIPTION:

APPLICATION SERVICE:

LINE SIZE:

POWER:

OUTPUT: 4-20 MADC

Congratulations and thank you for your purchase of a Thermal Instrument Company mass flow meter system.

CUSTOMER ORDER DETAILS

217 Sterner Mill Road

Trevose, PA 19053 U.S.A.

P: 215-355-8400

F: 215-355-1789

Info@ThermalInstrument.com

www.ThermalInstrument.com

OPERATIONS & INSTALLATION MANUAL

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 2

Rev: 9/2019

MODEL 9500P FLOW TRANSMITTER

WITH INSERTION OR IN-LINE

STYLE FLOW TRANSDUCER

Flow Meter Selection ..………………………………………………………………….. 3

Field Wiring Diagram ..…………………………………………………………………… 4

Outline Dimensions ..…………………………………………………………………….. 5

Flow Curves & Calibration ..…………………………………………………………… 6

Spec Sheet—Meter Configuration Page Introduction ..……………………… 7

Guidelines & Precautions ..……………………………………………………………. 8

Installation ..………………………………………………………………………………… 10

Insertion Probe Install Guide ..……………………………………………………….. 14 - 15

Operation & Info ..…………………………………………………………………………. 16

Totalizer Reset ..…………………………………………………………………………... 18

Block Diagram/Power Board ..………………………………………………………… 19

General Precautions ..……………………………………………………………………. 20

Instrument Housing ..…………………………………………………………………….. 28

Field Calibration ..…………………………………………………………………………. 33

Troubleshooting ..…………………………………………………………………………. 34-36

Spare Parts ..………………………………………………………………………………… 37

PAGE

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 3

Rev: 9/2019

HART Communication - 24 VDC Internal Power

- 24 VDC External Power

Integral

24 VDC 110/120

24VDC Battery Powered

220 VAC

1A.2 Flow Meter Selection

4-20 mADC Temperature

4-20 mADC Flow Rate

None Flow Rate & Totalizer

Flow Rate

Remote

OUTPUT SIGNAL(S):

INPUT POWER:

DISPLAY TYPE:

TRANSMITTER / ELECTRONICS LOCATION:

Solar Powered

Modbus RS 485 (Included Flash Drive & Connection Cable)

Other:

Other:

Model #:

Pulse Output

Pulse Setup:_____________________________________________________

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 4

Rev: 9/2019

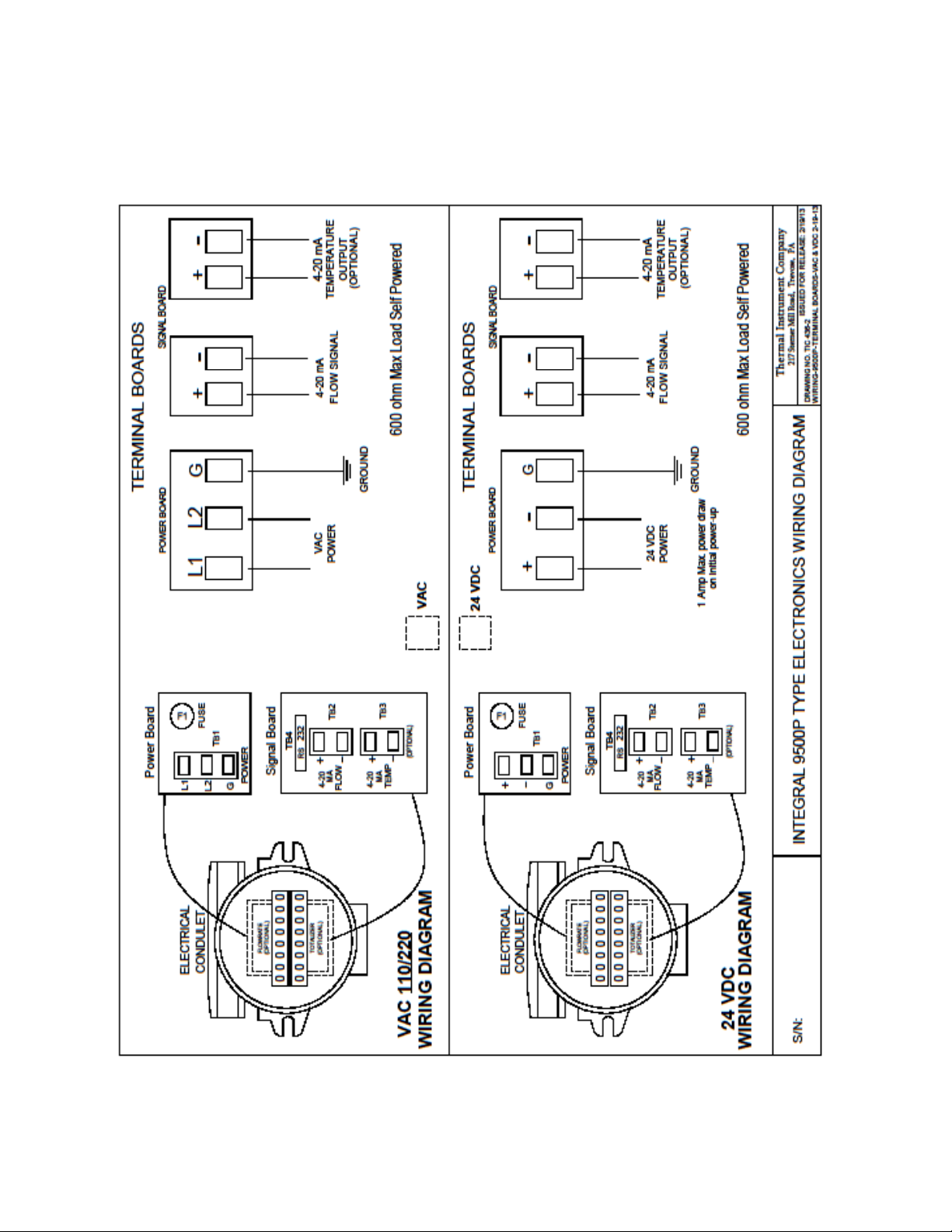

1A.3 Wiring Diagrams

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 5

Rev: 9/2019

Specific Outline Dimensions

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 6

Rev: 9/2019

All Flow Curves & Calibration Spec Sheet

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 7

Rev: 9/2019

Introduction

1.1 Preface

These instructions contain all of the information that you will require for using this flow meter

from Thermal Instrument Company.

These instructions are aimed at people mechanically installing the flow meter, connecting it

electrically, configuring the parameters and commissioning it as well as service and

maintenance engineers.

Note

It is the responsibility of the customer that the instructions and directions provided in the

manual are read, understood and followed by the relevant personnel before installing this

device.

1.2 Flow Meter Configuration

Items Inspection

1. Check for mechanical damage due to possible improper handling during shipment. All

claims for damage are to be made promptly with the shipping company.

2. Make sure that the information on the product identifier plate and labels (Figure 1 above)

corresponds to the ordering information.

1.3 Further Information

The contents of these operating instructions shall not become part of or modify any prior or

existing agreement such as the original quotation, or any other written communications.

These operating instructions are a guidance for this flow meter and do not create new

warranties or modify the existing warranty.

Product Information available on our website:

(http://www.thermalinstrument.com)

1.0

The Flow Meter Applicaon Details can be con-

rmed on Page #3 of this manual or by reviewing

the label and tags aached to each specic ow

meter as shown in Figure 1.

Each ow meter has a specic Serial # for iden-

caon purposes. Note: When Receiving Remote

Electronic Transmiers, the ow element and

transmier are a matched set.

Figure 1—Example Only

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 8

Rev: 9/2019

Receiving / Inspection

- Unpack carefully and inspect overall condition

- Check the packing list to compare what you received is all there

If the above items are fine, then move on to the next section, otherwise contact our customer

support group at (215) 355-8400 and provide us with purchase order number or serial number

of the flow meter.

Factory Calibration Note

This flow meter from Thermal Instrument Company has been factory calibrated to the

specifications and flow range as stipulated by the customer. There is no need to perform

any verification or calibration on this device prior to mounting and start-up in the application.

Prior to Installation

Qualified electrical personnel should be installing this instrument. The installation should be

done per National Electrical Code and the power to the electrical wiring should be off during the

installation. Where the instructions call out for use of electrical current, the operator assumes

all responsibilities for conformance to safety and practices.

Alerts

This flow meter is not designed for weld-in place applications with the exception of the

UHP (Ultra High Pure) in-line flow designs. The conventional welding technique can cause

damage to the Nickel or Platinum sensors from the current being passed from ground to the

hot weld side.

Damage due to moisture ingress into the enclosure is not covered under the warranty of this

product and proper conduit seals must be applied for all-weather conditions. This flow

transmitter contains electrostatic discharge (ESD) sensitive components, so use proper ESD

precautions when handling the device.

Verify Mounting Area for Insertion or In-Line Flow design to make certain that everything fits

properly.

Installation Point

Make sure that there are 10 pipe diameters upstream and 5 pipe diameters down stream of the

flow meter from any bends or interferences in the process piping or ductwork in order to achieve

the greatest accuracy.

2.0 General Guidelines & Precautions

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 9

Rev: 9/2019

2.0 General Guidelines (Continued)

Mechanical Care of Enclosure

Be careful of the enclosed electronics when removing the condulet cover. After the initial

installation, never open the condulet when the power is connected, especially in a classified

hazardous area. Gently lift the cover from the 9500P electronic assembly and place it in a safe

location where dirt cannot get inside or, if the display option has been selected, where dirt can

get on the inside of the viewing window. When replacing the cover, take special care that the

display legend plate is centered on the display and that the cover window lugs do not hit the

legend plate in the last two or three turns of the cover.

Electrical Care of Enclosure

Proper wire size or gauge selected for all connections should be the minimum allowable by

your plant standards and regulations. The enclosure has limited space available for large

gauge wire and we recommend no larger than 12 gauge for power. When snaking the wires around

the electronic assembly, special care should be taken of any protruding parts. The parts are capable

of withstanding some abuse, but still be cautious not to force the wire through.

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 10

Rev: 9/2019

2.1 Installation / Mounting of Flow Meter

Verify the Dimensions of the Flow Meter against your process connection and piping.

The Thermal Instrument Company Model 62-9 insertion probe has a variety of process mounting

connections, from MNPT to welded flange, The insertion probe commonly comes with an adjustable

mechanical connection which can be tightened down for permanent mounting. Verify all mounting

and installation variables before tightening process packing gland.

If the installation is for Thermal Instrument Company Model 600-9 in-line flow tube design, then make

certain that the pipe diameters and mounting sections are verified.

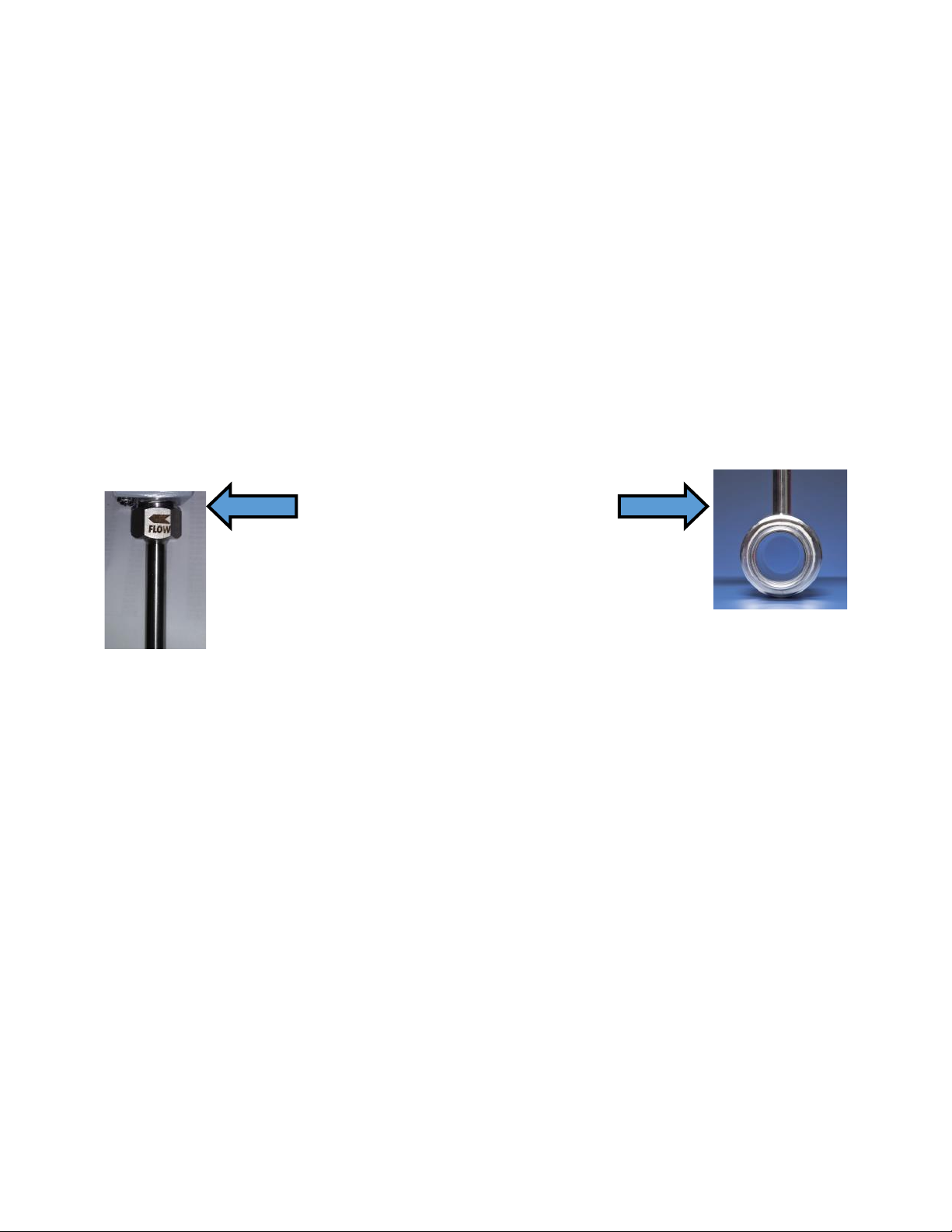

Verify the Flow Direction for the Flow Meter and Proper Placement

The 62-9 insertion probe has an indexing arrow on the flat portion of the process connection located

just below the base of the enclosure. On Model 600-9 it will be on flow element body. See Figure Be-

low.

Align the insertion probe during the installation so that the flat areas of the mechanical process

connection with the arrow are parallel to the direction of the process flow, and the arrow points

in the direction of the process flow.

For the 600-9 in-line flow tube assembly, the indexing arrow is etched on the flow tube, and

should be pointing in the direction of the flow. If the flow device is not mounted in the proper

direction, then there will be a reduction in accuracy.

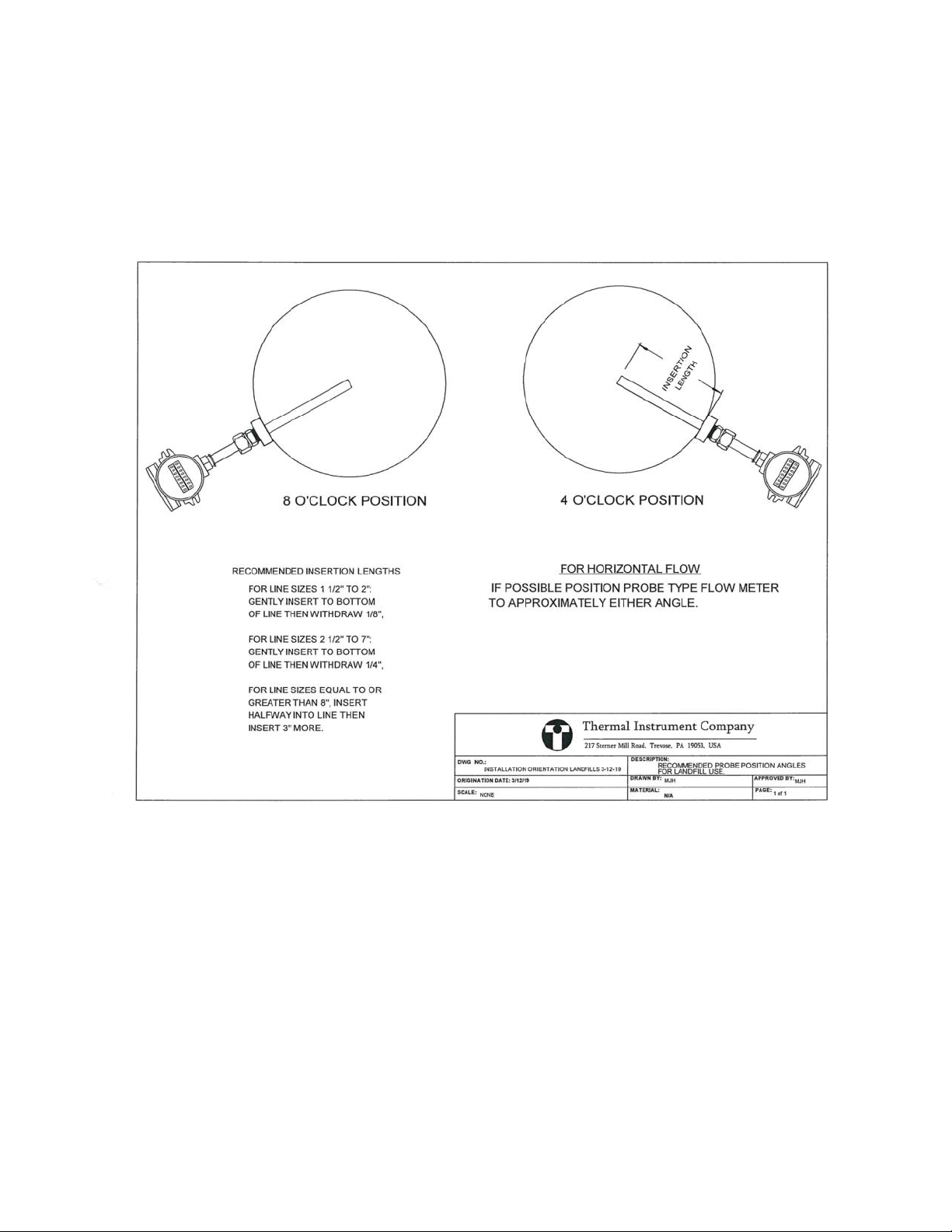

Compression Fitting Mounting (62-9 Insertion Probe Style)

A. Determine the inside diameter of the process pipe at the pre-determined mounting location. If the

Inner pipe diameter is 1-1/2” to 2”, then the insertion probe will utilize the dual tip design and would

be inserted to the bottom of the line and withdrawn up by 1/8”. For line sizes 2-1/2” to 7”, the probe

would be inserted completely to the bottom of the line, and then withdrawn 1/4”. For line sizes equal to

or greater than 8”, insert the probe halfway into the line, and then insert 3” further for optimal position-

ing.

B. Once inserted into the line at the proper positioning, tighten down the connection to ANSI B16.5

torque specifications. Make sure that proper thread sealants are applied prior to torque down of the

fitting.

Figure Left: Index Arrow

on 62-9 Insertion Probe

Figure Right: 600-9

In-Line Flow Tube

(actual tube will have flow

direction arrow)

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 11

Rev: 9/2019

Compression fitting Mounting Continued

C. Adjust the probe so that the flats of the mechanical process gland are parallel with the flow and

that the indexing arrow is also in the direction of the flow path.

D. Once the insertion length and probe positioning are correct, tighten the mechanical gland

assembly using two wrenches with one on the smaller connection and the other on the larger

connection. Do not over tighten by more than one and one half turn. The mechanical packing

gland assembly can be readjusted if needed.

NPT Pipe Thread Mounting (62-9 Insertion Probe Only)

A. Make certain that a proper environmental sealant is applied to the process threads of the

insertion probe prior to installation and tightening into line.

B. Make certain that the condulet is not rotated more than 180º with the insertion probe

fastened to the process line as the RTD (Resistance Temperature Detector) wires could be damaged.

C. The threads on the insertion probe are right handed and should not be over tightened or

cross threaded as this can cause moisture to leak out or ingress.

Flanged Mounting (62-9 Insertion Probe Only)

A. Make certain that the proper sized flow meter flange and ANSI rating is correct for the mating

process side of the flange. Verify the line pressure vs. the overall flange rating.

B. Make certain that a new gasket is available for the flange connection and that the area on

the process flange side is cleaned and free of any raised areas that could be a leakage path

for media inside the line.

C. Prior to fastening the flanges together, make sure that the indexing arrow is parallel with

the flow direction.

D. Carefully mount the flow meter with the flange to the process side flange and use the bolts

with nuts to secure the flanges together.

2.1 Installation/Mounting Continued

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 12

Rev: 9/2019

2.2 9500P Integral Electronics Design

The Model 9500P transmitter / electronics is available as an integral design. The integral design

features the transmitter / electronics mounted atop the insertion or in-line flow style sensors.

2.3 9500P Remote Electronics Design

The Model 9500P transmitter / electronics is also available as a remote mounted design whereby

the transmitter / electronics can be remotely located up to 2000 feet from the sensing element via

interconnecting cable. This remote mount version then comprises the 9500P transmitter /

electronics in the remote area and a junction box enclosure with a wiring terminal block mounted

atop the sensing element or probe design.

2.4 Insertion Style Probes Model 62-9

For installation of the 62-9 insertion probe, the 10 upstream and 5 down stream conditions

still apply. The insertion probe must be rotated so that the index arrow etched on the probe is

facing towards the flow of the media.

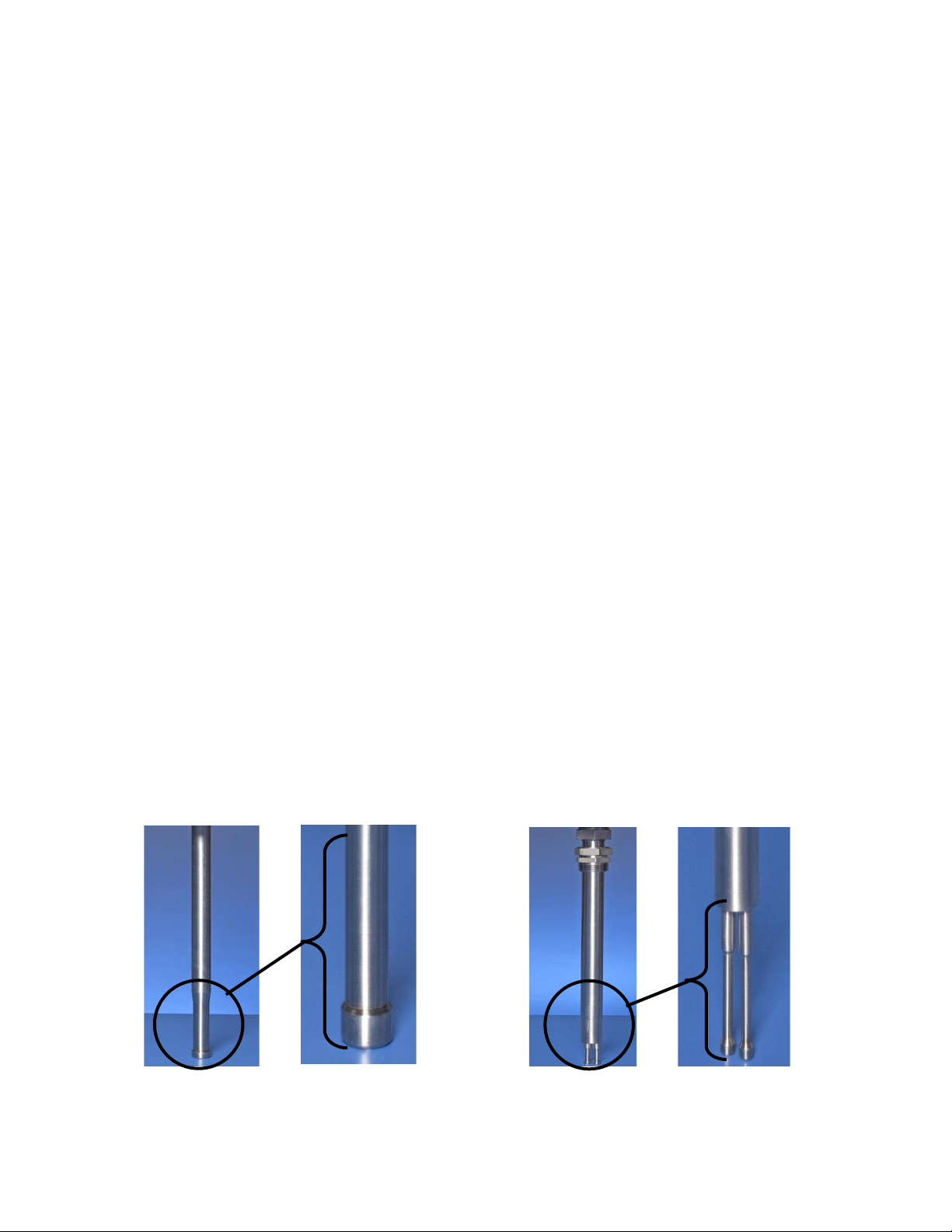

Thermal Instrument Company has two styles for the insertion probes; one is the dual tip which is

most often applied for lines smaller than 2” and the second design is the single piece machined

probe, which is available in 1/2”, 3/4” or 1” OD size or greater. The size of the probe is deter-

mined by the flow velocity of the media as well as the application parameters like operating

pressure. In Figure X & Y below, we show the insertion probes for the single piece machined

probe and the dual tip design.

Installation/Mounting Continued

Model 62-9 Single Piece

Machined Insertion Probe Model 62-9DT Dual

Tip Insertion Probe

FIGURE X FIGURE Y

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 13

Rev: 9/2019

2.5 Proper Sealing of the Transmitter / Electronics

Prior to mounting the insertion style probe into the tube or pipe line, make certain that there is a

proper seal applied to the process connection. If the process connection is an NPT style, then

Teflon tape or a liquid style sealant is applied. If the connection on the probe is a flange or other

type of surface connection, then an appropriate gasket material should be in place between the

probe connection and the pipe mounting section.

Additionally, the conduit seals on the transmitter / electronics enclosure should also be done

properly so that no external moisture can penetrate the threaded area. Also, be certain to

tighten down the enclosure cover for the integral / compact transmitter and / or remote junction

enclosure and remote mounted transmitter / electronics. Thermal Instrument Company is not

responsible for any 9500P transmitter, junction enclosure, or external equipment damage due

to negligence on improper sealing of any conduits going to the enclosures or the enclosure

covers not being secured with the O-ring gasket on the base of the transmitter / electronics.

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 14

Rev: 9/2019

Recommended Insertion Probe Installation

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 15

Rev: 9/2019

Recommended Insertion Probe Installation (cont.)

Recommended installation when customer process is known to have significant moisture in

the pipe. Significant moisture is characterized by the presence of water droplets contacting

the flow sensor.

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 16

Rev: 9/2019

3.0 Transmitter Information & Wiring

3.1 Operation

Flow Transducer

In this section, there will be references to functional block diagrams. See Figure 2 for the main

block diagram on page 17. The Thermal Instrument Company thermal mass flow meter utilizes a

unique compound bridge circuit that measures and controls the temperature of the precision RTD

that is bonded to the dry side of the media conduit.

The power required to maintain this temperature is proportional to the mass flow rate of the fluid

or gas. This raw measured signal then goes through a linearization circuit to straighten the flow

curve. Additionally, some method of temperature compensation must be performed on the signal.

Electronics Transmitter

The transmitter / electronics used with the majority of the flow transducers is the 9500P. This

electronics has a series of printed circuit boards with interconnectivity. The mass flow measurement

and functionality of the design is accomplished on the Bridge Voltage Control Board shown in

Figure 3 on page 17. The output signal is passed to the Logic Control Board where the non-linear

signal is digitized. This digital value is used to look up the corresponding flow value in an EEPROM

(Electrically Erasable Programmable Read-Only Memory). The linearized value is then used to drive

an LED flow rate display, an 8-digit totalizer, and the analog 4 to 20 mADC current flow signal.

The Logic Control Board incorporates a micro-processor, which controls the data flow and modifies

the calculations according to parameters stored in EEPROM. The microprocessor also controls the

communications link between the flow meter and a personal computer. This communication link is

used to monitor and change the operating factors for the flow device.

3.2 Input Power and Output Signals

110/220 VAC - The electronics may be powered by either 110 VAC or 220 VAC, but the selection

is made by jumpers not accessible in the field. As shown on the Field Wiring Drawing No. TIC-436-

2, the HI line is connected to Terminal Block 1, point 1 at the top. The LO (neutral) line is connect-

ed to point 2 and the earth line is connected to point 3. Take special note that the two-point termi-

nal blocks are for the output signals. DO NOT CONNECT HIGH VOLTAGE POWER TO THESE

BLOCKS. There are protective Poly Switch breakers on the output signal lines and they will

“open” up if overloaded but circuits can still be damaged.

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 17

Rev: 9/2019

3.0 Transmitter Information & Wiring

3.2 Input Power and Output Signals

24 VDC - (22 volts DC min, 30 volts DC max) - As shown on the Field Wiring Drawing No. TIC-436-2, (Page 4) the

positive line is connected to Terminal Block 1, point 1 at the top. The negative line is connected to point 2 and the earth

line (when used) is connected to point 3. Take special note that the two-point terminal blocks are for the output signals.

DO NOT CONNECT HIGH VOLTAGE POWER TO THESE BLOCKS. There are protective Poly Switch breakers on the

output signal lines and they will “open” up if overloaded, but circuits can still be damaged.

The 24 volt version of the Model 9500 can be connected in a three-wire configuration (four - wire with temperature output).

In this configuration the current signal common to the flowmeter is eliminated and the common line for the output signal is

connected at the 24 volt source negative. If plant regulations permit, the three-wire configuration could be two wires plus

shield for the common.

Output Signals

Terminals are provided for local instrument powered two-wire signals (positive and common). If the Temperature Trans-

miter option has been provided, a single wire common connection may be used or two-wire cables may be run. There are

protective Poly Switch breakers on the output signal lines and they will “open” up if overloaded but circuits can still be

damaged. When power is on if there is zero output current (there should be at least 4 mA even through a current meter)

disconnect the field wiring and check the terminal block points for a voltage. Presence of a voltage (typically 20 to 30 volts)

with no current flow indicates that the Poly Switch breakers have been tripped. Power must be turned off if the Poly Switch

breakers are tripped in order for them to reset. They do not need to be replaced as a fuse. Maximum load resistance is

500 ohms.

Flow - The 4-20 mA flow signal is at Terminal Block 2, the positive connection on point 1 (at the top of Block 2) and the

negative on point 2. The output current signal is a 4 mADC at zero flow and 20 mADC at 100% of rated flow.

Temperature (optional) - The 4-20 mA temperature signal is at Terminal Block 3, the positive connection on point

1 (at the top of Block 3) and the negative on point 2.

Totalizer Pulse Output - The 9500 pulse output’s standard configuration is 12 Volt DC pulse with a 20 millisecond on

time and 1 pulse per specified flow range. The three variables are, 1 - Voltage pulse or dry contact closures output, 2 –

Length of pulse 20 millisecond standard can be shorter or longer. (Example: 5 millisecond, 100 millisecond, 1 second, Etc.)

3 - Pulses per unit of Flow rate, example: 1 pulse per flow unit, 10 pulses per flow unit. The three variables are not field

changeable therefore Thermal Instrument needs to know what are the variables need to accommodate the equipment inter-

face.

Start-up Operation - With all connections having been completed and tested, a short but fast flow rate should be ob-

tained in order to clean gas bubbles and impurities from the flow tube.

CAUTION - Flow and transducer must be within 50º C (122°F) of operating temperature before power is applied. Sensors

may be damaged if transducer temperature is below this limit and/or calibration may not be accurate.

Apply power and allow a 10 minute warm-up period.

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 18

Rev: 9/2019

3.0 Transmitter Information & Wiring

3.3 Continued Operation

Electronics Unit Field Service Details

Terminal Board

Figure 2 (Pg.17) shows the block diagram. Figure 3 (Pg.17) shows the component configuration for

the two field wiring boards. All field wiring is made to the terminal board. There are two (optionally

three) terminalblocks. Connect the input power to the three-position block TB1 according to TIC-436-

2 on the field wiring diagram. Terminal Block TB2 carries the 4-20 mADC flow signal and, if optional-

ly ordered, TB3 carries the 4-20 mADC signal for the specified temperature range. Both current sig-

nal require a loop with a maximum resistance of 500 ohms. The signals are powered by the internal

electronics and must not be connected to an external power supply. (NOTE: Hart & Modbus options

require external power)

Flow Bridge Voltage Control Board

The flow bridge voltage control board controls the flow transducer sensor and provides the

non-linear flow signal to the logic board.

In calibration, the potentiometer R2 is set to balance the temperature sensor with the flow sensor

at the lowest temperature in the application range. A second pot, R11 is set to balance the bridge

at the high extreme of the application temperature range. These two adjustments are determined

in calibration and should NOT be changed.

Logic Board

The logic board converts the non-linear analog flow signal to a digital value, determines the linear

equivalent from the data stored in an Electronically Erasable Programmable Read Only Memory

(EEPROM), runs an 8-Digit totalizer and outputs the linear flow data as an analog signal (4 to 20

mADC) and a 5-1/2 digit flow rate display.

R6 is adjusted so that the voltage on TB5 pin 1 is equal to the zero flow voltage from the flow bridge.

Adjustment is then made to R7 so, when the maximum voltage is applied to the S+ input,the voltage

at TB5 pin 3 equals 4.096 volts. Potentiometer R17 provides the 4 mA adjustment for the output cur

rent signal.

Access to Menu System & Resetting Totalizer is done on the Logic Board

To Reset Totalizer Display to “0”. Press and hold the black push button (See Figure 3 on Page

19) labeled (SW4) in for 5 seconds until display flashes. Totalizer has been reset at this point.

See Addendum on Page 35 for additional information on the Integral Menu System.

To Reset Totalizer Display

to “0”. Press and hold the

black push button (See

Figure 3 on Page 19)

labeled (SW4) in for 5

seconds until display

flashes. Totalizer has been

reset at this point.

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 19

Rev: 9/2019

Figures for Electrical Diagrams from Previous Page

Figure 2 - Block Diagram

Figure 3 - Two Field Wiring Boards

Thermal Instrument Company (215) 355-8400 info@thermalinstrument.com 20

Rev: 9/2019

General Precautions

Table of contents

Popular Measuring Instrument manuals by other brands

Omicron Lab

Omicron Lab Bode 100 Detailed Functional & Calibration Check

Stabila

Stabila Laser Distancer LD 320 operating instructions

Apera Instruments

Apera Instruments DO8500 instruction manual

OptoTest

OptoTest OP250 Short instructions

GRAUPNER

GRAUPNER 1955 user manual

Agilent Technologies

Agilent Technologies ESA-E Series user guide