8

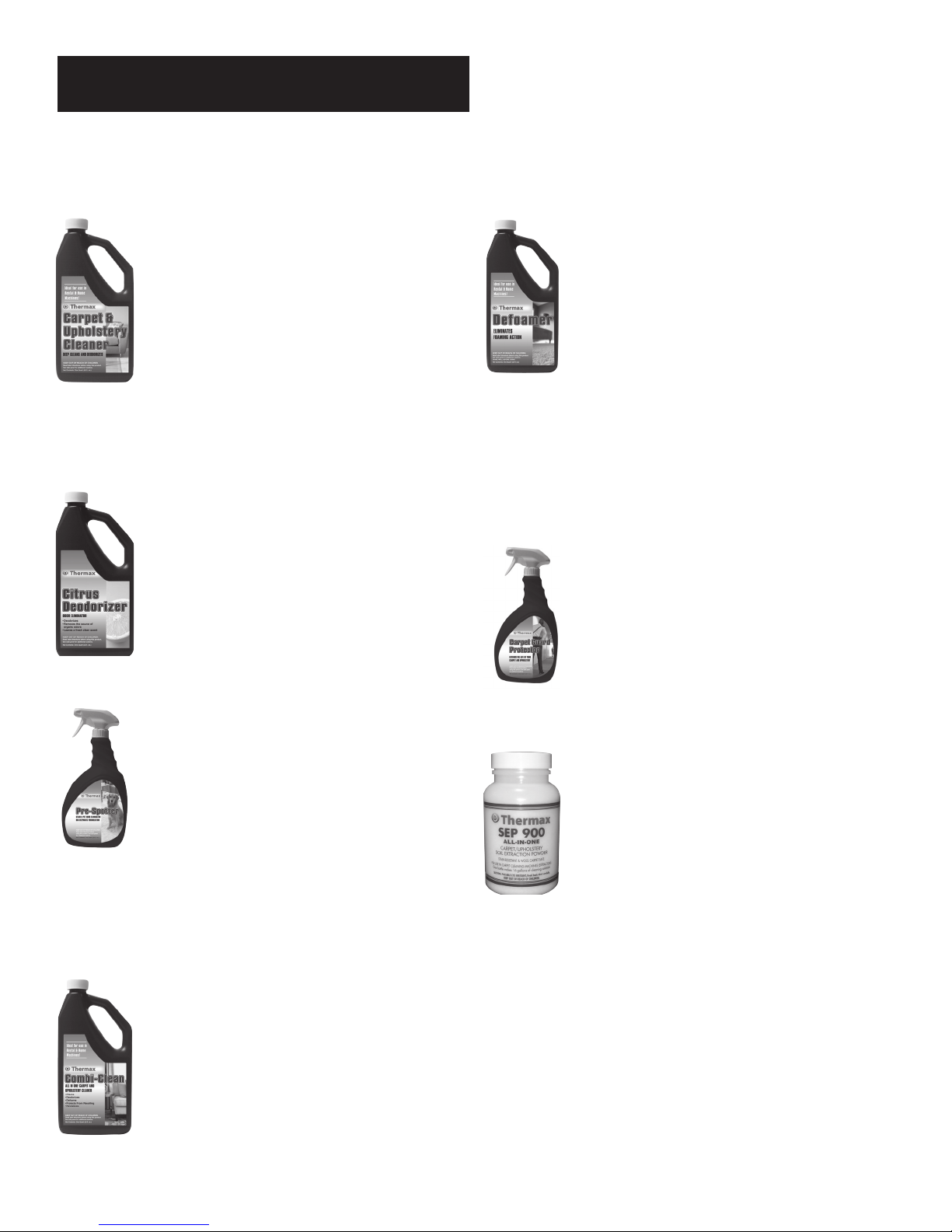

LIQUID CARPET & UPHOLSTERY

CLEANER ( B-360-32): (32oz. or 1 gal.)

Designed for any extraction type machine,

this product is designed to lift oils, stains,

and deeply embedded soils from carpets

and upholstery for easy extraction.

Professionally formulated to dispense

a perfect blend of gentle yet eective cleansing

agents for cleaning carpets, upholstery, vehicles,

boats & RV’s. Cleans and brightens leaving surfaces

soft to the touch with no “soapy” residue.

CITRUS DEODORIZER (B-350-32):

(32oz.) Citrus Deodorizer can be used alone or

mixed with ermax Carpet & Upholstery Cleaner

to neutralize and remove oensive odors from

carpets, upholstery, draperies and bed mattresses at

their source…especially pet urine, smoke and other

organic matters. Eliminates bothersome odors and

leaves rooms with a fresh, pleasant citrus scent.

PRE-SPOTTER W/BIO-ENZYMES-

STAIN & PET ODOR ELIMINATOR

(B-390-32): (32oz.) ermax Pre-Spotter w/

Bio-Enzymatic Formulation is designed to treat

spots, stains and odors caused by pets and other

organic materials. Pre-Spotter uses naturally

occurring Bio-Enzymatic digesters to attack and

remove spots, stains and odors.

Use as a pre-treat solution before cleaning or

alone as a spotter. It can also be used to clean and

deodorize bathrooms, kitchens, laundries, and

liquies solid waste in drain lines and pipes.

COMBI-CLEAN, ALL-IN-ONE

CLEANER (B-361-32): (32oz. & 1 gal.)

ermax Combi-Clean is an All-in-One cleaner!

is unique formula 1) Cleans, 2) Deodorizes,

3) Defoams, 4) Protects carpets and upholstery

from resoiling and 5) Revitalizes the appearance

of carpets and upholstery using a single product!

DEFOAMER (B-310-32): ermax

Defoamer is designed to eliminate foaming

action in the return tanks of carpet extraction

machines during cleaning. Use of Defoamer

will improve the performance of the extraction

machine giving better results and is required for

use in the recovery tank to control the

potentially damaging foam build-up within the

tank from overowing into the motor.

Every carpet being cleaned contains foreign matter

and/or left over residue from a previous cleaning

within its bers which has a tendency to excessively

foam when extracted into the recovery tank.

CARPET GUARD PROTECTOR

(B-523): (32oz.) Protects against stains and

makes your carpet & upholstery much easier to

clean and maintain, keeping them looking newer

longer. is product is a non-staining liquid

which provides soil and water resistance to

fabrics. By partially inhibiting fabric friction, it

also increases the life of the fabric and carpeting.

SEP 900, SOIL EXTRACTION

POWDER (19-075-08): (8oz. & 50lb.)

Powerful, yet safe, and formulated to meet the

most demanding cleaning requirements of today’s

modern carpets & upholstery. It does it all in one

proprietary formula, leaving your carpets &

upholstery clean and fresh. Safe on New

Generation stain resistant and wool carpeting.

STEAM CLEANING SOLUTIONS

Over forty years of extensive eld use and renement have proven our safe and eective cleaning solution formulas. For use in

both home & rental machines, ermax has a product for essentially every carpet and upholstry cleaning application.