Thermion BRIDGEMASTER User manual

File: c:\msoffice\winword\thermion\manuals\bridgemaster 2005

MANUAL July 19, 20075

Patent # 4512513; 4624410; 5791560; 6683271 B2

OWNER’S MANUAL

(OPERATIONS AND MAINTENANCE)

MANUFACTURED BY

SILVERDALE, WASHINGTON, USA

Phone: 360-692-6469

Toll Free: 877-884-6428

Fax: 360-447-8314

Web Site: www.thermioninc.com

B

BR

RI

ID

DG

GE

EM

MA

AS

ST

TE

ER

R

SERIAL #

________________________________________

ii

The US Thermal-Spray Standards Program:

Thermal-spray standards in the United States are developed by several professional

societies that include American Society for Testing and Measurement (ASTM) for test &

measurements methods and composition specifications; American Welding Society (AWS)

for feedstock, equipment acceptance, application process, training & certification;

American Water Works Association (AWWA) for thermal-spray zinc potable water tank

linings; International Association of Corrosion Engineers (NACE) for corrosion application

processes and inspection; and Society of Protective Coatings (SSPC) for test &

measurement methods, application specification & inspection in regards to protective

coatings for the protection of steel.

US Published Standards:

C2.16-92, Guide for Thermal-Spray Operator Qualification.

This guide sets forth recommended thermal-spray operator qualification procedures. It

covers applicable documents relating to thermal-spray equipment, consumables, and

safety. It also contains operator qualification and coating system analysis forms.

AWS C2.18-93, Guide for the Protection of Steel with Thermal Sprayed Coatings of

Aluminum and Zinc and Their Alloys and Composites.This guide sets forth

recommended thermal-spray operator qualification procedures. It covers applicable

documents relating to thermal-spray equipment consumables, and safety. It also contains

operator qualification and coating analysis forms. Note: This standard is being

incorporated into ANSI/AWS C2.18A-XX/SSPC CS 23.00A-XX/NACE TPC #XA, Guide for

the Application of Thermal Spray Coatings (Metalizing) of Aluminum, Zinc, and Their Alloys

& Composites for the Corrosion Protection of Steel, in preparation.

SSPC CS 23.00, Guide for Thermal Spray Metallic Coating Systems.

This guide covers the requirements of thermal-spray metallic coatings, with and

without, sealers and topcoats, as a means to prevent the corrosion of steel surfaces.

Types of metallic coatings include pure zinc, pure aluminum and zinc/aluminum

alloy, 85% zinc/15%luminum by weight. Note: This standard is being incorporated

into ANSI/AWS C2.18A-XX/SSPC CS 23.00A-XX/NACE TPC #XA, Guide for the

Application of Thermal Spray Coatings (Metalizing) of Aluminum, Zinc, and Their

Alloys & Composites for the Corrosion Protection of Steel, in preparation.

ASTM C 633, Test Method for Adhesion or Cohesive Strength of Flame-Sprayed

Coatings.

This test method covers the determination of the degree of adhesion (bonding strength) of

a coating to a substrate, or the cohesive strength of the coating in a tension normal to the

surface. The test consists of coating one face of a loading fixture, and subjecting this

assembly of coating and fixtures to a tensile load normal to the plane of the coating.

iii

US Published Standards:

ASTM D 4541, Test Method for Pull-Off Strength of Coating Using Portable Adhesion

Testers.

This test method covers a procedure for evaluating the pull-off strength (commonly

referred to as adhesion) of a coating by determining either the greatest

perpendicular force (in tension) that a surface area can bear before a plug of

material is detached, or whether the surface remains intact at a prescribed force

(pass/fail). Failure will occur along the weakest plane within the system comprised

of the test fixture, adhesive, coating system, and substrate. This test method

maximized tensile stress as compared to the shear stress applied by other methods,

such as a scratch or knife adhesion, and the results may not be comparable.

Further, pull-off strength measurements depend upon both material and

instrumental parameters. Results obtained using different devices or results for the

same coating on substrates having different stiffness may not be comparable.

MIL-STD-1687A(SH), Thermal spray processes for naval ship machinery

applications, 2/11/87.

This standard covers thermal-spray processes for machinery element repair of ferrous and

non-ferrous substrates. Included are requirements for the qualification of thermal spray

procedures and operators, requirements and guidance for use of thermal spray material

and equipment, quality assurance requirements, and descriptions of applicable

qualification tests. Note: This standard is being revised.

MIL-STD-2138A(SH), Metal Sprayed Coatings for Corrosion Protection Aboard Naval

Ships.

This standard covers the requirements for the use of metal-sprayed coatings (Aluminum)

for corrosion control applications on board naval ships. This standards covers certification

of facilities, certification of operators, application procedures, metal-spray procedures, and

production quality assurance (including test procedures and records). Note: This standard

is being incorporated into ANSI/AWS C2.18A-XX/SSPC CS 23.00A-XX/NACE TPC #XA,

Guide for the Application of Thermal Spray Coatings (Metalizing) of Aluminum, Zinc, and

Their Alloys & Composites for the Corrosion Protection of Steel, in preparation.

MIL-P-85856, Powder Materials, 7 December 1988.

This specification describes three (3) material categories for use in constructing thermal-

spray coatings, consisting of metallic and/or non-metallic components. These powder

materials may be suitable for application using wither plasma arc or combustion gas (flame

spray) techniques.

iv

US Standards In-Preparation

ANSI/AWS A5.33/A5.33M:199X, Specification for Solid and Composite Wires, and

Ceramic Rods for Thermal Spraying, 01/19/99 (ballot to publish).

This specification defines the as manufactured, chemical composition classification

requirements for solid and composite wires and ceramic rods for thermal spraying.

Requirements for standard sizes, marking, manufacturing, and packaging are

included.

ANSI/AWS C2.16A, Guide for Thermal-Sprayer Qualification, WD #2, March 5, 1999.

This standard contains the thermal sprayer (operator) performance qualification

tests for thermal sprayers. Qualification tests are included for job knowledge, flame

spraying, arc spraying, plasma spraying, and high velocity oxygen fuel (HVOF)

spraying.

ANSI/AWS C2.18A-XX/SSPC CS 23.00A-XX/NACE TPC #XA, Guide for the Application

of Thermal Spray Coatings (Metallizing) of Aluminum, Zinc, and Their Alloys &

Composites for the Corrosion Protection of Steel, WD-2, February 25, 1999.

This standard is a procedure for the application of metallic thermal spray coatings (TSC) of

aluminum, zinc, and their alloys and composites for the corrosion protection of steel.

Required equipment, application procedures, and in-process quality control (QC)

checkpoints are specified.

ANSI/AWS C2.18B-XX/SSPC CS 23.00B-XX/NACE TPC #XB, Specification for the

Application of Thermal Spray Coatings (Metallizing) of Aluminum, Zinc, and Their

Alloys & Composites for the Corrosion Protection of Steel, WD-2, February 25, 1999.

This standard is a specification for the application of thermal spray coating (TSC)

systems for the corrosion protection specifies procedures for surface preparation

and the application of the TSC with in-process quality control (QC) check points.

Annexes provide amplifying information which include safety, job reference

standards and job control record, selection of TSC’s, TSC operator and inspector

qualification, inspection, material and equipment, and maintenance and repair of

TSC’s. This standard may be used as a procurement document.

ANSI/AWS C2.19-XX, Machine Element Repair with Thermal-Spray Coatings, in

preparation.

This standard covers thermal-spray processes for machinery element repair of ferrous and

non-ferrous substrates. Included are requirements for the qualification of thermal spray

procedures and operators, requirements and guidance for use of thermal spray material

and equipment, quality assurance requirements, and descriptions of applicable

qualification tests. Note: NAVSEA (Charles Null) requested AWS incorporate MIL-STD-

1687A(SH) into an AWS standard, April 1998.

v

US Standards In-Preparation

ANSI/AWS C2.20-9X, Specification for Thermal Spraying Zinc Anodes on Steel

Reinforced Concrete, Committee Draft #2, February 18, 1999. Ballot CD-205,

Approval to publish. Due 03/31/99.

This AWS standard is a specification for thermal spraying zinc anodes on steel

reinforced concrete. This standard is formatted as an industrial process instruction.

The scope includes: job description, safety, pass/fail job reference standards,

feedstock materials, equipment, a step-by-step process instruction for surface

preparation, thermal spraying, and quality control. There are three annexes: job

control record, operator qualification, and portable adhesion testing.

ANSI/AWS C2.21-9X, Specification for Thermal Spray Equipment Acceptance

Inspection, WD-4, May 15, 1998.

This standard specifies the thermal spray equipment acceptance requirements for plasma,

arc-wire, flame-powder, -wire, -rod, and -cord, and high-velocity-oxygen-fuel (HVOF)

equipment. Proof of suitability shall be provided by the equipment supplier. Example

inspection reports are provided in four non-mandatory appendices.

ANSI/AWS C2.22-9X, Guide for Metallographic Sample Preparation and Evaluation of

Thermal Spray Coatings. Note: No comparable ISO standard. Inactive

This guide presents the recommend practices for the metallographic techniques and

procedures for characterizing thermal spray coatings. Cutting, mounting, grinding, and

polishing materials and procedures are summarized. Coating analysis covers the

interpretation of the microstructure (percentage of porosity, oxides, and other phases) and

the correlation of that information with the overall properties of the thermal spray coating by

comparison with a standard using the Line-Intercept Method and the Grid Area Method.

SSPC/NACE/AWS Tri-Society on Corrosion Protection of Steel with Thermal Spray Coatings (TSTSC)

The SSPC/NACE/AWS Tri-Society on Corrosion Protection of Steel with Thermal Spray

Coatings was formed November 1996, at the SSPC C.1.2.B meeting, Dallas, TX.

Membership inducted from the AWS C2B, SSPC C2.1.B, and NACE T-6H-45 thermal

spray committees on corrosion protection of steel. Two Task Groups were formed:

TG-A, for developing a process specification for the protection of steel with thermal

spray coatings of aluminum and zinc and their alloys. The scope of TG-A is to develop

a process specification updating and merging the content AWS C2.18, SSPC CS

23.00, and MIL-STD-2138.

TG-B, for developing a guide for the inspection of thermal spray coatings on steel. The

TG-B inspection guide is a necessary complement to TG-A process specification.

vi

ISO Standards of TC 107 SC 5, Thermal Spraying

(12 standards issued)

ISO 2063:1991 Metallic and other inorganic coatings -- Thermal spraying -- Zinc, aluminum

and their alloys

ISO/DIS 14231 Thermal spraying -- Acceptance inspection of thermal spraying equipment

ISO/DIS 14232 Thermal spraying -- Powders -- Composition -- Technical supply conditions

ISO/DIS 14916 Thermal spraying -- Determination of tensile adhesive strength

ISO/DIS 14917 Thermal spraying -- Terminology, classification

ISO/DIS 14918 Thermal spraying -- Approval testing of thermal sprayers

ISO/DIS 14919 Thermal spraying -- Wires, rods and cords for flame and arc spraying --

Classification -- Technical supply conditions

ISO/DIS 14920 Thermal spraying -- Spraying and Fusing of thermally sprayed coatings of

self-fluxing alloys

ISO/DIS 14922-1 Thermal spraying -- Quality requirements of thermally sprayed structures

--

Part 1: Guidance for selection and use

ISO/DIS 14922-2 Thermal spraying -- Quality requirements of thermally sprayed structures

--

Part 2: Comprehensive quality requirements

ISO/DIS 14922-3 Thermal spraying -- Quality requirements of thermally sprayed structures

--

Part 3: Standard quality requirements

ISO/DIS 14922-4 Thermal spraying -- Quality requirements of thermally sprayed structures

--

Part 4: Elementary quality requirements

ISO 2063:1991, Metallic and other inorganic coatings -- Thermal spraying -- Zinc,

aluminum and their alloys. Edition: 2 (monolingual) -- Number of pages: 10 --Price code:

E-- ICS:25.220.40 Descriptors: aluminum plating, classification, coatings, iron and steel

products, metal coatings, metal spraying, protective coatings, specifications, tests, zinc

coatings. Last updated on 1998-01-17.

ISO/DIS 14231, Thermal spraying -- Acceptance inspection of thermal spraying

equipment. Edition: 1 (monolingual) -- ICS: 25.220.20 Descriptors: acceptability, coating

processes, coatings, equipment, inspection, quality control, specifications, spraying,

thermal spraying -- Last updated on 1998-01-17.

ISO/DIS 14232, Thermal spraying -- Powders -- Composition -- Technical supply

conditions. Edition: 1 (monolingual) -- ICS: 25.220.20 -- Descriptors: certificates of

conformity, chemical composition, chemical properties, classification, coating processes,

coatings, delivery condition, designation, microstructure, physical properties, powdery

materials, size classification, specifications, spraying, thermal spraying -- Last updated on

1998-01-17.

vii

ISO Standards of TC 107 SC 5, Thermal Spraying

ISO/DIS 14916, Thermal spraying -- Determination of tensile adhesive strength.

Edition: 1 (monolingual) ICS: 25.220.20 Descriptors: adhesion tests, adhesive strength,

coating processes, coatings, determination, spraying, tension tests, tests, thermal spraying

-- Last updated on 1998-01-17

ISO/DIS 14917, Thermal spraying -- Terminology, classification. Edition: 1

(monolingual) -- ICS: 01.040.25, 25.220.20 -- Descriptors: classification, coating processes,

coatings, spraying, thermal spraying, vocabulary -- Last updated on 1998-01-17.

ISO/DIS 14918, Thermal spraying -- Approval testing of thermal sprayers. Edition: 1

(monolingual) -- ICS: 25.220.20 -- Descriptors: coating processes, coatings, instructions,

personnel, procedure, qualification, qualification approval, spraying, thermal spraying --

Last updated on 1998-01-17.

ISO/DIS 14919, Thermal spraying -- Wires, rods and cords for flame and arc spraying

-- Classification -- Technical supply conditions. Edition: 1 (monolingual)--ICS:

25.220.20 -- Descriptors: certificates of conformity, classification, coating processes,

coatings, cordages, delivery condition, designation, diameters, dimensions, marking, metal

bars, packaging, properties, specifications, spraying, thermal spraying, wire -- Last updated

on 1998-01-17.

ISO/DIS 14920, Thermal spraying -- Spraying and fusing of thermally sprayed

coatings of self-fluxing alloys. Edition: 1 (monolingual) -- ICS: 25.220.20 -- Descriptors:

coating processes, coatings, melting, specifications, spraying, thermal spraying -- Last

updated on 1998-01-17.

ISO/DIS 14922-1, Thermal spraying -- Quality requirements of thermally sprayed

structures -- Part 1: Guidance for selection and use. Edition: 1 (monolingual) -- ICS:

25.220.20 -- Descriptors: coating processes, coatings, quality, rules (instructions),

specifications, spraying, thermal spraying -- Last updated on 1998-01-17.

ISO/DIS 14922-2, Thermal spraying -- Quality requirements of thermally sprayed

structures -- Part 2: Comprehensive quality requirements. Edition: 1 (monolingual) --

ICS: 25.220.20 -- Descriptors: coating processes, coatings, inspection, personnel,

qualification, quality, specifications, spraying, thermal spraying -- Last updated on 1998-01-

17.

ISO/DIS 14922-3, Thermal spraying -- Quality requirements of thermally sprayed

structures -- Part 3: Standard quality requirements. Edition: 1 (monolingual) -- ICS:

25.220.20 -- Descriptors: coating processes, coatings, inspection, personnel, qualification,

quality, specifications, spraying, thermal spraying -- Last updated on 1998-01-17.

ISO/DIS 14922-4, Thermal spraying -- Quality requirements of thermally sprayed

structures -- Part 4: Elementary quality requirements. Edition: 1 (monolingual) -- ICS:

25.220.20 -- Descriptors: coating processes, coatings, inspection, personnel, qualification,

quality, specifications, spraying, thermal spraying -- Last updated on 1998-01-17.

viii

Important Safeguards

WARNING! WATCH OUT! There are possible hazards with this procedure! The possible hazards

are shown in the below symbols. Your end user (applicator, operator or helper) should read and

understand these safeguards. The operator should read and understand the operating and installation

instructions provided with this Thermion Inc. arc spray system.

The arc spray process and Thermion Inc. arc spray equipment share similarities with welding

processes and equipment. Improper use or maintenance may cause serious injury or death. Your end

user should have training or experience in safe practices for the arc spray process before operating

the arc spray equipment.

WARNING-ELECTRIC SHOCK MAY KILL

DO NOT touch bare conductors or terminals when energized. DO NOT work in wet or damp areas.

Wear dry insulated gloves and dry protective clothing. Remember that when the power source is on,

the electrode (wire) is electrically hot. DO NOT touch the wire with bare skin while touching the

electrical ground. Install and maintain your electrical equipment using the correct electrical code

standards appropriate for your requirements. A certified electrician should always hook primary

leads to the electrical grid source with the appropriate safety disconnects.

WARNING-ARC RAYS MAY INJURE EYES AND BURN SKIN

The arc spray process produces extreme heat and strong ultraviolet rays. Never try to arc spray

without a welding helmet equipped with the proper lens. Protect helpers, observers and bystanders.

Failure to protect may cause permanent damage to eyes. Also, protect skin from both arc rays and

burns from heat. Always where protective clothing which does not allow skin to become exposed.

WARNING-FUMES AND GASES MAY BE DANGEROUS TO YOUR HEALTH

Follow the precautions specified by the wire material manufacturers. Breathing any fumes created

by the arc spray process may cause illness or death when there is not proper ventilation and

protection. Keep your head out of the fumes. If ventilation is not adequate, wear approved

respiratory protection.

WARNING-WIRE FEED ROLLS CAN INJURE

Keep clear of wire feed rolls, these gears are hazardous during operation.

Keep clear of all moving parts, moving wire and rolling wire spools.

WARNING-NOISE CAN BE DAMAGING TO YOUR HEARING

Wear ear protection at all times. In some conditions, double ear protection may be required.

ix

Warranty Information

A. Limited Warranty

1) Subject to the terms and conditions hereof, Thermion Inc. warrants to the user that all

new and unused equipment furnished by Thermion Inc. is free from defect in

workmanship and materials as of the time and place of delivery by Thermion Inc. or its

agent. With respect to trade accessories or other items manufacture by others, such

items are sold subject to the warranties of their respective manufacturers, if any.

2) Thermion Inc. will honor an original user's warranty claim on warranted equipment in

the event of failure resulting from a defect for a period of 90 (ninety) days from date of

purchase.

3) Thermion Inc. will honor an original user's warranty claim on component and any

defects in workmanship on the wire feed unit for a period of 90 (ninety) days from date

of purchase.

B. Express Warranty

Any express warranty not provided herein and any implied warranty, guarantee or

representation as to performance, and any remedy for breach of contract which, but for this

provision, might arise by implication, operation of the law, custom of trade or course of

dealing, including any implied warranty of merchantability or of fitness for particular

purpose, with respect to any and all equipment furnished by Thermion Inc. is excluded and

disclaimed by Thermion Inc.

C. Consumer

Except as expressly provided by Thermion Inc. in writing, Thermion Inc. products are

intended for purchase and use by commercial/industrial users and for operation by persons

trained and experienced in the use and maintenance of thermal arc spray equipment and not

for domestic use. Thermion Inc. warranties do not extend to, and no reseller is authorized to

extend, Thermion Inc. warranties to any consumer.

x

Preface

This manual has been designed for experienced thermal arc spray operators and must be read

completely before using the equipment. If you lack experience or are unfamiliar with the

practices and safe operation of welding equipment, please consult your foreman. Do not

attempt to install, operate, or perform maintenance on this equipment unless you are qualified

and have read and understood this manual. If in doubt about installing or operating this

equipment, contact your distributor.

For the safe and successful use of this equipment, be sure the information contained in this

manual reaches the operator. Extra copies of this manual are available upon request. Please

specify your machine serial number.

This manual is divided into nine sections:

Section 1: Introduction

Section 2: Safety Measures

Section 3: System Assembly

Section 4: Controls

Section 5: Operation (General)

Section 6: Principles of Operation

Section 7: Liner Replacement

Section 8: Parts Required for Various Wire Sizes

Section 9: Components Section

The information contained in this manual represents our best judgment; however, Thermion

Inc. assumes no liability for its use.

xii

Table of Contents

Page Section Contents

1 1 Introduction

1.1 General Information and Safety

1.2 Receiving and Handling

1.3 General Description

1.3.1 Wire Feeder

1.3.2 Spray Gun

1.3.3 Arc Shorting Control

1.3.4 Remote Control of Power Source

3 2 Safety Measures

2.1 Reduction of Fire and Explosive Hazards

2.2 Reduction of Respiratory Hazards

2.3 Threshold Limits for Air Concentration of

Hazardous Material

2.4 Personal Protection

2.5 Eye Protection

2.6 Environment

7 3 System Assembly Diagram

3.1 Location

3.2 Power Supply

3.3 Component Interconnection

3.3.1 Wire Feeder Hook Up to Power Supply

3.3.2 Gun Hook Up

3.3.3 Gun Tip/Air Nozzle Alignment

3.3.4 Service Air

10 4 Controls (START UP PROCEDURES)

4.1 Voltage

4.2 Amperage

4.3 Wire Inch

4.4 Fusing

4.5 Gun Switch

4.6 Air Sweep/Inch

4.7 Wire Runback

13 5 Operation (General)

5.1 Power Supply

5.2 Wire Loading and Drive Adjustment

xiii

Table of Contents, continued

Page Section Contents

14 6 Principles of Operation

6.1. Operating Parameters

6.2. Air Nozzle Alignment 3/16” (4.8 mm) Wire Head

6.2.1. Angle Spray Nozzle 3/16” (4.8 mm) Wire Head

6.3. Air Nozzle Alignment <= 1/8” (3.2 mm) Wire Head

6.3.1. Angle Spray Nozzle <= 1/8” (3.2 mm) Wire Head

6.4. Maintenance

6.4.1. Spray Head/Parts Maintenance

6.4.2. Combination Leads

6.4.3. Feeder Unit

6.4.4. Control Cables

22 6.5 Maintenance Schedule

6.5.1 Constant Operations Checks

6.5.2 Daily Maintenance (8 hours)

6.5.3 Weekly Maintenance (40 hours)

6.5.4 Monthly Maintenance (160 hours)

24 7 Liner Replacement

7.1 Installation/Replacing Small Wire Liners

26 8 Parts Required for Various Wire Sizes

27 9 Components Section

9.1 Cable Components

9.2 Feeder Components

9.2.1 Wire Drive Components

9.2.2 Motor Components

9.2.3 Industrial Cart Assembly

9.3 Front End Assembly

9.3.1 Lead Components 3/16” Wire

9.3.1.1 Lead Components 1/8” (3.2 mm) Wire

9.3.1.2 Lead Components 3/32” & Smaller Wire

9.3.2 Spray Head Components 3/16” (4.8 mm) Wire

9.3.2.1 Spray Head Components<= 1/8” (3.2 mm) Wire

9.3.2.2 Angle Spray Head Components 3/16” (4.8 mm) Wire

9.3.2.3 Angle Spray Head Components<= 1/8” (3.2 mm) Wire

9.3.3 Handle and Trigger Assembly

9.4 Control Box

9.4.1 System Wiring

9.5 GENERAL TROUBLESHOOTING

1

1 Introduction

1.1 General Information and Safety

A. General Information presented in this manual and in the power supply manual,

and on labels, tags and plates provided on the unit pertains to equipment design,

installation, operation, maintenance, and troubleshooting all of which should be

read, understood, and followed for the safe and effective use of the equipment.

B. The installation, operation, maintenance and troubleshooting of the arc spray

equipment requires practices and procedures, which ensure personal safety and the

safety of others. Therefore, this equipment is to be installed and operated only by

qualified persons in accordance with the manual and all applicable codes.

C. Safety instructions pertaining specifically to this equipment appear throughout this

manual and the power supply manual, highlighted by signal words DANGER,

WARNING, CAUTION, and IMPORTANT, which identify different levels of

hazards.

DANGER: indicates an operational procedure, which if not followed, will cause SEVERE

injury to the operator, service personnel or bystanders.

WARNING: statements include hookup, operating and maintenance instructions and

procedures which, if not followed carefully, could result in SEVERE personal

injury or damage to the equipment.

CAUTION: indicates an operation procedure, which, if not followed, may cause MINOR

injury to the operator, service personnel and/or bystanders.

IMPORTANT: highlights instructions, which need special emphasis to obtain the most

efficient and safe operation of this equipment.

1.2 Receiving and Handling

Prior to installing this equipment, remove all packing material from around the unit and

carefully inspect for any damage, which may have occurred during shipment. The

purchaser must file any claims for loss or damage that may have occurred during transit

with the carrier.

When requesting information concerning this equipment, model description and serial

number of the equipment must be supplied.

2

1.3 General Description

Thermion Inc.’s Bridgemaster Spray Machine is a push type arc spray system that has a

patented feature, which controls arc shorting. This equipment is designed to spray most

wires, i.e., stainless, low alloy steels, bronzes, aluminum, zinc, zinc-aluminum, babbitt,

etc.

1.3.1 Wire Feeder

The feeder is compact with a carrying handle. The meters, dials, and switches are located

on the front of the feed unit for ease of viewing and operation. The drive assembly is a

four-roll heavy-duty drive unit. An Industrial Cart is available for easy mounting of the

wire feed unit.

1.3.2 Front End Assembly

The Head and Trigger/Handle Assemblies combine to make a simple, durable, and

lightweight Spray Gun. The patented combination leads carry the atomization air, spray

wire, and power to the spray gun from the feeder. These three assemblies make up the

Front End Assembly.

1.3.3 Arc Shorting Control

Arc spray systems typically have an inherent problem of arc shorting. This condition

occurs on all systems; the larger the wire diameter, the more severe the problem. A

patented feature of the Thermion Inc. system controls arc shorting. As the arc attempts to

short, a sensor detects a change in arc conditions, and the patented feature compensates,

recreating atomization. This feature has allowed continuous usage of 3/16" aluminum

and zinc wires producing over 40 lbs. and 150 lbs., per arc hour spray rate at a power

level of 400 amperes.

1.3.4 Remote Control of Power Source

The standard Thermion Inc. system must include a welding-type power source. All

functions of the system can be remotely controlled at the wire feeder; this allows the

power supply to be located remote from the work area. Refer to your power supply

manual for methods used to activate remote capabilities.

3

2 Safety Measures

WARNING Arc spraying can be hazardous because it requires the use of electric

voltages and currents, hoses under high pressure, and potentially irritating or toxic

spray materials. It may involve air contaminated by dusts, fumes, etc,. However, it can

be a completely safe process when performed by a capable operator with proper

understanding of arc spraying practices and knowledge of the equipment, one who

takes care in operation and follows the recommended precautionary measures.

2.1 Reduction of Fire and Explosive Hazards

WARNING Remember that the stream of sprayed metal is HOT. Point the gun away

from yourself and away from materials that will burn. Carelessness in pointing the gun

at paper, wood, or oily rags can result in fire.

CAUTION Be especially careful not to spray on the hoses when operating the gun.

Hoses will burn. Keep them out of the way. All air lines, compressors, regulators, etc.,

should be inspected regularly for leaks and loose connections.

EQUIPMENT MAINTENANCE: Maintain the arc spray equipment in first-class

condition. Follow the maintenance recommendations in this Thermion Instruction

Manual located in Sections 6.4-6.5.4.

DANGER: All dust, having considerable caloric value, can be explosive. This dust

includes: flour, starch, hard rubber dust, wood flour, aluminum dust, and the dust of

other metals. Aluminum and magnesium dusts are particularly hazardous. The greatest

care should be used in handling them. To minimize the danger of a dust explosion in an

arc spray booth or other confined spaces, prevent the accumulation of fumes and dust.

Ventilation and good housekeeping in the work area is essential. Inspect and clean

regularly to assure that there is no potentially dangerous accumulation of dust.

Dust Collectors must be suitable for metal spray dust. All closed collectors must be

provided with blowout holes or relief panels. All fans, pipes, dust colletors and motors

should be electrically grounded. Motors should be external to the dust system.

When cleaning booths, pipes, etc., the ventilating fan should be kept running to prevent

the accumulation of fumes or dust in the system. Non-sparking tools should be used in

cleaning and repair operations.

When emptying the collector, all sources of ignition in the area should be eliminated.

When making repairs on the ventilating or dust collecting equipment, no welding or

cutting should be done before the equipment is washed down and all metal dust

removed.

4

2.2 Reduction of Respiratory Hazards

WARNING For shop work being performed by an operator without an air fed hood, a

suitable spray booth and an adequate exhaust system are required to avoid the toxic or

noxious effects of dust, fumes, and mists which may be generated by arc spraying. The

following is for information only; your Governmental Safety and Health Agency should

determine the actual requirements.

For ordinary arc spray work, air at a velocity of 200 FPM (1.0 m/s) should pass into the

opening of the spray booth. With the arc spray gun at the booth opening, the exhaust

system must be able to exhaust 200 CFM (0.1m3/s) of air for every square foot of booth

opening. If the booth has an opening of four square feet (.37 m²), a system that will

exhaust 4 x 200 or 800 CFM (0.4 m3/s) should be provided. If there is any question as to

the effectiveness of the ventilating and exhaust system or as to the presence of airborne

particles which the operator might inhale, consult a competent industrial hygienist.

Because any finely divided material may damage the respiratory system, respirators are

recommended for all thermal spraying.

IMPORTANT: it is strongly recommended that complete and current information be

obtained from your Governmental Health Agency.

Some materials, such as beryllium, tellurium, and their oxides, are dangerous to the

respiratory system and should not be used at all except under the supervision of a

competent safety engineer.

BLASTING and SPRAYING both produce dust. Blasting of toxic materials should be

considered to be hazardous, as is spraying such materials.

Completely sealed, mask-type, pressurized respirators are recommended for all

applications of thermal spray. However, with proper ventilation that maintains proper

threshold limits of hazardous material, element type filters of the proper type will protect

satisfactorily.

5

2.3 Threshold Limits for Air Concentration of Hazardous Material

WARNING Obtain up to date, exact figures from your governmental health agency.

CERTAIN SOLVENTS: Certain solvents may decompose when exposed to ultra

violet rays. Avoid exposing solvents, or parts when wet with solvent, to the radiation

from the arc.

When the electric arc spray system is set up and operated in accordance with the

instructions in this manual, the metalizing wires are electrically energized only when the

gun is spraying. When the spray is shut off, electrical charge is removed from both

metalizing wires.

DANGER If, while the gun is spraying, a person should touch both energized wires,

or any part that the wire is in contact with, that person could receive an electrical shock,

the volume and current of which are capable of developing a harmful or fatal electric

shock or burns.

Do not clean the inside of the power supply unit with a wire brush or any other tool. Use

clean, dry compressed air only.

2.4 Personal Protection

WARNING The electric arc generated at the front of the gun is very bright and emits

ultraviolet light rays. The eyes and skin must be guarded against these rays. Standard

air fed welding, or sand blasting, personal protection equipment fitted with a dark lenses,

has proven to provide adequate protection for thermal spraying.

Possible allergic reaction of dust, fumes, and the like or other unknown causes of health

impairment due to contact with the body cannot, in most cases, be predicted. To avoid

such reaction, never permit spray dust to enter the eyes, mouth, cuts, scratches, or open

wounds. After spraying, and especially before eating or handling foods, wash hands

thoroughly. Wear fireproof or flame resistant protective clothing if available. Protect

eyes, ears, and skin through use of gloves, facemask, ear and body protectors that are

standard in the welding industry.

REDUCTION OF NOISE HAZARDS:

Noise from a Thermion Inc. arc spray gun range between 80 and 120 decibels. At this

level, most Governmental Health Agencies require ear protection and sometimes double

ear protection.

6

2.4 Personal Protection (continued)

WARNING the noise made by the arc spray gun is loud enough to cause the operator

discomfort and can cause hearing damage. Adequate protection should always be used.

The operator and other personnel close to the arc spray operation must be protected from

excessive noise. If possible, the spray operation should be isolated. Hearing protection

should be used. Do not rely on wads of cotton for hearing protection. They are

ineffective against high-intensity noise.

Noise level at any location depends on factors such as equipment operating parameters,

background noise, work area size, and wall, floor, and ceiling materials. To determine

the exact noise level, it is necessary to measure the sound level to determine the method

needed for adequate protection.

2.5 Eye Protection (Standard Welding Shields and Lens)

CAUTION the hardened green (Shade 9) lens is within the shade range recommended

for arc spraying. However, the choice of lens shade may be based on visual sensitivity

and sharpness (acuity) and may vary widely from one individual to another. Check with

your Government Health Agency for current and complete shade number

recommendations.

Always wear proper eye protection when operating or watching the arc spray operation.

Inspect the lens and cover plates frequently. Lenses and cover plates that are scratched,

pitted, or damaged can impair vision and seriously reduce protection.

2.6 Environment

DANGER The Thermal Spraying operation can produce materials that are hazardous

for plants, animals, fish, or water quality. Precautions must be taken to prevent any

danger to the environment. Collect all residues from the metal spray operation and

dispose of as hazardous material or determine that it is safe to the environment prior to

disposal.

7

3 System Assembly (drawing shows optional straighteners)

Table of contents

Other Thermion Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

EUROPRO

EUROPRO MIXPRO 14 user manual

Central Pneumatic

Central Pneumatic CENTRAL PNEUMATIC 92841 owner's manual

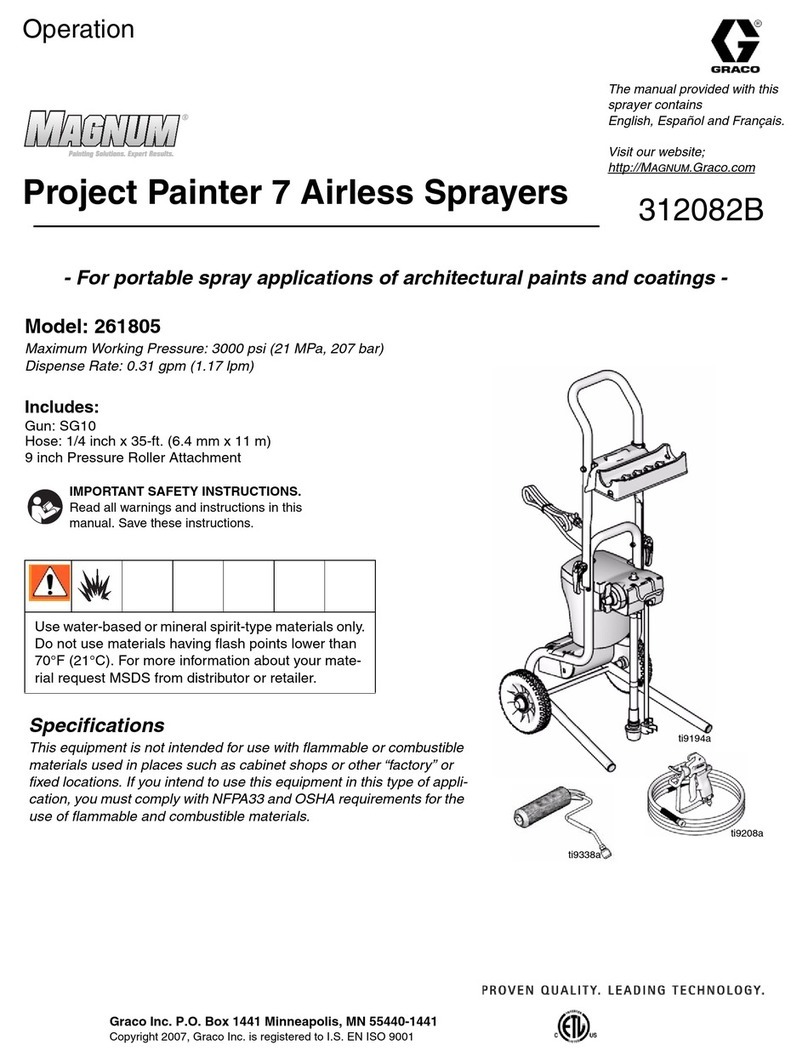

Magnum

Magnum 261805 Operation manual

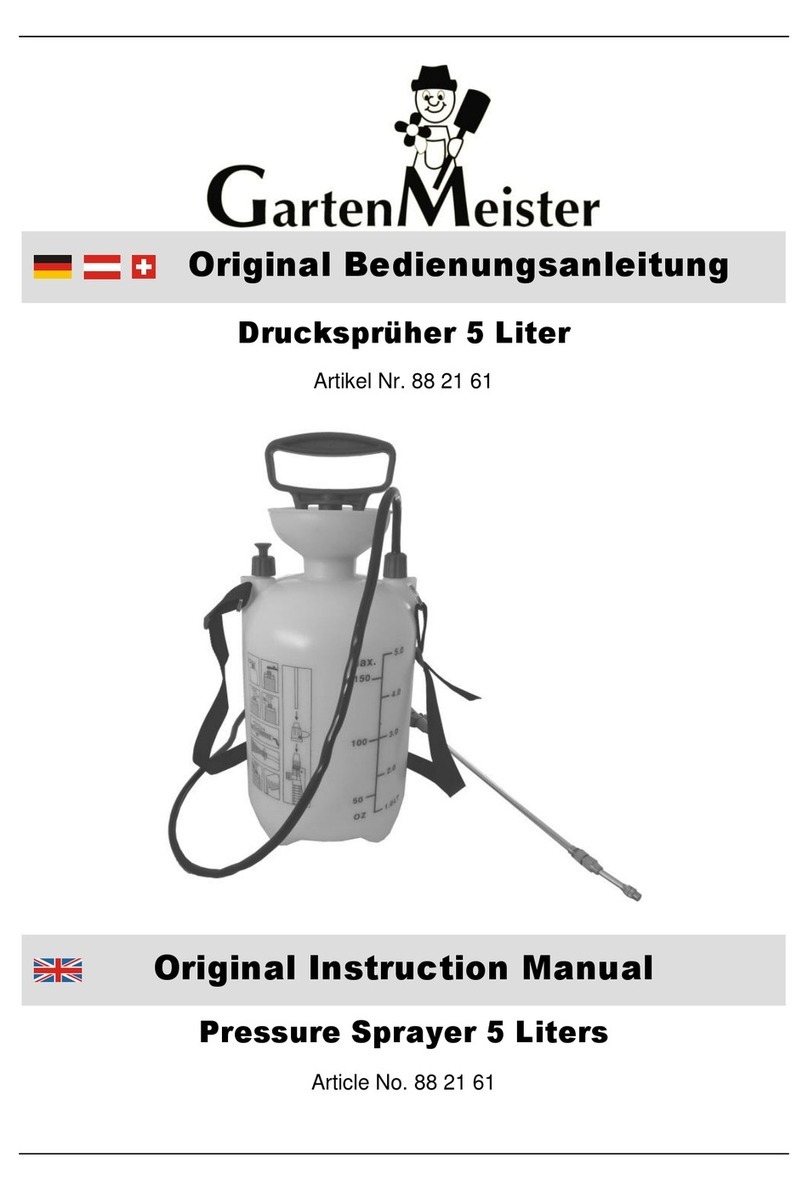

Garten Meister

Garten Meister 88 21 61 Original instruction manual

Central Pneumatic

Central Pneumatic 62381 owner's manual

Husqvarna

Husqvarna 321S15 Operator's manual