321S15/25

GB-8

• When starting work, please pay all due consideration

to the spraying time, wind direction, etc., to ensure that

no noise disturbance or chemical hazard is caused to

nearby residents, passers-by, farm crops, and so on.

• While spraying please hold the grip •rmly at all times

and be careful not to point the nozzle in the direction

of people or animals.

• While spraying please be careful of the wind direction

and always stand on the upwind side, to avoid spraying

yourself with chemicals.

• Should you begin to feel even slightly unwell while

spraying, consult a doctor immediately. When doing

so, inform the doctor of the name of the chemical you

were using, the conditions of use, etc.

• If the sprayer is tilted the chemical may leak out

through the air holes in the cap. When spraying always

make sure you have a •rm footing and maintain your

balance.

• Do not touch the spark plug or plug cords while the

engine is running, as you may get an electric shock.

• Do not touch the muf!er, spark plug, or other metal

parts with your bare hands while the engine is running

or immediately after stopping the engine, as there is

the risk of burns due to high temperatures.

Precautions after spraying

• Please seal unused chemicals and store them out of

the reach of children.

• Do not simply discard empty chemical containers,

but dispose of them safely by incinerating, burying, or

another similar method. In addition, please take every

care that the water used to clean spraying tools does

not create any hazard.

• Fully inspect and maintain protective clothing, masks,

gloves, and other protective gear in preparation for

the next session.

• After completing the work and tidying away chemicals

and spraying tools, you should immediately take a bath

or wash your hands, feet, face, etc. thoroughly with

soap, as well as washing your mouth out.

• You should change all clothes worn, including under-

wear, and wash them thoroughly. Clothes worn during

spraying should not be worn again the following day.

• After spraying, please limit your alcohol intake and

rest thoroughly by going to bed early. If you feel even

slightly unwell, please see a doctor as soon as pos-

sible.

Other precautions

• When engaged in spraying work over a protracted pe-

riod of time, please have your health checked regularly.

• Please carry out spraying in a planned fashion, keep-

ing a daily record of the date and time of spraying, the

chemicals used, the target pest, contents of the work,

duration of the work, and other details.

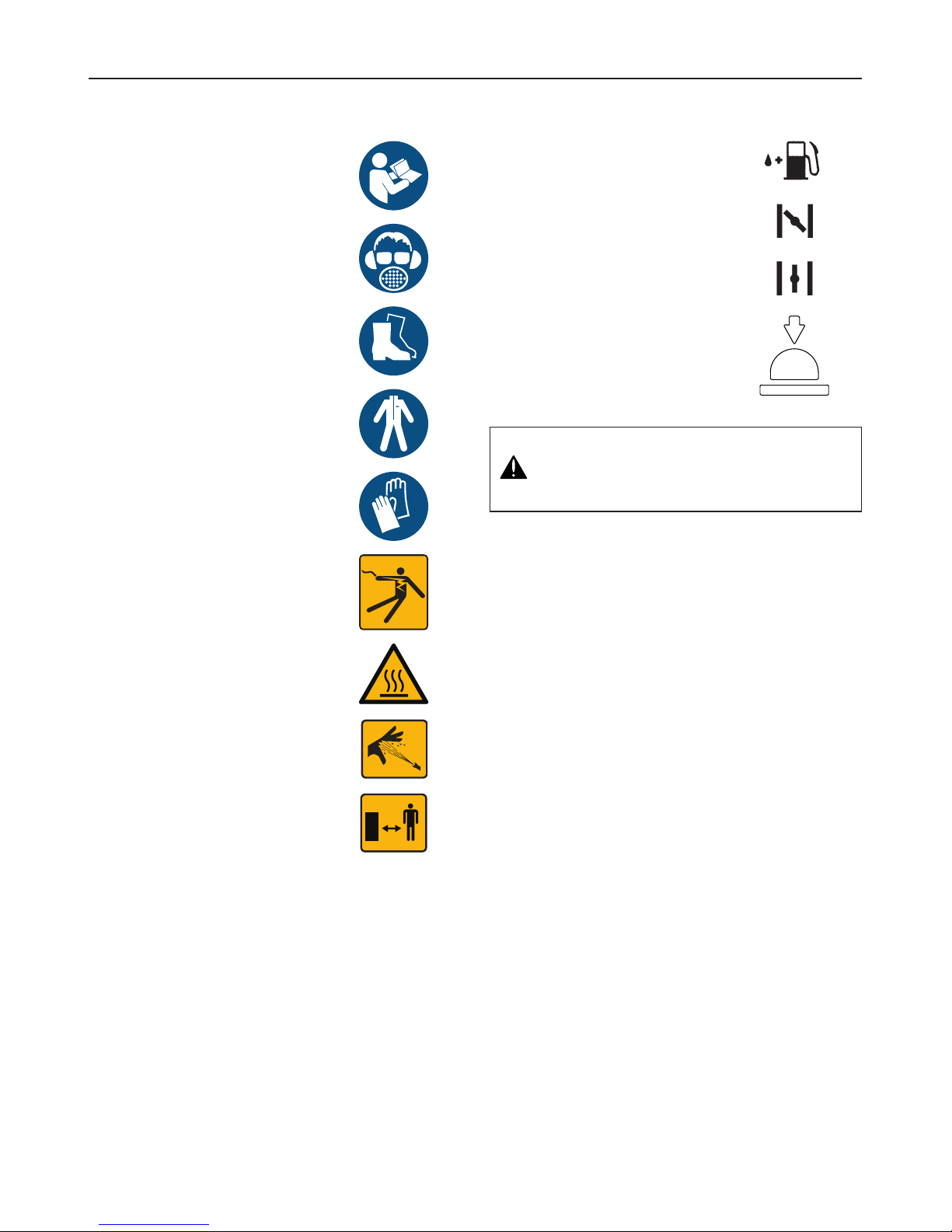

• Please keep the following points in mind when select-

ing or using protective gear.

A. Protective clothing. Choose clothing that is cool to

wear and offers good ventilation and waterproo•ng.

In addition, wear items that enable you to carry out

spraying work in total comfort and safety.

B. Spraying hood. Use a hood with a brim that is water-

proof and covers your neck and shoulders.

C. Gloves. Use gloves that are dif•cult for chemicals to

penetrate and do not slip even if you perspire while

doing the work.

D. Rubber apron. When mixing chemicals, wear a long,

thick, and wide apron that cannot be penetrated by

chemical splashes.

E. Protective goggles, mask, etc. Select suitable protec-

tive goggles, mask, rubber boots, eye washer, and

protective cream, etc., paying attention to standards

and the recommendations of farm work safety promo-

tion organizations.

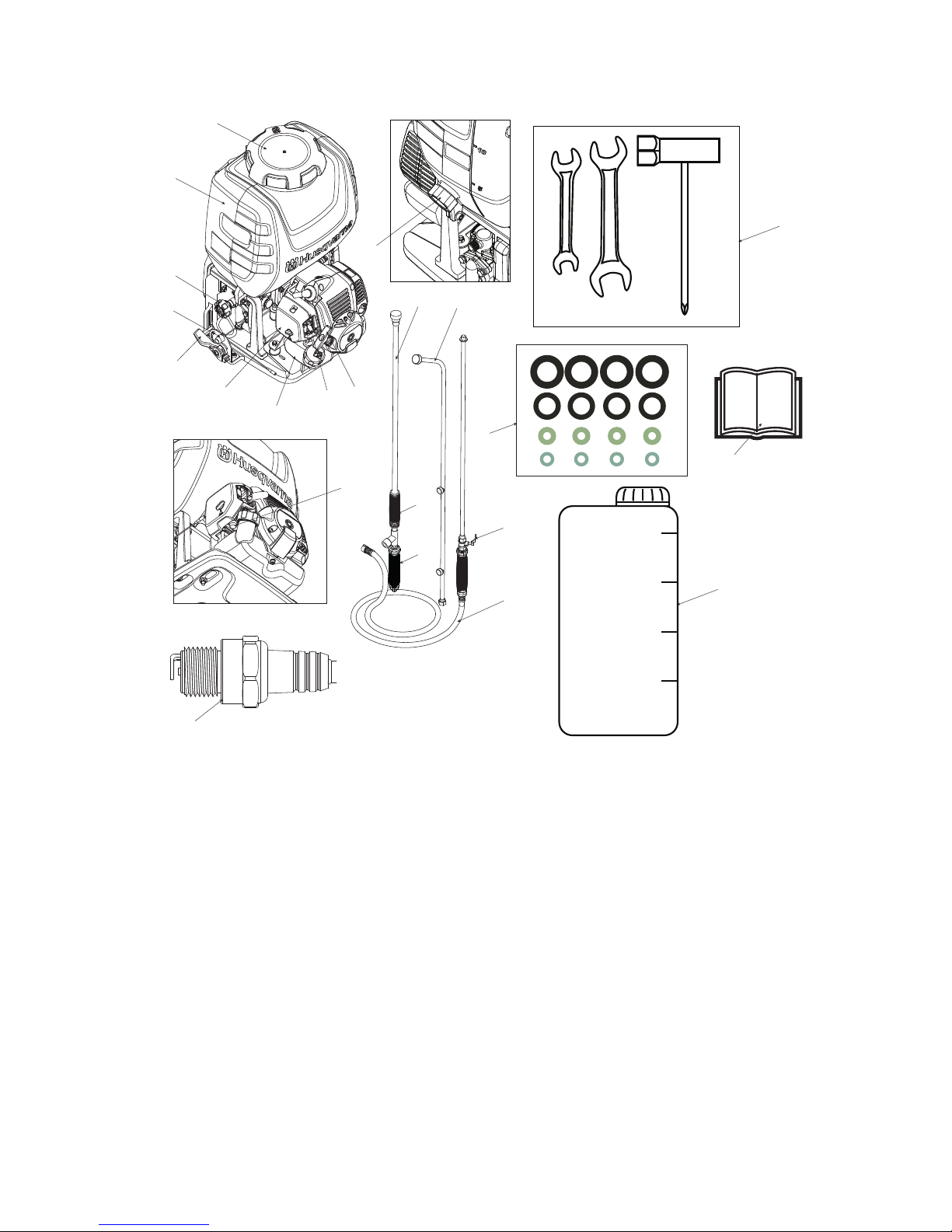

Maintenance precautions

• In order to maintain the functions of the product,

regularly carry out the maintenance inspections listed

in this Manual. When maintenance or parts replace-

ment not indicated in this Manual are required, please

consult your product supplier or nearest Husqvarna

product dealer.

• Never keep the engine running while carrying out

inspections or maintenance.

• Do not modify the sprayer or dismantle the engine.

This could lead to breakdown and serious accidents

during operation.

• Do not touch the muf!er or spark plug with your bare

hands immediately after stopping the engine. There is

the risk of burns due to high temperature.

• For replacement parts, please use original Husqvarna

parts or brands designated by Husqvarna .

Maintenance of labels

1. Please keep warning labels clean and unmarked.

2. If warning labels become soiled or peel off, please

order from your supplier and replace with new ones.

3. When af•xing new labels please wipe off all dirt and

moisture.