Thermo EC EC600-90 User manual

Instruction Manual

THERMO EC

EC2060/EC3000-90/

EC600-90/6000-90

Series 90 Power Supplies

IMPORTANT

Please read these instructions carefully

before using this power supply

WARNING

Please read these instructions carefully

before using this power supply.

▲

!

AVERTISSEMENT

Veuillez, avant tout emploi du générateur,

lire attentivement ce manuel d´utilisation.

▲▲

!

▲

▲

▲

159-3037-00 Rev. A ©02/01 Printed in USA

100 Colin Drive

Holbrook, NY 11741-4306

Tel: 1-631-244-2929

Toll Free: 1-800-EC-RANGE

FAX: 1-631-244-0606

For Technical Service: 1-800-327-2643

Email: savantec@savec.com

www.thermoec.com

A Thermo Electron business

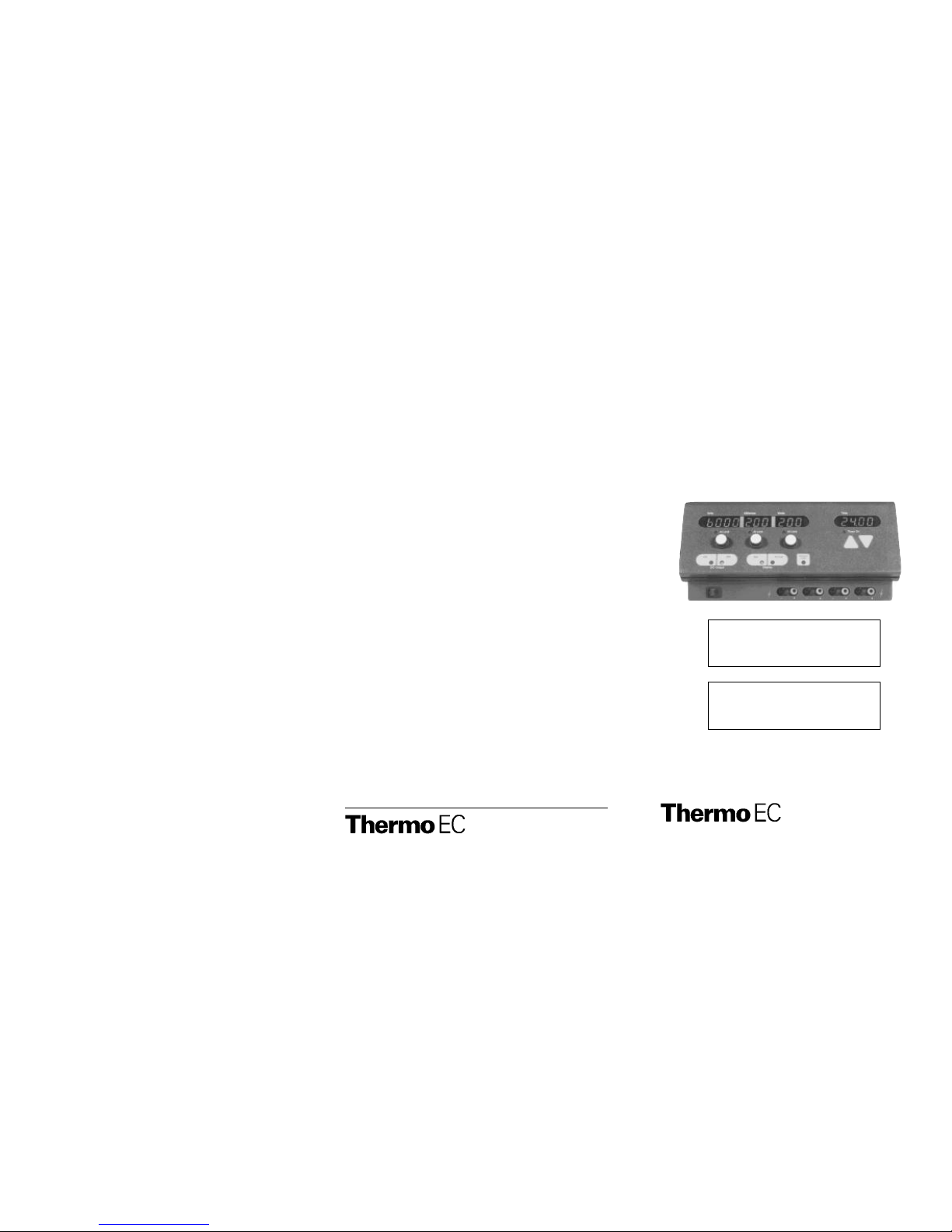

1. Volts adjustment knob

2. Yellow At Limit light (Volts)

3. Volts display

4. Yellow At Limit light (Milliamps)

5. Milliamps display

6. Milliamps adjustment knob

7. Watts display

8. Yellow At Limit light (Watts)

9. Watts adjustment knob

10. Time display

11. Yellow Timer On light

12. Arrow Down key to adjust the timer

13. Arrow Up key to activate and to adjust the timer

14. 4 mm sockets

15. Red Ground Leak light

16. Actual Display key

17. Yellow Actual Display light

18. Yellow Set Display light

19. Set Display key

20. D.C. Output Off key.

21. Green D.C. Output Off light

22. Power On/Off switch

23. Red D.C. Output On light

24. D.C. Output On key

2122

1

24

15

23

3 6 7 854 9 10

11

12

13

14

20 19 18 17 16

2

WARNING

This power supply is designed for use as a source of DC power for electrophore-

sis. It is capable of generating lethal currents. Use the same precautions as with

any electrical device. Do not operate without the cover in place. Do not connect

the output to earth ground. Do not operate in a damp, humid, environment

where condensing moisture may short out internal electrical components. Do not

operate with connecting cables which have exposed live wires. Follow all appro-

priate safety measures outlined by the chamber manufacturer.

AVERTISSEMENT

Ce générateur a été conçu pour être utilisé comme source de courant (DC) pour

l´électrophorèse, et il est capable de générer un courant mortel. Prenez les

mêmes précautions que pour tout autre appareil électrique. N´utilisez pas

l´appareil sans que le couvercle de la chambre soit placé. Ne raccordez pas

les sorties à la terre. N´utilisez pas l´appareil dans des environnements humides,

où la condensation pourrait causer des dommages aux composants électriques

internes. Ne mettez pas l´appareil en route avec des câbles ou partie de câble

dénudé. Ne retirez pas les câbles des sorties de 4 mm pendant que l´appareil

est en fonctionnement. Prendre toutes les précautions recommandé par le fabri-

quant de la chambre d´électrophorèse.

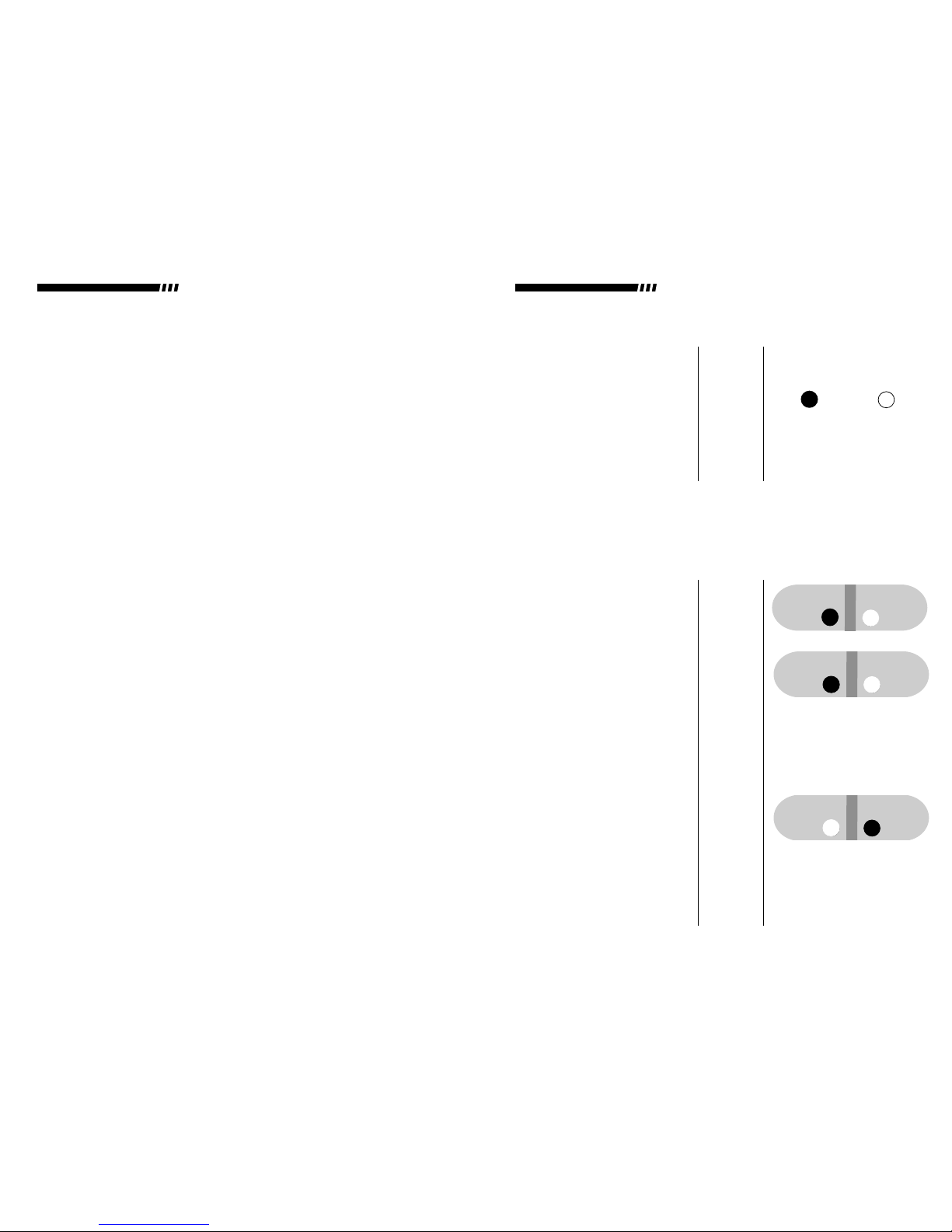

SAFETY NOTICES

NOTICES DE SÉCURITÉ

WARNING: This notice alerts you to a potentially dangerous

situation.

AVERTISSEMENT:

Cette notice attire votre attention sur des dangers

potentiels.

CAUTION: This notice means serious damage may occur to your

power supply or chamber.

ATTENTION: Cette notice attire votre attention sur des dangers

sérieux pour votre générateur ou votre chambre

d´électrophorèse.

NOTE:

This notice gives useful advice or suggestions to raise

the performance or reliability of your power supply.

NOTE:

Cette notice vous donne des conseils vous permettant

d´augmenter la performance et la fiabilité de votre

générateur.

▲

▲

▲

▲

!

▲

!

▲

▲

▲

▲

▲

THERMO EC HIGH VOLTAGE POWER SUPPLIES

THERMO EC HIGH VOLTAGE POWER SUPPLIES

1. The voltage applied to both Cell “A” and Cell “B” is 100 volts. (Rule 1)

2. The sum of the currents flowing through Cell “A” and Cell “B” is equal to

60 milliamps. (Rule 3)

Switch off the power supply and momentarily disconnect Cell “B”. Switch the power

supply back on and note how the output current reading drops to 35 milliamps.

From this, the following information can be derived.

1. The current flow through Cell “B” is equal to 60 milliamps, minus 35 milliamps,

i.e., a net value of 25 milliamps. (Rule 3)

2. The reason Cell “A” and Cell “B” have different current readings is due to the

difference in resistance between Cells “A” and “B”. (Rule 2)

TABLE OF CONTENTS

Intended Uses .............................................. 2

Set-Up ........................................................ 2

Basic Operating Instructions............................ 2

Choosing Safe Operating Limits....................... 5

Setting and Resetting the Timer ........................10

Troubleshooting Guide...................................11

Service .......................................................13

Specifications...............................................14

Appendix A. Relationship Between Volts,

Milliamps, Watts and Chamber Resistance........15

Appendix B. Running Multiple Chambers...........15

Guarantee...................................................16

Locator Guide..............................................fold out back page

1

GUARANTEE

This laboratory equipment was produced by Thermo EC with the highest

practical standards of materials, workmanship, and design. The design

and manufacture of parts have been conceived with one purpose — to

produce a unit which will give satisfactory service.

Thermo EC guarantees this unit to be free from defects in materials or

workmanship under normal use or service for four years from date of

shipment. If, during this time, this unit proves defective in materials or

workmanship, the Company will repair or replace it free of charge if

returned to us prepaid. This guarantee does not cover damage in transit,

damage caused by carelessness, misuse or neglect, or unsatisfactory

performance as a result of conditions beyond our control or consequen-

tial losses as a result of failure of our product.

16

THERMO EC HIGH VOLTAGE POWER SUPPLIES THERMO EC HIGH VOLTAGE POWER SUPPLIES

15

INTENDED USES

This power supply is intended to be used with electrophoretic devices which

operate below the rated output levels listed below. The maximum output levels

are shown for each model using this instruction manual. Four sets of output

connectors operate in parallel to provide an output of constant voltage, constant

current (milliamps) or constant power (watts).

• Model EC600-90 4000 V, 300 mA, 300 W

• Model EC2060 2000 V, 600 mA, 300 W

• Model EC3000-90 3000 V, 300 mA, 300 W

• Model EC6000-90 6000 V, 200 mA, 200 W

SET-UP

Unpacking of the Unit: Unpack and inspect the power supply carefully

for any damage. Do not use the unit if it is damaged. If damage is found,

save the packing material and report the problem to Thermo EC or your local

distributor.

Location: Make sure that the unit is set up in a location where it is pro-

tected from physical damage, moisture, corrosive agents and extreme tem-

peratures, and make sure that the “fins” at the rear are not obstructed. The

unit should be readily accessible for safe operation.

Connection with the AC Mains: Connect the unit to the AC mains

carrying the appropriate specified voltage (V) in accordance with the rating

label located at the rear of the unit. Make sure that the mains receptacle and

the power supply plug both have the proper 3–wire (grounded or earthed)

connections.

BASIC OPERATING INSTRUCTIONS

(See fold out locator guide on last page)

Notes on General Operation: The output of this power supply is con-

trolled by three separate operating limits. An operating limit, with a value

above zero, must be set for voltage, milliamps and watts in order to generate

an output. Once activated, the output of the power supply will then increase

until an operating limit is reached. When this occurs, one of the three yellow

At Limit lights will be illuminated. This light will indicate which operating limit

has been reached and which mode of control (constant volts, current or

power) has been established. The detailed instructions contained in this man-

ual refer to adjustment for operation in constant voltage. In principal, the

method is the same for any mode of operation; only the value of operating

limits change.

For added convenience, this power supply will restart itself in the event of a

power failure. This will not reset the operation of the count–down timer.

2

▲

▲

!

▲

!

▲

APPENDIX A. Relationships Between Volts, Milliamps,

Watts and Chamber Resistance

There are three fundamental concepts which form the basis for understanding the

relationship between volts, milliamps and chamber resistance. When combined with

the power formula they also define watts.

1 A movement of free electrons from atom to atom forms an electric current which

is measured in milliamps (mA) or amps (A).

2. Electrostatic lines of force between two different charges produce a pressure that

can move electrons (measured in volts).

3. All substances oppose the movement of electrons to some extent and are said to

have resistance (measured in ohms).

These three factors are always present in any operating electric circuit. It is possible

to incorporate them into one inclusive statement:

Ohm’s Law

The value of the current that will flow in any circuit will be

directly proportional to the value of the voltage applied and

inversely proportional to the value of the resistance.

or

amps = volts / resistance

combined with

The power formula:

volts x amps = watts

(where 1 amp = 1000mA)

Together, these two formulas define all aspects of the relationship between volts,

milliamps, watts and chamber resistance.

APPENDIX B. Running Multiple Chambers

This power supply is equipped with four sets of 4 mm output connectors which are

connected in parallel. The significance of this is explained by following statements:

1. The voltage is applied equally to all branch paths in a parallel circuit.

2. The current flow in the branch paths of a parallel circuit is determined by the

resistance of the individual paths.

3. The sum of the currents entering the branch paths of a parallel circuit is equal to

the sum of the currents leaving the branch paths of a parallel circuit.

A practical example of this is described as follows:

The power supply is connected to two identical horizontal submarine electrophoresis

chambers (cells A and B). The power supply output is adjusted to 100 volts, at con-

stant voltage, and the current display indicates 60 milliamps. By applying the three

rules for parallel circuits we can determine the following information.

THERMO EC HIGH VOLTAGE POWER SUPPLIES THERMO EC HIGH VOLTAGE POWER SUPPLIES

SPECIFICATIONS

High Voltage Power Supplies (refer to page 2 for models)

Type Output: Constant Voltage, Constant Watts or

Constant Milliamps with automatic crossover

Maximum Voltage: 2000 – 6000 Volts, (depending on model)

Maximum Current: 200 – 600 Milliamps (depending on model)

Maximum Power: 200 – 300 Watts (depending on model)

Regulation: ≤1%

Accuracy: ± 1.5% full scale for each display

Number of

Output Terminals: Four recessed sets of 4 mm sockets

Safety Interlock: Load sensing shut-down-on-disconnect. D.C.Output On

key actuation necessary to begin voltage generation.

In the event of shutdown due to power interruption,

automatic restart is provided.

Timer: 00 to 99 hrs. 59 min.

Ground Leakage: Leakage of 400 microamps or more will interrupt the

generation of high voltage.

Input Power: 115 VAC/60 Hz./400 W

230 VAC/50 Hz./400 W

Ambient Operating

Temperature Range: 0 ° – 30 °C (non-condensing atmosphere)

Dimensions: 11.25

"

(D) x 12.6

"

(W) x 5

"

(H)

28.6 cm x 32 cm x 12.7 cm

Weight: net: 15.4 lbs. 7 kgs.

shipping: 17 lbs. 7.7 kgs.

14

BASIC OPERATING

INSTRUCTIONS

Operation in

Constant Voltage:

1. The electrophoresis chamber

should first be set up, then filled

with buffer and sample, before

plugging the chamber’s leads

into the appropriate positive

and negative 4 mm sockets

(14) on the power supply.

2. Switch on the power supply

using the Power On/Off

switch (22). The main power

switch is marked with a 1 to

indicate on and a 0 to indicate

off. Once on, the Green D.C.

Output Off light (21) and

Yellow Actual Display light (17)

will be illuminated. The Volts

display (3), Milliamps display

(5) and Watts display (7) will

all indicate zero. The Time dis-

play (10) will indicate zero as

well.

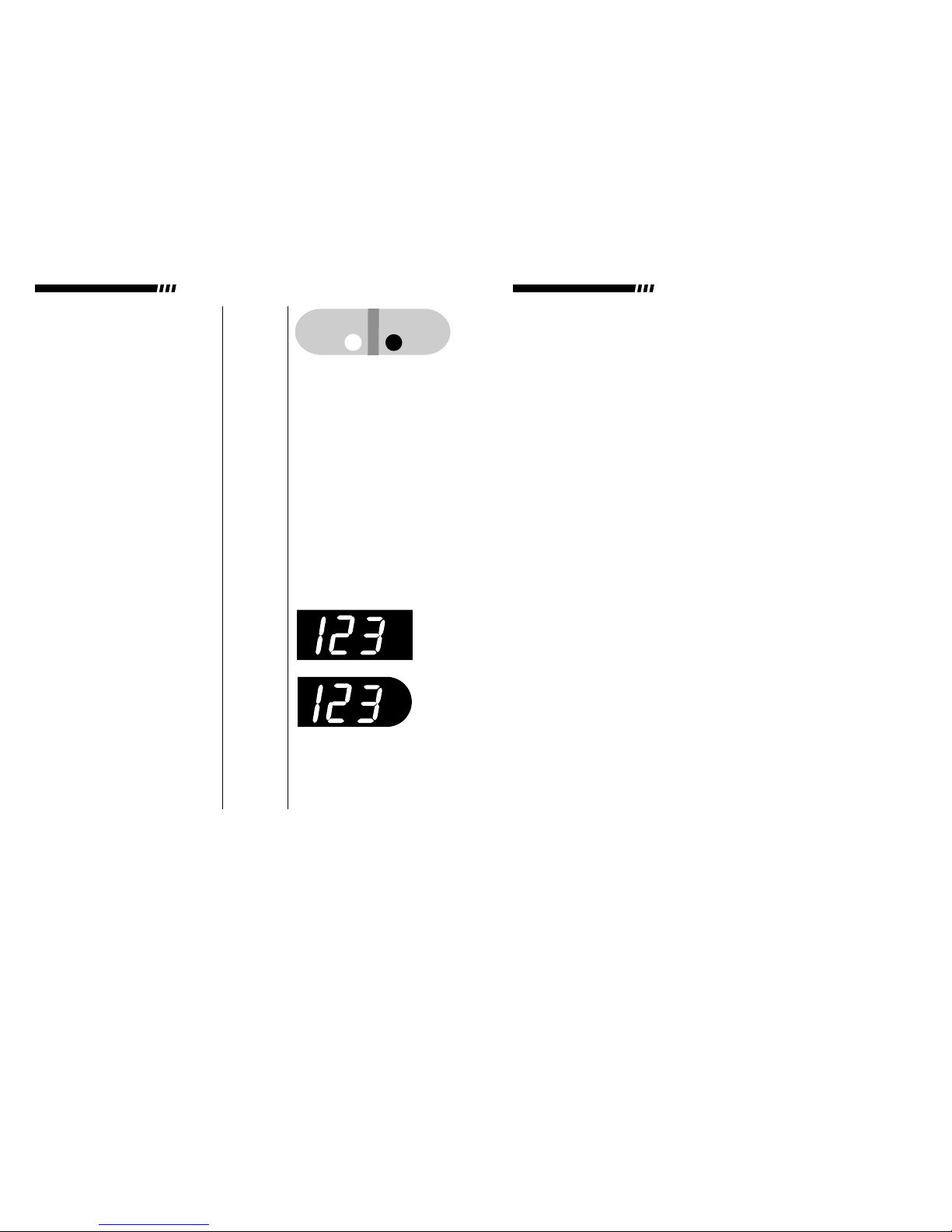

3. Gently press the Set Display

key (19). The actual switch itself

is located in the grey area

located immediately below the

word “Set” in the Set Display

key. When pressed, there will

be a tactile sensation, the

power supply will beep and

the Yellow Set Display (18) light

will be illuminated. Each key on

Set Actual

On Off

14

22, 21,

17, 3,

5, 7, 10

19, 18 Set Actual

Locator

Number

Light Off Light On

DC Output

Display

Display

NOTE: An alterntive procedure favored by some users is as follows:

Sample is withheld from the chamber until the power supply has been properly

adjusted and successfully started. Once the user has confirmed that the chamber and

power supply are both functional, the power supply is turned off and sample is

loaded. The power supply will remember its settings, so it can be turned on and start-

ed without further adjustment.

(See fold out locator on last page)

BASIC OPERATING INSTRUCTIONS

3

THERMO EC HIGH VOLTAGE POWER SUPPLIES THERMO EC HIGH VOLTAGE POWER SUPPLIES

13

this power supply has a similar

switch location and sensory cue

upon activation.

4. Using the Volts adjustment knob

(1), select the operating voltage

limit by turning the knob until

the desired value appears on

the Volts display (3).

Rotating the knob slowly in

the clockwise direction will

increase the displayed value

in one–volt increments.

Rotating the knob slowly in the

counterclockwise (anticlock-

wise) direction will reduce the

displayed value in the same

manner. Rotating the same

knob (1) rapidly in either

direction will cause the

displayed value to change in

ten–volt increments.

5. Using the Milliamps Adjustment

knob (6) and Watts Adjustment

knob (9), select the desired

operating limits for milliamps

and watts, respectively. The

method used to select these val-

ues is the same as that used to

select the operating voltage

limit.

CHOOSING SAFE OPERATING

6,9 Milliamps

Watts

WARNING: This power supply is capable of producing output levels well in

excess of the maximum safe operating limits for most electrophoretic chambers. For

this reason, it is important to determine the safe operating limits for milliamps and

watts. The section entitled “Choosing Safe Operating limits” has been included to

guide the user in selecting proper operating limits. This section details both the

method and rationale used in selecting these operating limits.

Volts

1, 3

NOTE: Each adjustment knob has a RAPID ADJUSTMENT MODE which is

activated whenever the knob is rotated rapidly.

4

WARNING

This power supply is not equipped with

any user serviceable parts.

Erratic Operation: Unstable, erratic displays, inoperable timer and/or

adjustment knobs are all possible symptoms of corrupted memory. To clear

this condition turn off the power supply, depress and hold any key and turn

the power supply back on before releasing the key.

Ground Leakage: Ground leakage is the interconnection of earth ground

and either high voltage output. This interconnection will defeat the primary

operator safety feature of this power supply. Do not operate the power supply

when this condition exists. For further assistance, call the telephone number

listed in the service section or contact your local distributor.

SERVICE

Contact Thermo EC for technical assistance if problems occur. The telephone

numbers are 631-244-2929, 1-800-EC-RANGE (toll free U.S.).

▲

▲

▲

▲

NOTE:

If this power supply experiences an electrostatic discharge

of ≥8000 volts an overcurrent message will be displayed and DC

output will shut down.

THERMO EC HIGH VOLTAGE POWER SUPPLIES THERMO EC HIGH VOLTAGE POWER SUPPLIES

C. Ground Leakage Detected: A continuous tone accompanied by the

illumination of the ground leakage light. The voltage and wattage displays

will hold their last value. The milliamps display will go blank. (See below

“Ground Leakage”)

D. Power On Restart: Nine short bursts in groups of three each with

each output display showing decimal points. This alarm activates to alert

the operator to the fact that auto-restart will occur at the end of a mains

power failure. The alarm will clear itself.

E. Overheating Detected: A continuous tone accompanied by flashing

displays. This alarm indicates the heatsink, located at the rear of the unit,

has exceeded safe operating temperatures. Momentarily turning off the

power supply will clear the alarm. (See Service)

F. Mains Overload: A continuous tone accompanied by flashing displays.

This alarm is indistinguishable from the “Overheating detected” alarm. It

indicates an internal fault or a temporary surge in the mains supply.

Momentarily turning off the power supply will clear the alarm. (See Service)

Unit Will Not Start: This power supply is equipped with a load sensing

interlock which is designed to inhibit the generation of high voltage whenever

an open connection is detected at the output.

Open Connection: An open connection is defined as a break in the path

in which electricity normally flows. This could be caused by any of the follow-

ing conditions:

1. A broken electrode within the electrophoretic chamber.

2. A broken wire within the connecting cord (either positive or negative).

3. Insufficient buffer levels within the electrophoretic chamber.

4. Loose connectors in any electrical connection going to or coming from the

power supply or chamber.

5. Electrochemical energy stored within the chamber. (See below, “Unit Will

Not Restart”)

Unit Will Not Restart: Certain types of electrophoretic techniques will,

over a period of time, store energy within the electrophoretic chamber. This

charge may inhibit the normal function of the load sensing interlock when

attempting to restart an experiment which has been temporarily interrupted.

To overcome this effect depress and hold the D.C.Output On key until the

power supply reaches its proper operating voltage. Upon releasing the D.C.

On key the power supply should remain engaged. If it will not remain

engaged refer to the section entitled “Unit Will Not Start”.

No Displays Light: This power supply is equipped with 2 circuit breakers

located at the rear of the instrument. If either circuit breaker is activated the

power supply will not turn on. When activated, the circuit breakers expose a

white stem.

12

6. Gently press the D.C. Output

On key (24). The Red D.C.

Output On light (23) should illu-

minate and the D.C. output as

indicated by the three displays

(3, 5, 7) should rapidly

increase until the operating volt-

age limit is reached. At this

point the Yellow At Limit light

(volts) (2) should be the only “at

limit” light illuminated.

On Off

DC Output

LIMITS

Electrophoretic chambers are generally designed for a relatively specific purpose.

For example, horizontal chambers use agarose gels to separate DNA or RNA frag-

ments while a DNA Sequencing chamber is almost always used to separate DNA

in a denaturing polyacrylamide gel. In each case, the voltage, milliamp and

wattage requirements are well–defined within a reasonable range of values. In

cases such as these, the user can safely assume that the manufacturer has designed

the chamber to withstand the voltage and heat energy necessary to perform the

electrophoretic separation when standard protocols are followed.

Some types of electrophoretic chambers are specifically designed to be multipur-

pose devices. For example, a vertical slab gel chamber could be used for anything

from DNA Sequencing to Isoelectric Focusing depending on the gel type and buffer

system used. Choosing safe operating limits for a chamber of this type requires a

24, 23,

3, 5,

7, 2

5

NOTE: The power supply output may be adjusted while operating. If you turn any

of the three adjustment knobs while the D.C. Output On light is illuminated, the

power supply will automatically switch to the Set Display Mode. Each display will

show the set operating limit while in this mode and new limits may be set. One sec-

ond after releasing the adjustment knob the power supply will revert to the Display

Actual Mode.

Operation in Constant Current: The method used to set the power supply

in constant current is the same as the method used for constant voltage. The only

difference involves the selection of an operating limit for current which, as the out-

put increases, is attained before the operating limits for voltage or watts.

Operation in Constant Watts: The method used to set the power supply in

constant watts is the same as the method used for constant voltage. The only dif-

ference involves the selection of an operating limit for watts which, as the output

increases, is attained before the operating limits for voltage or current.

THERMO EC HIGH VOLTAGE POWER SUPPLIES THERMO EC HIGH VOLTAGE POWER SUPPLIES

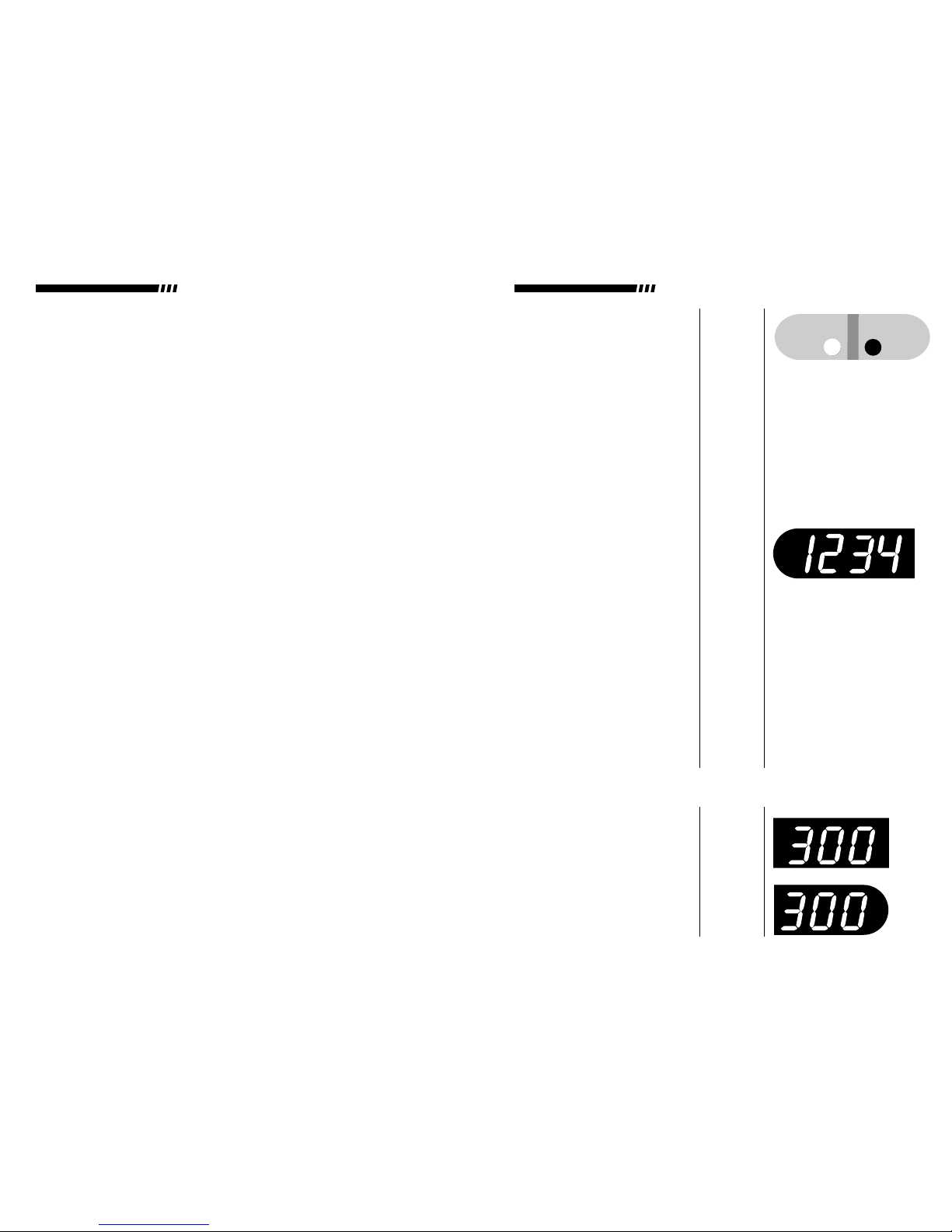

Alarm Tones and Displays:

A.Tone Pattern:

Display Pattern:

B. Tone Pattern:

Display Pattern:

C. Tone Pattern:

Display Pattern:

Ground Leakage:

D. Tone Pattern:

Display Pattern:

E. Tone Pattern:

Display Pattern:

F. Tone Pattern:

Display Pattern:

n o L o AD

oo o

GOES BLANK LAST VALUE

. . . . . .

FLASHINGFLASHING FLASHING

FLASHING FLASHING

LAST VALUE

. . . .

FLASHING

Ground

Leak

TROUBLESHOOTING GUIDE

Unit Alarms: This power supply is equipped with both audible and visual

alarms. Items A through F listed immediately below are graphical representa-

tions of each alarm mode. To understand which alarm has been activated and

why, match the letter (A-F) to the corresponding text below.

A. Open Connection: A continuous tone which is generated as soon as

the D.C. Output On key is depressed. The displays will spell noLoAD.

Depressing D.C. Output Off key will cancel the alarm mode. (For cause

see, “Unit will not start”.)

B. Timer At Zero: Nine short bursts in groups of three followed by the

D.C. Off light illuminating. The three output displays will indicate zero.

This indicates that the set time interval has expired.

11

higher degree of caution. Chamber manufacturers normally rate their product for

maximum voltage and/or maximum wattage. Whenever possible, contact the

manufacturer and request this information. It is the safest method of determining if a

chamber is suitable for a particular procedure.

Whether you use special purpose or multipurpose chambers, the maximum operat-

ing temperature the chambers will withstand is a critical aspect of safe operation.

Most electrophoretic chambers (with a few notable exceptions) are made of acrylic

plastic and must operate well below a temperature of 55 °C. If there is a lack of

information about the capabilities of the chamber being used, regular monitoring of

the operating temperature is recommended. This should be done without coming

into physical contact with the chamber when voltage is applied. Use the procedure

listed below to select operating parameters.

PROCEDURE:

(See fold out on last page)

1. The electrophoresis chamber

should first be set up, then

filled with buffer and sample,

before plugging the cham-

ber’s leads into the appropri-

ate positive and negative

4 mm sockets (14) on the

power supply.

2. Switch on the power supply

using the Power On/Off

switch (22). Once on, the

Green D.C. Output Off light

(21) and Yellow Actual

Display light (17) will be illumi-

nated. The Volts display (3),

Milliamps display (5) and

Watts display (7) will all indi-

cate zero. The Time display

(10) will indicate zero as well.

On Off

14

22, 21,

17, 3,

5, 7, 10 DC Output

NOTE: An alternative procedure favored by some users is as follows:

Sample is withheld from the chamber until the power supply has been properly

adjusted and successfully started. Once the user has confirmed that the chamber and

power supply are both functional the power supply is turned off and sample is

loaded. The power supply will remember its settings, so it can be turned on and start-

ed without further adjustment.

Set Actual

Display

6

THERMO EC HIGH VOLTAGE POWER SUPPLIES THERMO EC HIGH VOLTAGE POWER SUPPLIES

SETTING AND RESETTING THE TIMER (See fold out locator on last page)

Notes on Timer Operation: This power supply is equipped with a multi-

function timer. In the passive mode the timer accrues elapsed time whenever the

D.C. On light is illuminated. The elapsed time resets to zero whenever the D.C. Off

light is illuminated or the mains power is switched off. To function as a count–down

timer, a time interval must be set using the up/down arrow keys. Each arrow key

adjusts the timer in a single direction. For convenience, the time increments switch

from minutes to hours after continuously depressing either key for several seconds.

Once set, the timer will count down whenever the D.C. On light is illuminated. The

Timer On light will illuminate whenever the count–down mode is activated. Upon

reaching zero time remaining, the power supply will sound an alarm and switch off

the output. After timer goes to zero it will reset itself to the original time. To disable

the count–down mode of operation the time interval must be reset to zero.

Setting:

1. Switch on the power supply using the Power On/Off switch (22). Once on, the

Green D.C. Output Off light (21) and the Yellow Actual Display light (17) will be

illuminated. The Volts display (3), Milliamps display (5), and Watts display (7) will

all indicate zero.

2. Gently depress the center of the Arrow Up key (13). When pressed there will be

a tactile sensation and the time shown on the Time display (10) will begin to

increase. Continue depressing the Arrow Up key until the Time display indicates

the desired time interval.

Note: For convenience, the incremental changes in time switch to hours after

continuously depressing either Arrow key for several seconds.

3. Confirm that all operating limits are correct, the power supply is properly connect-

ed to the electrophoretic chamber and gently depress the D.C. Output On key

(24). Once on, the Red D.C. Output On light (23) and the Yellow Timer On light

(11) will be illuminated and the timer will begin counting down.

Resetting:

1. Switch on the power supply using the Power On/Off switch (22). Once on, the

Green D.C. Output Off light (21) and the Yellow Actual Display light (17) will be

illuminated. The Volts display (3), Milliamps display (5), and Watts display (7) will

all indicate zero.

2. Gently depress the center of the Arrow Down key (12). When pressed there will

be a tactile sensation and the time shown on the Time display (10) will begin to

decrease. Continue depressing the Arrow Down key until the Time display indi-

cates zero time remaining.

3. Confirm that all operating limits are correct, the power supply is properly connect-

ed to the electrophoretic chamber and gently depress the D.C. Output On key

(24). Once on, the Red D.C. Output On light (23) will be illuminated and the

timer will begin accruing elapsed time.

10

Watts

3. Gently press the Set Display

key (19). The actual switch

itself is located in the gray

area located immediately

below the word “Set” in the

Set Display key. When

pressed there will be a tactile

sensation, the power supply

will beep and the Yellow Set

Display (18) light will be illumi-

nated. Each key on this

power supply has a similar

switch location and sensory

cue upon activation.

4. Using the Volts adjustment

knob (1), select the operating

voltage limit by turning the

knob until the desired value

appears on the Volts display

(3). Rotating the knob slowly

in the clockwise direction will

increase the displayed value

in one–volt increments. Rotat-

ing the knob slowly in the coun-

terclockwise (anticlockwise)

direction will reduce the dis-

played value in the same man-

ner. Rotating the same knob (1)

rapidly in either direction will

cause the displayed value to

change in ten–volt increments.

5. Using the Milliamps and Watts

adjustment knobs (6, 9), select

the maximum operating limits of

300 milliamps and 300 watts

respectively.

19, 18

1, 3

6, 9

Volts

NOTE: Each adjustment knob has a RAPID ADJUSTMENT MODE which is

activated whenever the knob is rotated rapidly.

7

▲

!

Set Actual

Display

Milliamps

THERMO EC HIGH VOLTAGE POWER SUPPLIES THERMO EC HIGH VOLTAGE POWER SUPPLIES

NOTE: Utilizing Automatic Crossover

Certain electrophoretic techniques require the careful adjustment of operating limits

to utilize a function of this power supply known as automatic crossover. Automatic

crossover is a method used when the experiment requires two or more modes of

operation during the course of the experiment.

The most common example of a technique which requires this function is semi-dry

electrophoretic transfers of proteins or nucleic acids. Semi-dry transfer chambers

consist of two closely spaced parallel plates which serve as electrodes. Positioned

between these plates is a sandwich consisting of buffer–saturated filter paper

sheets on the outside and the gel and charged membrane on the inside. Typically,

the transfer process is most efficiently accomplished by applying a constant current

flow between the two plates. As the transfer progresses, the buffer in the filter

paper begins to break down. This leads to an increase in overall resistance

between the two plates.Since the power supply is trying to maintain constant cur-

rent, it increases the voltage output to compensate for the increased resistance. Left

unchecked, the increasing voltage would eventually reach a potential great

enough to arc over between the plates, resulting in damage to the chamber and

experiment failure.

Automatic crossover can be used to prevent this unfortunate incident from

occurring. Set an operating limit for voltage at a value below the arc–over

threshold (for example, a limit that is 10% above the starting voltage). As the

voltage increases during the experment, it will eventually reach the operating

limit for voltage and “automatically crossover” to constant voltage operation.

At this point, the current will start to drop as the buffer breaks down, but the

experment and chamber will be unharmed.

9

6. Gently press the D.C. Output On

key (24). The Red D.C. Output

On light (23) should illuminate

and the D.C. output as indicated

by the three displays (3, 5, 7)

should rapidly increase until the

operating voltage limit is

reached. At this point the Yellow

At Limit light (volts) (2) should be

the only “at limit” light illuminat-

ed.

7. Once the power supply has

reached the operating voltage

limit, note the actual values

displayed for milliamps and

watts.

8. Add 10 watts and 15 milliamps

to the actual values noted

above.

9. Rotate the Milliamps Adjustment

Knob (6). The power supply will

automatically switch to the

Display Set Mode and the

Yellow Set Display light (18) will

be illuminated. Adjust the

Milliamps Adjustment Knob

downward until the new limit

value has been achieved.

Repeat this process with the

Watts Adjustment Knob (9) .

Once set to the new operating

limits, the power supply will auto-

matically return to the Actual

Display Mode and the Yellow

Actual Display light (17) will be

illuminated.

6, 18,

9, 17

24, 23,

3, 5,

7, 2

On Off

DC Output

Milliamps

Watts

8

NOTE: It may be necessary to readjust the watt or milliamp operating limit during

the course of the separation process to ensure that the entire procedure is performed

at a constant voltage. This readjustment, if necessary, is required to compensate for

large changes in resistance which occur during certain types of electrophoresis.

THERMO EC HIGH VOLTAGE POWER SUPPLIES THERMO EC HIGH VOLTAGE POWER SUPPLIES

This manual suits for next models

3

Table of contents