Badger II Power Supply Operator’s Manual

Badger II Power Supply

Power Factor Corrected AC-DC Switcher

Overview

The Badger II is a ruggedized, extremely low-profile AC-DC power supply that combines the advantages of

power factor correction, high power density, and user-selected isolated outputs. Accepting input voltages of 85

to 254 VAC, and 85 to 380 VDC, the Badger II can provide up to 1,800 watts in a package size of 2.55″H x

7.0″W x 13.75″L. The Badger II can provide up to 12 isolated outputs and is factory configured to meet user

requirements. Its inherent flexibility comes from its use of Vicor Maxi, Mini and Micro DC-DC converters.

Standard Features

Power Factor Correction: 0.99 at 115 VAC; 0.95 at 230 VAC

Universal Input: 85-254 VAC, 47-500 Hz, or 85-380 VDC

Power Output @ 45°C: up to 1,500 W at 220 VAC; 800 W at 110 VAC

Up to 12 isolated outputs

Fan cooled

Up to 1,800 W @ 35°C; 1,500 W @ 45C; 750 W @ 65C

Soft start for limiting inrush current

Conducted EMI Compliance: FCC Class B, EN 55022 B; MIL-STD-461E, CE101 & CE102

Transient Protection: MIL-STD-704E

-20, -40, or -55°C operating temperature

Active Power Factor Correction .95 min @ 120/230 Full Load

AC Power OK status signal

Output Sequencing and General Shutdown

Local Sense standard on all outputs. Remote Sense available with the removal of two jumpers

Output overcurrent protection on all outputs

Output overvoltage & overtemperature protection

Ride-through (holdup) time: 20 ms at 1,200 W

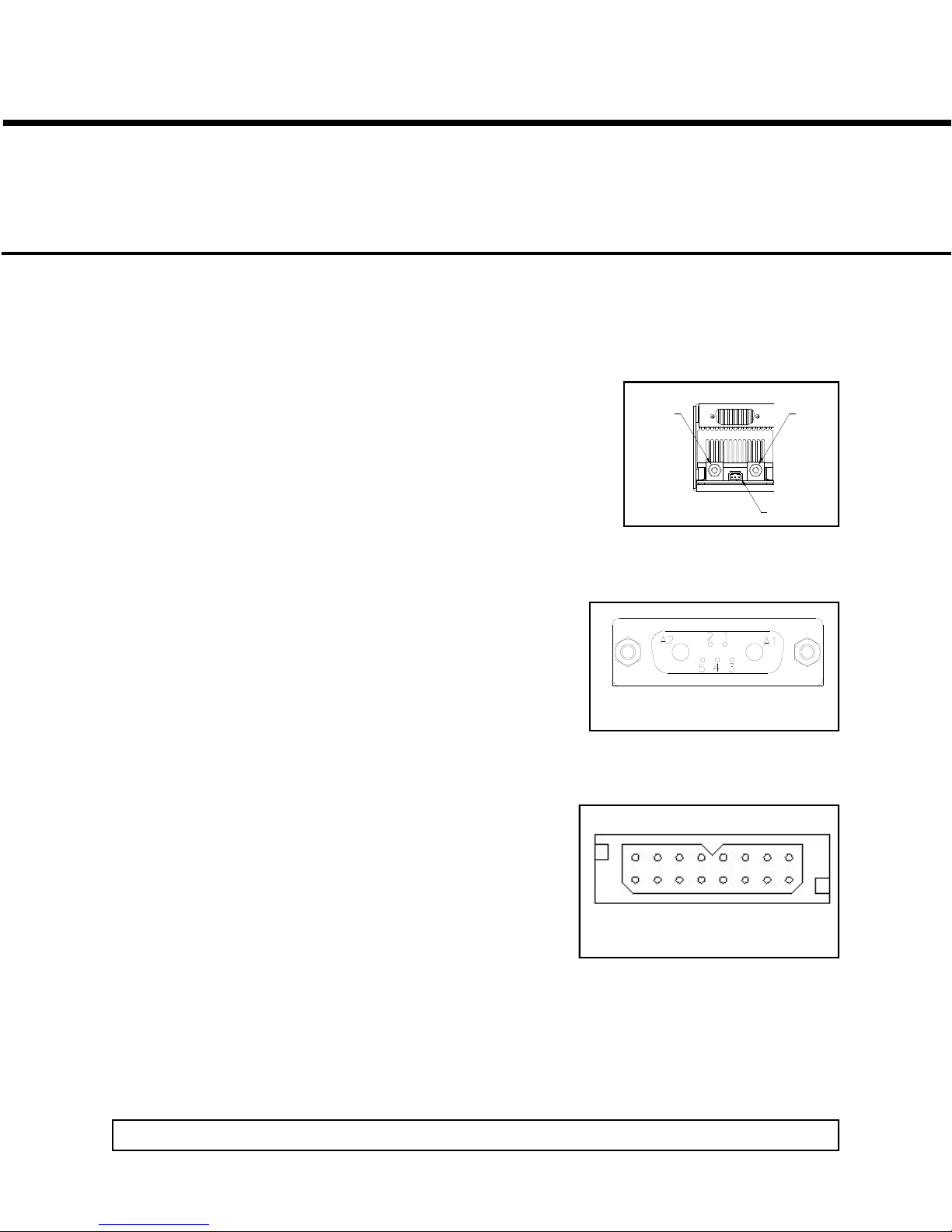

Size: 2.55″H x 7.0″W x 13.75″L

Heavy-duty rugged enclosure designed for a high shock and vibration environment

Extra cooling provided for higher output with increased altitude capability

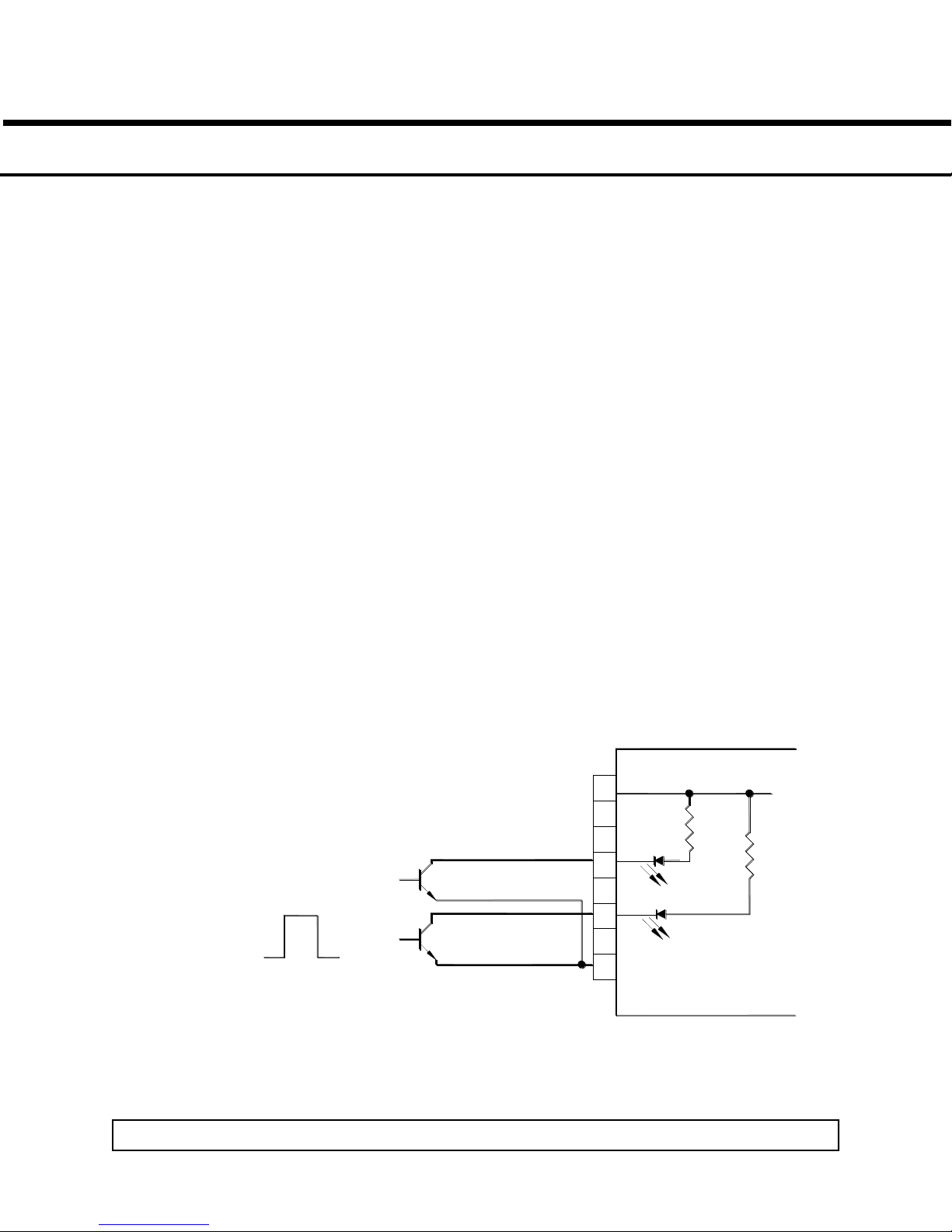

“D” shell connectors for input and output connections; bus bars provided for output currents greater than

40 Amps

Optional conformal coating

Technical Description

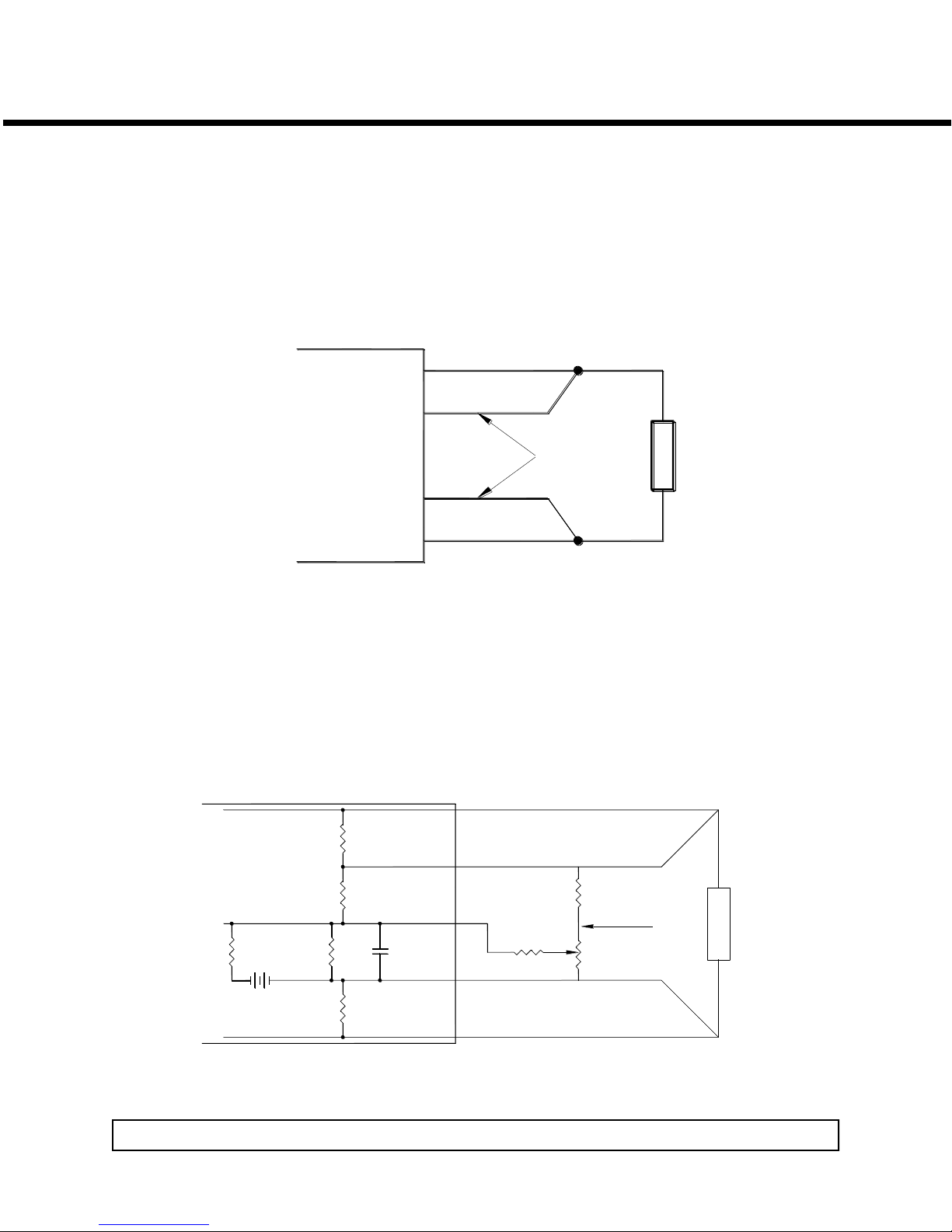

The Badger II consists of an off-line single phase, power-factor-corrected front end, EMI filter, cooling fan,

customer interface, associated housekeeping circuits, and a selection of Vicor’s DC-DC converters.

Input AC mains voltage is applied to a 3-pin power connector. The input current is passed through an EMI

filter to meet conducted noise limits.