Thermo King Precedent S-600 User manual

Operator’s Manual

Operator’s Manual

Ingersoll Rand’s Climate Solutions sector delivers energy-effi cient HVACR solutions for

customers globally. Its world class brands include Thermo King, the leader in transport

temperature control and Trane, a provider of energy effi cient heating, ventilating and

air conditioning systems, building and contracting services, parts support and advanced

controls for commercial buildings and homes.

Ingersoll Rand’s Climate Solutions sector delivers energy-effi cient HVACR solutions for

customers globally. Its world class brands include Thermo King, the leader in transport

temperature control and Trane, a provider of energy effi cient heating, ventilating and

air conditioning systems, building and contracting services, parts support and advanced

controls for commercial buildings and homes.

©2012 Ingersoll-Rand Company

Printed in U.S.A.

©2012 Ingersoll-Rand Company

Printed in U.S.A.

Precedent

S-600 and S-700

TK 55538-2-OP (Rev. 3, 01/2014)

Precedent

S-600 and S-700

TK 55538-2-OP (Rev. 3, 01/2014)

Copyright© 2012 Thermo King Corp., Minneapolis, MN, USA

Printed in USA

PrecedentTM

S-600 and S-700

TK 55538-2-OP (Rev. 3, 01/2014)

2

Disclaimer

This manual is published for informational purposes only. Thermo King Corporation makes no

representations or warranties, express or implied, with respect to the information, recommendations

and descriptions contained in this manual and such information, recommendations and descriptions

should not be regarded as all-inclusive or covering all contingencies. In the event you have any

questions or require further information, please contact your local Thermo King dealer.

The procedures described herein should only be undertaken by suitably qualified personnel. Failure to

implement these procedures correctly may cause damage to the Thermo King unit or other property or

personal injury.

Thermo King Corporation and its affiliates shall have no liability in contract or tort (including negligence

and/or strict liability) or otherwise, to any person or entity for any personal injury, property damage or

any other direct, indirect, special or consequential damage or liability whatsoever, arising out of or

resulting from any actions by any person that are contrary to this manual or any of the information,

recommendations or descriptions contained herein or the failure of any person to implement the

procedures described herein correctly or to follow caution and safety decals located on the Thermo

King unit.

1

Table Of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

EPA Emission Control System

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Thermo King Corporation Responsibilities . . . . . . 10

Owner Responsibilities . . . . . . . . . . . . . . . . . . . . . 11

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Safety Practices . . . . . . . . . . . . . . . . . . . . . . 13

Automatic Start/Stop Operation . . . . . . . . . . . . . . . . . 14

Electrical Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery Installation and Cable Routing . . . . . . . . . . . . 15

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Refrigerant Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

First Aid–Refrigerant . . . . . . . . . . . . . . . . . . . . . . . 16

First Aid–Refrigerant Oil . . . . . . . . . . . . . . . . . . . . 17

Safety Decals and Locations . . . . . . . . . . . . . . . . . . . 17

Condenser and Evaporator Fans . . . . . . . . . . . . . . . . .18

High Voltage Components . . . . . . . . . . . . . . . . . . . . . .18

Do Not Use Ether Starting Aids . . . . . . . . . . . . . . . . . .20

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Unit Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Features and Options . . . . . . . . . . . . . . . . . . . . . . . . .22

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

ELC (Extended Life Coolant) . . . . . . . . . . . . . . . . . . . .24

EMI 3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Thermo King X430 Reciprocating Compressor . . . . . .25

Electronic Throttling Valve . . . . . . . . . . . . . . . . . . . . . .25

SMART REEFERTM 4 (SR-4) Control System . . . . . . .26

Diesel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Electric Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

CYCLE-SENTRYTM Start-Stop Controls . . . . . . .27

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

OptiSetTM Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

FreshSetTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2

Opening the Front Doors . . . . . . . . . . . . . . . . . . . . . . . 30

Engine Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Unit Protection Devices . . . . . . . . . . . . . . . . . . . . . . . . 32

Remote Status Display (Optional) . . . . . . . . . . . . . . 37

Manual Pretrip Inspection

(Before Starting the Unit) . . . . . . . . . . . . . . . . . . . . . 41

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . 43

SMART REEFERTM 4 (SR-4) Controller Overview . . . 43

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Control Panel Display . . . . . . . . . . . . . . . . . . . . . . 44

Display Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Hard Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Typical soft key applications: . . . . . . . . . . . . . . . . . . . . 46

Turning Unit On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

If a Flash Drive is Connected: . . . . . . . . . . . . . . . . 48

Display Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

If a Language is Enabled . . . . . . . . . . . . . . . . . . . 50

If Log Alarms are Present . . . . . . . . . . . . . . . . . . . 52

Turning The Unit Off . . . . . . . . . . . . . . . . . . . . . . . . . . 53

The Standard Display . . . . . . . . . . . . . . . . . . . . . . . . . 54

The TemperatureWatch Display . . . . . . . . . . . . . . . . . 55

Changing The Setpoint . . . . . . . . . . . . . . . . . . . . . . . . 56

Numerical Setpoints . . . . . . . . . . . . . . . . . . . . . . . 56

Named Products - OptiSet Plus . . . . . . . . . . . . . . 56

Both Numerical Setpoints and Named Products . 57

Changing the Setpoint - Numerical Setpoint . . . . 57

Changing the Setpoint - Named Product . . . . . . . 60

Changing the Setpoint - Both Numerical Setpoint and

Named Product Available . . . . . . . . . . . . . . . . . . 64

Starting the Diesel Engine . . . . . . . . . . . . . . . . . . . . . 66

Starting the Electric Motor . . . . . . . . . . . . . . . . . . . . . 67

Switching from Diesel to Electric . . . . . . . . . . . . . . . . 68

Switching from Electric to Diesel . . . . . . . . . . . . . . . . 69

Initiating a Manual Defrost Cycle . . . . . . . . . . . . . . . . 70

Terminating a Defrost Cycle . . . . . . . . . . . . . . . . 72

Selecting Cycle Sentry or Continuous Mode . . . . . . . 73

Using the Gauges Key . . . . . . . . . . . . . . . . . . . . . 76

Gauges Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Using The Sensors Key . . . . . . . . . . . . . . . . . . . . . . . 78

Sensors Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Using the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . 80

Main Menu Choices . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Pretrip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Pretrip Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . 82

Conditions where Pretrip Tests are not allowed . . . . . 82

3

Pretrip Test Sequence . . . . . . . . . . . . . . . . . . . . . . . . 82

Pretrip Test Considerations . . . . . . . . . . . . . . . . . . . . 83

Performing a Pretrip Test . . . . . . . . . . . . . . . . . . . 83

Flash Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Flashload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

OptiSet Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Flash Drive Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Selecting the Flash Drive Menu from the

Main Menu (If Already Connected) . . . . . . . . . . . . . . . 88

Flash Drive (If Connected While the Unit is

Turned On) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Removing the Flash Drive . . . . . . . . . . . . . . . . . . . . . . 89

Languages (If Enabled) . . . . . . . . . . . . . . . . . . . . 90

Available Languages . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Language Menu Quick Access . . . . . . . . . . . . . . . . . . 93

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Log Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Check Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Shutdown Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Pretrip Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Alarm Codes When Switching Between

Diesel and Electric . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Clearing Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . 96

Displaying and Clearing Alarm Codes . . . . . . . . . . . . .97

Important Alarm Notes . . . . . . . . . . . . . . . . . . . . . . . . .99

Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Displaying Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Displaying Sensors . . . . . . . . . . . . . . . . . . . . . . . . . .102

Data Logger (CargoWatch) . . . . . . . . . . . . . . . . .103

Sending Start of Trip Marker to CargoWatch and Service-

Watch Data Loggers . . . . . . . . . . . . . . . . . . . . . . . . .104

Printing CargoWatch Data Logger Reports . . . . . . . .105

Hourmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Viewing Hourmeters . . . . . . . . . . . . . . . . . . . . . . . . . .107

Hourmeter Names and Definitions . . . . . . . . . . . . . . .108

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Using the Change Mode Menu . . . . . . . . . . . . . . . . .110

Turn Cycle Sentry On or Off . . . . . . . . . . . . . . . . . . .111

Select Temperature Units . . . . . . . . . . . . . . . . . . . . .112

Fresh Air Exchange Open or Closed . . . . . . . . . . . . .113

Keypad Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Start Sleep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

SmartPower Electric Standby Option . . . . . . . . .116

Electric Mode Operation . . . . . . . . . . . . . . . . . . . . . .116

Diesel Mode Operation . . . . . . . . . . . . . . . . . . . . . . .116

Switching from Diesel to Electric . . . . . . . . . . . . . . . .117

4

Electric Standby Power Fails or is Disconnected . . . 118

Switching from Electric to Diesel . . . . . . . . . . . . . . . . 118

Adjust Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Clear All ECU Faults . . . . . . . . . . . . . . . . . . . . . .122

Optional Rear Remote Control Panel . . . . . . . . . . 125

Rear Remote Control Panel Functionality . . . . . . . . . 125

Rear Remote Control Action set to Run . . . . . . . 125

Rear Remote Control Action Set to Stand By . . . 126

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Reading a Typical Remote Standard Display . . . . . . 130

Remote Control Panel Lockout . . . . . . . . . . . . . . . . . 130

Turning the Unit ON or OFF (Configured for

STAND BY Operation) . . . . . . . . . . . . . . . . . . . . . . . . 131

Turning the Unit On and Off (Configured for RUN

Operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Changing the Setpoint . . . . . . . . . . . . . . . . . . . . . . . . 132

Selecting Cycle-Sentry or Continuous Mode . . . . . . . 133

Displaying the Discharge Air Temperature . . . . . . . . 134

Viewing and Clearing Alarm Codes . . . . . . . . . . . . . . 135

Starting a Manual Defrost Cycle . . . . . . . . . . . . . . . .136

Sending a Start of Trip Marker . . . . . . . . . . . . . . . . . 137

Running a Pretrip Test . . . . . . . . . . . . . . . . . . . . . . . 138

Loading and Enroute Inspections . . . . . . . . . . . . 141

Pre-Loading Inspection . . . . . . . . . . . . . . . . . . . . . . 141

Post-Loading Inspection . . . . . . . . . . . . . . . . . . . . . . 143

Enroute Inspections . . . . . . . . . . . . . . . . . . . . . . 144

Inspection Procedure . . . . . . . . . . . . . . . . . . . . . . . . 144

Inspection Troubleshooting . . . . . . . . . . . . . . . . . . . 144

Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Pretrip Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . 149

Clearing Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . 150

Jump Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . 185

Electrical Control System . . . . . . . . . . . . . . . . . . . . . 186

Electrical Components . . . . . . . . . . . . . . . . . . . . . . . 187

Electrical Standby (Smart Power Units Only) . . . . . . 191

5

Electric Motor and Overload Relay . . . . . . . . . . . 191

Electric Heater Strips . . . . . . . . . . . . . . . . . . . . . 191

Standby Power Cord Requirements . . . . . . . . . . 192

Electric Fuel Heater (Optional) . . . . . . . . . . . . . . . . . 192

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Maintenance Inspection Schedule . . . . . . . . . . . . 201

Serial Number Locations . . . . . . . . . . . . . . . . . . . . 207

Emergency Cold Line . . . . . . . . . . . . . . . . . . . . . . . 211

Recover Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . 212

CALIFORNIA Proposition 65 Warning . . . . . . . . . . 213

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

6

7

Introduction

There is nothing complicated about operating and maintaining

your Thermo King unit, but a few minutes studying this

manual will be time well spent.

Performing pre-trip checks and enroute inspections on a

regular basis will minimize on-the-road operating problems. A

regular maintenance program will also help to keep your unit

in top operating condition. If factory recommended procedures

are followed, you will find that you have purchased the most

efficient and dependable temperature control system available.

All service requirements, major and minor, should be handled

by a Thermo King dealer for four very important reasons:

• They are equipped with the factory recommended tools to

perform all service functions

• They have factory trained and certified technicians

• They have genuine Thermo King replacement parts

• The warranty on your new unit is valid only when the

repair and replacement of component parts is performed

by an authorized Thermo King dealer.

IMPORTANT: This manual is published for informational

purposes only and the information furnished herein should

not be considered as all-inclusive or meant to cover all

contingencies. If more information is required, consult your

Thermo King Service Directory for the location and

telephone number of the local dealer.

Introduction

8

9

EPA Emission Control System Warranty

Statement

Thermo King warrants to the initial owner and each subsequent

owner that the certified, non-road diesel engine in your unit is:

1. Designed, built and equipped so as to conform, at the time

of sale, with all applicable regulations adopted by the

United States Environmental Protection Agency (EPA).

2. Free from defects in materials and workmanship in

specific emission related parts for a period of five years or

3,000 hours of operation, whichever comes first, after date

of delivery to the initial owner.

If an emission-related part or component fails during the

warranty period, it will be repaired or replaced. Any such part

or component repaired or replaced under warranty is warranted

for the warranty period.

During the term of this warranty, Thermo King will provide,

through a Thermo King authorized service dealer or other

establishment authorized by Thermo King, repair or

replacement of any warranted part at no charge to the non-road

engine owner.

In emergency, repairs may be performed at any service

establishment, or by the owner, using any replacement part.

Thermo King will reimburse the owner for their expenses,

including diagnostic charges for such emergency repair. These

expenses shall not exceed Thermo King’s suggested retail price

for all warranted parts replaced, and labor changes based on

Thermo King’s recommended time allowance for the warranty

repair and the geographically appropriate hourly labor rate.

EPA Emission Control System Warranty Statement

10

Any replacement part can be used for maintenance or repairs.

The owner should ensure that such parts are equivalent in

design and durability to genuine Thermo King parts. However,

Thermo King is not liable for parts that are not genuine

Thermo King parts.

A part not being available within 30 days or repair not being

completed within 30 days constitutes an emergency.

As a condition of reimbursement, replaced parts and received

invoices must be presented at a place of business of a Thermo

King authorized service dealer or other establishment

authorized by Thermo King.

This warranty covers the following emission-related parts and

components:

• Fuel Injection System

• Intake Manifold

• Exhaust Manifold

• Miscellaneous hoses, clamps, connectors and sealing

devices used in the above systems.

If failure of one of these parts or components results in failure

of another part or component, both will be covered by this

warranty.

Responsibilities

This warranty is subject to the following:

Thermo King Corporation

Responsibilities

During the emission warranty period, if a defect in material or

workmanship of a warranted part or component is found,

Thermo King will provide:

• New, remanufactured, or repaired parts or components

required to correct the defect.

NOTE: Items replaced under this warranty become the

property of Thermo King.

• Labor, during normal working hours, required to make the

warranty repair. This includes diagnosis and labor to

remove and install the engine, if necessary.

EPA Emission Control System Warranty Statement

11

Owner Responsibilities

During the emission warranty period, the owner is responsible

for:

• The performance of all required maintenance. A warranty

claim will not be denied because the scheduled

maintenance was not performed. However, if the lack of

required maintenance was the reason for the repair, then

the claim will be denied.

• Premium of overtime cost.

• Cost to investigate complaints that are not caused by

defects in Thermo King material or workmanship.

• Providing timely notice of a warrantable failure and

promptly making the product available for repair.

Limitations

Thermo King is not responsible for resultant damages to an

emission-related part or component resulting from:

• Any application or installation Thermo King deems

improper as explained in this Operator’s Manual, or any

other manuals provided for the unit.

• Attachments, accessory items, or parts not authorized for

use by Thermo King.

• Improper off-road engine maintenance, repair or abuse.

• Owner’s unreasonable delay in making the product

available after being notified of a potential product

problem.

This warranty is in addition to Thermo King’s standard

warranty applicable to the off-road engine product involved.

Remedies under this warranty are limited to the provision of

material and services as specified herein. Thermo King is not

responsible for incidental or consequential damages such as

downtime or loss of engine powered equipment.

EPA Emission Control System Warranty Statement

12

13

Safety Precautions

Thermo King recommends that servicing be done only by a

Thermo King dealer. However, you should be aware of several

safety practices. This chapter gives basic safety precautions for

working with Thermo King units and describes the safety

stickers on your unit that you should be familiar with.

General Safety Practices

DANGER: NEVER operate the unit with the

compressor discharge valve closed. Doing so could

cause the compressor to explode, causing death or

serious injury.

WARNING: Always wear goggles or safety glasses

when working with or around the refrigeration system

or battery. Refrigerant or battery acid can cause

permanent damage if it comes in contact with your

eyes.

WARNING: Keep hands and loose clothing clear of

fans and belts at all times when the unit is operating

or when opening or closing compressor service

valves.

WARNING: Exposed coil fins can cause painful

lacerations. Service work on the evaporator or

condenser coils should be done by a certified Thermo

King technician.

WARNING: Do not apply heat to a closed cooling

system. Before applying heat to a cooling system,

drain it. Then flush it with water and drain the water.

Antifreeze contains water and ethylene glycol. The

ethylene glycol is flammable and can ignite if the

antifreeze is heated enough to boil off the water.

Safety Precautions

14

Automatic Start/Stop Operation

This unit is capable of automatic operation and could start at

any time without warning.

Electrical Hazard

CAUTION: Use extreme caution when drilling holes

in the unit. Drilling into electrical wiring or

refrigerant lines could cause a fire. Do not drill into

structural components.

WARNING: The unit can start at any time without

warning. Press the OFF key on the control panel and

place the microprocessor On/Off switch in the Off

position before inspecting or servicing any part of the

unit.

DANGER: Dangerous three phase AC electric power

is present whenever the unit is operating in either

Diesel Mode or Electric Mode and whenever the unit

is connected to a source of external standby power.

Voltages of this magnitude can be lethal. Exercise

extreme caution when working on the unit.

Safety Precautions

15

Battery Installation and Cable

Routing

WARNING: Improperly installed battery could result

in a fire or explosion. A Thermo King approved

battery must be installed and properly secured to the

battery tray.

WARNING: Improperly installed battery cables could

result in fire or explosion. Battery cables must be

installed, routed and secured properly to prevent

them from rubbing, chaffing or making contact with

hot, sharp or rotating components

WARNING: Do not attach fuel lines or any

additional wiring harnesses to the battery cables as

this could cause an electrical fire.

CAUTION: Do not connect other manufacturer’s

equipment or accessories to the Thermo King unit.

This could result in severe damage to equipment and

void the warranty.

CAUTION: Set all unit electrical controls to the OFF

position before connecting battery cables to the

battery to prevent unit from starting unexpectedly and

causing personal injury.

CAUTION: Always wear protective clothing, gloves

and eye wear when handling and installing batteries.

Battery acid can cause serious burns when exposed to

eyes or skin. If battery acid contacts skin or clothing,

wash immediately with soap and water. If acid enters

your eye, immediately flood it with running cold

water for at least twenty minutes and get medical

attention immediately

CAUTION: Always cover battery terminals to prevent

them from making contact with metal components

during battery installation. Battery terminals

grounding against metal could cause the battery to

explode.

Safety Precautions

16

Refrigerant

Although fluorocarbon refrigerants are classified as safe, use

caution when working with refrigerants or in areas where they

are being used.

Refrigerant Oil

Observe the following precautions when working with or

around refrigerant oil:

First Aid

First Aid–Refrigerant

Eyes: For contact with liquid, immediately flush eyes with

large amounts of water. Get prompt medical attention.

Skin: Flush areas with large amounts of warm water. Do not

apply heat. Wrap burns with dry, sterile, bulky dressing to

protect from infection or injury. Get prompt medical attention.

DANGER: Fluorocarbon refrigerants can produce

toxic gases. In the presence of an open flame or

electrical short, these gases are severe respiratory

irritants CAPABLE OF CAUSING DEATH.

DANGER: Fluorocarbon refrigerants tend to

displace air and can cause oxygen depletion which

could result in DEATH BY SUFFOCATION. Provide

adequate ventilation in enclosed or confined areas.

WARNING: Fluorocarbon refrigerants evaporate

rapidly, freezing anything they contact if accidentally

released into the atmosphere from the liquid state.

WARNING: Always wear goggles or safety glasses to

protect eyes from refrigerant oil contact.

WARNING: Protect skin and clothing from

prolonged or repeated contact with refrigerant oil.

Rubber gloves are recommended.

WARNING: Wash thoroughly immediately after

handling refrigerant oil to prevent irritation.

Safety Precautions

17

Inhalation: Move victim to fresh air and restore breathing if

necessary. Stay with victim until emergency personnel arrive.

First Aid–Refrigerant Oil

Eyes: Immediately flush eyes with large amounts of water for

at least 15 minutes while holding the eyelids open. Get prompt

medical attention.

Skin: Remove contaminated clothing. Wash thoroughly with

soap and water. Get medical attention if irritation persists.

Inhalation: Move victim to fresh air and restore breathing if

necessary. Stay with victim until emergency personnel arrive.

Ingestion: Do not induce vomiting. Immediately contact

local poison control center or physician.

Safety Decals and Locations

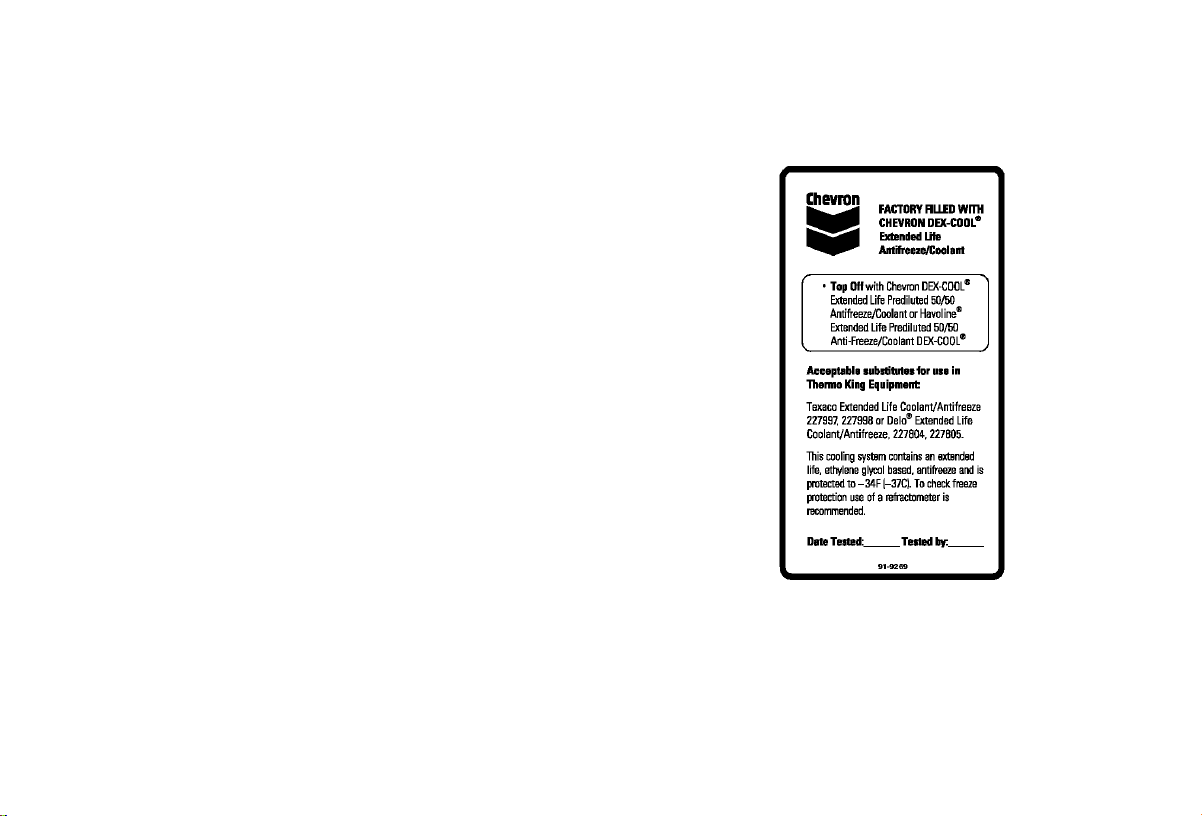

Figure 1: ELC (Extended Life Coolant) Nameplate

(On expansion tank)

AJA1947

Other manuals for Precedent S-600

1

This manual suits for next models

1

Table of contents