Thermo King X214 User manual

Distributed by:

Ingersoll Rand’s Climate Solutions sector delivers energy-effi cient HVACR solutions for

customers globally. Its world class brands include Thermo King, the leader in transport

temperature control and Trane, a provider of energy effi cient heating, ventilating and air

conditioning systems, building and contracting services, parts support and advanced controls

for commercial buildings and homes.

SB-210+

Additional text information

to be placed here

TK 5XXXX-X-PL

TK 6875-8-OM

©1998 Ingersoll Rand Company

Printed in U.S.A.

314 West 90th Street

Minneapolis, MN 55420

Direct (952) 887-2200

Thermo King Corporate

Distributed by:

SB-210+

Additional text information

to be placed here

TK 5XXXX-X-PL

314 West 90th Street

Minneapolis, MN 55420

Direct (952) 887-2200

Thermo King Corporate

SB-210+

Additional text information

to be placed here

TK 5XXXX-X-PL

Distributed by:

314 West 90th Street

Minneapolis, MN 55420

Direct (952) 887-2200

Thermo King Corporate

Distributed by:

X214, X418, X426 &

X430 Compressor

TK 6875-8-OM (Rev. 9, 02/14)

314 West 90th Street

Minneapolis, MN 55420

Direct (952) 887-2200

Thermo King Corporate

Overhaul ManualOverhaul Manual

Overhaul ManualOverhaul ManualOverhaul Manual

Overhaul Manual

X214, X418,

X426 & X430

Compressor

TK 6875-8-OM (Rev. 9, 02/14)

Copyright©1998 Thermo King Corp., Minneapolis, MN, U.S.A. Printed in

U.S.A.

Overhaul Manual

2

Revision History

Rev. 9 – TK 6875-8-OM (Rev. 9, 02/14) Update for Oil Collection Container, Pressurized Seal

Cavity, and Internal Oil Filter.

This manual is published for informational purposes only and the information so provided should

not be considered as all-inclusive or covering all contingencies. If further information is required,

Thermo King Corporation should be consulted.

Sale of product shown in this manual is subject to Thermo King’s terms and conditions

including, but not limited to, the Thermo King Limited Express Warranty. Such terms and

conditions are available upon request. Thermo King’s warranty will not apply to any

equipment which has been “so repaired or altered outside the manufacturer’s plants as,

in the manufacturer’s judgment, to effect its stability.”

No warranties, express or implied, including warranties of fitness for a particular

purpose or merchantability, or warranties arising from course of dealing or usage of

trade, are made regarding the information, recommendations, and descriptions

contained herein. Manufacturer is not responsible and will not be held liable in contract

or in tort (including negligence) for any special, indirect or consequential damages,

including injury or damage caused to vehicles, contents or persons, by reason of the

installation of any Thermo King product or its mechanical failure.

3

Recover Refrigerant

At Thermo King, we recognize the need to preserve the environment

and limit the potential harm to the ozone layer that can result from

allowing refrigerant to escape into the atmosphere.

We strictly adhere to a policy that promotes the recovery and limits

the loss of refrigerant into the atmosphere.

In addition, service personnel must be aware of Federal regulations

concerning the use of refrigerants and the certification of technicians.

For additional information on regulations and technician certification

programs, contact your local Thermo King dealer.

4

CHANGES, COMMENTS and SUGGESTIONS

You are invited to comment on this manual so it can be updated and improved to better meet you

needs. Any corrections, comments or suggestions are welcome. Please complete the following

information:

Manual Form Number _____________________________________________________

Section and Page # _______________________________________________________

Your Name ______________________________________________________________

Company Name __________________________________________________________

Phone Number ___________________________________________________________

Corrections, Comments and Suggestions _____________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Return to:

NORTH AMERICA

THERMO KING CORPORATION

314 West 90th Street

Mail Stop 38

Minneapolis, MN 55420

Attn: Service Department

EUROPEAN SERVED AREA

THERMO KING CORPORATION

Ingersoll Rand Climate Control Technologies

Monivea Road

Mervue, Galway, Ireland

Attn: Service Department

5

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Battery Installation and Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Battery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Refrigerant Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Refrigerant Oil Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electrical Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

First Aid, Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

First Aid, Refrigerant Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

First Aid, Engine Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

First Aid, Electrical Shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Compressor Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compressor Model Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Two Cylinder Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Four Cylinder Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Oil Collection Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

General Compressor Repair Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dirt and Moisture can Easily Ruin Compressors! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Compressor Oil Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Compressor Oil Color Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Disassembly Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reassembly Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fastener Torque Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cleaning Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Drive Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Discharge Valve Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Two-piece Compressor Seal Plate and Mounting Flange Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Seal Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installation of Spring Loaded Neoprene Bellows Type Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installation of Metal Bellows Seal With Set Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installation of Metal Bellows Seal With Drive Tangs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installation of Metal Bellows Seal With Hex Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Oil Sump and Oil Pickup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table of Contents

6

Internal Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Pre-Lubrication of Oil Pump Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Connecting Rod, Piston and Sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Compressor Crankshaft Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Removal and Installing Crankshaft Counterweights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Compressor Body Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Check Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Unloader Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Check Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Leak Testing, Storage, and Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Leak Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Compressor History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Compressor History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Released . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Two-piece Compressor Seal Plate and Mounting Flange Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Metal Bellows Crankshaft Seal with Set Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Polyol Ester (POE) Compressor Oil for HFC Refrigerants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Groove Top Pistons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Teflon Seal Type Drive End Ball Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

New Coupling Mounting Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Large Shaft Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Metal Bellows Crankshaft Seal with Drive Tangs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

8 Pin Coupling and Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Fins Eliminated from Crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Seven Quart Oil Sump on Four Cylinder Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Deep Oil Sump on Two Cylinder Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Increase Bronze Bearing Bore Diameter in Oil Pump Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Improve Heat Treating on Oil Pump Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

HPCO Switch with Straight Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

C5 Crankshaft Drive End Bearing and Cast Iron Oil Pump Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Oil Collection Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Check Valve in Oil Collection Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Pressurized Seal Cavity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Internal Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

7

Safety Precautions

Thermo King recommends that all service be

performed by a Thermo King dealer. However,

you should be aware of several general safety

practices:

The symbol appears next to a point that is

particularly important

General Practices

DANGER: Denotes the possibility of

serious injury or death.

WARNING: Denotes the possibility of

serious equipment damage or serious

personal injury.

CAUTION: Denotes the possibility of

minor to severe equipment damage or

personal injury.

DANGER: Do not operate the compressor

with the discharge service valve closed.

This condition increases internal pressure,

which can cause an explosion.

DANGER: Never apply heat to a sealed

refrigeration system or container. Heat

increases internal pressure, which might

cause an explosion.

DANGER: Refrigerant in the presence of

an open flame, spark or electrical short

produces toxic gases that are severe

respiratory irritants.

DANGER: Keep your hands, clothing and

tools clear of fans when working on a unit

that is running. Loose clothing might

entangle moving pulleys or belts, causing

serious injury or possible death.

DANGER: Do not inhale refrigerant. Use

caution when working with refrigerant or

a refrigeration system in any confined

area with a limited air supply, such as a

cargo area or garage. Refrigerant

displaces air and can cause oxygen

depletion, resulting in suffocation and

possible death.

DANGER: Avoid engine operation in

confined spaces and areas or

circumstances where fumes from the

engine could become trapped and cause

serious injury or death.

WARNING: Make sure your gauge

manifold hoses are in good condition

before using them. Never let them come in

contact with moving belts, fans, pulleys or

hot surfaces. Defective gauge equipment

can damage components or cause serious

injury.

WARNING: Always wear goggles or safety

glasses when working on a unit.

Refrigerant liquid, oil and battery acid can

permanently damage your eyes. See “First

Aid” on page 10.

WARNING: Use extreme caution when

drilling holes in a unit. Holes might

weaken structural components. Holes

drilled into electrical wiring can cause a

fire or explosion.

WARNING: Exposed coil fins can cause

lacerations. Service work on the

evaporator or condenser coils is best left to

a certified Thermo King technician.

WARNING: Do not apply heat to a closed

cooling system. Before applying heat to a

cooling system, drain it. Then flush it with

water and drain the water. Antifreeze

contains water and ethylene glycol. The

ethylene glycol is flammable and can

ignite if the antifreeze is heated enough to

boil off the water.

WARNING: Be careful when using

ladders or scaffolding to install or service

a unit. Observe the manufacture’s safety

labels and warnings.

CAUTION: Make sure all mounting bolts

are tight and are the correct length for

their applications. Improper torque and

incorrect bolt lengths can damage

equipment.

Safety Precautions

8

NOTE: In the USA, EPA Section 608

Certification is required to work on refrigeration

systems.

Battery Installation and Cable

Routing

Battery Removal

This order is important because the frame is

grounded to the negative battery terminal. If the

negative terminal is still connected, a complete

circuit exists from the positive terminal of the

battery to the frame. Metal objects contacting the

positive side and the frame simultaneously will

cause sparks or arcing. If there are sufficient

hydrogen gases emitted from the battery, an

explosion might occur, causing equipment

damage, serious injury, even death.

Refrigerant Hazards

WARNING: Improperly installed battery

could result in a fire or explosion! A

Thermo King approved battery must be

installed and properly secured to the

battery tray.

WARNING: Improperly installed battery

cables could result in fire or explosion!

Battery cables must be installed, routed

and secured properly to prevent them from

rubbing, chaffing or making contact with

hot, sharp or rotating components.

WARNING: Do not attach fuel lines or

any additional wiring harnesses to the

battery cables as this could cause an

electrical fire!

CAUTION: Do not connect other

manufacturer’s equipment or accessories

to the Thermo King unit. This could result

in severe damage to equipment and void

the warranty!

CAUTION: Set all unit electrical controls

to the OFF position before connecting

battery cables to the battery to prevent unit

from starting unexpectedly and causing

personal injury.

CAUTION: Always wear protective

clothing, gloves and eye wear when

handling and installing batteries. Battery

acid can cause serious burns when

exposed to eyes or skin. If battery acid

contacts skin or clothing, wash

immediately with soap and water. If acid

enters your eye, immediately flood it with

running cold water for at least twenty

minutes and get medical attention

immediately.

CAUTION: Always cover battery

terminals to prevent them from making

contact with metal components during

battery installation. Battery terminals

grounding against metal could cause the

battery to explode.

DANGER: Disconnect the negative

battery terminal (-) first when removing a

battery. Connect the positive terminal (+)

first when installing a battery.

DANGER: Do not use a Halide torch.

When a flame comes in contact with

refrigerant, toxic gases are produced.

These gases can cause suffocation, even

death.

DANGER: Store refrigerant in proper

containers, out of direct sunlight and away

from intense heat. Heat increases pressure

inside storage containers, which can cause

them to burst.

DANGER: Do not use oxygen (O2 ) or

compressed air for leak testing. Oxygen

mixed with refrigerant is combustible.

WARNING: Wear butyl lined gloves when

handling refrigerant to help prevent

frostbite.

Safety Precautions

9

Refrigerant Oil Hazards

Electrical Hazards

High Voltage

Low Voltage

CAUTION: Refrigerant in a liquid state

evaporates rapidly when exposed to the

atmosphere, freezing anything it contacts.

Be careful when handling refrigerant to

protect your skin from frostbite.

CAUTION: When being transferred,

refrigerant must be in liquid state to avoid

possible equipment damage.

CAUTION: When transferring

refrigerant, use a process that prevents or

greatly restricts refrigerant from escaping

into the atmosphere. Refrigerant damages

the earth’s upper ozone layer.

WARNING: Protect your eyes from

contact with refrigerant oil. The oil can

cause serious eye injuries. Avoid

prolonged or repeated contact with

refrigerant oil. To prevent irritation, wash

your hands and clothing thoroughly after

handling the oil.

CAUTION: Use the correct oil in Thermo

King systems to avoid damaging

equipment and invalidating its warranty.

CAUTION: Do not mix refrigerant oils

because that can cause system damage.

CAUTION: Use dedicated equipment to

prevent contaminating systems with the

wrong type of oil.

CAUTION: Store refrigerant oil in an

approved sealed container to avoid

moisture contamination.

CAUTION: Do not expose the refrigerant

oil to the air any longer than necessary.

The oil will absorb moisture, which results

in much longer evacuation times and

possible system contamination.

CAUTION: Wipe up spills immediately.

Refrigerant oil can damage paints and

rubber materials.

DANGER: Lethal amounts of voltage are

present in some electrical circuits. Use

extreme care when working on an

operating refrigeration unit.

WARNING: Do not make rapid moves

when working on high voltage circuits in

refrigeration units. Do not grab for falling

tools because you might accidentally touch

a high voltage source.

WARNING: Use tools with well insulated

handles. Never hold uninsulated metal

tools near exposed, energized conductors.

WARNING: Treat all wires and

connections as if they were high voltage

until a meter and wiring diagram indicate

otherwise.

WARNING: Never work alone on high

voltage circuits in the refrigeration unit.

Another person should be nearby to shut

off the unit and provide aid in the event of

an accident.

WARNING: Safety glasses, rubber-

insulated gloves and cable cutters should

be near your work area, in the event of an

electrical accident.

WARNING: Use caution when working

with electrical circuits that contain

capacitors. Some capacitors hold a

significant charge that might cause burns

or shocks if accidentally discharged. Make

sure capacitors are discharged before

working on electrical circuits.

WARNING: Control circuits used in

refrigeration units are low voltage (12 to

24 volts dc). This voltage is not dangerous,

but the large amount of amperage

available from the alternator can cause

severe burns if accidentally shorted to

ground with metal objects, such as tools.

Safety Precautions

10

First Aid

First Aid, Refrigerant

In the event of frostbite, protect the frozen area

from further injury, warm the area rapidly and

maintain respiration.

EYES : For contact with liquid, immediately flush

eyes with large amounts of water. CALL A

PHYSICIAN.

SKIN: Flush area with large amounts of warm

water. Do not apply heat. Remove contaminated

clothing and shoes. Wrap burns with dry, sterile,

bulky dressing to protect from infection. CALL A

PHYSICIAN. Wash contaminated clothing before

reuse.

INHALATION: Move victim to fresh air and use

CPR (cardio pulmonary resuscitation) or

mouth-to-mouth resuscitation to restore breathing,

if necessary. Stay with victim until emergency

personnel arrive.

First Aid, Refrigerant Oil

EYES : Immediately flush with water for at least

15 minutes. CALL A PHYSICIAN. Wash skin

with soap and water.

INGESTION: Do not induce vomiting.

Immediately contact local poison control center or

physician.

First Aid, Engine Coolant

EYES : Immediately flush with water for at least

15 minutes. CALL A PHYSICIAN. Wash skin

with soap and water.

INGESTION: Do not induce vomiting.

Immediately contact local poison control center or

physician.

First Aid, Electrical Shock

Take IMMEDIATE action after a person has

received an electrical shock. Get quick medical

assistance, if possible.

The source of the shock must be quickly stopped,

by either shutting off the power or removing the

victim. If the power cannot be shut off, the wire

should be cut with an non-conductive tool, such as

a wood-handle axe or thickly insulated cable

cutters. Rescuers should wear insulated gloves

and safety glasses, and avoid looking at wires

being cut. The ensuing flash can cause burns and

blindness.

If the victim must be removed from a live circuit,

pull the victim away with a non-conductive

material. Use wood, rope, a belt or coat to pull or

push the victim away from the current. DO NOT

TOUCH the victim. You will receive a shock from

current flowing through the victim’s body. After

separating the victim from power source,

immediately check for signs of a pulse and

respiration. If no pulse is present, start CPR

(cardio pulmonary resuscitation). If a pulse is

present, respiration might be restored by using

mouth-to-mouth resuscitation. Call for emergency

medical assistance.

WARNING: Do not wear jewelry, watches

or rings because they increase the risk of

shorting out electrical circuits and

damaging equipment or causing severe

burns.

11

Compressor Description

General Description

The most significant part of the refrigeration

system is the compressor. Its function is to pump

low pressure gas out of the evaporator so that a

rapid and continuous boiling action is maintained

in the evaporator coil. The low pressure gas is

compressed and forced into the condenser coil

where it is cooled by air passing through the coil.

The high pressure and reduced temperature causes

it to liquefy (condense).

The compressors covered by this manual are

reciprocating piston type pumps, constructed

mainly of cast aluminum. The aluminum alloy

pistons and cast iron sleeves are machined to close

tolerances to that no rings are needed to seal the

piston to the cylinder wall. The compressor is

equipped with a high nickel alloy ductile iron

crankshaft. To prevent leakage around the

crankshaft, the compressor is fitted with a rotary

type refrigeration seal.

Pressurized lubrication is provided to the

connecting rods and bearings by a gerotor oil

pump in the compressor body. The oil level in the

compressor can be inspected through the oil level

sight glass in the body. Since the refrigeration

system is sealed, it should be necessary to add oil

only if there has been a large refrigeration leak in

the system, or if a major item in the refrigeration

system, such as an evaporator coil or a condenser

coil has been replaced.

A spring loaded discharge valve and spring loaded

valve cage provide pressure relief if liquid

refrigerant enters the compressor. The entire cage

lifts and prevents breaking or deforming of the

valves.

When any repairs or replacements are to be made

on the compressor, it is very important that the

parts used are clean and not nicked or scratched.

During disassembly, parts should be cleaned and

inspected; and if they are to be used in

reassembly, they should be wrapped in a clean

cloth to prevent marring the surfaces. Oil all parts

with compressor oil during assembly, and be sure

they are installed in the same position they were

in before disassembly.

NOTE: When replacement parts are required,

we recommend using only Factory Approved

Thermo King Replacement Parts. Only Genuine

Thermo King Replacement Parts deliver the

reliability,productivity, quality, and performance

you’ve come to expect from Thermo King.

NOTE: Most of the overhaul procedures for the

compressors covered in this manual are the

same. Photographs of an X426 compressor are

used in this manual as examples. Other

illustrations are provided in cases where the

photograph is not applicable.

Compressor Model

Identification

There are a number of compressor models. The

following information is provided to help identify

the different compressor models. Refer to the

appropriate Parts Manual to order the correct

parts.

Two Cylinder Compressors

The one basic model of the two cylinder

compressor is the X214. There are some minor

variations such as fittings and oil sumps, but

otherwise all X214 compressors are basically the

same.

Four Cylinder Compressors

There are four major differences in the four

cylinder compressors:

• The crankshaft drive shaft diameter is either

1.0 in. (small shaft), or 1.187 in. (large shaft).

• The crankshaft drive end bearing is either a C3

bearing, or a C5 bearing.

• A pressurized seal cavity was phased into use

on large shaft compressors starting in the first

quarter of 2014.

• An internal oil filter were phased into use on

large and small shaft compressors in truck and

trailer units that typically use compressors

with an external oil filter starting in the first

quarter of 2014.

Compressor Description

12

These differences combine to make five basic

types.

• The small shaft compressor with a C3

crankshaft drive end bearing. This type

includes the X418, X426, and X430.

• The small shaft compressor with a C5

crankshaft drive end bearing. This type

includes the X418C5, X426C5, and X430C5.

NOTE: Some small shaft compressors with a

C5 crankshaft drive end bearing used in

truck units also have an internal oil filter.

• The large shaft compressor with a C3

crankshaft drive end bearing. This type

includes the X426LS, and X430LS.

• The large shaft compressor with a C5

crankshaft drive end bearing. This type

includes the X426LSC5, and X430LSC5.

• The large shaft compressor with a C5

crankshaft drive end bearing, a pressurized

seal cavity, and an internal oil filter. This type

also includes the X426P, and X430P.

The following table shows the four cylinder

compressor models according to the shaft size and

the crankshaft drive end bearing used.

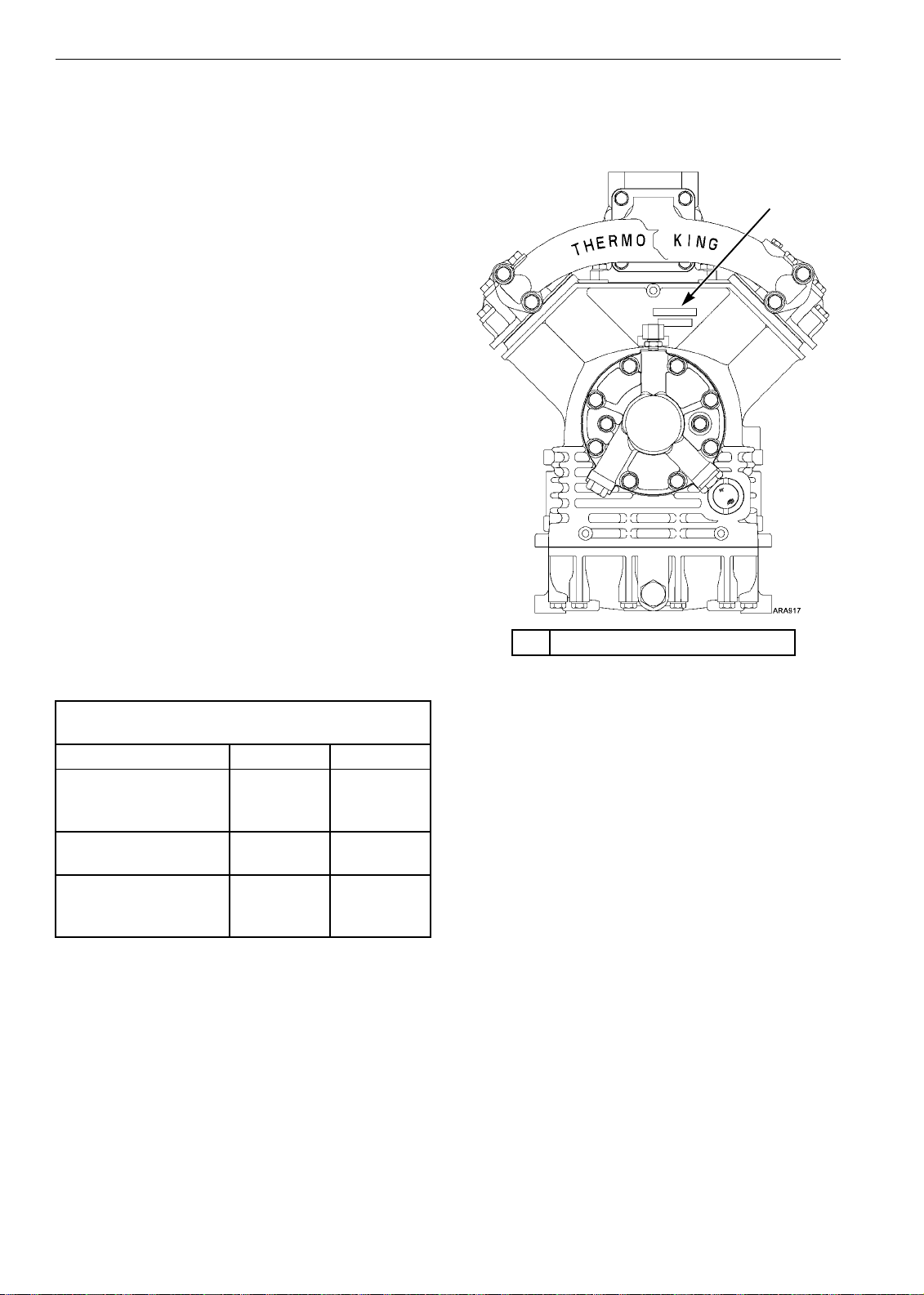

The compressor model is marked on the four

cylinder compressor body as shown below in

Figure 1.

Compressor Model by Shaft Size

and Bearing Type

C3 Bearing C5 Bearing

Small Shaft X418

X426

X430

X418C5

X426C5

X430C5

Large Shaft X426LS

X430LS X426LSC5

X430LSC5

Large Shaft with

Pressurized Seal

Cavity

X426P

X430P

1. Compressor Model Marked Here

Figure 1: Typical Compressor Model Location

1

Compressor Description

13

Compressors that have a C5 crankshaft drive end

bearing also have a cast iron oil pump housing,

which is painted black. Therefore, a compressor

with a C5 bearing can be identified by the black

oil pump housing as shown in Figure 2.

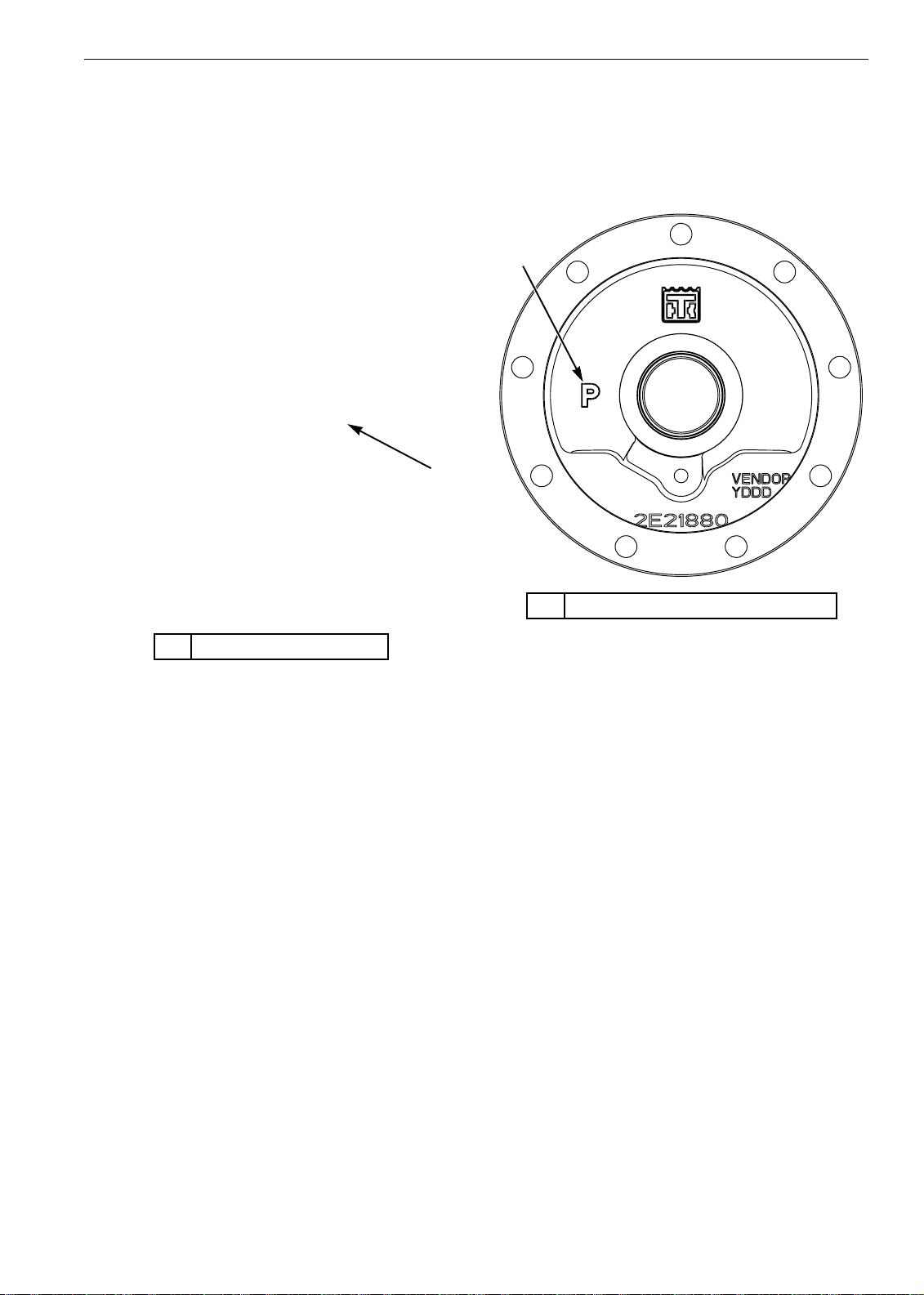

Compressors that have a pressurized seal cavity

have a “P” on the seal cover. Therefore, a

compressor with a pressurized seal cavity can be

identified by the “P” on the seal cover as shown in

Figure 3.

1. Black Oil Pump Housing

Figure 2: Compressor with C5 Bearing

1

1. “P” Indicates Pressurized Seal Cavity

Figure 3: Seal Cover for Compressor with

Pressurized Seal Cavity

ARA2163

1

Compressor Description

14

Oil Collection Container

The oil collection container was added to trailer

units starting in the first quarter of 2010. The oil

collection container collects the compressor shaft

seal seepage to keep the unit clean. This seepage

is normal and is necessary for shaft seal durability.

The oil collection container is mounted on the

body of the compressor. A tube connects the oil

collection container to the compressor shaft seal

cover. The oil that seeps from the seal will travel

through the tube and collect in the container.

Empty the container once per year during oil

changes, or during annual services. The container

has a drain spout with a cap. Remove cap and

drain the oil into a cup (not provided) and discard

the oil properly. Retighten the cap snugly by hand.

NOTE: The oil collection bottle is not used in

Europe.

The check valve was added in November 2012 to

improve the shaft seal reliability by ensuring oil

stays on the shaft seal when the suction pressure is

in a vacuum. It is made of silicone rubber, a

material that can be damaged easily. The check

valve is located on the end of the tube inside the

container. It is a very tight fit between the check

valve and the grommet in the oil collection

container.

NOTE: The check valve is no longer required on

Pressurized Seal Cavity Compressors.

If maintenance in the area requires removal of the

oil collection container or the tube, caution should

be observed to prevent damage to the check valve.

Although the check valve was glued to the tube at

production, pulling the check valve back through

the grommet may cause the Valve to fall off or be

damaged.

Several options are available:

1. If possible, disconnect the tube at the seal

cover drain barb and leave the tube in the oil

collection container.

2. The grommet can be pried off the bottle with

the tube still inserted, allowing the tube and

check valve to be easily removed from the

container.

1. Tube to Compressor Shaft Seal Cover

2. Compressor Mounting Flange

(Sectioned to Show Detail)

3. Oil Collection Container

4. Cap (Remove to Drain Oil)

Figure 4: Oil Collection Container Components

1

3

4

2

1. Seal Cover Drain Barb

2. Tube from Seal Cover to Oil Collection

Container

3. Grommet

4. Check Valve (Starting in November 2012)

5. Oil Collection Container

Figure 5: Oil Collection Container Showing Check

Valve

1

5

3

4

2

Compressor Description

15

3. If option 1 or 2 are not feasible and it is

necessary to pull the check valve back through

the grommet, gently twist as pulling back.

If the check valve does come off the tube, install a

new check valve from stock.

Compressor Description

16

Figure 6: Two Cylinder Compressor

ARC018

Compressor Description

17

1. Compressor Body 45. Oil Pump Shaft Key

2. Cylinder Head Gasket 46. Oil Pump Housing

3. Cylinder Head 47. Oil Pump Assembly

4. O-ring 48. Oil Pump Cover O-ring

5. Sealing Washer 49. O-ring

6. Bolt (3/8-16 x 2) 50. Oil Pump Cover Plate

7. Bolt (3/8-16 x 2-5/8) 51. Bolt (5/16-18 x 1-1/8)

8. Discharge Valve Assembly Bolt (3/8-16 x 2-1/4)

12. Stud 52. Flatwasher

20. Valve Plate O-ring 53. Oil Pressure Regulator Assembly

21. Cylinder Sleeve 54. Regulator O-ring

22. Adapter Gasket 55. Plug

23. Suction Port Screen 56. Plug O-ring

25. Piston Assembly 57. Oil Line Fitting or Valve

26. Piston Pin 58. Oil Sump

27. Piston Pin Retaining Ring 59. Oil Sump Gasket

31. Connecting Rod Assembly 60. Bolt

32. Connecting Rod Bolt 61. Bolt

33. Connecting Rod Nut 62. Copper Washer

34. Bearing Set (Standard) 63. Oil Sump Screen

Bearing Set (0.005) 64. Oil Pickup O-ring

Bearing Set (0.010) 65. Bolt

Bearing Set (0.020) 66. Lockwasher

Bearing Set (0.030) 67. Flatwasher

35. Pump Shaft O-ring 68. Check Valve Assembly

36. Crankshaft Pump End Bearing 69. Oil Fill Screw

37. Plug 70. Oil Fill O-ring

38. Dowel Pin 71. Crankshaft Seal

39. Crankshaft 72. Crankshaft Seal Plate

40. Metering Plug 73. Bolt

41. Key 74. Lip Seal

42. Crankshaft Drive End Bearing 75. Seal Plate O-ring

43. Housing Gasket 76. Sight Glass

44. Oil Pump Shaft 77. Sight Glass O-ring

Two Cylinder Compressor (for Figure 6)

Compressor Description

18

Figure 7: Early Style Four Cylinder Compressor

NOTE: The early style compressor had a spring loaded shaft seal,

and the seal plate and mounting flange were made in one piece.

ARC019

Compressor Description

19

1. Compressor Body 33. Check Valve Assembly

2. Connecting Rod Nut 34. Pump End Gasket

3. Connecting Rod Bolt 35. Oil Pump Housing

4. Connecting Rod Assembly 36. O-ring

5. Bearing Set (Standard) 37. O-ring

Bearing Set (0.005) 38. Oil Pump Cover Plug and Copper Washer

Bearing Set (0.010) 39. Oil Pump Cover

Bearing Set (0.020) 40. Oil Pump Cover Bolt and Washer

Bearing Set (0.030) 41. Oil Pump Cover Bolt and Washer

7. Piston Pin 42. Regulator O-ring

8. Piston Assembly 43. Oil Pressure Regulator

9. Retaining Ring 44. Regulator Spring

10. Key 45. Plunger

11. Crankshaft Drive End Bearing 46. Regulator Retaining Ring

12. Metering Plug 47. Oil Line Fitting or Valve

13. Crankshaft 48. Oil Pump Assembly

14. Crankshaft Oil Pump End Bearing 49. O-ring

15. Dowel Pin 50. Oil Pump Shaft

16. Suction O-ring and Screen 51. Oil Pump Drive Key

17. Copper Washer and Bolt 52. Seal Plate/Mounting Flange

18. Cylinder Sleeve 53. Screw and Washer

19. O-ring 54. O-ring

20. Discharge Valve Plate Assembly 55. Oil Sump Gasket

21. Sight Glass O-ring 56. Oil Sump

22. Sight Glass 57. Oil Sump Bolt and Washer

23. Cylinder Head Gasket 58. Check Valve Assembly

24. Cylinder Head 59. Check Valve Assembly

25. Cylinder Head Bolt and Flat Washer 60. O-ring

26. Cylinder Head Bolt and Flat Washer 61. Oil Suction Screen Assembly

27. Manifold Gasket 62. Mounting Screen Hardware

28. Manifold 63. Screen Bracket

29. Pipe Plug 64. Mounting Bracket Bolt and Washer

30. Manifold Mounting Bolt 65. Crankshaft Seal Assembly

31. Flatwasher 66. Seal Plate Gasket

32. Magnetic Plug and Copper Washer 67. Rotation Nameplate

Early Style Four Cylinder Compressor (for Figure 7)

Other manuals for X214

1

This manual suits for next models

3

Table of contents

Other Thermo King Air Compressor manuals

Popular Air Compressor manuals by other brands

Hanbell

Hanbell LBII-PLUS Technical manual

Plug-in Festivals

Plug-in Festivals IceCube 25 Operation manual

EINHELL

EINHELL TE-AC 6 Silent Original operating instructions

Emerson

Emerson Copeland 4MTL-05 Application guidelines

Prematic AG

Prematic AG AIRSTAR 45 Original instructions

Husky

Husky C202H Use and care guide