LBII-PLUS Technical Manual

1

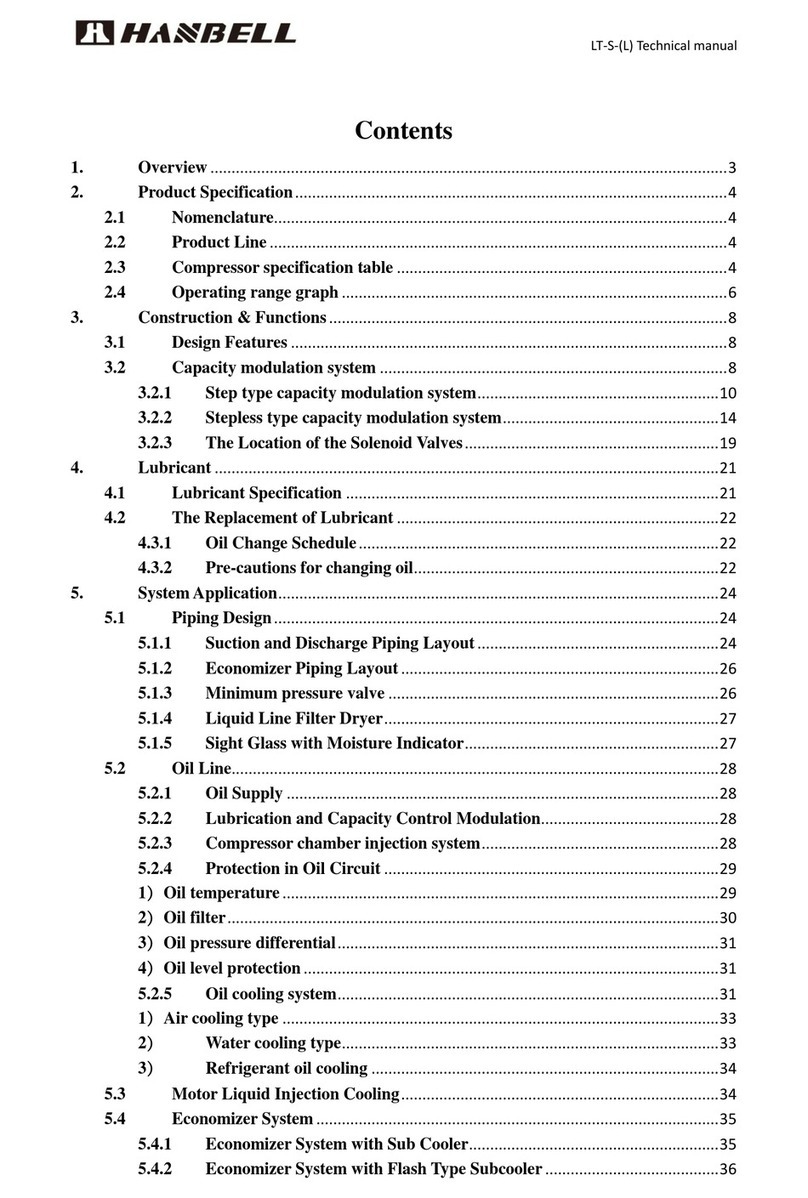

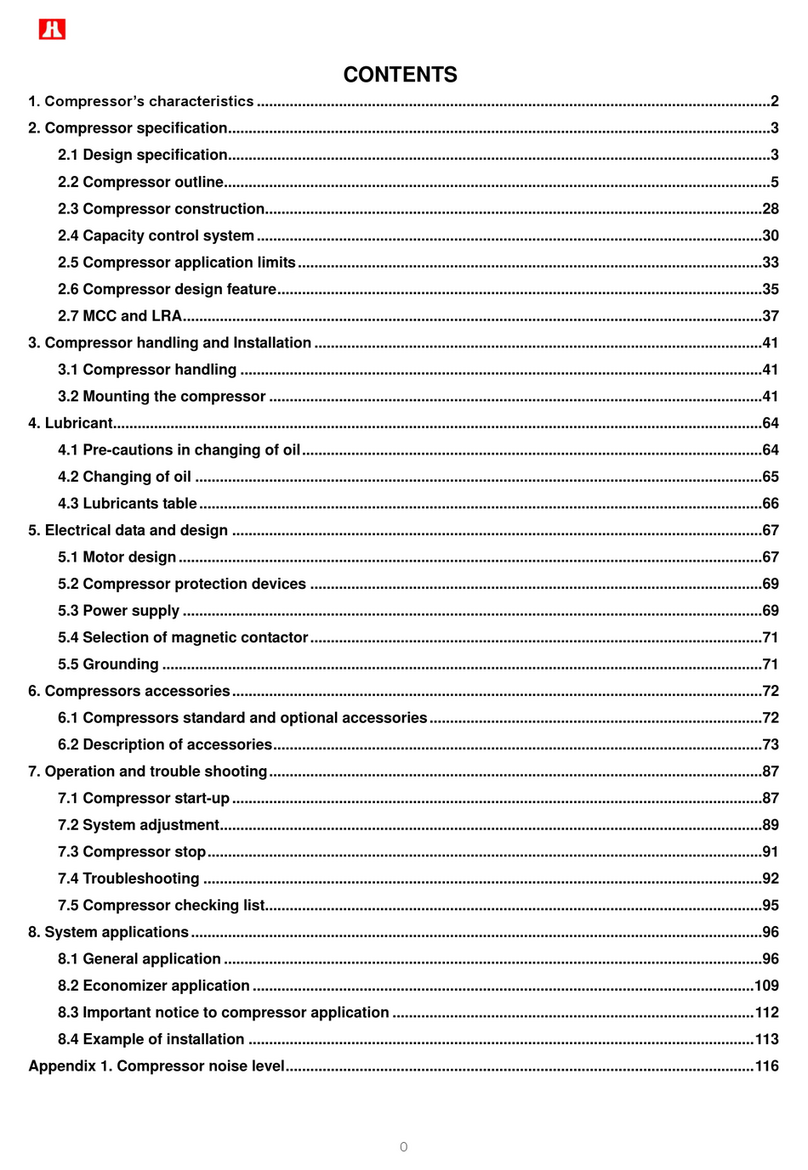

CONTENT

1. General ...................................................................................................................................................................... 3

1.1 Product Introduction...................................................................................................................................... 3

1.2 Nomenclature ................................................................................................................................................ 3

1.3 Product range................................................................................................................................................. 4

1.4 Design Specification ....................................................................................................................................... 4

1.5 Operation range ............................................................................................................................................. 5

1.6 Design Features.............................................................................................................................................. 6

2. Application................................................................................................................................................................. 7

2.1 Compressor application ................................................................................................................................. 7

2.2 Lubricant Application ..................................................................................................................................... 9

2.3 System application .......................................................................................................................................11

2.4 Motor control............................................................................................................................................... 21

2.5 Installation and fixation ............................................................................................................................... 24

3. Accessory................................................................................................................................................................. 26

3.1 Accessory list................................................................................................................................................ 26

3.2 Oil circuit parts............................................................................................................................................. 27

3.3 System parts................................................................................................................................................. 29

3.4 Electrical parts.............................................................................................................................................. 31

4. Maintenance............................................................................................................................................................38

4.1 Items to be checked before machine starting..............................................................................................38

4.2 Items to be checked during operation......................................................................................................... 38

4.3 Faults analysis ..............................................................................................................................................40

5. Appearance and functions.......................................................................................................................................42

5.1 Appearance structure ..................................................................................................................................42

5.2 LBII-100~410-PLUS Connector ................................................................................................................... 45

5.3 LBII-100~280-PLUS Dimension................................................................................................................... 46

5.4 LBII-100~280P-PLUS Dimension................................................................................................................. 47

5.5 LBII-360/410-PLUS Dimension ................................................................................................................... 48