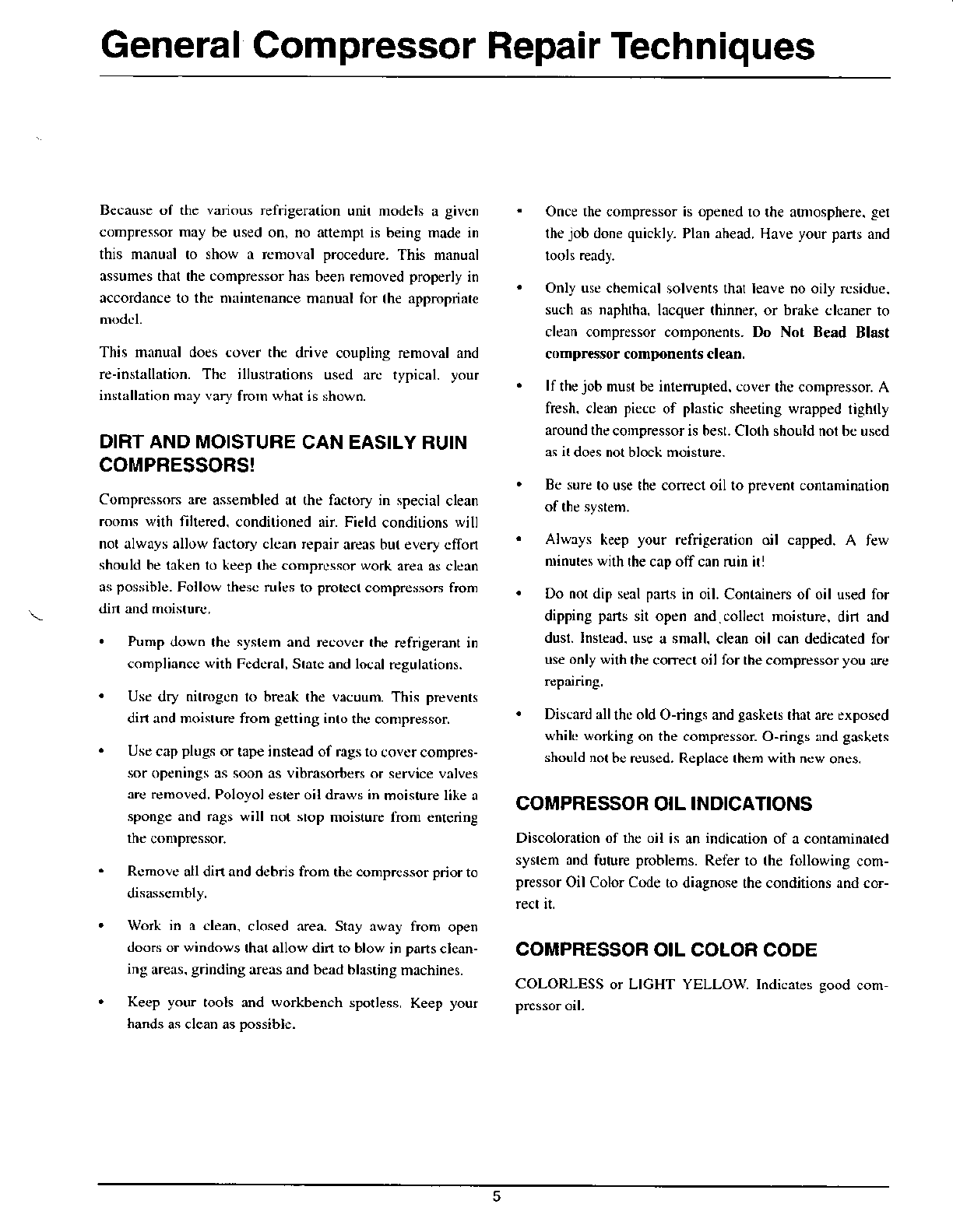

Disassembly

andReassembly

(Flev.

7. 12lO1)

manufncturedby Themo King,butlheyareall hcldon by a

single

bolt threadedinto theend of the conpressor

crank-

shafl.Oncethisboltisremoved,thecouplingor clutch can

beremovedfrom rhcshaft.Remove

thebolt andrhenusc a

puller

to rcmovcthccoupling

or clutch.

CAUTION: as. a puler to rcmovethe drit'e cou-

plins or pu cr fton the crunkhafL PuAer

(P/N2U-139) or pu et wuh handte(P/N 204-991)

ue availablc

tor useon conprcstu. couplinss wilh

threadcdholes.DO NOT usea hanncr to pound

thc couptins ot pu et oJJ.Thit s'i damase the

lnstallation

ThermoKingempbys

a hpcrcd

joint lo securerhe

drive

couplingor dnlc pulley

to thecompr€ssorshdr.Thishas

twodvantages:firstil pr€vcnts

anyloosencss

thatmight

occur

aswhen

usingi slidingfit on a shafi.

Thesecond

advantageis lhal whcn torqucdpmperlythe fricrion

berwccn

thctwotap€rscanbeusedrodrive

rhecompressor

A keyisuscdinthctapered

ioint

toguarmree

propcrposi-

tioning

of lhecouplertothecompressor,

andtotheengine

or driv€ pulley.

Usingr kcy can alsoprevent

slippagc

bctweentheiapersurfmesincase

ofextremeshockloads.If

thetrpersarerllowcd

toslip,

galling

ofthesurfaces

occurs.

Grllcdsurfaces

nalicdisassemblydifficult.

aodreassem-

blinggalledpanswillnotassure

prop€r

aligoment.

Keyways

arecut

with

atoolwhichleaves

aradiusattheend

oflhekeyw:ty.Ifrhekey

beinginstalledispushcd

onto

rhe

rdius atthe

end

ofthe

keyway.thetaperwill nolseatprop-

erlymd th€

coupling

will wobble.Thiscrusesstr€ss

robe

pul

onthecrankshaflandreducesitslife.Makesurekeys

areof lhe correctlengthto fit entirely

in theirrespective

keyway

prior

toinstallation.

The

following

procedure

shouldbcusedto installa com-

pressor

couplingonto

thecompressorshaft.

l. Cleanthe compressorshafl and raper

andthe rap€red

boreof lhe couplingwith a solvent

lhalleavesno oily

residue.suchasnaphtha,

lacquerthinner,bral€ clcaDer

or lhelike.

2- Inspectboth m ing surfaces

for burs. oxidarionmd

othersurtuceinrperfections.

Dresswirhcrocuscloth if

necessaryandreclean

asrequired.

NOTE: Do not sand o.lop .he tapcred a.ea as component

fftcturc nar nsull

L Using no lubricants.set thc couplingon the crank-

shaft and align the keywry using the Keywry Tool

(P,4.,1

:0,1-972)-lnscn the tapercdendof ihe lool inro

thekeywayandgently movethc coupling

on the shafi

whilc pressingth€ lool imo rhc keyway.This will

align thc keyway in the crankshaftwi(hthdkeywayin

Figurc 1: Ke!*at ToolP/N2M-972

CAUTION: If you arc assenbhns a used

coupleror crunkshalt and tho tool doesnol fi

eosily ,hen k a pnbln wilh one o[ the

kcli,als! Do not renmvethecoupb andpla.(

thekq in thecrunkshaltkerwarandthendrop

the couplcr on. If the tool doesnotfir, the kef

|'iA not lit, and it eil hoA the taper in thc

coupdngofl the bper on thesh4ft.Checkboth

keywrs for buns ot corrosion.A her can be

c.ntetl |'ilh Jine lappinstonaound anduseda!

a lapping tool to cleanthe keru)aJs.Cleanthe

ket and kelwar virh solyent bclon linat