Thermo NESLAB RTE Series Owner's manual

Installation

Operation

Basic Maintenance

Thermo Manual P/N U00694

Rev. 05/20/04

NESLAB RTE Series

Refrigerated

Bath/Circulators

No part of this publication may be repro-

duced or reprinted except for personal use

without the prior permission of Thermo

Electron.

Table of Contents

Preface

Compliance .............................................................................................................. 2

After-sale Support.................................................................................................... 2

Unpacking ................................................................................................................ 3

Feedback ................................................................................................................. 3

Warranty................................................................................................................... 3

N S-care xtended Warranty Contract ................................................................... 3

Section I Safety

Warnings .................................................................................................................. 4

Section II General Information

Quick Reference Operating Procedures ................................................................. 6

Description ............................................................................................................... 7

Specifications ........................................................................................................... 7

Section III Installation and Operation

Site ......................................................................................................................... 11

lectrical Requirements ......................................................................................... 12

Plumbing Requirements ........................................................................................ 14

Fluids ..................................................................................................................... 16

Filling Requirements .............................................................................................. 17

Controller (Digital One/Digital Plus) ...................................................................... 17

Start Up/Shut Down ................................................................................................ 19

Setup/Tuning Loop ................................................................................................ 21

Controller (Digital Plus) ......................................................................................... 22

Computer Setup Loop .......................................................................................... 24

Timer Setup Loop .................................................................................................. 25

Offset Setup Loop .................................................................................................. 26

Analog A I/O Port - Optional ................................................................................... 27

High Temperature Cutouts ..................................................................................... 28

Nitrogen Purge ....................................................................................................... 29

Accessories ............................................................................................................ 29

Section IV Basic Maintenance

Reservoir Fluid ...................................................................................................... 33

Reservoir Cleaning ................................................................................................ 33

Algae ...................................................................................................................... 33

Condenser Cleaning .............................................................................................. 33

Internal Temperature Sensor (rtd1) Calibration .................................................... 34

xternal Temperature Sensor (rtd2) Calibration ................................................... 35

Optional Analog Port/Calibration - Optional .......................................................... 36

Section V Troubleshooting

rror Codes ........................................................................................................... 37

xternal Sensor Connector ................................................................................... 38

Checklist................................................................................................................. 39

Service Assistance ................................................................................................. 40

PID Values .............................................................................................................. 40

BOM Decoder ........................................................................................................ 41

Displaying Software Version Number .................................................................... 41

Appendix A luids

Appendix B NC Serial Communications Protocol

Appendix C International Quick Reference Operating Procedures

WARRANTY

- 2 -

Preface

Compliance

UL Listed to UL3101-1 (UL61010A-1)

Certified to CSA C22.2 No. 1010.1

Complies with IEC EN 61010-1

Products tested and found to be in compliance with the requirements defined in

the EMC standards defined by 89 336 EEC as well as Low Voltage Directive

(LVD) 73 23 EEC can be identified by the CE label on the rear of the unit. The

testing has demonstrated compliance with the following directives:

LVD, 73 23 EEC EN 610010-1:1993

EMC, 89 336 EEC EN 61326-1:1998

For any additional information, refer to the Letter of Compliance that shipped

with the unit (Declaration of Conformity).

After-sale Support

Thermo Electron Corporation is committed to customer service both during and

after the sale. If you have questions concerning the unit operation, contact our

Sales Department. If your unit fails to operate properly, or if you have questions

concerning spare parts or Service Contracts, contact our Service Department.

Before calling, please obtain the following information:

- unit BOM number_________________________________

- unit serial number ________________________________

- unit software version ______________________________

- voltage of power source ____________________________

The units BOM number and serial number are printed on the name plate label

located on the rear of the unit. See page 41 for instructions on how to decode

your unit's BOM number. See page 41 for instructions on how to display the

software version.

S/N: 101039026

- 3 -

Unpacking

Retain all cartons and packing material until the unit is operated and found to

be in good condition. If the unit shows external or internal damage contact the

transportation company and file a damage claim. Under ICC regulations, this is

your responsibility.

Feedback

We appreciate any feedback you can give us on this manual. Please e-mail us

at [email protected]. Be sure to include the manual part number

and the revision date listed on the front cover.

Warranty

Units have a warranty against defective parts and workmanship for 24 months

from date of shipment. See back page for more details.

NES-care Extended

Warranty Contract

Extend parts and labor coverage for an additional year.

Worry-free operation.

Control service costs.

Eliminate the need to generate repair orders.

No unexpected repair costs.

Other contract options are available. Please contact Thermo for more

information.

- 4 -

Section I Safety

Warnings

Warnings are posted throughout the manual. These warnings are designated

by an exclamation mark inside an equilateral triangle and text highlighted in

bold. Read and follow these important instructions. Failure to observe these

instructions can result in permanent damage to the unit, significant property

damage, or personal injury or death.

The lightning flash with arrow symbol, within an equilateral triangle, is intended

to alert the user to the presence of non-insulated "dangerous voltage" within

the unit's enclosure. The voltage may be of significant magnitude to constitute

a risk of electrical shock.

This label, engraved into the front of the tank lip, indicates the presence of hot

surfaces.

Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, contact our Sales Department.

Performance of installation, operation, or maintenance procedures

other than those described in this manual may result in a hazardous

situation and may void the manufacturer's warranty.

Transport the unit with care. Sudden jolts or drops can damage the

refrigeration lines. The units weigh approximately RTE 7, 60 pounds (27

kilograms); RTE 10, 68 pounds (31 kilograms); RTE 17, 71 pounds (32

kilograms); RTE 740, 87 pounds (39 kilograms). Units should be trans-

ported with equipment designed to lift these weights.

Observe all warning labels.

Never remove warning labels.

Never operate damaged or leaking equipment.

Never operate the unit without bath fluid in the bath.

The user is responsible for the fluid used. Never use pure ethylene

glycol as a bath fluid, the flash point of 100% ethylene glycol is 111°C.

100% ethylene glycol may produce flammable vapors that can be

ignited by an open flame or an ignition source. When mixed with

water, ethylene glycol is not flammable. Also, at high temperatures

pure ethylene glycol may produce hazardous vapors.

Always turn off the unit and disconnect the line cord from the power

source before performing any service or maintenance procedures, or

before moving the unit.

Always empty the bath before moving the unit.

Never operate equipment with damaged line cords.

Refer service and repairs to a qualified technician.

- 5 -

Circuit Breaker(s).

Reservoir. See page 16.

Controller. See page 17.

Condenser Access Panel.

See page 33.

Section II General Information

Indicates refrigeration

system status. See

page 17.

Indicates t e controller is

displaying t e setpoint. Press

t e arrow buttons to c ange t e

value. See page 18.

Indicates t e controller is

displaying t e unit's low

temperature alarm setpoint.

Press t e arrow buttons to

c ange t e value. See page 18.

Indicates t e controller is displaying

t e high temperature alarm

setpoint. Press t e arrow buttons

to c ange t e value. See page 18.

Press to select t e serial

communication mode.

See page 22. Digital Plus

controller only.

Press to change t e

displayed value. See

page 17.

Press to start/stop t e

unit. See page 17.

Press to mute t e alarm. See page

22. Digital Plus controller only.

Press to sequence

t roug t e t ree indicators

and accept t e displayed

value. See page 17.

NOTE: None of t e t ree

setpoint indicators are

visible unless t is key is

pressed.

Indicates heater status.

See page 17.

Press to select external

sensor. See page 22. Digital

Plus controller only.

Press to select t e timer

function. See page 23

Digital Plus controller

only.

Press to select t e

temperature offset

mode. See page 23.

Digital Plus controller only.

1/8"OD Autorefill fluid

connection. See page 29.

1/4" MPT Pumping

Return Connection. See

page 14.

Optional External Sensor

Connector. Digital Plus

controller only.

1/*4" MPT Pumping

Supply Connection. See

page 14.

RS-232/RS-485

connections. See

Appendix B. Digital

Plus controller only.

Power connection.

See page 12.

Drain. See page 14.

Hig Temperature Cutout.

See page 28.

1/8"OD N2 Nitrogen

Purge. See page 29.

General Information

Autorefill connection.

See page 29.

Analog Output

Connector. Digital

Plus controller only.

See page 27.

- 6 -

Quick Reference perating Procedures

Operation

Before starting the unit, double-check all electrical

and plumbing connections. Make sure the bath is

properly filled with fluid.

To start the unit, press . To turn the unit off

press again.

The LED indicates the status of the heater. It

illuminates to indicate the heater is on.

The LED indicates the status of the refrigera-

tion system. It illuminates to indicate the refrigera-

tion system is removing heat from the cooling fluid.

Temperature Adjustment

To display the temperature setpoint, press on

the controller. The indicator will illuminate and

the display will flash the current setpoint value. To

adjust the temperature setpoint, press the arrow

buttons until the desired temperature setpoint is

indicated. Press again to confirm the change.

The display will rapidly flash the new value for a

short time and then return to the recirculating fluid

temperature.

Periodic Maintenance

Periodically inspect the reservoir fluid. If cleaning is

necessary, flush the reservoir with a cleaning fluid

compatible with your application.

The reservoir fluid should be replaced periodically.

Frequency depends on the operating environment

and amount of usage.

Before changing the reservoir fluid ensure it is

at a safe handling temperature.

Periodic vacuuming of the condenser fins is neces-

sary. The frequency of cleaning depends on the

operating environment. We recommend a monthly

visual inspection of the condenser after initial

installation. After several months, the cleaning

frequency will be established.

Installation

Locate the unit on a sturdy work area. Ambient

temperatures should be inside the range of +50°F to

+104°F (+10°C to +40°C). The maximum operating

relative humidity is 80%.

Never place the unit in a location where excessive

heat, moisture, or corrosive materials are present.

The unit has an air-cooled refrigeration system. Air

is drawn through the front panel and discharged

through the rear panel. The unit must be positioned

so the air intake and discharge are not impeded. A

minimum clearance of 12 inches (30 centimeters) at

the front and rear of the unit is necessary for

adequate ventilation. Inadequate ventilation will

reduce cooling capacity and, in extreme cases, can

cause compressor failure.

Excessively dusty areas should be avoided and a

periodic cleaning scheduleshould be instituted.

The unit will retain its full rated capacity in ambient

temperatures up to approximately +75°F (+24°C).

Make sure the voltage of the power source meets

the specified voltage, ±10%.

The pump connections are located at the rear of the

pump box and are labelled and . These

connections are angled upward so the recirculating

fluid will drain back into the reservoir when the

hoses are disconnected. Both connections are

capped with stainless steel serrated plugs.

The pump lines have ¼" MPT for mating with

standard plumbing fittings. For your convenience

stainless steel adapters, ¼" FPT to 38" O.D.

serrated fitting, are provided.

The bath work area has a high and low level marker

to guide filling. The markers are 1 inch horizontal

slits located in the center of the stainless steel

baffle separating the work area and the pump

assembly. The correct fluid level falls between

these two markers. The unit will not start if the fluid

level is below the lower slit.

General Information

- 7 -

Description

The NESLAB RTE Refrigerated Bath Circulators are designed to provide

temperature control for applications requiring a fluid work area or pumping to an

external system. Units consist of a non-CFC air-cooled refrigeration system,

circulation pump, seamless stainless steel bath, work area cover, and a micro-

processor temperature controller.

Specifications1

Temperature Range2

Temperature Stability3

Cooling Capacity4,

Pump Capacity4

RTE 7 RTE 10 RTE 17 RTE 740

-25°C to +150°C -22°C to +150°C -40°C to +200°C

±0.01°C

General Information

-40-30-20-10 0 10 20 30 40 5060 7080 90100

Temperature °C

1100

1000

900

800

700

600

500

400

300

200

100

Heat Removal (Watts)

A=115/60 RTE-740 units

B=230/50 RTE-740 units

C=RTE-7, 10, 17

A

B

C

P

r

e

s

s

u

r

e

Meters Feet

4.9 16

3.7 12

2.4 8

1.2 4

0.8 1.6 2.4 3.2 4.0 Gpm

3691215Lpm

Flow

- 8 -

Time to Temperature

115V/60 Hz units

230V/50 Hz units

RTE-740 units

General Information

- 9 -

RTE 7 RTE 10 RTE 17 RTE 740

658 x 7¼ x 6

16.8 x 18.3 x 15.2

8¾x 9 38 x 6

22.4 x 23.9 x 15.2

8¾ x 9 38 x 9

22.4 x 23.9 x 22.9

1.9

7.2

2.6

9.8

4.5

17.0

658 x 7¼ x 6

16.8 x 18.3 x 15.2

1.9

7.2

200170

60

27.2

68

30.8

71

32.2

87

39.5

R134a (6 ounces) R404a (8 ounces)

Heater (Watts)

115V/60 Hz Models

230V/50 Hz Models

100V/50-60Hz Models

Refrigerant

Bath Work Area5

(W x L x )

Inches

Centimeters

Bath Volume

Gallons

Liters

Air Flow Requirements

SCFM

Weight5

Pounds

Kilograms

General Information

1. Specifications subject to change.

2. Baths are tested at temperatures below freezing with denatured alcohol. This fluid is HIGH Y

flammable and is not recommended by Thermo. Above 80°C, baths are tested at with silicone

oil. This fluid is known to release a formaldehyde vapor (which is carcinogenic) above 150°C.

3. 20°C ambient. 20°C bath temperature using water. Sea level. Measured at the center of the

work area, work cover on, no external flow, stable ambient, full refrigeration (RTE-740 in

Energy Saving Mode). For some applications, agitation and stability above ambient may be

improved by connecting a small length of hose between the pump connections on the rear of

the unit.

4. 20°C ambient. 20°C bath temperature using water. Pump fully loaded. Sea level.

5. See next page for unit dimensions.

6. Add approximately 3 pounds (1.4 kilograms) for shipping weight.

800 1600 800

2000 2000 2000

800 1200 800

- 10 -

Unitl Dimensions (inches)

General Information

B

A

C

1½

E

D

F

30°

½

Rear View Side View

105° 17/8

7/8

1

3¼

15/8

Unit Dimensions

Dimension A

Dimension B

Dimension C

Dimension D

Dimension E

Crate Dimensions

(D x W x H)

RTE 7 RTE 10 RTE 17 RTE 740

23 5/8 23 5/8 26 5/8 26 5/8

9 1/4 11 3/8 11 3/8 11 3/8

19 20 1/8 20 1/8 20 1/8

17 3/8 17 3/8 20 3/8 20 3/8

10 5/8 10 5/8 10 5/8 12 3/8

26½ x 18 x 33½

- 11 -

Section III Installation and Operation

Site

Locate the unit on a sturdy work area. Ambient temperatures should be inside

the range of +50°F to +104°F (+10°C to +40°C). The maximum operating

relative humidity is 80%.

Never place the unit in a location where excessive heat, moisture, or

corrosive materials are present.

The unit has an air-cooled refrigeration system. Air is drawn through the

front panel and discharged through the rear panel. The unit must be

positioned so the air intake and discharge are not impeded. A minimum

clearance of 12 inches (30 centimeters) at the front and rear of the unit is

necessary for adequate ventilation. Inadequate ventilation will reduce

cooling capacity and, in extreme cases, can cause compressor failure.

Excessively dusty areas should be avoided and a periodic cleaning schedule

should be instituted (see Section IV, Condenser Cleaning).

Using 20°C water as a bath fluid, 115 60 units will retain their full rated capac-

ity in ambient temperatures up to +20°C. Reduce the cooling capacity approxi-

mately 15 watts for every 1°C above +20°C, to a maximum ambient tempera-

ture of +40°C. For 230 50 units, reduce the cooling capacity approximately 18

watts for every 1°C. Lower reductions in cooling capacity occur as the bath

fluid temperature increases.

Installation and Operation

- 12 -

Electrical

Requirements

The unit construction provides protection against the risk of electrical

shock by grounding appropriate metal parts. The protection may not

function unless the power cord is connected to a properly grounded

outlet. It is the user's responsibility to assure a proper ground connec-

tion is provided.

We recommend the use of a dedicated outlet.

Refer to the serial number label on the rear of the unit to identify the specific

electrical requirements of your unit. Ensure the voltage of the power source

meets the specified voltage, ±10%.

The RTE-7 is not designed to be used beyond the voltage range or have

momentary power interruptions. Install an un-interruptible power supply or a

line loss detection method.

All units are:

Pollution Category 2

Overcurrent Protection II

The following power options are available:

Unit Amps1Breaker Power Inlet

RTE 7 115 60 1 12 15A IEC 320-C-13

100 50-60 1 12 15A IEC 320-C-13

230 50 1 12 15A IEC 320-C-19

RTE 10 115 60 1 12 15A IEC 320-C-13

100 50-60 1 12 15A IEC 320-C-13

230 50 1 12 15A IEC 320-C-19

RTE 17 115 60 1 16 20A IEC 320-C-19

100 50-60 1 16 20A IEC 320-C-19

230 50 1 12 15A IEC 320-C-19

RTE 740 115 60 1 16 20A IEC 320-C-19

100 50-60 1 16 20A IEC 320-C-19

230 50 1 12 15A IEC 320-C-19

Installation and Operation

1. Average Amp draw.

- 13 -

1. Power cord length, if supplied, is 2 meters.

Unit Type1Amperage Plug Type

115 60 1 15 NEMA 5-15

115 60 1 20 NEMA 5-20

100 50-60 1 15 NEMA 5-15

100 50-60 1 20 NEMA 5-20

230 50 1 All Country Specific

Installation and Operation

Power Cord Set

230 Volt, 50 Hertz units do not come with a power cord set. To select the

proper power cord, follow these guidelines:

nThe cord set must consist of a plug, cable and receptacle.

nIf the unit is rated greater than 12 Amps, use a cord set rated for 20A.

nIf the unit is rated less than 12 Amps, use a cord set rated for 15A.

nThe cord set must be approved by local electrical authority or other

acceptable agency.

nEnsure the plug is compatible with your local outlets and receptacles.

- 14 -

Installation and Operation

Plumbing Requirements

Ensure the unit is off before connecting tubing to the unit.

To prevent damage to the plumbing lines, always support the fittings

while installing/removing the pumping caps and lines.

Hose Connections

The pump connections are located at the rear of the pump box and are labelled

(pump outlet) and (pump inlet). These connections are bent upward

so the recirculating fluid will drain back into the reservoir when the hoses are

disconnected. Both connections are capped with stainless steel serrated plugs.

The pump lines have ¼" MPT for mating with standard plumbing fittings. For

your convenience stainless steel adapters, ¼" FPT to 38" O.D. serrated fitting,

are provided. (To assure proper fit, they should be installed using 1½ turns of

Teflon® tape around the threads.)

Make sure all tubing connections are securely clamped. Avoid running

tubing near radiators, hot water pipes, etc. If substantial lengths of tubing

are necessary, insulation may be required to prevent loss of cooling capacity.

Tubing and insulation are available from Thermo. Contact our Sales Department

for more information (see Preface, After-sale Support).

It is important to keep the distance between the unit and the external system

as short as possible, and to use the largest diameter tubing practical. Tubing

should be straight and without bends. If diameter reductions must be made,

make them at the inlet and outlet of the external system, not at the unit.

If substantial lengths of cooling lines are required, they should be pre-filled with

bath fluid before connecting them to the unit. This will ensure that an adequate

amount of fluid will be in the bath once it is in operation.

Drain

Ensure the bath fluid is at a safe handling temperature before draining

the unit.

The unit is equipped with a drain located at the back of the unit labelled .

To drain the reservoir attach a hose to the barb and loosen the fitting.

The fitting has a stop to prevent it from coming off.

Pumping

The pump is designed to deliver a flow of 15 liters per minute (4 gallons per

minute) at 0 feet head. To prevent external circulation, the pump inlet and

outlet lines on the rear of the unit are capped. The caps must be removed when

external circulation is required.

To properly secure external hose connections to the unit, wrap Teflon® tape

around the pipe line threads before installation. Once the hose connections are

made, the hoses must be properly plumbed to an external system. It is

important the bath is not in operation until all plumbing is complete.

- 15 -

Circulating to an open container

A stainless steel leveling device is available to aid circulation to an open

vessel. Contact our Sales Department for more information (see Preface).

Support the leveling device over the open container with a ringstand. Stagger

the tubes in the leveling device so one tube is submerged in the vessel fluid,

and the other tube is level with the fluid surface. Connect the deeper tube to

the pump outlet and the shorter tube to the pump inlet.

Adjust the flow rate using the accessory flow control valve connected to the

pump outlet, or by partially restricting the outlet tubing. When properly

adjusted, the pump inlet will draw an occasional air bubble to prevent over

flow, and the pump outlet will force fluid through the submerged tube to

prevent aeration of the vessel.

To avoid siphoning the bath work area when the unit is shut off, lift the

leveling device out of the vessel and above the level of the unit.

Circulating through two closed-loops

The pump can be used to circulate through two closed-loop systems. Connect

the shortest practical length of flexible tubing from the pump outlet to the inlet

of external system #1. Connect the outlet of system #1 directly into the bath

work area. Connect tubing from the bath work area to the inlet of system #2.

Connect the outlet of system #2 to the pump inlet.

System #1

System #2

Bath

Work Area

Pump Box

Bath (Top View)

Bath (Rear View) Open Container

Outlet Inlet

evelling

Device

Installation and Operation

- 16 -

Installation and Operation

Fluids

The user is always responsible for the fluid used. Never use flammable

or corrosive fluids with this unit. The use of chlorine or sodium

hypochlorite in the baths will cause pitting that could leave to failure of

the refrigeration system.

Handling and disposal of liquids other than water should be done in

accordance with the fluid manufacturers specification and/or the MSDS

for the fluid used.

For fluid selection consider application requirements, operating temperature

range, material compatibility, safety concerns, and environmental issues.

Wetted materials of bath include; 316 and 304 Stainless steels, Ryton® (PPS),

Teflon®(PTFE) and Ethlyene-Propylene rubber (EPDM).

Deionized (up to 18 Meg-ohm cm) and distilled water are recommended to

control corrosion and algae bloom. See Water Quality Standards and Recom-

mendation in Appendix A.

Ethylene glycol, propylene glycol, silicone oil, and filtered water are acceptable

fluids.

NOTE Kinematic viscosity of the selected fluid should not exceed 50

centistokes at the lowest operating temperature.

Please call Thermo customer service to discuss high and low temperature fluid

selections. However, we will often refer you to chemical companies specializ-

ing in heat transfer fluids.

Filling

Requirements

Ensure the drain on the back of the unit is closed before filling the unit.

The bath work area has a high and low level marker to guide filling. The

markers are 1 inch horizontal slits located in the center of the stainless steel

baffle separating the work area and the pump assembly. The correct fluid

level falls between these two markers.

NOTE The unit is equipped with a reservoir level float switch. The switch

prevents the unit from starting if the fluid is below the lower slit.

When pumping to an external system, keep extra fluid on hand to maintain

the proper level in both the circulating lines and the external system.

Avoid overfilling, fluids expand when heated.

- 17 -

Controller

(Digital One/Digital Plus)

The controller controls temperature using a Proportional-Integral-Derivative

(PID) algorithm. It is designed with self-diagnostic features and easy to use

operator interface. Two controller options are available: Digital One and Digital

Plus. The information on the following two pages applies to both controllers.

ON/OFF. Use this key to toggle the unit on or off and to clear error mes-

sages.

SCROLL. Use this key to scroll through the controller's LEDs. It is also

used to save new changes.

YES/ARROW. Use this key to increment numerical values when setting

values and to accept new settings.

NO/ARROW. Use this key to decrement numerical values when setting

values and to abort new settings.

Indicates refrigeration system status. It illuminates to indicate the refrigeration

system is removing heat from the bath fluid. The indicator is off when heat is not

being removed.

Indicates heater status. It illuminates to indicate the heater is adding heat from

the bath fluid. The indicator is off when heat is not being added.

Digital One Controller

Yes

No

Installation and Operation

- 18 -

Installation and Operation

NOTE The following indications are not visible until is depressed.

Setpoint. Indicates the controller is displaying the current setpoint.

Low Temperature Alarm. Indicates the controller is displaying the current

low temperature alarm.

High Temperature Alarm. Indicates the controller is displaying the current

high temperature alarm.

To adjust the displayed value use the arrow buttons. Pressing an arrow button

will cause the display to stop flashing and to indicate the new setpoint value.

Save the change by pressing SCROLL. The new setpoint value will rapidly flash

for two cycles and then the controller will return to the reservoir fluid tempera-

ture display.

If SCROLL is not pressed within 60 seconds the change will time out and revert

to the original setpoint. The controller will automatically return to the reservoir

fluid temperature display.

NOTE You can not adjust the setpoint closer than 0.1°C of either temperature

limit, and you can not adjust either temperature limit within 0.1°C of the

setpoint. Trying to do so will cause the indicator to flash and, on Digital Plus

controllers, the alarm to beep.

On units with the Digital Plus controller, pressing the Mute button prior to

pressing SCROLL will abort any changes and return to the reservoir fluid

temperature display.

- 19 -

Start Up/Shut Do n

(Digital One/Digital Plus)

Before starting the unit, recheck all electrical and plumbing connections.

Ensure the bath reservoir is properly filled. The unit will not start if the reservoir

fluid level is below the lower horizontal slit.

The unit can be configured for automatic restart. If the unit shuts down as

a result of a losing power, once power is restored the unit will restart.

See Setup/Tuning Loop on page 21 to enable this feature.

Press . The controller does a self-test (sequences through the LEDs, and

Digital Plus units momentarily sound the alarm), then quickly displays the

setpoint before displaying the reservoir fluid temperature. The pump starts and,

after a 30 second delay, the refrigeration comes on. The RTE-740 refrigeration

system is designed to start with the pump.

NOTE If the unit's recirculating fluid is outside either temperature limit, the unit

will start but the appropriate indicator will flash until the fluid is within the limit.

If refrigeration is needed for operation above 50°C, turn on the Full Range

Cooling Mode. See Setup Tuning Loop on page 21 to enable this feature.

To display change the setpoint press until illuminates. The display

will flash the current setpoint value. Use the arrow buttons to change the value.

The controller will not allow you to enter a setpoint closer than 0.1°C of either

temperature alarm setting, see next page. Attempting to causes the indicator

to flash and, on Digital Plus controllers, sounds the alarm.

Once an arrow button is depressed starts to flash. If an arrow button is not

pressed within 10 seconds the display will return to the reservoir temperature.

On units with the Digital Plus controller, pressing Mute prior to pressing

SCROLL will abort any change and return you to the fluid temperature display.

Once the desired setpoint is displayed, press again to confirm the

change. The display will rapidly flash the new value twice and then return to the

recirculating fluid temperature. If the new value is not confirmed within 60

seconds the display will return to the fluid temperature and ignore any change.

Controller

Pre-Start

Starting

Setpoint

Installation and Operation

Full Range Cooling

This manual suits for next models

4

Table of contents

Other Thermo Chiller manuals

Popular Chiller manuals by other brands

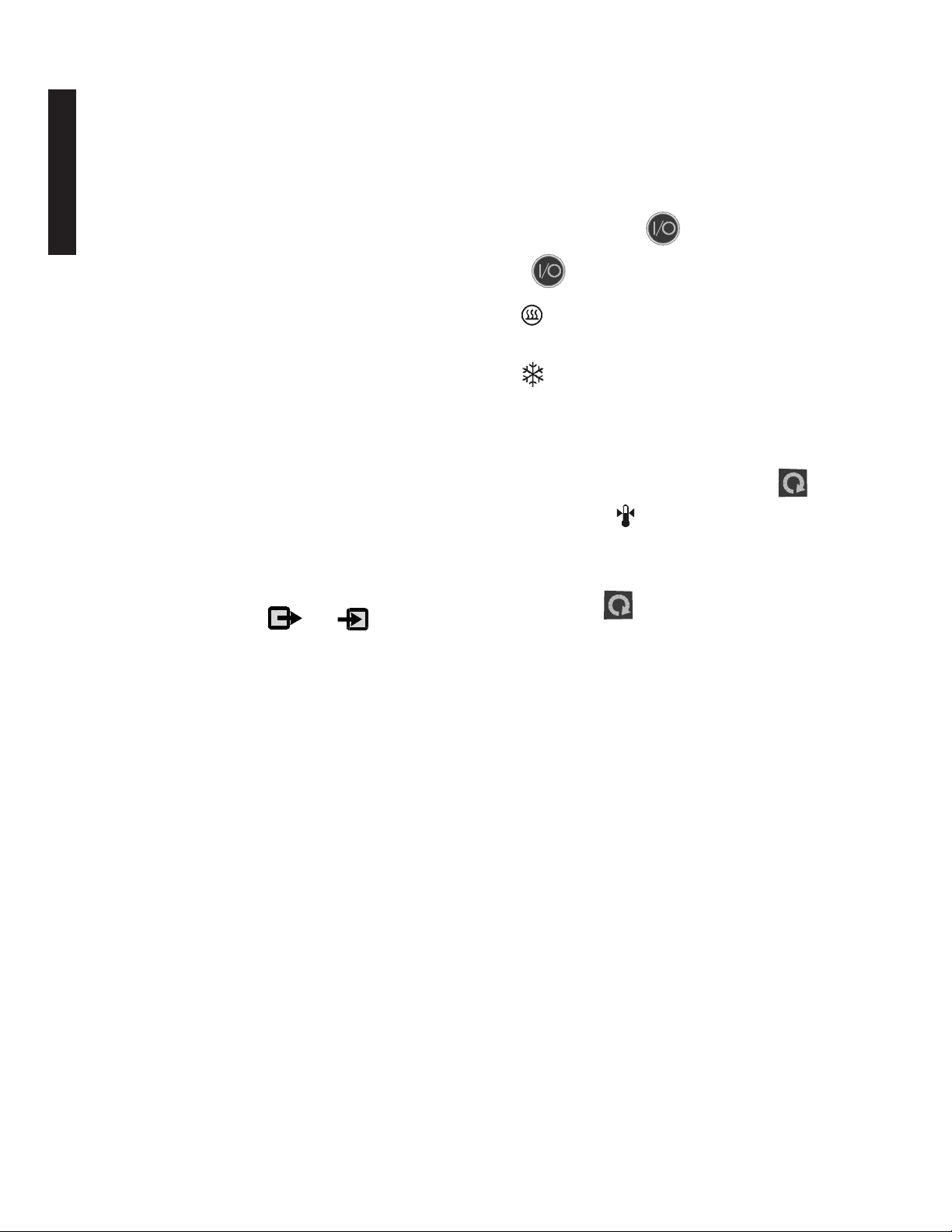

Carrier

Carrier 30HR Series Wiring diagrams

CIAT

CIAT POWERCIAT2 LXC instruction manual

Johnson Controls

Johnson Controls York YCAL0014E Series Installation, operation & maintenance instructions

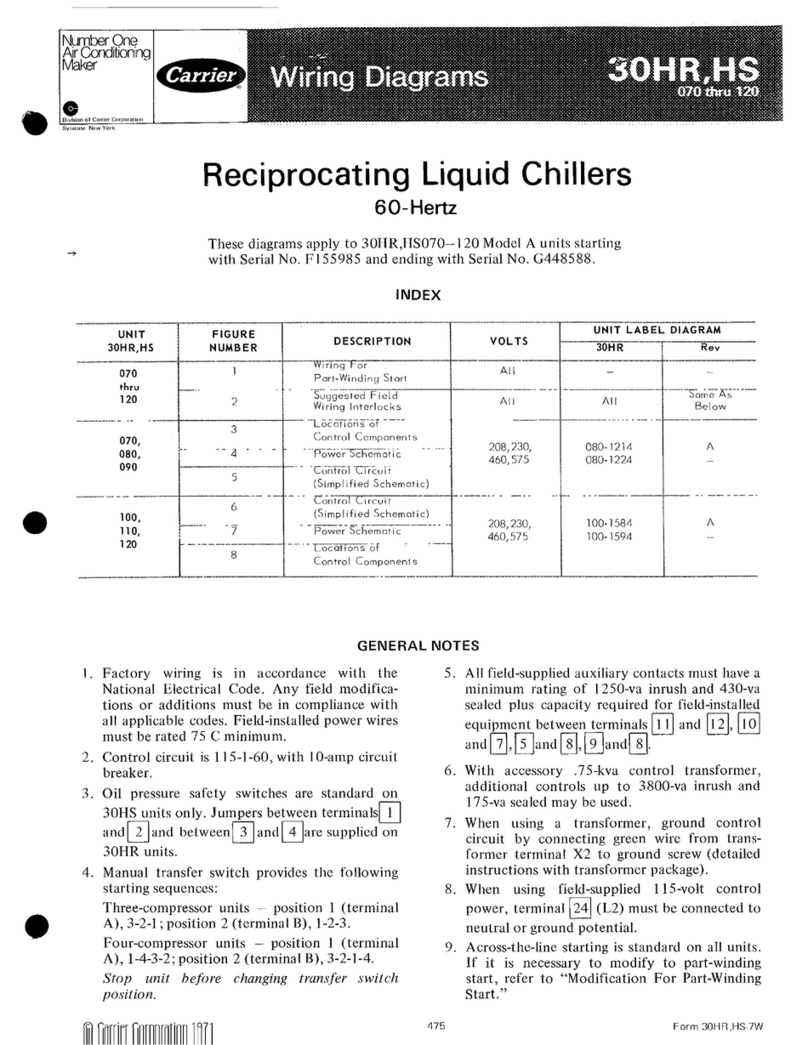

VALERA

VALERA GM 21-C TRIPLE DOOR datasheet

Husky

Husky C Series user manual

Henny Penny

Henny Penny BCF-24 Operator's manual

Carrier

Carrier 30HH Installation and maintenance instructions

Carrier

Carrier PH4G-K Series installation instructions

AAON

AAON LF Series Installation operation & maintenance

HL

HL HL-i Series Use and maintenance handbook

Carel

Carel pCO1 series instructions

Carrier

Carrier GEMINI 09DPS018 Installation, start-up and maintenance instructions