Thermo NESLAB HX 150 User manual

Refrigeration

Service

Thermo Manual P/N U00058

Rev. 09/09/97

NESLAB HX 150

Recirculating Chiller

No part of this publication may be

reproduced or reprinted except for

personal use without the prior permission

of Thermo Electron.

2

Contents

General Information

After Sale Support ..................................................................................................... 2

CAUTION .................................................................................................................. 3

Theory of operation ................................................................................................... 4

Cool mode ............................................................................................................ 4

Heat/idle mode...................................................................................................... 5

Troubleshooting

Troubleshooting Chart: Runaway cold ...................................................................... 6

Troubleshooting Chart: Runaway hot........................................................................ 7

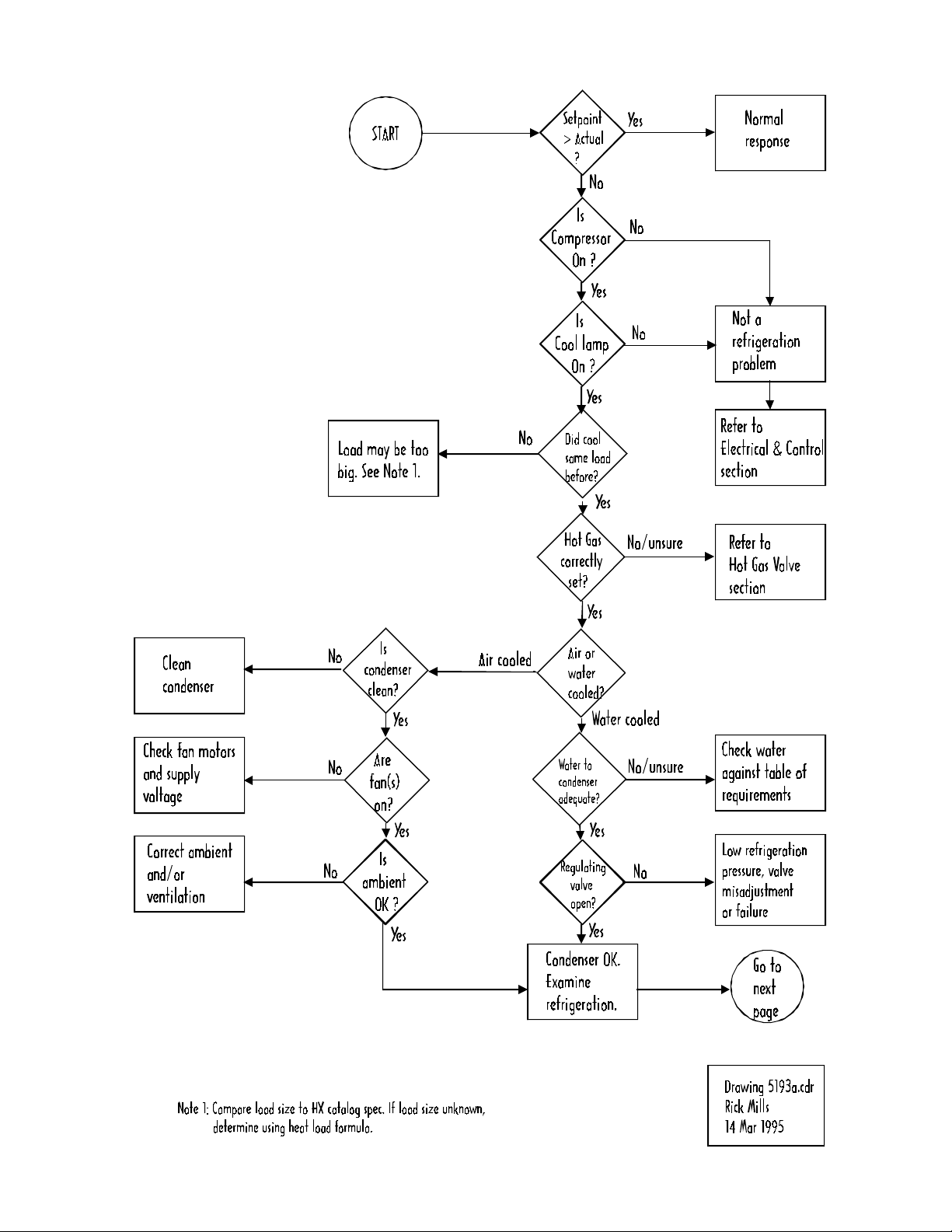

Troubleshooting Chart: Weak cooling ...................................................................... 8

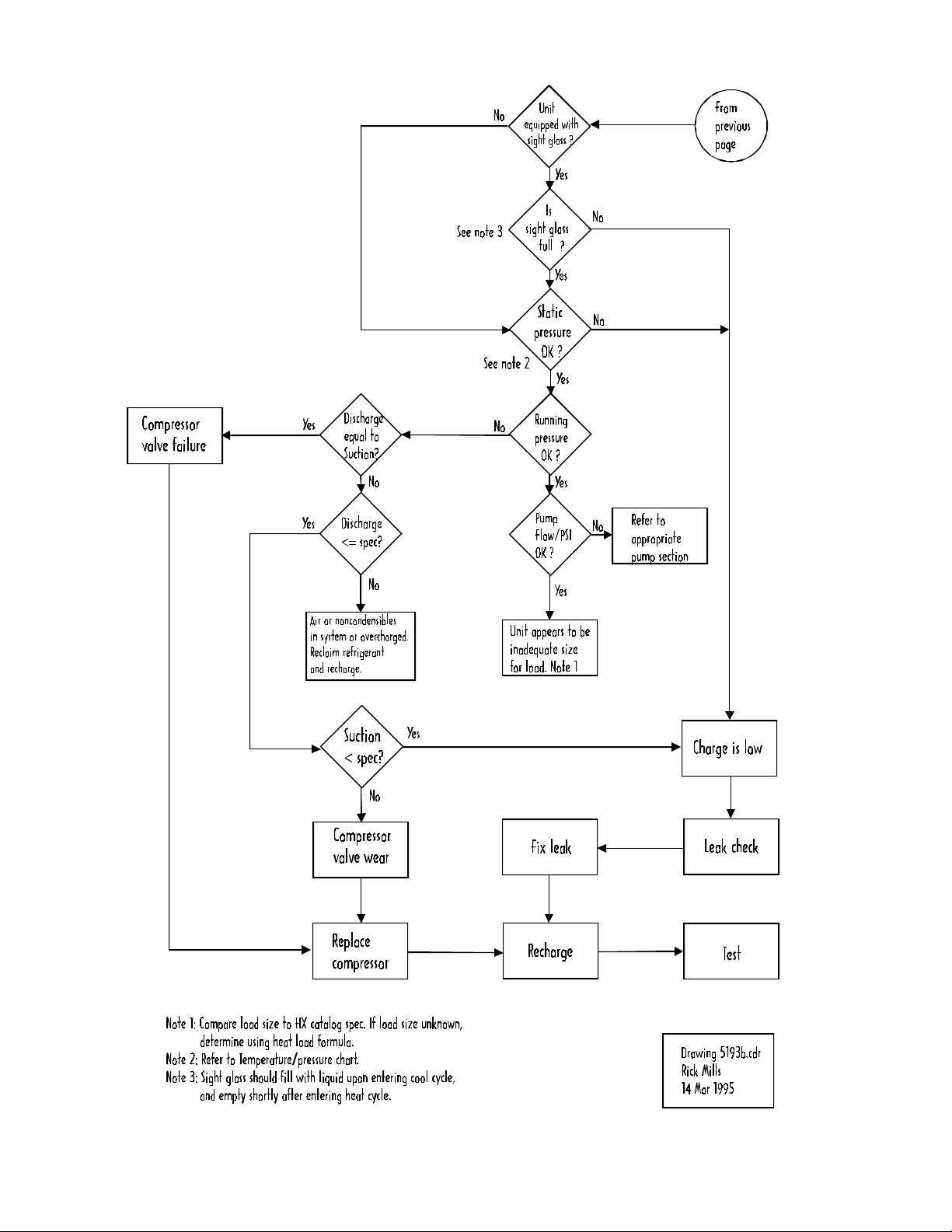

Troubleshooting Chart: Refrigeration pressures..................................................... 10

Replacement

Compressor............................................................................................................. 11

Fan Motor ................................................................................................................ 13

Filter/dryer ............................................................................................................... 14

Solenoid valve......................................................................................................... 15

Tank coil assembly (TCA) ....................................................................................... 17

Water regulating valve............................................................................................. 21

Capillary tube........................................................................................................... 23

Refrigeration components (general) ........................................................................ 25

Procedures

Speed check............................................................................................................ 27

Suction Discharge pressure and speed check ........................................................ 28

Condenser maintenance (air cooled & water cooled).............................................. 29

Flushing (closed facility system).............................................................................. 29

Flushing (tap water system) .................................................................................... 30

Flushing (unit off)..................................................................................................... 31

Commercial flushing chemicals ............................................................................... 32

Hot gas valve (Automatic Discharge Relief (ADR)) ................................................ 33

Schrader valves....................................................................................................... 37

Leak test and repair of leak ................................................................................ 38

Solenoid coil test ..................................................................................................... 39

Solenoid valve rebuild ............................................................................................. 40

Tank Coil Assembly (TCA) failure and repair ........................................................ 42

Water regulating valve setting ................................................................ 43

Reference

Refrigeration Specifications ................................................................... 44

R22 pressure-temperature chart ............................................................ 45

Heat load calculation .............................................................................. 46

Condenser re uirements: Air-cooled units ............................................ 47

Condenser re uirements: Water-cooled units ....................................... 48

15-pin accessory connector (optional) pinout ......................................... 49

Part numbers ......................................................................................... 50

3

4

This section is intended for use by qualified refrigeration techni-

cians only. Servicing refrigeration systems is hazardous and

must be performed only by qualified persons.

Refrigeration systems contain various hazards, including (but

not limited to) the following:

1. Refrigeration systems contain refrigerant gases at very high

pressures, even when not running.

2. Sudden release of refrigerant gases will result in rapid expan-

sion and severe frostbite hazard. Refrigerant gases will

cause severe injury to unprotected flesh.

3. Refrigerant gases are not flammable and are chemically

inert. However, they are heavier than air and will displace

oxygen. They can cause suffocation if released in a confined

area.

4. Refrigerant gases used in this product are classified as

Ozone Depleting Chemicals by the US Environmental Protec-

tion Agency. While they pose no hazard sealed inside the

refrigeration system, intentional release into the atmosphere

is outlawed under the 1990 Clean Air Act.

5. Compressor start and run capacitors store hazardous levels

of electricity, even when the unit is not running or plugged in.

6. Refrigeration system components operate at high tempera-

tures and present a severe burn hazard.

CAUTION

5

THEORY OF OPERATION

The chiller operates in two modes: COOL or HEAT/IDLE. The

controller compares setpoint to actual temperature and decides

which mode is required. This is a thermostatic (not proportional)

control system. The compressor, pump, and fan motor all run

continuously, regardless of mode.

The thermal transfer of the HEAT/IDLE mode is not as efficient

as the COOL mode. This results in units running at little or no

load to spend most of their time in the HEAT/IDLE mode with

brief periodic COOL periods. A duty cycle of 20% COOL / 80%

HEAT/IDLE may be typical for units running under no load. This

duty cycle will reverse as increasing load is applied, reaching

100% COOL / 0% HEAT/IDLE at full load.

This system results in tighter temperature control than continu-

ally cycling the compressor on and off, as is typical in a house-

hold refrigerator.

The default mode is HEAT/IDLE. A failure of the temperature

sensor or controller will generally result in the HEAT/IDLE

mode. This prevents a possible freezing of the cooling fluid and

resulting damage from fluid expansion.

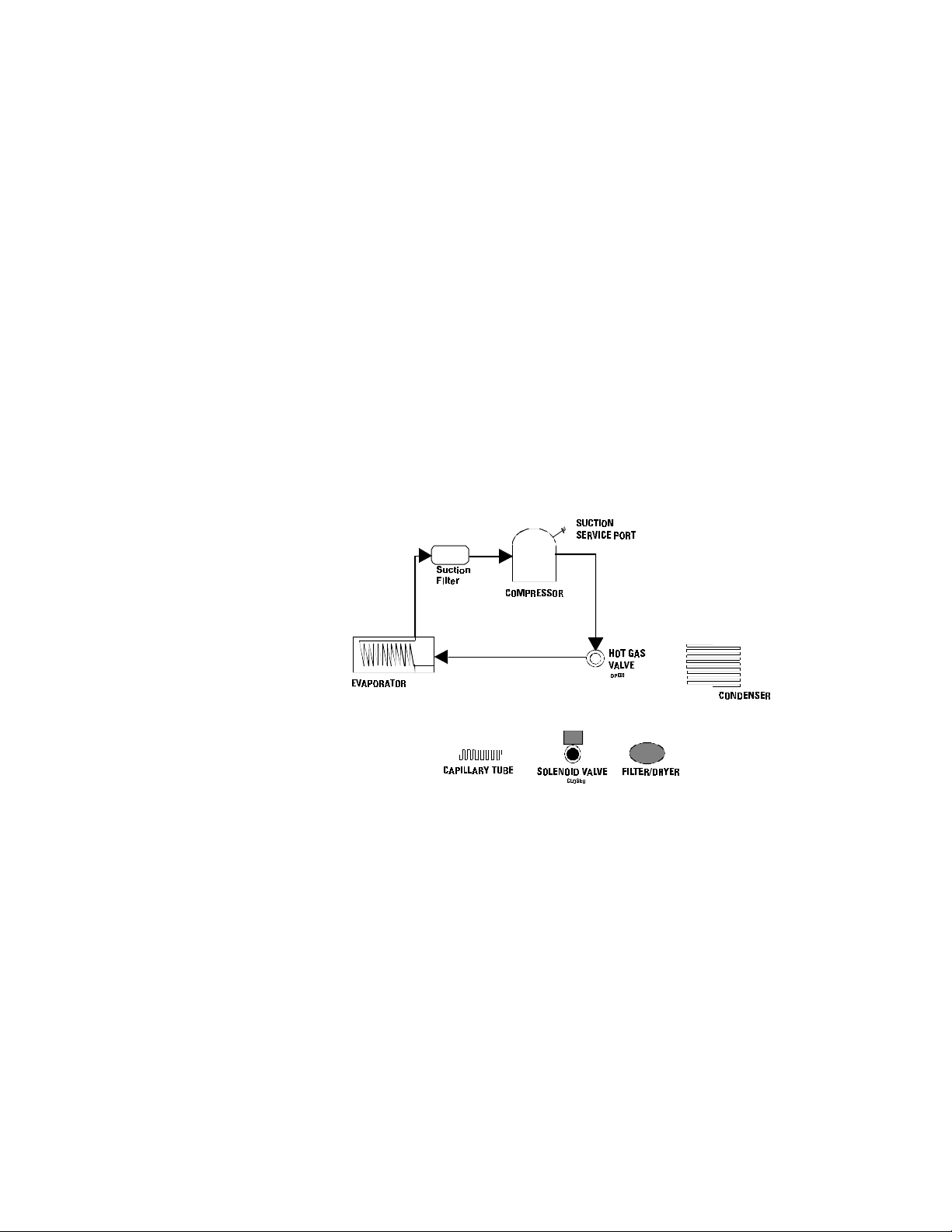

COOL MODE

If the setpoint is below the actual temperature, the controller is

in COOL mode. The controller triac output provides a closure

to supply line voltage to the solenoid coil. The solenoid valve,

which is normally-closed, is then pulled open by the coil and a

standard refrigeration cooling loop exists.

6

Refrigerant,asagas,ispressurizedinthe compressor.Itthen

enters the condenser and changes to a liquid due to the cooling

provided by the fan and condenser fins. Heat is given up to the

air at this point. The liquid refrigerant exits the condenser and

passes through a filter/dryer which traps contaminants and

absorbs any water moisture in its desiccant element. The refrig-

erant then passes through the open solenoid valve and enters

the capillary tube. The restriction of the tube meters the flow.

The capillary tube ends at the evaporator.

The evaporator is a coil located inside the fluid tank. As the

liquid refrigerant encounters the increased volume of the evapo-

rator, it expands tremendously, changing from a liquid to a gas,

and absorbing heat from the fluid (cooling it) in the process. The

refrigerant, now a gas, exits the evaporator and passes through

the suction filter. The refrigerant then enters the compressor at

low pressure and is re-compressed.

HEAT/IDLE MODE

If the setpoint is above the actual temperature, the controller is

inHEAT/IDLEmode. The triacoutputopens,turningthe solenoid coiloff.The

solenoidvalvethendropsclosed. This closed valve stops theflowofrefrigerant.

Duringthe heat/idle mode whentheliquidline solenoid valve isclosed,the

pressure drops in the suction line back to the compressor. When the pressure

dropstoa predetermined value, thehotgasbypassvalvewill open and allow

hotgas to flowtothe evaporator asstated.Thehot gas valveopenson a

decrease in pressure on its discharge port. The discharge port is connected to

theevaporator side ofthesystem.Therefrigerant gas isnowrouteddirectly to

the evaporator. The gas is not allowed to condense, as it has bypassed the

condensercompletely.Thehotgas passing through the evaporator

coil adds some heat to the fluid, then returns directly through the suction filter

tothe compressor.Thisunloads the compressor, resultinginlowerdischarge

pressure,highersuction pressure, and lesspowerconsumption.Observingthe

suction pressure in this mode will indicate the setting of the Hot Gas (ADR)

valve.

7

START

Is

Setpoint

< actual

?

Calibration

error

NO

YES

Replace

valve

Valve is

mechanically OK

Test

STOP

Refer to

ELECTRICAL & CONTROL

section

Remove coil

from valve

Drawing 67.cfl

Rick Mills

13 March 1995

YES

YES

NO

Valve is

stuck open

Not a

Refrigeration

Problem

Problem is in

Controller or

sensor

See VALVE

REPLACEMENT

Does

unit

warm up?

YES

NO

UNSURE

YESNO

NO

Can you

get cool

lamp off? *

Is

cool lamp

on?

* by manipulating setpoint

Is

coil

on?

Normal

Response

Troubleshooting Chart: Runaway cold

8

START

Is

Setpoint

> actual

?

Normal

response

Calibration

Error

NO

YES

Replace

valve

Test

STOP

Refer to

ELECTRICAL & CONTROL

section

Drawing 68.cfl

Rick Mills

13 March 1995

YES

NO

Valve is

stuck closed

Not a

refrigeration

problem

See VALVE

REPLACEMENT

UNSURE

Can you

get cool

lamp on? *

Is

cool lamp

on?

YES

NO

NO

YES

NO YES

NO

YES

NO

YES

*by manipulating setpoint

See TROUBLESHOOTING:

"WEAK COOLING"

Any

DC volts

on coil

?

Any

AC volts

on coil

?

Is

coil

on?

Problem is in

Controller or

Sensor

Is it

cooling

at all ?

Troubleshooting Chart: Runaway hot

9

Troubleshooting Chart: Weak cooling

10

Troubleshooting Chart: Weak cooling continued

11

Troubleshooting Chart: Refrigeration pressures

12

Compressor replacement

1. Remove all access panels.

2. Confirm that the problem is not external to the compressor

(electrical) before proceeding. If the compressor does not

start/run, check the following:

A. Is proper voltage present at the

compressor terminals?

B. Are all starting devices (capacitors,

potential relays) good?

Disconnect the unit from line voltage

C. Are the motor windings known to be

good or bad? If in doubt, Ohmmeter

readings of the windings may be compared

to the replacement compressor.

3. Recover the system refrigerant.

4. Disconnect wires, starting devices, etc. from compressor.

5. Remove valve cores from both Shrader valves.

6. Remove the coil from the solenoid valve and move it out of

the torch area. Wrap a damp rag around the solenoid valve

body.

7. Unsolder and remove compressor and dryer.

NOTE: If a compressor burnout is suspected, invert old

compressor and drain out a small sample of oil. Test the oil

for acidity, following the manufacturer’s recommendations on

the acid test kit. If the oil is acidic, the refrigeration system will

need flushing to remove the acidic oil. Replace with new oil.

13

8. Unpack new compressor. Remove plugs from the ports.

Compressors are typically shipped pressurized with a

dry nitrogen charge. Safety glasses are especially

necessary when removing plugs. Orient compressor so

the plug will exit the port pointing away from you and

others.

NOTE: Replacement Copeland compressors already con-

tain an adequate oil charge. It is not necessary to add any

oil to the new compressor.

9. Remove the suction service port stem from the old com-

pressor, and insert it into the new compressor.

10. Apply nitrogen purge gas to the stem.

11. Braze in place using BAg 28 (silver solder) compound.

12. Position the new compressor in place.

13. Position the new dryer in place. Ensure the flow direction

arrow points toward the solenoid valve.

14. Wrap a damp rag around the dryer.

15. Apply nitrogen purge gas to the suction service port.

16. Braze the suction and discharge lines to the compressor,

using BAg 28.

17. Braze the dryer in place, using BAg 28.

18. Insert new valve cores in the Shrader valves.

19. Pressurize system and leak check.

20. Evacuate system.

21. Charge system to specification.

22. Test system.

14

Fan Motor Replacement

1. Disconnect unit from its electrical power supply.

2. Note the location and orientation of the electrical wiring for

installation.

3. Disconnect the electrical wiring.

4. Unbolt the fan from the base of the condensing unit.

5. Pull the fan assembly (motor, blade, and bracket) out of the

unit.

6. Transfer the blade, conduit, and/or bracket to the new motor.

7. Reassemble in reverse order.

15

FILTER/DRYER REPLACEMENT

NOTE: The filter/dryer contains a desiccant which will absorb

moisture from the atmosphere. The filter/dryer should be

replaced whenever the refrigeration system has been opened

and allowed to go to atmospheric pressure. Unsealing and

installing the new filter/dryer should be left until the last pos-

sible minute to minimize contamination of its

desiccant.

Disconnect the unit from line voltage

1. Recover the system refrigerant.

2. Remove all Shrader valve cores.

3. Remove solenoid valve internal components (See “Solenoid

valve replacement procedure” for drawing) Wrap a damp rag

around the solenoid valve body.

4. Apply purge gas to the system.

5. Desolder and remove old filter/dryer.

6. Place new filter/dryer in position, with direction-of-flow arrow

pointing towards the liquid line solenoid valve.

7. Wrap the filter/dryer body in a damp rag.

8. Introduce nitrogen purge gas into the discharge service port.

9. Braze connections using BAg 28. Orient torch flame away

from the filter/dryer body. Any bubbling of the paint on the

filter/dryer indicates excessive temperature is being ap-

proached - stop and allow to cool if this occurs.

10. Remove the damp rags and the nitrogen supply.

11. Insert new schrader valve cores.

12. Assemble the solenoid valve (Do Not over tighten - Use two

wrenches).

11. Pressurize and leak check.

12. Evacuate system.

13. Charge system.

14. Test.

15. Install any access panels removed.

16

Solenoid valve replacement:

Disconnect the unit from line voltage

1. Recover refrigerant.

2. Remove coil.

3. Remove all valve cores from the Shrader valves.

4. Note the direction of flow so that the new valve can be prop-

erly positioned during assembly. Disassemble solenoid valve

and remove internal components as shown below.

17

5. Protect all components that could be affected by the solder-

ing flame with damp rags and metal shielding.

6. Apply a nitrogen purge gas to the system.

7. Unsolder the valve and dryer and remove.

8. Place new valve and dryer in position. Check that the flow

direction arrows on both devices point towards the capillary

tube.

9. Wrap a damp rag around the valve and dryer and protect any

other components/wiring with damp rags and metal shields.

10. Apply nitrogen purge gas to the system.

11. Braze in place using BAg 28 compound (silver solder).

12. Remove rags and inspect brazing.

13. Install new valve cores in the Shrader valves.

14. Assemble solenoid valve assembly. (Use two wrenches and

do not over tighten.)

15. Pressurize system and leak check. The solenoid valve is

closed, so be sure to pressurize both sides.

12. Evacuate the refrigeration system.

13. Install coil.

14. Charge system to specification.

15. Test system.

16. Install any access panels removed.

18

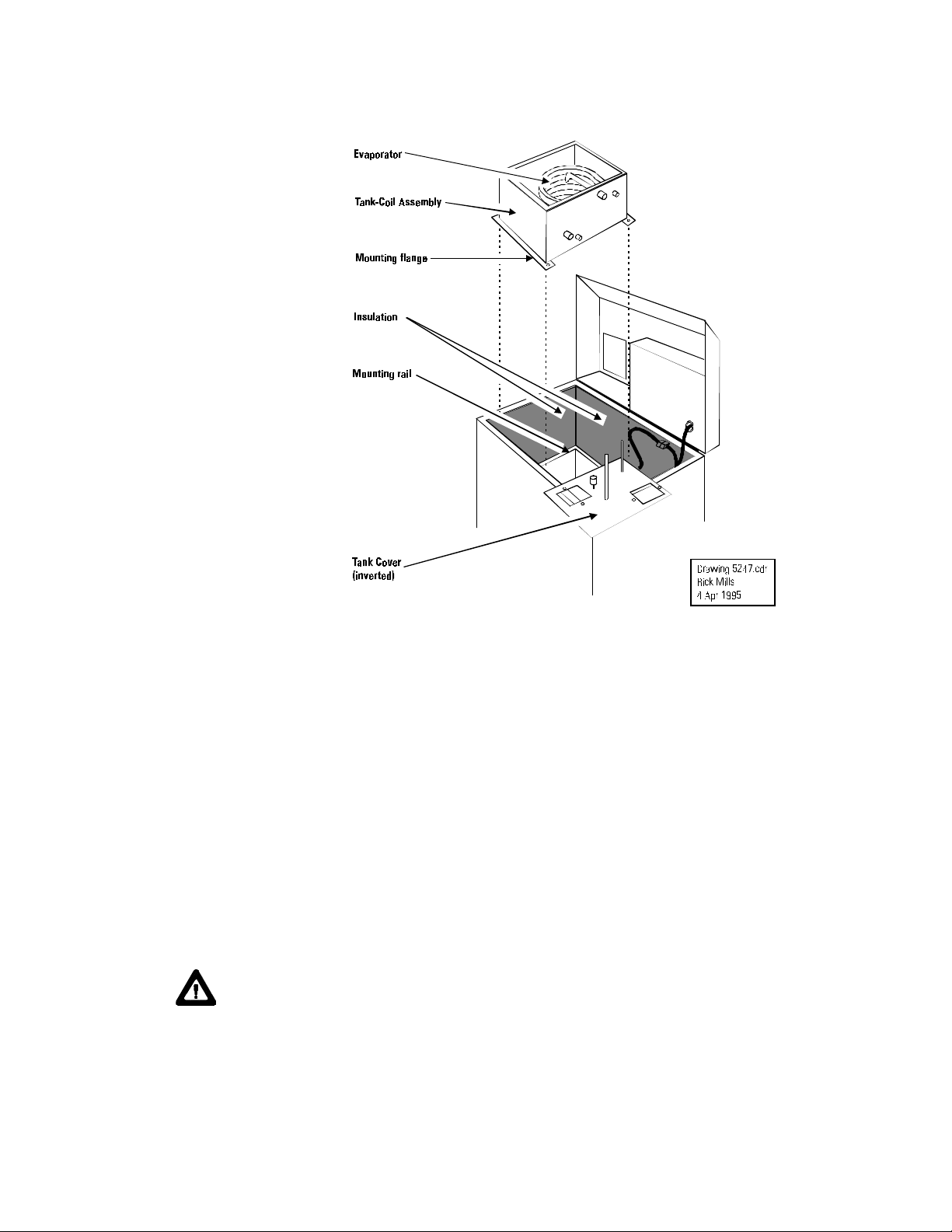

NOTE: The evaporator coil and the water tank are one unit.

They cannot be separated. The following procedure assumes

that the pump along with its plumbing has been removed.

Disconnect unit from line voltage.

1. Recover refrigerant, if any remains.

2. Drain fluid from system.

3. Remove valve cores from both Shrader valves.

Tank Coil Assembly (TCA) replacement

19

4. Remove screws from Tank Cover and lift it off the tank with

all wires, motors, sensors, etc. intact. Invert it and place it to

the side as shown. If more slack is required in the wires,

unplug the connector shown.

5. Remove the two fluid hoses from the water inlet and outlet

stubs.

6. Remove the insulation from the refrigerant inlet and outlet

lines.

7. Unsolder the refrigerant inlet and outlet lines.

CAUTION: The refrigerant inlet and outlet lines are stain-

less steel. They are easily damaged by excessive heat.

Never apply the torch flame directly to the stainless. Warm

the copper fittings up slowly and evenly until the solder

liquefies.

8. Remove the four screws that hold the TCA mounting flange

to the mounting rails.

20

9. Lift the TCA straight up out of the unit.

10. Inspect the insulation on the inside of the case walls while the

TCA is removed. Replace any that is wet. Install insulation

on the new TCA.

11. Transfer the strainer from inside the old TCA to the new TCA,

if required.

12. Clean the refrigeration stubs on the new TCA carefully prior

to installation. Clean the inside of the mating copper lines

prior to installation.

13. Lower the TCA into place and secure the mounting flange to

the mounting rails.

CAUTION: The refrigerant inlet and outlet lines are stain-

less steel. They are easily damaged by excessive heat.

Solder the fittings as follows:

A. Ensure all fittings have been carefully cleaned.

B. Apply a paste-type flux.

Table of contents

Other Thermo Chiller manuals

Popular Chiller manuals by other brands

Elkay

Elkay ECP8 1H Series Installation, care & use manual

Carrier

Carrier Flotronic 30GB user manual

Carrier

Carrier ECOLOGIC 30GXN installation instructions

SMC Networks

SMC Networks HRS018-A*-20-* Operation manual

Carrier

Carrier AQUASNAP 30RB060-390 Controls, start-up, operation, service and troubleshooting instructions

Cres Cor

Cres Cor CCBC-12-75 Installation, operation & service manual