2

Table of Contents

AAON LF Series Features and Options Introduction..................................................................... 4

Safety .............................................................................................................................................. 5

LF Series Feature String Nomenclature.......................................................................................... 7

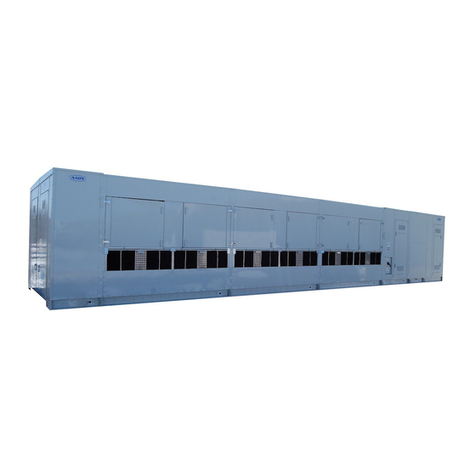

General Description...................................................................................................................... 12

Receiving Unit........................................................................................................................... 12

Chiller........................................................................................................................................ 13

Wiring Diagrams....................................................................................................................... 14

General Maintenance................................................................................................................. 14

Primary Pumping Package ........................................................................................................ 14

Glycol........................................................................................................................................ 15

Compression Tank..................................................................................................................... 15

Pressure Relief Valve................................................................................................................ 15

Manual and Automatic Air Vent............................................................................................... 15

Dual Pumps ............................................................................................................................... 15

Differential Pressure Gauge and Thermometers....................................................................... 16

Pipe Insulation........................................................................................................................... 16

Installation..................................................................................................................................... 16

Forklifting the Unit (4-17, 22 and 24 ton)................................................................................. 16

Lifting the Unit.......................................................................................................................... 17

Locating the Unit....................................................................................................................... 18

Water Connection...................................................................................................................... 18

Mounting Isolation.................................................................................................................... 19

Access Doors............................................................................................................................. 19

Low Ambient Operation............................................................................................................ 19

LAC Valve............................................................................................................................. 20

Condenser Flooding............................................................................................................... 21

Electrical.................................................................................................................................... 21

Startup........................................................................................................................................... 23

Maintenance.................................................................................................................................. 24

General ...................................................................................................................................... 24

Compressors.............................................................................................................................. 24

Refrigerant Filter Driers............................................................................................................ 24

Adjusting Refrigerant Charge ................................................................................................... 24

Lubrication ................................................................................................................................ 26

Service....................................................................................................................................... 27

Warranties ................................................................................................................................. 27

Condenser Tube Inspection....................................................................................................... 27

Pump Operation......................................................................................................................... 27

Access Doors............................................................................................................................. 27

Pump Bearings - Lubrication .................................................................................................... 27

Air Inlet ..................................................................................................................................... 27

Propeller Fans and Motors ........................................................................................................ 28