THERMODYNE 742HW-CT User manual

INSTALLATION &

OPERATION MANUAL

(01-20)

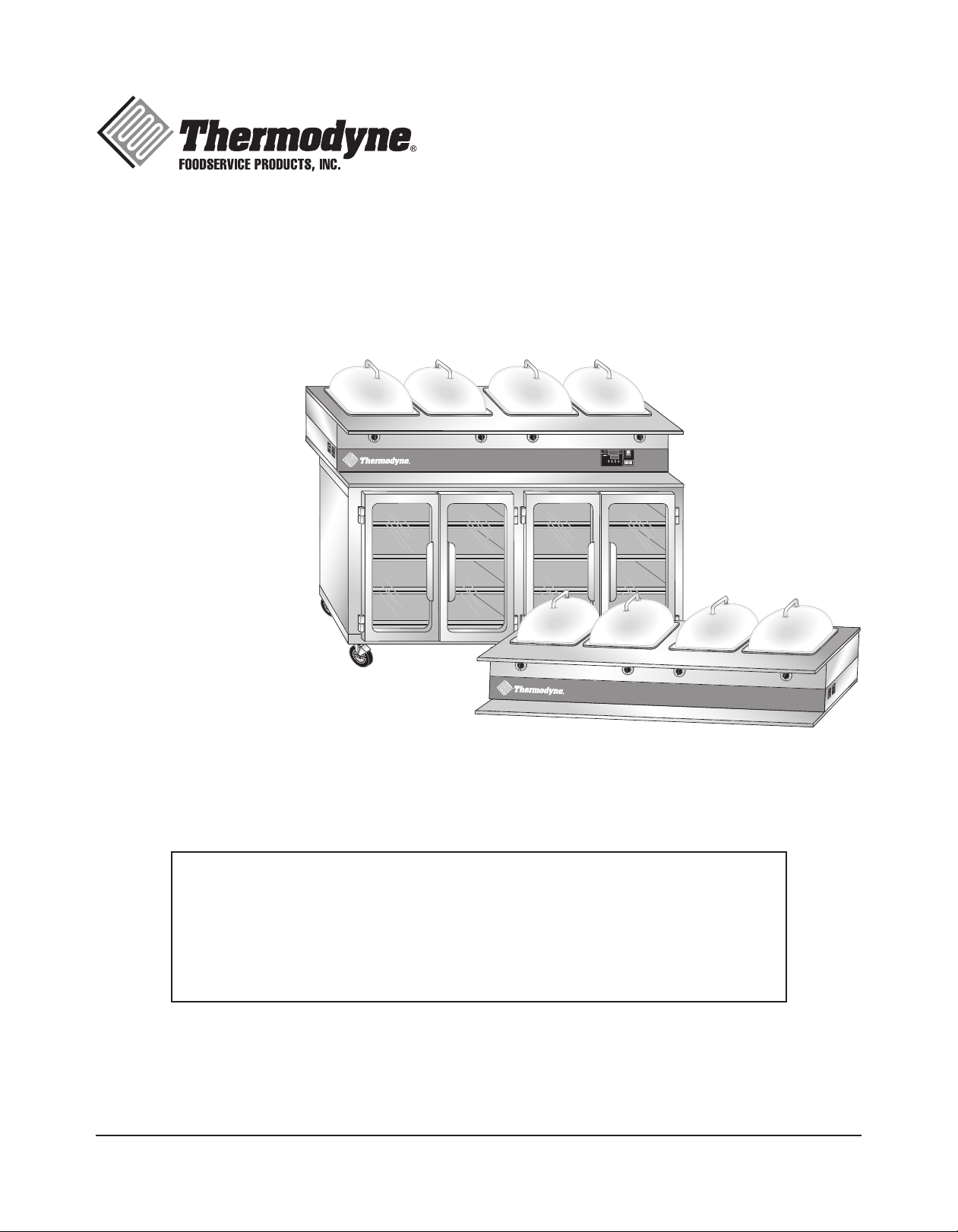

DRY WELL MODELS

742HW 742HW-CT (Countertop 6 Inch Deep Wells)

744HW 744HW-CT (Countertop 4 Inch Deep Wells)

744HW-CT (Countertop 6 Inch Deep Wells)

Thermodyne Foodservice Products, Inc.

4418 New Haven Avenue 1-800-526-9182

Fort Wayne, IN 46803 www.tdyne.com

For additional information on Thermodyne Foodservice Products, Inc.,

or to locate an authorized parts and service provider in your area,

visit our website at www.tdyne.com.

Please visit our website to Register your Thermodyne unit. Registration ensures that you

get up-to-date warranty and product information, along with fast and convenient service.

http://www.tdyne.com/register.aspx

— 2 —

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL ELECTRICAL

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND ADJUSTMENTS OF

THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORMING

MAINTENANCE ON THE EQUIPMENT.

: Failure to follow all the instructions in this manual can cause property damage,

injury or death.

: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death.

: Electrical connections should be performed only by a certified professional.

: Electrical and grounding connections must comply with the applicable portions

of the National Electric Code and/or all local electric codes. Failure to comply with this

procedure can cause property damage, injury or death.

: Before connecting the unit to the electrical supply, verify that the electrical and

grounding connections comply with the applicable portions of the National Electric Code and/or

other local electrical codes. Failure to comply with this procedure can cause property damage,

injury or death.

: Before connecting the unit to the electrical supply, verify that the electrical

connection agrees with the specifications on the data plate. Failure to comply with this

procedure can cause property damage, injury or death.

: UL73 grounding instructions:This appliance must be connected to a grounded,

metal, permanent wiring system. Or an equipment-grounding conductor must be run with the

circuit conductors and connected to the equipment-grounding terminal or lead on the appliance.

Failure to comply with this procedure can cause property damage, injury or death.

: Appliances equipped with a flexible electric supply cord, are provided with

a three-prong grounding plug. It is imperative that this plug be connected into a properly

grounded three-prong receptacle. Failure to comply with this procedure can cause property

damage, injury or death.

: If the receptacle is not the proper grounding type, contact an electrician. Do not

remove the grounding prong from the plug. Failure to comply with this procedure can cause

property damage, injury or death.

: Before performing any service that involves electrical connection or

disconnection and/or exposure to electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure to comply with this procedure

can cause property damage, injury or death.

— 3 —

: Before removing any sheet metal panels or servicing this equipment, always

perform the Electrical LOCKOUT/TAGOUT Procedure. Be sure all circuits are disconnected.

Failure to comply with this procedure can cause property damage, injury or death.

: Do not operate this equipment without properly placing and securing all covers

and access panels. Failure to comply with this procedure can cause property damage, injury or

death.

: Do not use or store gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance. Failure to comply can cause property damage, injury or death.

: In the event of a power failure, do not attempt to operate this appliance. Failure to

comply can cause property damage, injury or death.

CAUTION: These models have glass doors. Remove carton carefully.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE. FAILURE TO COMPLY CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

— 4 —

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY................................................................................................... 2

INTRODUCTION .............................................................................................................................. 5

GENERAL .................................................................................................................................. 5

SPECIFICATIONS ...................................................................................................................... 5

UNPACKING............................................................................................................................... 8

Thermodyne Damaged Goods Policy................................................................................... 8

INSTALLATION CODES AND STANDARDS.............................................................................. 8

ELECTRICAL SPECIFICATIONS............................................................................................... 9

INSTALLATION................................................................................................................................. 9

LOCATION.................................................................................................................................. 9

ELECTRICAL CONNECTION .................................................................................................... 9

OPERATION................................................................................................................................... 10

CONTROLS AND INDICATORS............................................................................................... 10

STARTUP ................................................................................................................................. 10

Setting Cabinet Temperature .............................................................................................. 11

Setting Well Temperature.................................................................................................... 11

Preheating .......................................................................................................................... 11

FLUID REPLENISHMENT........................................................................................................ 12

CLEANING AND MAINTENANCE ................................................................................................. 13

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE.................................................................. 13

WHEN TO CLEAN .................................................................................................................... 13

STAINLESS STEEL CARE....................................................................................................... 13

Cleaning.............................................................................................................................. 13

Preserving & Restoring....................................................................................................... 13

Heat Tint ............................................................................................................................. 14

CLEANING HEAT TRANSFER PLATES................................................................................... 14

CLEANING DOOR GASKETS ................................................................................................. 14

CHANGING FLUID................................................................................................................... 14

CLEANING THE DRY WELL .................................................................................................... 15

TROUBLESHOOTING.................................................................................................................... 17

SCHEMATIC WIRING DIAGRAM................................................................................................... 18

WARRANTY ................................................................................................................................... 19

HEAT TRANSFER FLUID MSDS ................................................................................................... 19

— 5 —

SPECIFICATIONS

INTRODUCTION

GENERAL

Thermodyne cabinets are produced with quality

workmanship and materials. Proper installation,

operation and maintenance will result in many

years of satisfactory performance. It is suggested

that you thoroughly read this manual in its entirety

and carefully follow all of the instructions provided.

The cabinets described in this manual are

programmable for the desired holding temperature.

The factory setting is 185° F unless otherwise

specified. Each shelf in the cabinet maintains an

exact temperature, allowing for extended holding

times without sacrificing appearance or taste.

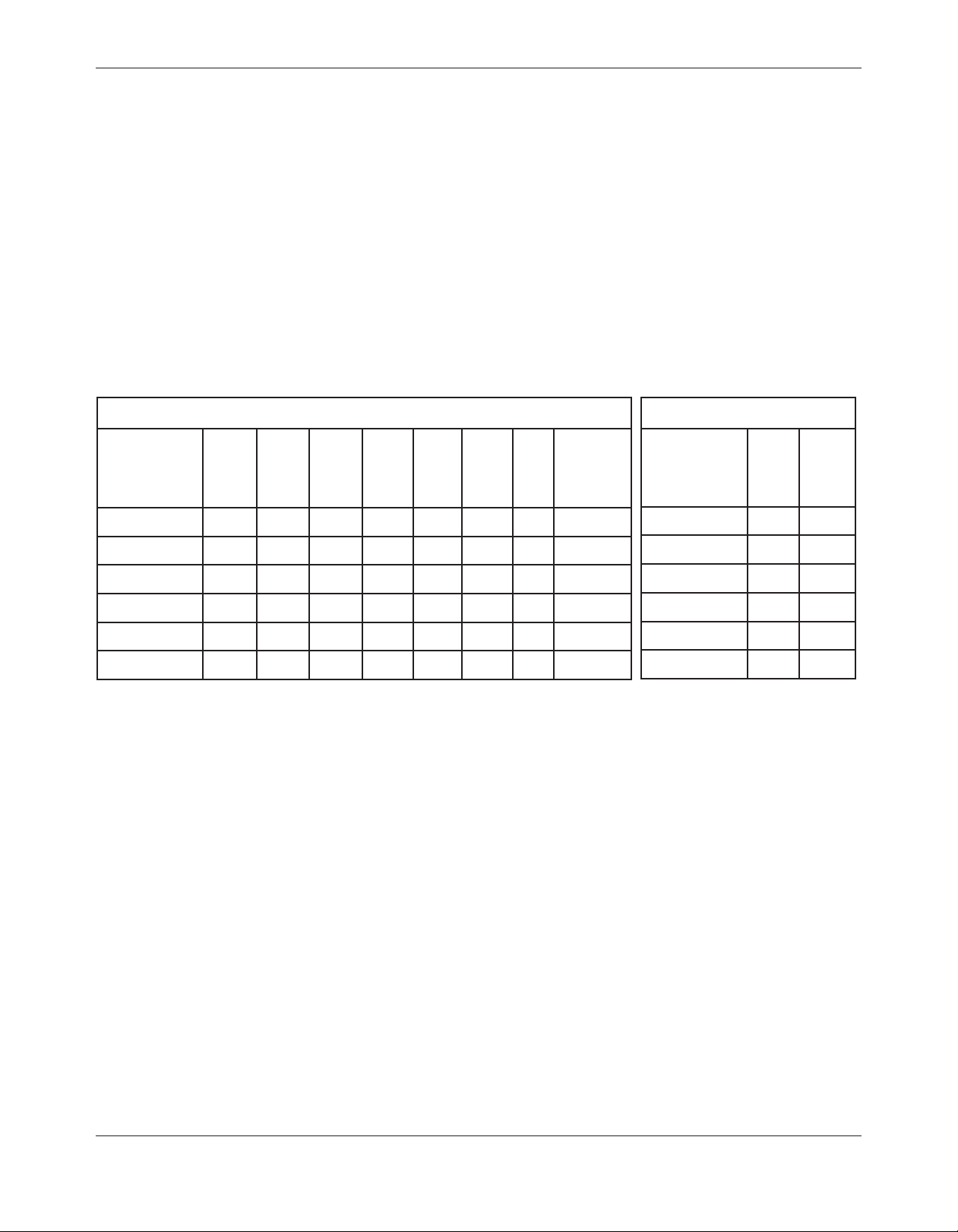

DIMENSIONS AND MAXIMUM TEMPERATURE

Model

Ext.

Width

inches

Ext.

Depth

inches

Ext.

Height

inches

Int.

Width

inches

Int.

Depth

inches

Int.

Height

inches

Max.

Oper.

Temp

°F

Max. Oper.

Temp Dry

Well °F

742HW

31.750 33.625 37.50 26.50 22.50 20.00 230 250

744HW

60.125 33.625 37.50 56.00 22.50 20.00 230 250

742HW-CT

30.50 27.50 13.125 – – – – 250

744HW-CT

60.125 33.00 13.125 – – – – 250

742HW-CT (6in)

30.50 33.00 15.125 – – – – 250

744HW-CT (6in)

60.125 33.00 15.125 – – – – 250

WEIGHT

Model

Net

Weight

lbs

Shipping

Weight

lbs

742HW

265 340

744HW

470 560

742HW-CT

110 200

744HW-CT

215 310

742HW-CT (6in)

145 245

744HW-CT (6in)

205 430

— 6 —

Figure 2: Outline Dimensional Drawing, 742HW-CT Countertop with 6 Inch Deep Wells

Figure 1: Outline Dimensional Drawing, 742HW-CT Countertop

DEEP HOUSING LID SHELF OPTION SHOWN

DEEP BASE SHELF

OPTION SHOWN

33"

13" 8"

Exterior Depth

FRONT VIEW

TOP VIEW

SIDE VIEW

ELECTRICAL

10 3/8"

30 1/2"

Exterior Width

15 1/8"

Exterior

Height

27 1/2"

Exterior Depth

FRONT VIEW

TOP VIEW

SIDE VIEW ELECTRICAL

23 7/8"

30 1/2"

Exterior Width

13 1/8"

Exterior

Height

— 7 —

Figure 4: Outline Dimensional Drawing, 744HW with Casters

Figure 3: Outline Dimensional Drawing, 744HW-CT Countertop

32"

11"

11"

8"

ELECTRICAL

ELECTRICAL

60 1/8"

Ext. Width

56"

Int. Width

FRONT VIEW

SIDE VIEW

TOP VIEW

20"

Int.

Height

37 1/2"

Ext.

Height

1-3/4" WIDE

2" DIA. WHEEL

2 1/2"

SPACING

4" PAN

SPACING

33 5/8"

Ext. Depth

22 1/2"

Int. Depth

OFF

60

100

250

150

200

OFF

60

100

250

150

200

OFF

60

100

250

150

200

OFF

60

100

250

150

200

33"

Exterior Depth

60 1/8"

Exterior Width

13 1/8"

Exterior

Height

FRONT VIEW

TOP VIEW

SIDE VIEW

REAR VIEW

ELECTRICAL

ELECTRICAL

ELECTRICAL

11"

8"

OFF

60

100

250

150

200

OFF

60

100

250

150

200

OFF

60

100

250

150

200

OFF

60

100

250

150

200

11"

— 8 —

UNPACKING

All Thermodyne cabinets are factory tested for

performance and certified free from defects.

Thermodyne Damaged Goods Policy

There are two types of damaged merchandise:

A. Visible Damage and B. Concealed Damage.

A. Visible Damage: The product being received

is visibly damaged.

1. The receiver should refuse the damaged

merchandise.

2. Receiver should sign the bill of lading

indicating which merchandise is being

refused due to damage.

3. Contact Thermodyne Customer Service

Representatives immediately.

B. Concealed Damage:Damaged merchandise

cannot be externally detected.

Your receiving operation should inspect for this

type of damage. Please inspect your delivery

carefully.

If the product is damaged:

1. Save all packing material.

2. Contact Thermodyne Customer Service

Representatives immediately.

3. Receiver must call the carrier to schedule

an inspection of the damaged merchandise

within 5 business days.

INSTALLATION CODES

AND STANDARDS

These installation instructions are for the use of

qualified installation and service personnel

only.

1. Installation or service by other than qualified

personnel may result in damage to the

Thermodynecabinet and/orinjuryto theoperator.

2. National Electrical Code (ANSI/NFPA No. 70,

latest edition) available from the National Fire

Protection Association, Batterymarch Park,

Quincy, MA 02269.

In Canada, the cabinet must be installed in

accordance with:

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No.

3, latest edition) available from the Canadian

Standards Association, 5060 Spectrum Way,

Mississauga, Ontario, Canada L4W 5N6.

Figure 5: Outline Dimensional Drawing, 744HW-CT Countertop with 6 Inch Deep Wells

OFF

60

100

250

150

200

OFF

60

100

250

150

200

OFF

60

100

250

150

200

OFF

60

100

250

150

200

DEEP HOUSING LID SHELF OPTION SHOWN

DEEP BASE SHELF

OPTION SHOWN

WELLS FOR 6" PANS

33"

Exterior Depth

60 1/8"

Exterior Width

15 1/8"

Exterior

Height

FRONT VIEW

TOP VIEW

SIDE VIEW

REAR VIEW

ELECTRICAL

ELECTRICAL

ELECTRICAL

13"

8"

10 3/8"

— 9 —

Before installing, verify the required electrical

supply agrees with the specifications on the data

plate located on the back or side of the unit. If

the supply and equipment requirements do not

agree, do not proceed with installation. Contact

your dealer orThermodyne Foodservice Products,

Inc. immediately.

CAUTION: These models have glass doors.

Remove carton carefully.

1. Allow ample overhead clearance for removal

of carton.

2. Cut banding (2 pieces) and remove nails (not

for all units).

3. To remove cabinet from carton, slide carton

up and off the cabinet.

4. Check packing list against items received:

A. Thermodyne Heat Transfer Fluid

B. Installation & Operation Manual

5. Use proper lifting equipment to raise the

cabinet.

6. Remove the plastic covering from glass door

frames and hinges.

7. Mount doors on cabinet, and then check doors

for alignment.

8. Set cabinet on a level surface.

LOCATION

Allow adequate space for electrical connections.

The electrical cord and plug are located at the right

rear of the unit.The minimum clearance for proper

air circulation on back should be 4”, and 2” on at

least one side. Allow adequate access space for

operating and servicing the unit.

NOTICE: Louvers on the sides of the oven

are used to circulate cool air throughout the

electrical components. The unit must not be

placed where extensive airborne grease is

present, such as near deep fryers or griddles.

ELECTRICAL CONNECTION

: Electrical and grounding

connections must comply with applicable

portions of the National Electrical Code and/

or other local electrical codes.

: Disconnect the electrical

power to the Thermodyne unit and follow

LOCKOUT/TAGOUT procedures.

Refer to the wiring diagrams in this manual for

wiring information.

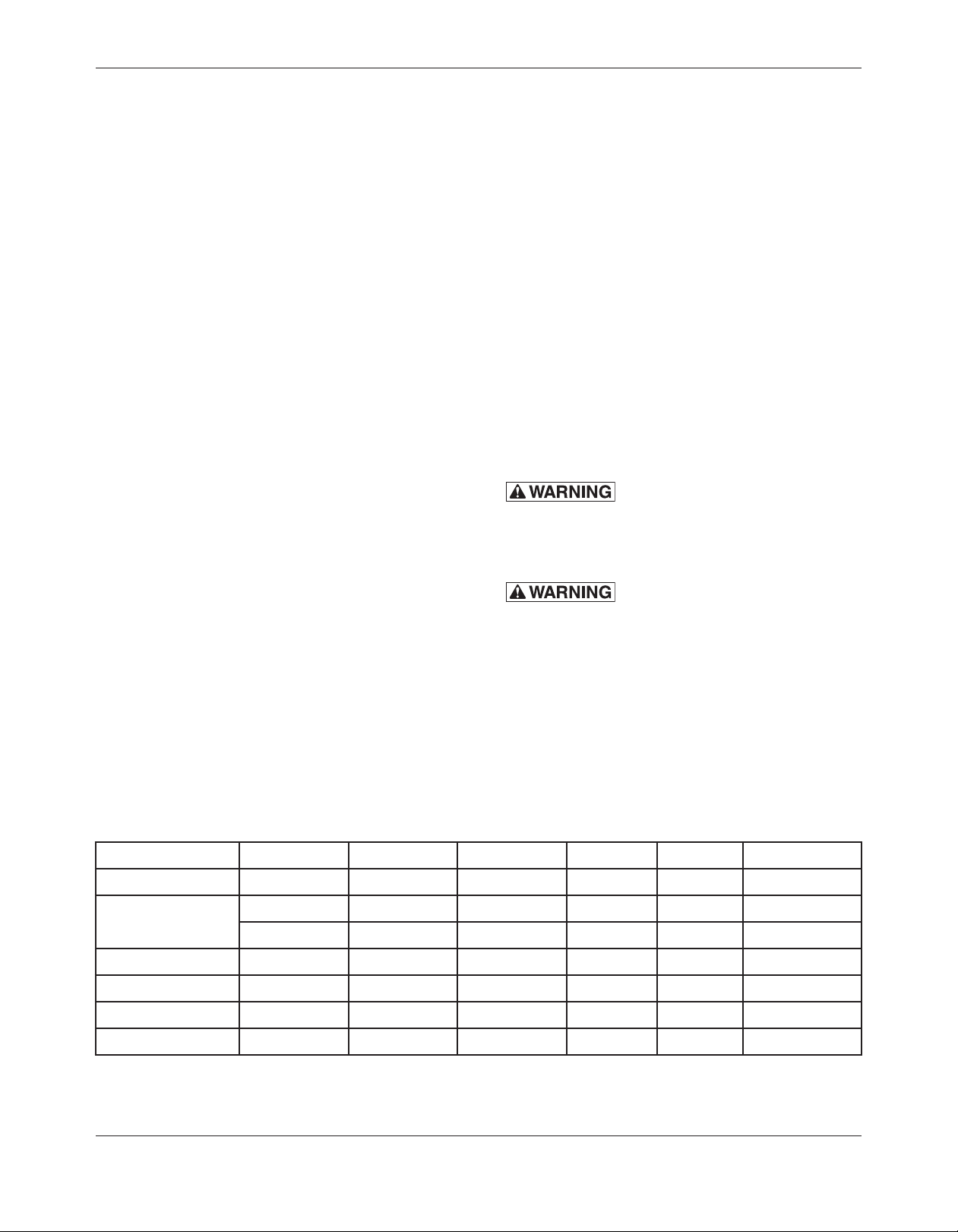

MODEL VOLTS AMPS WATTS HERTZ PHASE PLUG

742HW 208/240 22/23 4730/5500 60 1 NEMA 14-30

744HW* 208/240 25/27 5250/7000 60 1 NEMA 14-30

208/240 15/17 3440/4000 60 1 NEMA 6-30

742HW-CT 208/240 8/9 1770/2000 60 1 NEMA 6-30

744HW-CT 208/240 15/17 3440/4000 60 1 NEMA 6-30

742HW-CT (6in) 208/240 8/9 1540/2040 60 1 NEMA 6-15

744HW-CT (6in) 208/240 15/17 3120/4080 60 1 NEMA 6-30

* Two (2) plugs required for this unit.

ELECTRICAL SPECIFICATIONS

INSTALLATION

— 10 —

OPERATION

STARTUP

: The oven cabinet and hot

wells are hot. Use care when operating,

cleaning or servicing this equipment.

Once the cabinet is installed and electrical

connections have been made, thoroughly test the

Thermodyne cabinet before operation.

1. Check that all packing materials and other

items have been removed from the cabinet.

2. Press the Power ON/OFF Switches to the ON

position. The operating temperature will be

reached in approximately 30 minutes.

3. Check ADD FLUID Light.

• OVENCONTROL:Ifthelightremainson

or flickers continuously, it indicates that

some fluid was lost during shipment. Add

fluid as described in the section FLUID

REPLENISHMENT.

• HOT WELL CONTROL: Adjust knob to

desired temperature for each well. The

light remains illuminated until desired

temperature is reached. Knobs are labeled

1-10, with 10 being the hottest.

NOTE: The controller has an HEATER

INDICATOR (red lamp).This light blinks

as the controller maintains the desired

temperature.

Size, weight, pan loading, and product quality will

affect cooking times and should be adjusted to fit

the requirements of your operation.

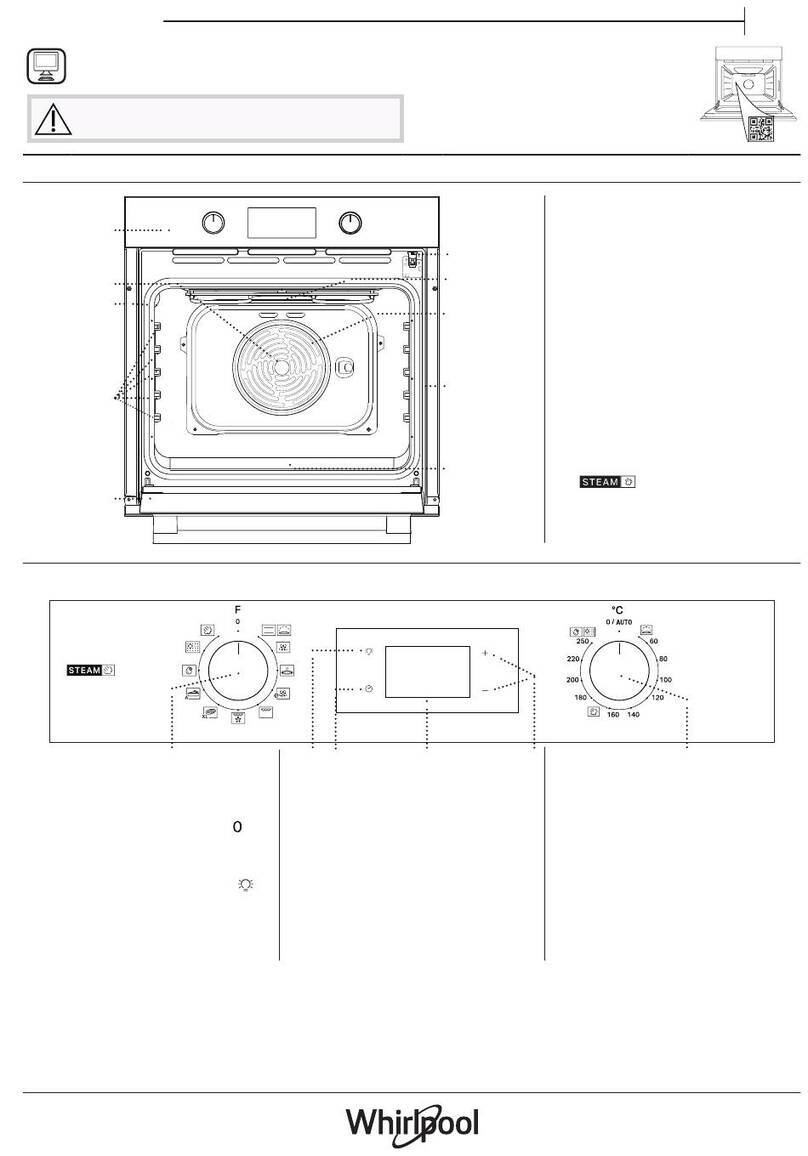

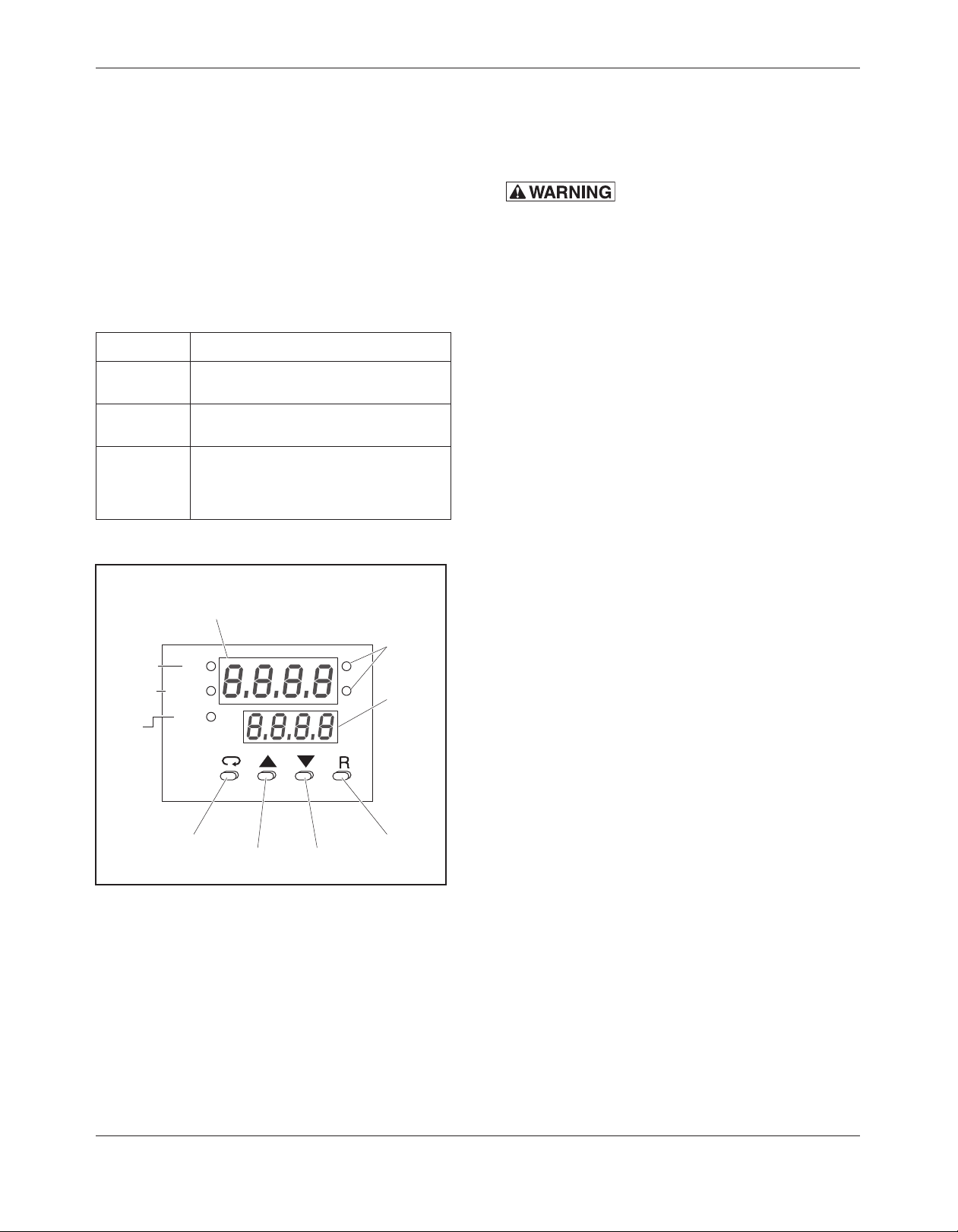

CONTROLS AND INDICATORS

All controls are located at the top right front of the

Thermodyne cabinet:

• Thedigitalcontrolnearthecabinet’sright

side controls the oven.

• Controlknobsareusedtoadjust

temperatures for each well opening.

ITEM FUNCTION

ON/OFF

Switch

When lit, it indicates the unit is turned on.

ADD FLUID

Light (Red)

When lit, it indicates additional fluid is

required.

Cabinet

Controller

Provides readout of actual temperature

and desired temperature. It has increase

and decrease buttons for setting the

desired temperature.

Heater

Indicator

Process

Unit

Indicator

(Contop,

Fonbottom)

Lower

Display

To display

set point

value,

parameter

value,

control

output

value, etc.

Upper Display

To display process value,

menu symbol, error code, etc.

Scroll

Key

Output 2

Indicator

Alarm

Indicator

Up

Key

Down

Key

Return/Reset

Key

HEAT

OUTPUT 2

ALARM

°C

°F

Figure 6: Control Panel

— 11 —

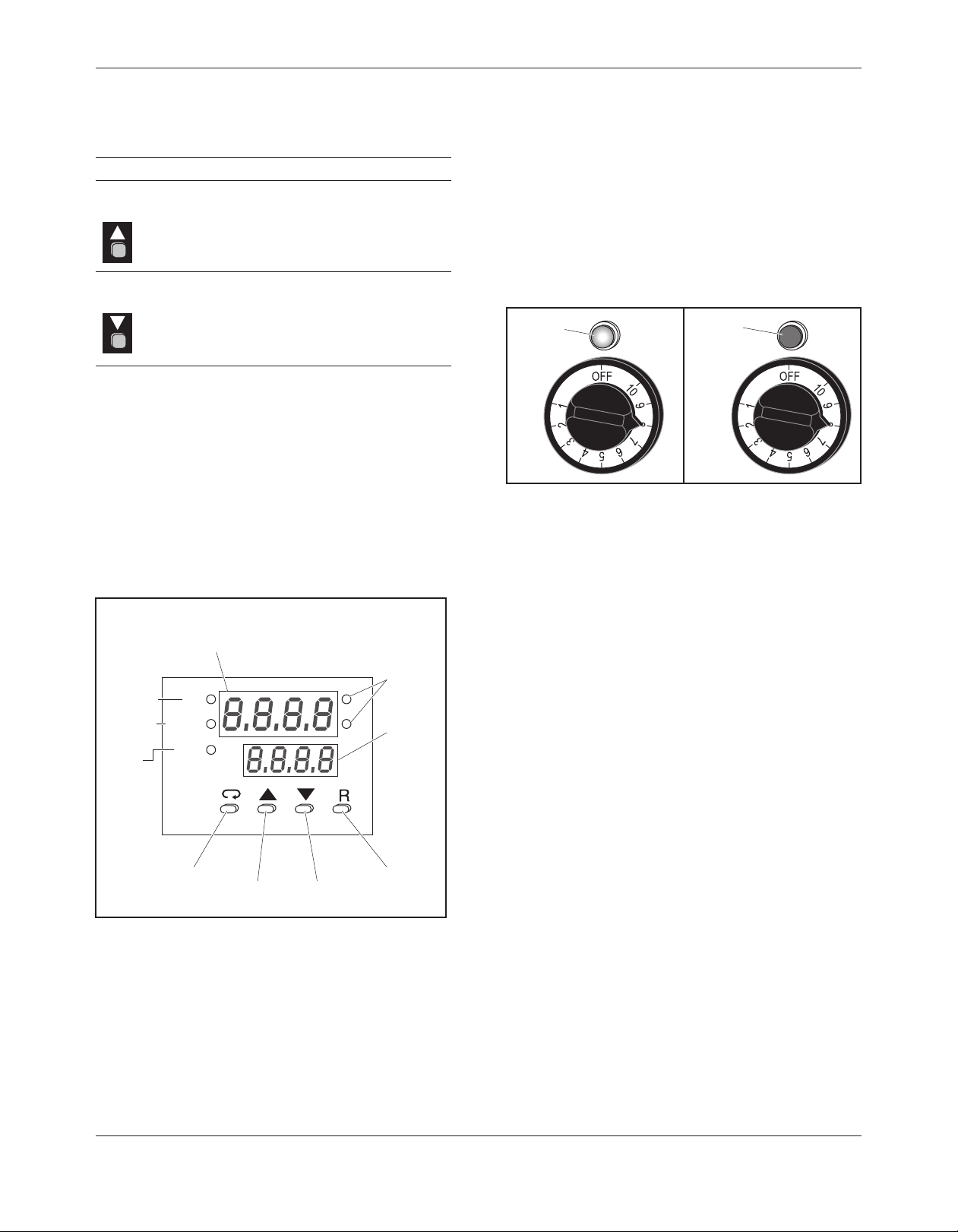

Setting Cabinet Temperature

1. To set temperature:

KEY FUNCTION

Up Press and release quickly to

Key increase the value of the

displayed parameter.

Press and hold to accelerate

increment speed.

Down Press and release quickly to

Key decrease the value of the

displayed parameter.

Press and hold to accelerate

decrement speed.

2. Heater Indicator light will illuminate while the

cabinet is warming up.

3. When the Heater Indicator light is blinking,

the cabinet has reached the desired/set

point temperature.

NOTE: The controller is not an indicator of fluid

level in the heater or reservoir tank.

Heater

Indicator

Process

Unit

Indicator

(Contop,

Fonbottom)

Lower

Display

To display

set point

value,

parameter

value,

control

output

value, etc.

Upper Display

To display process value,

menu symbol, error code, etc.

Scroll

Key

Output 2

Indicator

Alarm

Indicator

Up

Key

Down

Key

Return/Reset

Key

HEAT

OUTPUT 2

ALARM

°C

°F

Figure 7: Control Panel Functions

Setting Well Temperature

Each well can be set to its own temperature on a

1-10 scale, with 10 being the hottest setting. The

light is illuminated while the well is heating, however

it will turn off once set temperature is reached.

NOTE: The wells in this unit are dry wells and

water should not be added for heating.

Well is

heating

Set

temperature

is reached

Figure 8: Well Temperature Light

Preheating

Preheat the Thermodyne cabinet when first used

for the day or whenever the unit is cold.Preheating

takes approximately 30 minutes at which time the

temperature set point and the actual temperature

will display the same temperature. If the cabinet

has door(s), keep the doors closed during the

preheat cycle.

— 12 —

FLUID REPLENISHMENT

CAUTION: Use only supplied Thermodyne

Heat Transfer Fluid.

: Disconnect the electrical

power to the hot well and perform

LOCKOUT/TAGOUT procedure.

CAUTION: The cabinet and the hot well may

be hot, allow them to cool before beginning

this procedure.

1. Move the Hot Well power ON/OFF switch to

its OFF position. DO NOT turn the oven off.

2. Using the handle, raise the hot well to gain

access to the power head.

3. Place the safety catch in its holder.

Safety

Catch

Figure 9: Hot Well in Raised Position

4. Remove the reservoir tank cap.

Reservoir

Tank

Observe ADD FLUID light.

Reservoir

Tank Cap

Figure 10: Reservoir Tank Replenishment

5. Fill reservoir tank until oven controller ADD

FLUID light turns off.

6. Re-install the reservoir tank cap and fill cap

cover.

NOTE: If the ADD FLUID Light remains on after

theThermodyne unit has been filled, refer

to TROUBLESHOOTING.

— 13 —

CLEANING AND MAINTENANCE

ELECTRICAL LOCKOUT/TAGOUT

PROCEDURE

: Before performing any

cleaning or maintenance that involves

electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/

TAGOUT Procedure. Disconnect all circuits.

Failure to comply can cause property

damage, injury or death.

The Electrical LOCKOUT/TAGOUT Procedure is

used to protect personnel working on an electrical

appliance. Before performing any maintenance

or service that requires exposure to electrical

components, follow these steps:

1. In electrical box, place appliance circuit breaker

into OFF position.

2. Place a lock or other device on electrical box

cover to prevent someone from placing circuit

breaker ON.

3. Place a tag on electrical box cover to indicate

that appliance has been disconnected for

service and power should not be restored until

tag is removed by maintenance personnel.

4. Disconnect appliance power cord from

electrical outlet.

5. Place a tag on the cord to indicate that unit

has been disconnected for service and power

should not be restored until tag is removed by

maintenance personnel.

WHEN TO CLEAN

It is recommended that all stainless steel

equipment be cleaned on a regular basis. Any

piece of stainless steel equipment that is soiled

should be cleaned daily to ensure the long life of

the equipment. Routine cleaning will also lessen

stainless steel abrasion.

STAINLESS STEEL CARE

Cleaning

Stainless steel contains 70-80% iron, which will

rust if not properly maintained. It also contains 12-

30% chromium, which forms an invisible passive,

protective film that shields against corrosion.If the

film remains intact, the stainless steel will remain

intact.However, if the film is damaged, the stainless

steel can break down and rust.To prevent stainless

steel breakdown, follow these steps:

CAUTION: Never use any metal tools.

Scrapers, files, wire brushes or scouring

pads (except for stainless steel scouring

pads) will mar the surface.

CAUTION: Never use steel wool, which will

leave behind particles that rust.

CAUTION: Never use acid-based or chloride-

containing cleaning solutions, which will

break down the protective film.

CAUTION: Never rub in a circular motion.

CAUTION: Never leave any food products or

salt on the surface. Many foods are acidic.

Salt contains chloride.

For routine cleaning, use warm water, mild soap

or detergent and a sponge or soft cloth.

For heavy-duty cleaning, use warm water, a

degreaser and a plastic, stainless steel or Scotch-

Brite pad.

Always rinse thoroughly. Always rub gently in the

direction of the steel grain.

NOTE: Thermodyne recommends covering the

plates in the hot well area with tin foil to

help minimize cleaning. (Hot well area

only, not the interior shelves.)

Preserving & Restoring

Special stainless steel polishing cleaners can

preserve and restore the protective film.

Preserve the life of stainless steel with a regular

application of a high quality stainless steel polishing

cleaner as a final step to daily cleaning.

— 14 —

If signs of breakdown appear, restore the stainless

steel surface. First, thoroughly clean, rinse and

dry the surface. Then, on a daily basis, apply a

high-quality stainless steel polish according to

manufacturer’sinstructions.

Heat Tint

Darkened areas, called heat tint, may appear on

stainless steel exposed to excessive heat, which

causes the protective film to thicken. It is unsightly

but is not a sign of permanent damage.

To remove heat tint, follow the routine cleaning

procedure. Stubborn heat tint will require heavy-

duty cleaning.

To reduce heat tint, limit the exposure of equipment

to excessive heat.

CLEANING HEAT TRANSFER PLATES

The Thermodyne unit operates on the principle

of conduction, rather than convection. Therefore,

it is very important to keep the heat transfer

shelves clean, so heat transfer may take place with

maximum efficiency. It is also very important to

keep the bottom contact surfaces of pots and pans

as clean as possible to ensure even and complete

heat transfer. The surface and flat coating of the

thermal heat transfer shelf is extremely hard, but

will react with strong caustic cleaning solutions

and deteriorate.

CAUTION: Most concentrated soaps and

ammonia cleaners are too caustic to be

used on the Thermodyne unit.

If the coating is destroyed, the heat transfer shelves

will lose their non-stick properties and their surface

hardness.

The cleaners should always be used at the

recommended concentrations. In the case of dry

powders, the powders must not be placed directly

on the surface of the heat transfer plate. Care

must be taken not to scratch the shelf surfaces

when using brushes or pads. If harsh scouring is

needed, use a nylon type scouring pad. NEVER

use steel wool.

It is recommended that a weekly cleaning schedule

be followed to avoid the buildup of heavy food

product deposits. In the event heavy deposits

occur that are difficult to remove with ordinary

cleaning procedures, stronger chemical cleaning

agents may be applied if the products are intended

for food service use and are also compatible with

hard coat anodized aluminum surfaces. When

using these stronger solvents, it is very important

that heat transfer shelves are rinsed thoroughly

with clean potable water after cleaning. Be sure to

remove all traces of the cleaning agent. Between

the regular scheduled cleaning, wipe off the

anodized aluminum surfaces periodically with a

clean damp cloth.

CLEANING DOOR GASKETS

Cleanthe gasket-sealing surfaceof theThermodyne

doors to remove food product acids for maximum

gasket life. Do not use any solvents or sharp

instruments as these will damage the gasket.

Wash with a cloth moistened in a solution of mild

detergent and warm water. Rinse with a fresh cloth

moistened with warm water to remove all traces of

detergent.Wipe dry with a clean cloth. Never apply

food product oils or petroleum lubricants directly

to the door gasket as these will reduce gasket life.

CHANGING FLUID

NOTICE:TheThermodyne HeatTransfer Fluid has

lubricating additives, anticorrosion additives, and

heat transfer properties that may decrease with

the passing of time. Thermodyne Heat Transfer

Fluid will protect the unit indefinitely if the fluid is

changed on an annual basis.

CAUTION:The following procedure is to be

performed by a qualified service technician only.

: Before removing any sheet

metal panels or servicing this equipment,

always perform the Electrical LOCKOUT/

TAGOUT Procedure. Be sure all circuits are

disconnected. Failure to comply with this

procedure can cause property damage,

injury or death.

1. Move Power ON/OFF switches to the OFF

position and perform LOCKOUT/TAGOUT

procedures.

— 15 —

2. Allow the unit to cool completely.

3. Using the overhang of the well section, raise

the hot well unit to its up position.

4. Place the safety catch in its holder.

Safety

Catch

Figure 11: Hot Well in Raised Position

5. Locate heater tank and remove cap.

Heater

Tank

Heater

Tank Cap

Figure 12: Heater Tank and Cap

6. Remove left side panel to gain access to drain

valve.

7. Place a pan or bucket beside drain plug in

order to catch drained fluid.

Return

Manifold

Drain

Hose

Drain

Valve

Figure 13: Drain Hose

8. Place drain hose into pan or bucket and turn

valve to open position.

9. Once unit has drained completely turn valve

to off position and tuck drain hose back into

cabinet.

10. Reattach the left side panel.

11. Refill the unit with Thermodyne Heat Transfer

Fluid only.Never substitute with water or other

liquids.

12. Reattach the heater tank cap.

13. Restore power to the unit and place the Power

ON/OFF switch in its ON position.

NOTE: Unit may run briefly and shut off due to

low fluid level.

14. Remove reservoir cap and heater tank cap

and fill heater tank.

Heater

Tank

Heater

Tank Cap

Figure 14: Heater Tank Cap & Reservoir Cap

— 16 —

15. Repeat steps 12-14 until unit is completely full

of fluid.

16. Once unit is completely filled, reattach the

heater tank cap and the powerhead lid.

NOTE: If ADD FLUID light is on, add fluid to

reservoir tank until light goes out.

17. Allow the unit to heat until set temperature is

reached.

18. Once set temperature is reached, place the

power switch in the OFF position and let the

unit cool down to at least 100°F.

19. Turn unit back on, and if ADD FLUID light is

on again, add fluid to reservoir tank until light

goes out.

NOTE: Steps 17-19 are very critical in order to

purge any trapped air from the unit.

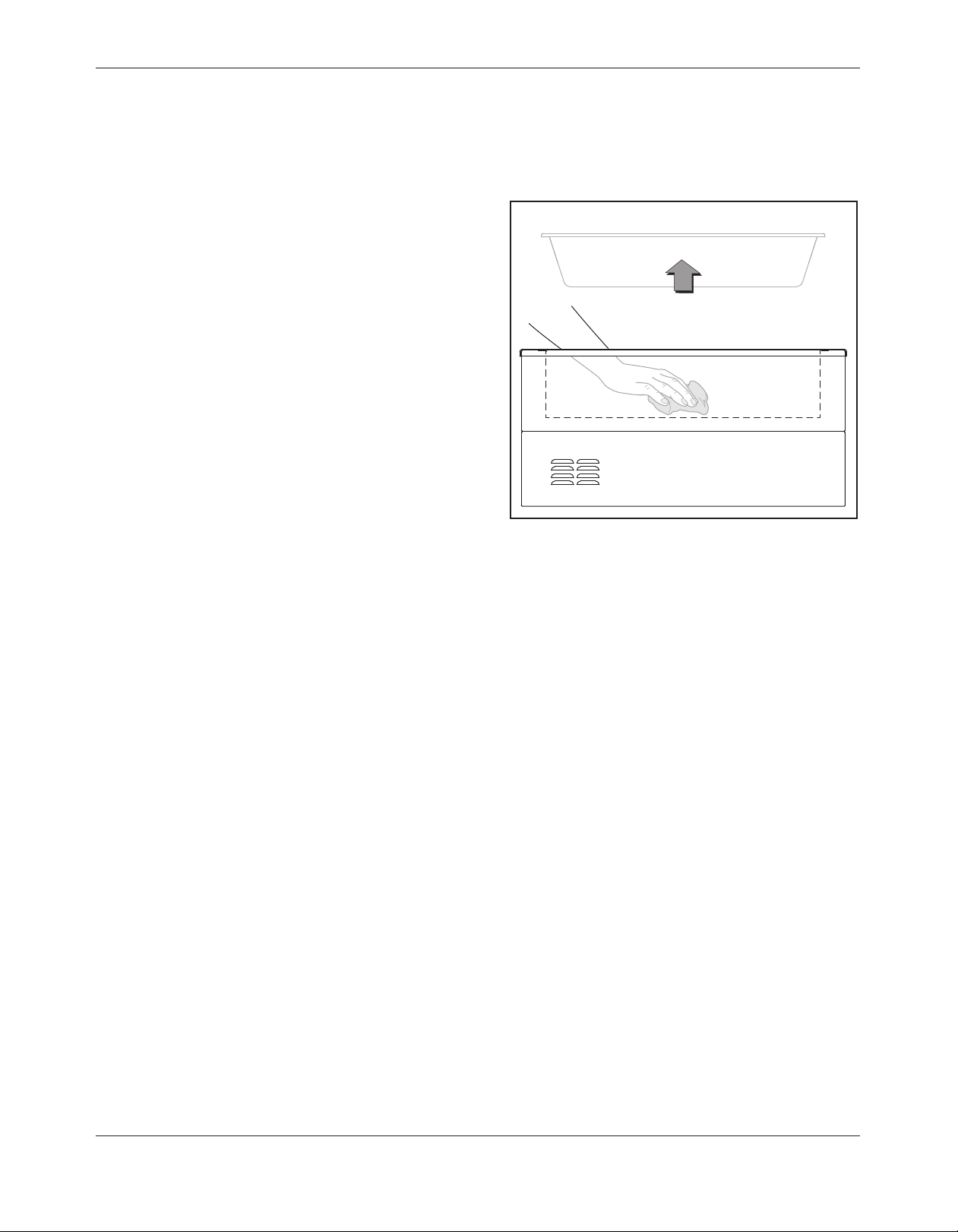

CLEANING THE DRY WELL

With the wells empty, wipe any debris or loose

food from dry well section with rag. (Be Careful,

well section can still be hot).

Holding Pan

Figure 15: Cleaning the Dry Well

— 17 —

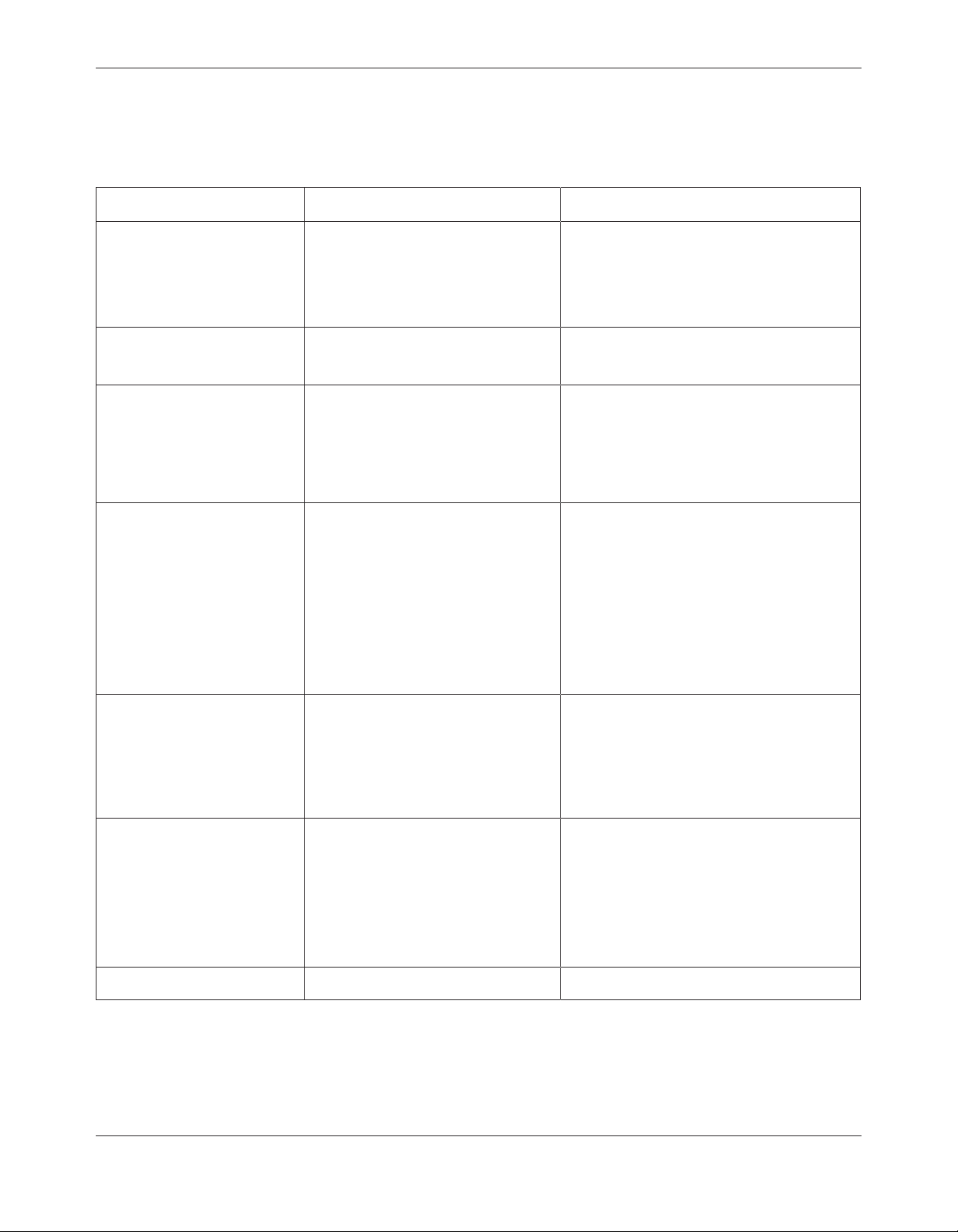

TROUBLESHOOTING

Most problems associated with the holding cabinet are due to low fluid level.

Always check fluid level first.

PROBLEM POSSIBLE CAUSE SOLUTION

No Power

1.Main power switch off.

2.Not plugged in.

3.Breaker off or tripped.

4.Bad contactor.

1.Turn switch on.

2.Check plug.

3.Check breaker.

4.Replace contactor.

LOW FLUID light is on –

Oven heating properly

1.Oven is low on fluid. 1.Add Thermodyne Heat Transfer Fluid

per instructions.

LOW FLUID light is on –

Oven not heating properly

1.Oven disabled due to low fluid

level cut out.

2.Fluid level probe defective.

3.System leak.

1.Main heater tanks low on fluid. Add

Thermodyne Heat Transfer Fluid and

determine cause of fluid loss.

2.Repair or replace.*

3.Repair leak.*

Heater(s) not working

1.Unit not properly wired.

2.Bad heater(s).

3.Contactor or solid state relays

not working.

4.Off due to low fluid cut out.

5.Failed temperature controller.

6.High limit snap disc tripped.

1.Check wiring.*

2.Replace heater(s).*

3.Repair or replace.*

4.Add Thermodyne Heat Transfer Fluid

per instructions.

5.Replace temperature controller.*

6.Reset snap disc and check for cause.*

Shelves hotter than

set point

1.Temperature controller out of

calibration.

2.Thermocouple defective.

3.Solid state relay(s) stuck on.

4.Failed temperature controller.

1.Recalibrate temperature controller.*

2.Replace thermocouple.*

3.Replace solid state relay(s).*

4.Replace temperature controller.*

Shelves colder than

set point

1.Low fluid in tank. (LOW FLUID

light should be lit)

2.Failed temperature controller.

3.Heater(s) not working.

4.Pump failure.

5.Thermocouple failure.

1.Add Thermodyne Heat Transfer Fluid

per instructions.

2.Replace temperature controller.*

3.See “Heater(s) not working”.

4.Repair or replace pump.

5.Replace thermocouple.

Oven heats up too slow 1.Heater(s) not working. 1.See “Heater(s) not working”.

*Recommended service to be done by a qualified service agency.

NOTE: Most problems associated with the Thermodyne cabinet are due to failure to add Thermodyne

Heat Transfer Fluid. Check fluid level first. In the event service is required on your Thermodyne

cabinet, please call: (800) 526-9182.

— 18 —

SCHEMATIC WIRING DIAGRAM

— 19 —

WARRANTY

Thermodyne Foodservice Products, Inc.

warrants to the original purchaser for use of

each new Thermodyne Conductive Cooking/

Holding Oven the following: Any part which

proves to be defective in materials or

workmanship within the warranty period

will, subject to the terms of this warranty,

be repaired or replaced at Thermodyne

Foodservice,Inc.’soption.Claimsunderthis

warranty must be presented to Thermodyne

Foodservice Products, Inc. in writing, promptly.

Thermodyne stainless steel cabinets are

warranted for 5 years and all other original

equipment parts such as heat transfer plates,

doors, casters, fluid system components and

electrical components are warranted against

defect for 2 years from the date of purchase.

This warranty applies only to Thermodyne

Conductive Cooking/Holding Ovens in the

Continental United States. This warranty shall

not apply if the oven or any part is subjected to

accident, casualty, alteration, misuse, abuse,

neglect, faulty installation, or if the date of

manufacture is altered or removed.

The obligation of Thermodyne Foodservice

Products, Inc. is limited specifically to the

aforementioned. No additional guarantees

or warranty, expressed or implied, to include

without limitation warranties of Fitness or

Merchantability with respect to Thermodyne

Conduction Ovens and Thermodyne

Foodservice Products, Inc. regarding other

liability with respect thereto including, without

limitation, liability for incidental, special, or

consequential damages.

RESPONSIBILITIES OF PURCHASER

It is the responsibility of the purchaser to:

1. Arrange on site electrical services

in accordance with Thermodyne

specifications.

2. Receive shipment of Thermodyne

conduction oven to include unloading,

uncrating, inspecting for damage in

shipment, and installation of the oven in

its proper location; in accordance with

installation instructions.

3. Arrange that the electric services are

connected properly by a qualified

technician. All such connections must

be in accordance with applicable code

requirements and Thermodyne installation

procedures.

Please note the specific details on the Warranty

and make certain that service connections

are made to the proper utility services. This

warranty and purchasers responsibility

information should be retained for future

reference.

For assistance please call:

Toll Free: (800) 526-9182

Local: (260) 428-2535

HEAT TRANSFER FLUID MSDS

Dow Chemical U.S.A.

Midland, MI 48674

Emergency Phone: 517-636-4400

Product Code: 23545

Product Name: PROPYLENE GLYCOL

HEAT TRANSFER FLUID

Effective Date: 03-02-88

Date Printed: 06/02/88

MSDS: 000130

1. INGREDIENTS:

Propylene glycol CAS# 000057-55-6

95%

Dipotassium phosphate CAS# 007758-

11-4 <5%

Deionized water CAS# 007732-18-5 <5%

This documentis prepared pursuant tothe

OSHA Hazard Communication Standard

(29CFR 1910.1200). In addition, other

substances not ‘Hazardous’ per this

OSHA Standard may be listed. Where

proprietary ingredient shows, the identity

may be made available as provided in

this standard.

2. PHYSICAL DATA:

BOILING POINT: 370F, 188C

VAP. PRESS: 0.22 mmHg @ 20C, 68F

VAP. DENSITY: 2.62

SOL. IN WATER; Complete

SP. Gravity: 1,050 @ 60/60F, 16C

APPEARANCE: Colorless.

ODOR: Odorless liquid.

3. FIRE AND EXPLOSION HAZARD DATA:

FLASH POINT: 215F, 102C

METHOD USED: COC

FLAMMABLE LIMITS

LFL: 2.6% @ 100C

UFL: 12.5% @ 130C

EXTINGUISHING MEDIA: Water fog,

alcohol foam, dry chemical

FIRE AND EXPLOSION HAZARDS:

None.

FIRE-FIGHTING EQUIPMENT: None.

4. REACTIVITY DATA:

STABILITY: (CONDITIONS TO AVOID)

Stable over normal

Operating temperature range of –30F

to 250F.

INCOMPATIBILITY: (SPECIFIC

MATERIALS TO AVOID)

Oxidizing material.

HAZARDOUS DECOMPOSITION

PRODUCTS: None

HAZARDOUS POLYMERIZATION: Will

not occur,

5. ENVIROMENTAL AND DISPOSAL

INFORMATION:

ACTIONTOTAKE FOR SPILLS/LEAKS:

Cover with absorbent material, soak up

and sweep into bag.

6. HEALTH HAZARD DATA:

EYE: May cause slight transient eye

irritation. Corneal injury is unlikely.

SKIN CONTACT:Essentially nonirritating

to skin on prolonged contact.

SKIN ABSORPTION:A single prolonged

skin exposure is not likely to result in

absorption of harmful amounts. The

LD50 for skin absorption in rabbits is

>10,000 mg/kg.

Repeated exposures may cause slight

flaking, tenderness and softening of skin.

INGESTION: Single does oral toxicity is

low. The LD50 for female rats is about

20.3 g/kg

INHALATION:A single prolonged (hours)

inhalation exposure is not likely to cause

adverse side effects. Mists are not to be

hazardous.

SYSTEMIC & OTHER EFFECTS:

Repeated excessive ingestion may

cause central nervous system effects.

No carcinogenic effects have been

seen in long-term animal studies. Birth

defects are unlikely. Exposures having

no adverse effects on the mother

should have no effect on the fetus. In

animal studies, has been shown not to

interfere with reproduction. Results of

mutagenicity tests in vitro (test tube) and

in animals have been negative.

7. FIRST AID

EYES: Irrigate immediately with water

for at least 5 minutes.

SKIN:wash off in flowing water or shower

INGESTION: Induce vomiting if large

amounts are ingested, consult medical

INHALATION: Remove to fresh air if

effects occur. Consult medical.

NOTE TO PHYSICIAN: No specific

antidote. Supportive care. Treatment

based on judgment of the physician in

response to reactions of the patient.

8. HANDLING PRECAUTIONS:

EXPOSURE GUIDELINE (S): Dow IHG

is 10mg/m3 for propylene glycol mist.

Dow IHG 440 ppm for propylene glycol

vapors.

VENTILATION;Good general ventilation

sufficient.

RESPIRATORY PROTECTION: No

respiratory protection should be needed.

SKIN PROTECTION: No precautions

other than clean body covering should

be needed.

EYE PROTECTION:Use safety glasses.

9. ADDITIONAL INFORMATION:

REGULATORY REQUIREMENTS:

SARA HAZARD CATEGORY: This

product has been reviewed according

to the EPA ‘Hazard Categories’

promulgated under Section 311 and

312 of the Superfund Amendment and

Reauthorization Act of 1986 (SARA

Title III) and is considered, under

applicable definitions, to meet the

following categories:A delayed hazard.

SPECIALPRECAUTIONSTOBETAKEN

IN HANDLING AND STORAGE:Exercise

reasonable care and caution.

MSDS STATUS: Revised Section 9

— 20 —

This manual suits for next models

3

Table of contents

Other THERMODYNE Oven manuals