THERMODYNE 125OC User manual

INSTALLATION &

OPERATION MANUAL

Rev. A (03-19)

For additional information on Thermodyne Foodservice Products, Inc.,

or to locate an authorized parts and service provider in your area,

visit our website at www.tdyne.com.

Thermodyne Foodservice Products, Inc.

4418 New Haven Avenue 1-800-526-9182

Fort Wayne, IN 46803 www.tdyne.com

ADD FLUID

ADD FLUID

ADD FLUID

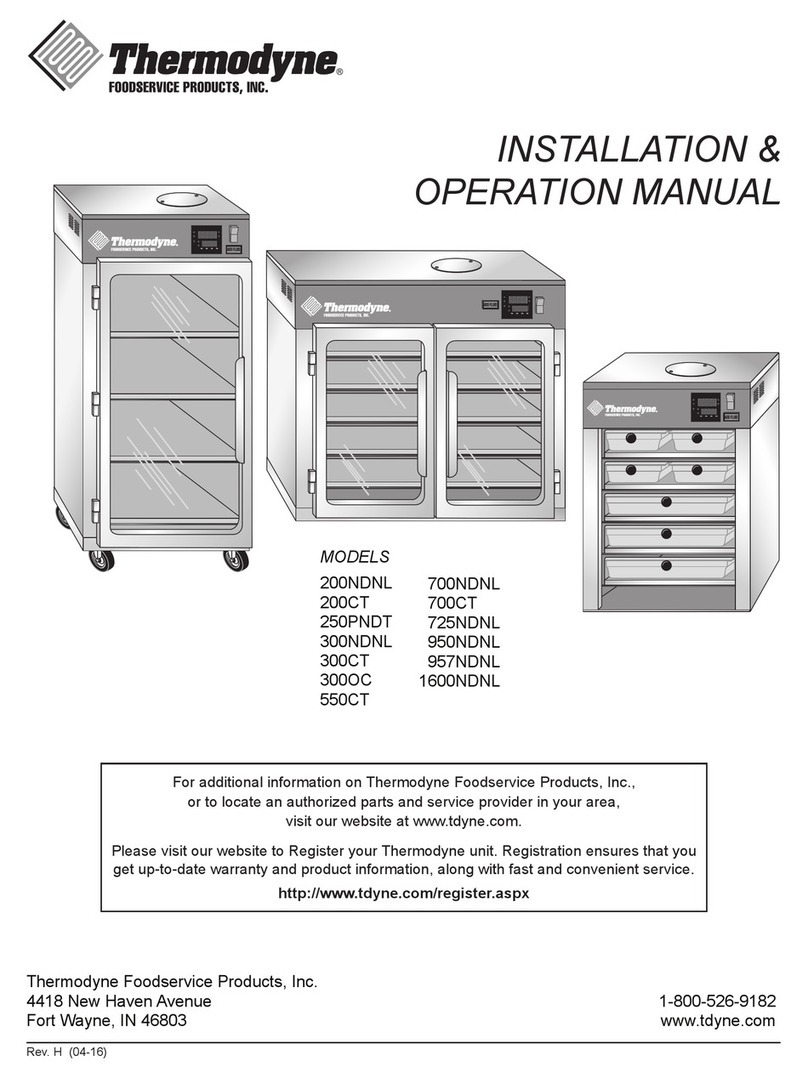

MODELS

125OC

200NDNL

200CT

250PNDT

300NDNL

300CT

300OC

550CT

700NDNL

700CT

725NDNL

950NDNL

957NDNL

1600NDNL

— 2 —

IMPORTANT FOR YOUR SAFETY

WARNING

IMPROPERINSTALLATION,ADJUSTMENT,ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING

OR SERVICING THIS EQUIPMENT. SERVICE

WORK SHOULD BE PERFORMED BY A LICENSED

PROFESSIONAL,QUALIFIEDTOSERVICEANDREPAIR

ELECTRIC FOOD SERVICE EQUIPMENT.

IN THE EVENT OF A POWER FAILURE,

DO NOT ATTEMPT TO OPERATE THIS DEVICE.

CAUTION

Models 200 CT, 300 CT, and 700 CT have glass doors.

Remove carton carefully.

— 3 —

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY...................................................................................................2

INTRODUCTION...............................................................................................................................4

GENERAL....................................................................................................................................4

SPECIFICATIONS .......................................................................................................................4

UNPACKING..............................................................................................................................10

Thermodyne Damaged Goods Policy..................................................................................10

INSTALLATION CODES AND STANDARDS ............................................................................10

INSTALLATION..........................................................................................................................10

LOCATION.................................................................................................................................11

ELECTRICAL CONNECTION ...................................................................................................11

OPERATION....................................................................................................................................12

TEMPERATURE CONTROLLER SET UP PROCEDURES .................................................12

Keypad Operation................................................................................................................12

Set-Up..................................................................................................................................12

To Toggle Between °F and °C Readout ...............................................................................12

Preheating ...........................................................................................................................12

Extended Shutdown.............................................................................................................12

FLUID REPLENISHMENT.........................................................................................................13

PRODUCT PANS AND COVERS....................................................................................................14

GENERAL..................................................................................................................................14

Dry Pan Without Pan Screen...............................................................................................14

Dry Pan With Pan Screen....................................................................................................14

Wet Pan With Pan Screen...................................................................................................15

Pans With “V” Rack .............................................................................................................15

Removing Lids.....................................................................................................................16

CLEANING AND MAINTENANCE...................................................................................................17

WHEN TO CLEAN ...................................................................................................................17

HOW TO CLEAN......................................................................................................................17

Cleaning Safeguards ...........................................................................................................17

Sterilizing Stainless Steel ....................................................................................................17

Cleaning Heat Transfer Plates.............................................................................................17

Stainless Steel Cabinet........................................................................................................18

Door Gasket (CT Units) .......................................................................................................18

CHANGING FLUID....................................................................................................................18

TROUBLESHOOTING ....................................................................................................................20

SCHEMATIC DIAGRAM..................................................................................................................21

WARRANTY ....................................................................................................................................22

HEAT TRANSFER FLUID MSDS ....................................................................................................22

— 4 —

INTRODUCTION

GENERAL

Thermodyne cabinets are produced with quality

workmanship and materials. Proper installation,

operation and maintenance will result in many

years of satisfactory performance. It is suggested

that you thoroughly read this manual in its entirety

and carefully follow all of the instructions provided.

The cabinets described in this manual are

programmable for the desired holding temperature.

The factory setting is 185° F unless otherwise

specied. Each shelf in the cabinet maintains an

exact temperature, allowing for extended holding

times without sacricing appearance or taste.

MODEL

GALLONS LITERS PER SHELF

(OZ)

125OC 1.5 3.78 14

200NDNL 1.75 6.62 6

200CT 1.75 6.62 6

250OC 1.65 6.62 20

250PNDT 2.1 7.95 6

BW3 1.65 6.25 6

BW4 1.7 6.44 6

300NDNL 1.91 7.23 6

300CT 1.91 7.23 6

550CT 1.7 6.45 6

700NDNL 2.25 8.52 14

700CT 2.25 8.52 14

950NDNL 2.16 8.18 20

300OC 2.24 8.48 14

FLUID CAPACITIES (STANDARD SHELF CONFIGURATION)

MODEL

GALLONS LITERS PER SHELF

(OZ)

1200G 2.22 8.40 13

1200DW 2.3 8.71 14

1300G 2.32 8.78 13

1600NDNL 2.1 7.95 6

1900G 3.02 11.43 13

1900DW 3.06 11.58 14

2100DW 3.59 13.59 20

6000P 4.95 18.74 23.8

700DP 2.25 8.52 14

1500DP 3.01 11.39 14

742HW 2.45 9.27 14

744HW 3 11.36 28

1600HZ 2.5 9.46 Top-14;

Bottom-6

MODEL

DIMENSIONS AND MAXIMUM TEMPERATURE WEIGHT

Ext.

Width

inches

Ext.

Depth

inches

Ext.

Height

inches

Int.

Width

inches

Int.

Depth

inches

Int.

Height

inches

Max

Oper.

Temp °F

Max

Oper.

Temp °C

Net

Weight

lbs

Shipping

Weight

lbs

125OC 46.0 13.75 5.63 42.0 12.0 4.63 230 110 96 160

200NDNL 17.5 23.0 18.6 13.5 22.0 13.0 230 110 102 155

300NDNL 17.5 23.0 25.9 13.5 22.0 20.3 230 110 123 185

700NDNL 30.5 23.0 27.3 26.5 22.0 20.3 230 110 173 233

725NDNL 30.5 23.0 28.5 26.5 22.0 21.5 230 110 188 248

950NDNL 45.0 23.0 20.0 41.0 22.0 13.0 230 110 170 310

957NDNL 45.0 23.0 27.25 41.0 22.0 20.3 230 110 220 360

1600NDNL 17.5 33.0 61.8 13.5 22.0 49.6 230 110 241 405

200CT 17.5 24.8 20.0 13.5 22.0 13.0 230 110 103 160

300CT 17.5 24.8 27.3 13.5 22.0 20.3 230 110 126 190

550CT 17.5 24.8 41.4 13.5 22.0 29.4 230 110 190 230

700CT 30.5 24.8 27.3 26.5 22.0 20.3 230 110 189 265

300OC 59.0 13.5 14.6 55.0 12.5 9.0 230 110 160 235

250PNDT 21.3 20.0 33.3 17.3 19.0 27.6 230 110 168 203

— 5 —

FRONT VIEW SIDE VIEW PLAN VIEW

17 1/2"

Ext. Width

13"

Int.

Height

18 5/8"

Ext.

Height

1/8"

Base

13 1/2"

Int. Width

23"

Ext. Depth

2 1/8"

5 1/2"

P.H.

22"

Int. Depth

Thermodyne

Electrical

Front

1"

Cord & Plug

6 1/8"

10 1/2"

Figure 1. Outline Dimensional Drawing, 200NDNL

FRONT VIEW SIDE VIEW PLAN VIEW

17 1/2"

Ext. Width

13 1/2"

Int. Width

13"

Int.

Height

22"

Int. Depth

3 1/2"

Electrical

Front

1"

Cord & Plug

24 3/4"

Ext Depth

6 1/8"

10 1/2"

20"

Ext.

Height

Thermodyne

Figure 2. Outline Dimensional Drawing, 200CT

FRONT VIEW SIDE VIEW PLAN VIEW

17 1/2"

Ext. Width

20 1/4"

Int.

Height

25 7/8"

Ext.

Height

13 1/2"

Int. Width

1"

Front

Cord & Plug.

Thermodyne

23"

Ext. Depth

2 1/8"

10 1/2"

6 1/8"

5 1/2"

P.H.

1/8"

Base

22"

Int. Depth

Electrical

Figure 3. Outline Dimensional Drawing, 300NDNL

— 6 —

FRONT VIEW SIDE VIEW PLAN VIEW

17 1/2"

Ext. Width

20 1/4"

Int.

Height

27 1/4"

Ext.

Height

13 1/2"

Int. Width

1"

Front

Cord & Plug.

Thermodyne

24 3/4"

Ext. Depth

3 1/2"

10 1/2"

6 1/8"

22"

Int. Depth

Electrical

Figure 4. Outline Dimensional Drawing, 300CT

ADD FLUID

FRONT VIEW SIDE VIEW

59" Ext. Width

49 1/2"

17 1/2"

5 1/2"

Pan Covers 6 Pans Drip Pan

2 3/4"

3/4"

5 3/4"

7 5/8"

55" Int. Width 13 3/4"

Ext. Depth

12"

Int. Depth

5 5/8"

Ext. Heigth

4 5/8"

Int. Heigth

Ø3/8 × 60" SS

Flex Line

3 1/2"

25 7/8"

22"

Figure 5. Outline Dimensional Drawing, 125OC

FRONT VIEW

PLAN VIEW

SIDE VIEW

59" Ext. Width

9"

Int.

Height

14 5/8"

Ext.

Height

55" Int. Width

13 1/2"

Ext. Depth

12 1/2"

Int. Depth

Thermodyne

2 1/8"

Electrical

1"

Cord & Plug

6"

19"

Front

Figure 6. Outline Dimensional Drawing, 300OC

— 7 —

17 1/2"

13 1/2"

36 3/8" 29 3/8"

1 1/2"

5 1/2"

6"

10 3/8"

41 3/8"

24 3/4"

EXTERIOR WIDTH

INTERIOR WIDTH

INTERIOR

HEIGHT

EXTERIOR

HEIGHT

POWER HEAD

BASE

22"

INTERIOR DEPTH

EXTERIOR DEPTH

ELECTRICAL

ELECTRICAL

FRONT VIEW SIDE VIEW PLAN VIEW

Front

Figure 7. Outline Dimensional Drawing, 550CT

FRONT VIEW SIDE VIEW PLAN VIEW

20 1/4"

Int.

Height

30 1/2"

Ext. Width

27 14"

Ext.

Height

26 1/2"

Int. Width

Thermodyne

23"

Ext. Depth

2 1/8"

5 1/2"

P.H.

1 1/2"

Base

22"

Int. Depth

Electrical

1"

Front

Cord & Plug.

11 5/8"

11

1/2"

Figure 8. Outline Dimensional Drawing, 700NDNL

FRONT VIEW SIDE VIEW PLAN VIEW

20 1/4"

Int.

Height

30 1/2"

Ext. Width

27 1/4"

Ext.

Height

26 1/2"

Int. Width

Thermodyne

24 3/4"

Ext. Depth

3 1/2"

22"

Int. Depth

Electrical

1"

Front

Cord & Plug.

11 5/8"

11

1/2"

Figure 9. Outline Dimensional Drawing, 700CT

— 8 —

1"

Cord &

Plug

11

1/2"

Refill

11

5/8"

Refill

3 1/2"

Electrical

1 1/2"

Base

5 1/2"

P.H.

23"

Ext. Depth

22"

Int. Depth

30 1/2"

Ext. Width

28 1/2"

Ext. Height

21 1/2"

Int. Height

26 1/2"

Int. Width

FRONT VIEW SIDE VIEW PLAN VIEW

Thermodyne

Figure 10. Outline Dimensional Drawing, 725NDNL

FRONT VIEW SIDE VIEW PLAN VIEW

45" Ext. Width

41" Int. Width

2 1/2"

Cord &

Plug

Thermodyne

23" Ext. Depth

22" Int. Depth

5 1/2"

13"

Int.

Height

20"

Ext.

Height

1 1/2"

Base

1"

Cord & Plug

11 5/8"

25 7/8"

Front

Figure 11. Outline Dimensional Drawing, 950NDNL

FRONT VIEW SIDE VIEW PLAN VIEW

45" Ext. Width

41" Int. Width

2 1/2"

Cord &

Plug

Thermodyne

23" Ext. Depth

22" Int. Depth

5 1/2"

P.H.

20 1/4"

Int.

Height

27 1/4"

Ext.

Height

1 1/2"

Base

1"

Cord & Plug

11 5/8"

26"

Front

Figure 12. Outline Dimensional Drawing, 957NDNL

— 9 —

FRONT VIEW SIDE VIEW PLAN VIEW

1"

10"

Work

Area

Cord & Plug

20 1/4"

Upper

Int.

Height

29 3/8"

Lower

Int.

Height

17 1/2"

Ext. Width

61 3/4"

Ext.

Height

13 1/2"

Int. Width

Thermodyne

22"

Lower

Int. Depth

1/8"

Base

1

1/2"

Base

33"

Ext. Depth

5 12"

P.H.

22"

Int. Depth

Electrical

Front

6

1/8"

Figure 13. Outline Dimensional Drawing, 1600NDNL

FRONT VIEW SIDE VIEW PLAN VIEW

21 1/4"

Ext. Width

27 5/8"

Int.

Height

1/8"

Base

17 1/4"

Int. Width

20"

Ext. Depth

2 1/8"

5 1/2"

P.H.

19"

Int. Depth

Thermodyne

Electrical

Front

33 1/4"

Int.

Height

8 3/4"

3 7/8"

1 1/8"

Electrical

Figure 14. Outline Dimensional Drawing, 250PNDT

— 10 —

UNPACKING

NOTE: All Thermodyne cabinets are factory tested

for performance and certied free from

defects.

Thermodyne Damaged Goods Policy

There are two types of damaged merchandise:

A.Visible Damage and B. Concealed Damage.

A. Visible Damage: The product being received

is visibly damaged.

1. The receiver should refuse the damaged

merchandise.

2. Receiver should sign the bill of lading indicating

which merchandise is being refused due to

damage.

3. Contact Thermodyne Customer Service

Representatives immediately.

B. Concealed Damage: Damaged merchandise

cannot be externally detected.

Your receiving operation should inspect for this type

of damage. Please inspect your delivery carefully.

If the product is damaged:

1. Save all packing material.

2. Contact Thermodyne Customer Service

Representatives immediately.

3. Receiver must call the carrier to schedule an

inspection of the damaged merchandise within

5 business days.

INSTALLATION CODES

AND STANDARDS

In the United States, the Thermodyne cabinet

must be installed in accordance with:

1. State and local codes.

2. National Electrical Code (ANSI/NFPA No. 70,

latest edition) available from the National Fire

Protection Association, Batterymarch Park,

Quincy, MA 02269.

In Canada, the cabinet must be installed in

accordance with:

1. Local codes.

2. Canadian Electrical Code (CSA C22.2 No. 3,

latest edition) available from the Canadian

Standards Association, 5060 Spectrum Way,

Mississauga, Ontario, Canada L4W 5N6.

INSTALLATION

Before installing, verify the required electrical

supply agrees with the specications on the data

plate located on the back or side of the unit. If

the supply and equipment requirements do not

agree, do not proceed with installation. Contact

your dealer or Thermodyne Foodservice Products,

Inc. immediately.

CAUTION

Models 200CT, 300CT, 550CT and 700CT

have glass doors. Remove carton carefully.

CAUTION

Packaging may have sharp edges and

banding; leather work gloves and safety

glasses are recommended for safe

unpacking.

1. Allow ample overhead clearance for removal

of carton.

2. Cut banding (2 pieces) and remove nails (not

for all units).

3. To remove cabinet from carton, slide carton

up and o the cabinet.

4. Check packing list against items received:

A. Thermodyne Heat Transfer Fluid.

B. Installation & Operation Manual

5. Use proper lifting equipment to raise the

cabinet.

6. Remove the plastic covering from glass door

frames and hinges. Mount doors on cabinet,

then check doors for alignment (on certain

models).

7. Set cabinet on a level surface.

— 11 —

LOCATION

Allow adequate space for electrical connections.

The electrical cord and plug are located at the right

rear of the unit. The minimum clearance for proper

air circulation on back should be 4", and 2" on at

least one side. Allow adequate access space for

operating and servicing the unit.

NOTICE; Louvers on the sides of the oven

are used to circulate cool air throughout the

electrical components. The unit must not be

placed where extensive airborne grease is

present, such as near deep fryers or griddles.

ELECTRICAL CONNECTION

WARNING

ELECTRICAL AND GROUNDING

CONNECTIONS MUST COMPLY WITH

APPLICABLE PORTIONS OF THE

NATIONAL ELECTRICAL CODE AND/OR

OTHER LOCAL ELECTRICAL CODES.

WARNING

DISCONNECT THE ELECTRICAL POWER

TO THE THERMODYNE UNIT

AND FOLLOW LOCKOUT/TAGOUT

PROCEDURES.

Refer to the wiring diagrams in this manual for

wiring information.

MODEL VOLTS HERTZ PHASE WATTS AMPS PLUG TYPE US PLUG TYPE CAN

200NDNL 120 60 1 1750 15 NEMA 5-15P NEMA 5-20P

300NDNL 120 60 1 1750 15 NEMA 5-15P NEMA 5-20P

700NDNL 208/240 60 1 5250/7000 25/29 NEMA L14-30 —

725NDNL 208/240 60 1 5250/7000 25/29 NEMA L14-30 —

950NDNL 208/240 60 1 5250/7000 25/29 NEMA L14-30 —

957NDNL 208/240 60 1 5250/7000 25/29 NEMA L14-30 —

1600NDNL 208/240 60 1 5250/7000 25/29 NEMA L14-30 —

200CT 120 60 1 1750 15 NEMA 5-15P NEMA 5-20P

300CT 120 60 1 1750 15 NEMA 5-15P NEMA 5-20P

550CT 120 60 1 1750 15 NEMA 5-15P NEMA 5-20P

700CT 208/240 60 1 5250/7000 25/29 NEMA L14-30 —

300OC 120 60 1 1750 15 NEMA 5-15P NEMA 5-20P

250PNDT 208/240 60 1 5250/7000 25/29 NEMA L14-30 —

— 12 —

OPERATION

TEMPERATURE CONTROLLER

SET UP PROCEDURES

Output 1

Indicator

Process

Unit

Indicator

(°C on top,

°F on bottom)

Lower

Display:

To display

set point

value,

parameter

value,

control

output

value, etc.

Upper Display:

To display process value,

menu symbol, error code, etc.

Scroll

Key

Output 2

Indicator

Alarm

Indicator

Manual

Mode

Indicator

Auto-Tuning

Indicator

Up

Key

Down

Key

Return/Reset

Key

Figure 15: Controller

Keypad Operation

Scroll Key:

This key is used to select a parameter to be viewed

or adjusted.

Up Key:

This key is used to increase the value of the

selected parameter.

Down Key:

This key is used to decrease the value of the

parameter.

Return / Reset Key: R

This key is used to:

1. Return the display to indicate the Process

Value (PV) and Set Value (SV).

2. Reset a Latching Alarm once the alarm

condition has cleared.

3. Discontinue Manual Control,Auto-Tuning and

Calibration Modes.

4. Clear error messages indicating

communication and auto-tuning errors.

5. Re-set the dwell timer function.

6. Enter the manual control menu if the sensor

has failed.

Set-Up

1. Press the “Up” and “Down” key as needed to

adjust the displayed set-point temperature.

2. The “OUT1” LED will be lit up solid during

warm up. (normal operation)

3. When the “OUT1” LED is blinking, the unit has

reached the desired temperature.

NOTE: This controller is not an indicator of uid

level in the Heater or Reservoir Tanks.

To Toggle Between °F and °C Readout:

1. Press the “Scroll” key 2 -3 times until the upper

display reads: “unit”.

2. Press the “Up” or “Down” key to choose.

Preheating

Preheat the Thermodyne cabinet when rst used

for the day or whenever the unit is cold. Preheating

takes approximately 30 minutes at which time the

temperature set point and the actual temperature

will display the same temperature. If the cabinet

has door(s), keep the doors closed during the

preheat cycle.

Extended Shutdown

1. Press Power ON/OFF Switch to OFF position.

2. Clean pans and shelves.

— 13 —

FLUID REPLENISHMENT

CAUTION

Use only supplied Thermodyne Heat

Transfer Fluid.

1. Remove 1 screw securing the ll cap cover

and turn cover 180°.

2. Remove the reservoir tank cap.

3. Fill reservoir tank until ADD FLUID light

turns off.

4. Re-install the reservoir tank cap, pivot the ll

cap cover and replace the screw.

Reservoir

Tank

Reservoir Tank

Cap

Fill Cap

Cover

Figure 16. Reservoir Tank Replenishment

NOTE: If the ADD FLUID Light remains on after

the Thermodyne unit has been lled, refer

to TROUBLESHOOTING.

— 14 —

GENERAL

NOTE: Food products can be held dry, moist,

assembled, and wrapped.

Dry Pan Without Pan Screen

Figure 17. Dry Pan Without Pan Screen

Used for products with high moisture, such as:

Sauces

Gravies

Casseroles

All products with fast turnover

Breaded Products – Vented/No Moisture

Ribs and Riblets

Potatoes

Scrambled Eggs

Vegetables

For crispier products, hold uncovered or vented.

Uncovered product should have an optional solid

back.

Dry Pan With Pan Screen

Figure 18. Dry Pan With Pan Screen

Used for dry and crisp products. Ideal for products

with high oil content, such as:

Bacon

Hot Dogs

Hamburger Patties

Breaded Chicken Patties

Biscuits

English Muns

Fried Fish

Fried Chicken – Vented or No Cover

Fried Sandwiches – Vented or No Cover

French Toast

PRODUCT PANS AND COVERS

— 15 —

Wet Pan With Pan Screen

Insert stainless steel insert rack; pour in water

prior to adding food product. Water will typically

last for several hours, but will vary by temperature

setting. Never allow water to sit overnight.

Figure 19. Wet Pan With Pan Screen

Used for products susceptible to drying, such as:

Grilled Chicken Breast

Egg Products for Sandwiches, Sausage Links,

and Patties

Hamburger Patties (extended holding)

Bagels

Pancakes

Assembled Wrapped Sandwiches

Pans With “V” Rack

Water can be added to the bottom of the pan for

moisture.

Figure 20. Pans With “V” Rack

Used for products such as:

Tacos

Burritos

Assembled Hot Dogs

Small Wrapped Sandwiches

Hot Spring Rolls

— 16 —

Removing Lids

CAUTION

Lid may be extremely hot.

CAUTION

Handle with care; lids may have sharp

edges.

Out 1

Out 2

Alm 1

MAN

°C

°F

A/T

ADD FLUID

Figure 21. Removable Lid

1. Remove lid by taking out the pans and lifting

up on the metal lid. Lids can then be cleaned

and sanitized.

2. When changing pans to different food

products, lids should be cleaned to avoid cross

contamination of food product or migration of

avors.

— 17 —

CLEANING AND MAINTENANCE

WARNING

DISCONNECT ELECTRICAL POWER TO

THE THERMODYNE UNIT AND FOLLOW

LOCKOUT/TAGOUT PROCEDURES

BEFORE CLEANING.

CAUTION

Stainless steel lids may have sharp edges;

handle with extreme care while cleaning.

WHEN TO CLEAN

It is recommended that all stainless steel

equipment be cleaned on a regular basis. Any

piece of stainless steel equipment that is soiled

should be cleaned daily to ensure the long life of

the equipment. Routine cleaning will also lessen

stainless steel abrasion.

HOW TO CLEAN

To remove most soil, use a non-abrasive, non-

chlorinated soap solution. Rinse thoroughly with

warm water and wipe dry using an absorbent

cloth. To remove heavy soil, rub the area with a

non-metallic, ne-grain scouring cloth. Be sure to

rub in the same direction as the metal grain. Rinse

thoroughly with warm water and wipe using a soft

absorbent cloth. As a nal step, a stainless steel

polish may be applied. The polish will shine the

stainless steel and provide a protective nish to

reduce future soiling.

Cleaning Safeguards

1. Always rub in the direction of the metal grain.

Never use steel wool or metallic scouring

cloths. These two measures will help prevent

scratching and possible damage to the

surface nish.

2. Use the recommended dilution. Do not exceed

concentration levels as this may cause long

term deterioration of the surface. Be certain

to rinse surface thoroughly to prevent buildup

of cleanser.

3. Never use chlorine or bleach solutions.

Check the ingredients of cleaning solutions

or disinfectants used as they may contain

chlorinated solvents.

4. Always read the label of the cleaning

solutions. Check for warnings about use

on stainless steel or aluminum products.

Repeated use of chlorinated solvents may

cause a chemical reaction with stainless

steel or aluminum; resulting in damage to

the surface and rusting.

Sterilizing Stainless Steel

When sterilizing stainless steel equipment, pay

particular attention to agents containing chlorine

compounds such as potassium hypochlorite. These

compounds may break down and release free

chlorine or hydrolyze to form hydrochloric acid.

Stainless steel can resist attack by the compounds

for up to 2 hours. Severe localized pitting may

occur with longer exposure. For safe use of the

agents, keep contact time short, ush thoroughly

with water, and operate equipment normally

between applications. Using these precautions,

the sterilization process can be repeated as often

as necessary.

Cleaning Heat Transfer Plates

The Thermodyne unit operates on the principle

of conduction, rather than convection. Therefore,

it is very important to keep the heat transfer

shelves clean, so heat transfer may take place

with maximum eciency. It is also very important

to keep the bottom contact surfaces of pots and

pans as clean as possible to ensure even and

complete heat transfer.

The surface and at coating of the thermal heat

transfer shelf is extremely hard, but will react with

strong caustic cleaning solutions and deteriorate.

CAUTION

Most concentrated soaps and ammonia

cleaners are too caustic to be used on the

Thermodyne unit.

— 18 —

If the coating is destroyed, the heat transfer

shelves will lose their non-stick properties and

their surface hardness.

The cleaners should always be used at the

recommended concentrations. In the case of dry

powders, the powders must not be placed directly

on the surface of the heat transfer plate. Care

must be taken not to scratch the shelf surfaces

when using brushes or pads. If harsh scouring is

needed, use a nylon type scouring pad. Never

use steel wool.

It is recommended that a weekly cleaning schedule

be followed to avoid the buildup of heavy food

product deposits. In the event heavy deposits

occur that are dicult to remove with ordinary

cleaning procedures, stronger chemical cleaning

agents may be applied if the products are intended

for food service use and are also compatible with

hard coat anodized aluminum surfaces. When

using these stronger solvents, it is very important

that heat transfer shelves are rinsed thoroughly

with clean potable water after cleaning. Be sure to

remove all traces of the cleaning agent. Between

the regular scheduled cleaning, wipe o the

anodized aluminum surfaces periodically with a

clean damp cloth.

Stainless Steel Cabinet

1. Any pot and pan detergent acceptable for food

service cleaning and compatible with aluminum

and stainless steel may be used on shelf and

cabinet surfaces.

2. A #20 plastic bristled brush used with the

appropriate detergent is acceptable for

cleaning. It is very important when cleaning

the heat transfer shelves that the undersides

of the shelves are thoroughly cleaned also.

3. Hot water hose rinsing is preferred. If a hose

is not available, rinsing with a sponge or cloth

and clean hot water is acceptable. Be sure

all surfaces are completely rinsed during the

rinsing procedure. Do not allow water to come

in contact with the Powerhead located on the

top of the Thermodyne unit.

4. The glass doors can be cleaned with any

commercial window-cleaning product,

provided they are free of ammonia or chlorine

and are food service compatible.

Door Gasket (CT Units)

Clean the gasket-sealing surface of the

Thermodyne doors to remove food product acids

for maximum gasket life. Do not use any solvents

or sharp instruments as these will damage the

gasket. Wash with a cloth moistened in a solution

of mild detergent and warm water. Rinse with a

fresh cloth moistened with warm water to remove

all traces of detergent.

Wipe dry with a clean cloth. Never apply food

product oils or petroleum lubricants directly to

the door gasket as these will reduce gasket life.

CHANGING FLUID

NOTE: The Thermodyne Heat Transfer Fluid

has lubricating additives, anticorrosion

additives, and heat transfer properties

that may decrease with the passing of

time. Thermodyne Heat Transfer Fluid

will protect the unit indenitely if the uid

is changed on an annual basis.

CAUTION

The following procedure is to be performed

by a qualied service technician only.

WARNING

DISCONNECT THE ELECTRICAL

POWER TO THE THERMODYNE UNIT

AND FOLLOW LOCKOUT/TAGOUT

PROCEDURES.

1. Disconnect the unit from its power source and

allow the unit to cool completely.

2. Remove the stainless steel panel covering the

left side of the unit.

3. Remove the powerhead lid; 4 screws.

— 19 —

Powerhead

Lid

Heater

Tank

Out 1

Out 2

Alm 1

MAN

C

F

A/T

ADDFLUID

Figure 22. Powerhead Lid

4. Place a pan or bucket beside drain plug in

order to catch drained uid.

Supply Rail

Drain

Hose

Drain

Plug

Figure 23. Drain Hose

5. Aim drain hose into pan or bucket and turn

valve to open position.

Heater

Tank

Heater Tank

Cap

Out 1

Out 2

Alm 1

MAN

°C

°F

A/T

ADDFLUID

Figure 24. Heater Tank Cap

6. Locate heater tank and remove cap.

7. Once oven has drained completely turn valve

to o position and place drain hose back in

cabinet.

8. Return stainless steel panel to left side.

9. Rell the unit with Thermodyne Heat Transfer

Fluid only. Never substitute with water or other

liquids.

10. Return heater tank cap.

11. Place lid back on, but do not tighten screws.

12. Plug unit in and turn on.

13. Unit will run briey and shut o due to low uid

level.

14. Remove powerhead lid and heater tank cap

and ll heater tank.

Heater Tank

Heater Tank Cap

Figure 25. Heater Tank Fill

15. Repeat steps 11-15 until unit is completely full

of uid.

16. Once unit is completely lled, place power-

head lid back on unit and tighten screws snug.

17. If ADD FLUID light is on, add uid to reservoir

tank until light goes out.

18. Let unit run until maximum temperature is

reached.

19. Once full temperature is reached, shut unit

down and let it cool down to at least 100°F.

20. Turn unit back on, and if ADD FLUID light is

on again, continue adding uid to reservoir

tank until light goes out.

NOTE: Steps 19 and 20 are very critical in order

to purge oven from any air trapped in unit.

— 20 —

TROUBLESHOOTING

Most problems associated with the holding unit are due to low uid level. Always check uid level rst.

*Recommended to be done by a qualied service agency.

NOTE: Most problems associated with the Thermodyne cabinet are due to failure to add Thermodyne

Heat Transfer Fluid. Check uid level rst. In the event service is required on your Thermodyne

Oven, please call: (800) 526-9182.

PROBLEM POSSIBLE CAUSE SOLUTION

No Power:

1. Main power switch o.

2. Not plugged in.

3. Breaker o or tripped.

4. Bad contactor.

1. Turn switch on.

2. Check plug.

3. Check breaker.

4. Replace contactor.*

LOW FLUID light is on -

Oven heating properly:

1. Oven is low on uid. 1. Add Thermodyne Heat Transfer Fluid

per instructions.

LOW FLUID light is on -

Oven not heating

properly:

1. Oven disabled due to low uid level

cut out.

2. Fluid level probe defective.

3. System leak.

1. Main heater tanks low on uid. Add

Thermodyne Heat Transfer Fluid and

determine cause of uid loss.

2. Repair or replace.*

3. Repair leak.*

Heater(s) not working:

1. Unit not properly wired.

2. Bad heater(s).

3. Contactor or solid state relays not

working.

4. O due to low uid cut out.

5. Failed temperature controller.

6. High limit snap disc tripped.

1. Check wiring.*

2. Replace heater(s).*

3. Repair or replace.*

4. Add Thermodyne Heat Transfer Fluid

per instructions.

5. Replace temperature controller.*

6. Reset snap disc and check for cause.*

Shelves hotter than set

point:

1. Temperature controller out of

calibration.

2. Thermocouple defective.

3. Solid state relay(s) stuck on.

4. Failed temperature controller.

1. Recalibrate temperature controller. *

2. Replace thermocouple.*

3. Replace solid state relay(s).*

4. Replace temperature controller.*

Shelves colder than set

point:

1. Low uid in tank. (LOW FLUID light

should be lit)

2. Failed temperature controller.

3. Heater(s) not working.

4. Pump failure.

5. Thermocouple failure.

1. Add Thermodyne Heat Transfer Fluid

per instructions.

2. Replace temperature controller.*

3. See “Heater(s) not working”.

4. Repair or replace pump.

5. Replace thermocouple.*

Oven heats up too slow: 1. Heater(s) not working. 1. See “Heater(s) not working”.

This manual suits for next models

13

Table of contents

Other THERMODYNE Oven manuals

Popular Oven manuals by other brands

Aroma

Aroma ABT-208S Instruction manual & recipe guide

Elba

Elba EBO-N6770 owner's manual

Signature Kitchen Suite

Signature Kitchen Suite SKSLV2401S owner's manual

Officine Gullo

Officine Gullo FES8EMU Instructions for installation and use

AEG

AEG Competence B 2100 operating instructions

Siemens

Siemens HB78AB 90B Series instruction manual