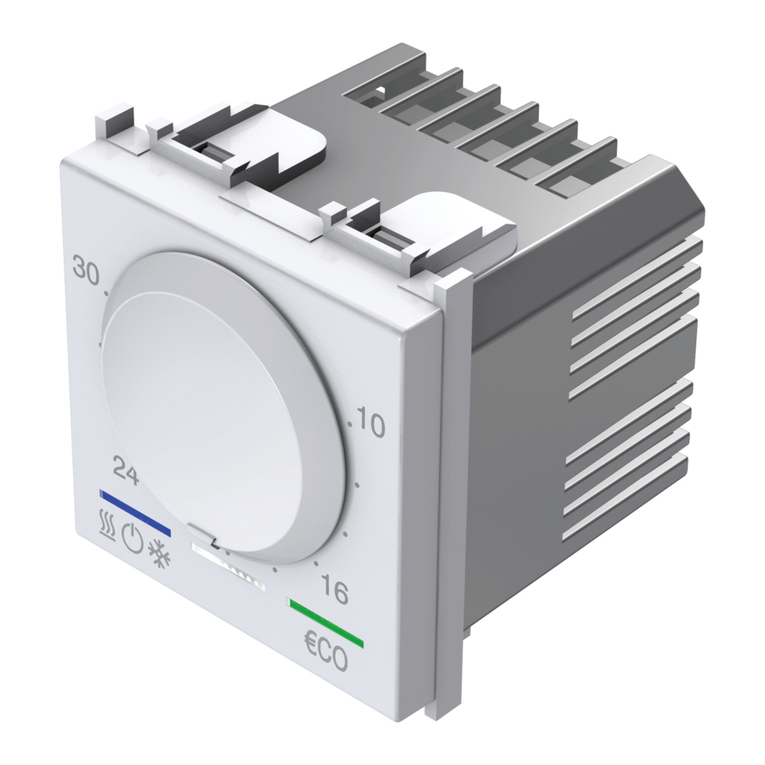

Thermokon JOY Fancoil EC 3AO RS485 Modbus User manual

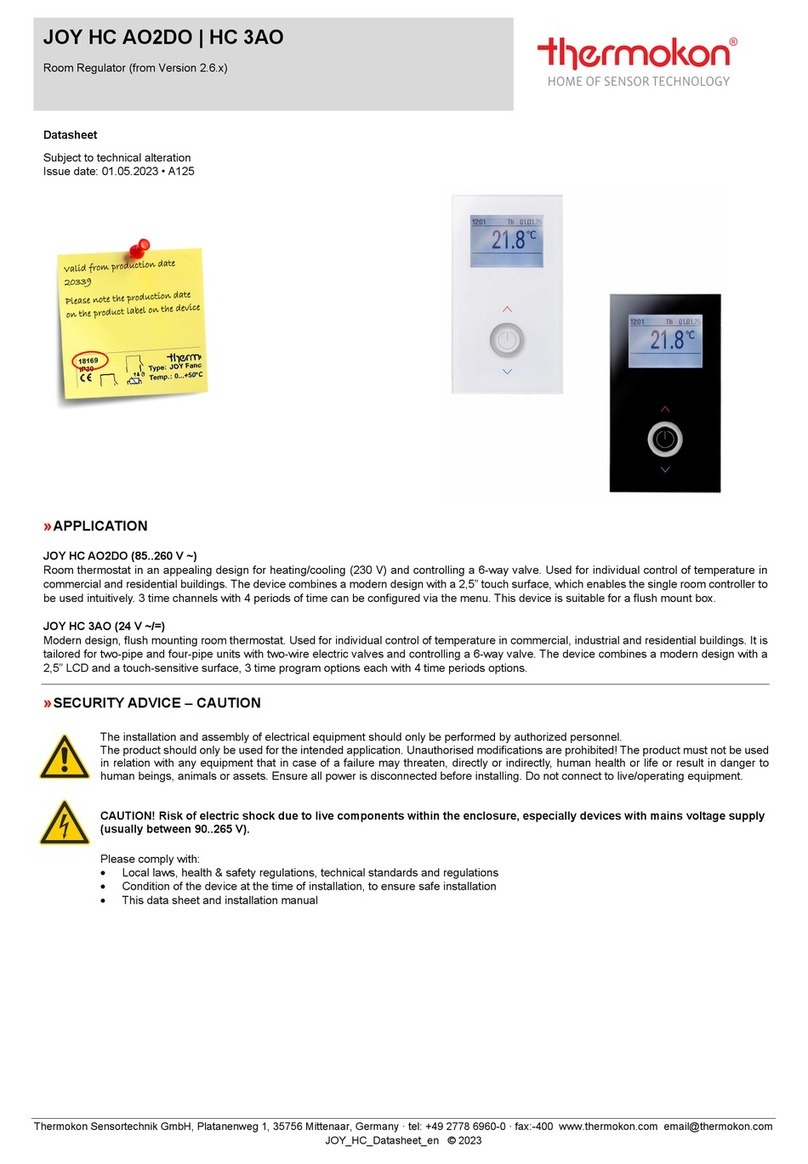

JOY Fancoil EC 3AO RS485 Modbus

Electronic Fan Coil Thermostat (Flush mounting)

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 · fax:-400 · www.thermokon.com · email@thermokon.de

JOY_Fancoil_EC_3AO_Modbus_Datasheet_v1.6.0+_en.docx © 2017

Datasheet

Subject to technical alteration

Issue date: 24.11.2017 • A002

Application

Modern design, flush mounting fan coil room thermostat. Used for individual control of temperature in commercial, industrial and

residential buildings. It is tailored for two-pipe and four-pipe fan coil units with two-wire electric valves or controlling a 6-way valve

(Sauter or Belimo). The device combines a modern design with a 2,5” LCD and a touch-sensitive surface, 3 time program

options each with 4 time periods options.

Security Advice –Caution

The installation and assembly of electrical equipment should only be performed by authorized personnel.

The product should only be used for the intended application. Unauthorised modifications are prohibited! The

product must not be used in relation with any equipment that in case of a failure may threaten, directly or indirectly,

human health or life or result in danger to human beings, animals or assets. Ensure all power is disconnected

before installing. Do not connect to live/operating equipment.

Please comply with

Local laws, health & safety regulations, technical standards and regulations

Condition of the device at the time of installation, to ensure safe installation

This data sheet and installation manual

Page 2 / 8 Issue date: 24.11.2017

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 · fax:-400 · www.thermokon.com · email@thermokon.de

JOY_Fancoil_EC_3AO_Modbus_Datasheet_v1.6.0+_en.docx © 2017

Notes on Disposal

As a component of a large-scale fixed installation, Thermokon products are intended to be used permanently as

part of a building or a structure at a pre-defined and dedicated location, hence the Waste Electrical and Electronic

Act (WEEE) is not applicable. However, most of the products may contain valuable materials that should be

recycled and not disposed of as domestic waste. Please note the relevant regulations for local disposal.

Remarks to Room Sensors

Location and Accuracy of Room Sensors

The room sensor should be mounted in a suitable location for measuring accurate room temperature. The accuracy of the

temperature measurement also depends directly on the temperature dynamics of the wall. It is important, that the back plate is

completely flush to the wall so that the circulation of air occurs through the vents in the cover. Otherwise, deviations in

temperature measurement will occur due to uncontrolled air circulation. Also the temperature sensor should not be covered by

furniture or similar devices. Mounting next to doors (due to draught) or windows (due to colder outside wall) should be avoided.

The temperature dynamics of the wall will influence the temperature measurement. Various wall types (brick, concrete, dividing

and hollow brickwork) all have different behaviours with regards to thermal variations.

Surface and Flush Mounting

The temperature dynamics of the wall influence the measurement result of the sensor. Various wall types (brick, concrete,

dividing and hollow brickwork) have different behaviours with regard to thermal variations. A solid concrete wall responds to

thermal fluctuations within a room in a much slower way than a light-weight structure wall. Room temperature sensors installed in

flush boxes have a longer response time to thermal variations. In extreme cases they detect the radiant heat of the wall even if

the air temperature in the room is lower for example. The quicker the dynamics of the wall (temperature acceptance of the wall)

or the longer the selected inquiry interval of the temperature sensor is the smaller the deviations limited in time are.

Technical Data

Measuring values

temperature

Network technology

RS485 Modbus, baud rate 9.600, 19.200, 38.400 or 57.600, parity none (2 stopbits), even or odd (1 stopbit)

Output voltage

3x 0..10 V, EC Fan control, heating & cooling

or control 6-way valves (configurable via Software)

Power supply

24 V = (±10%) or 24 V ~ (±10%) SELV

Power consumption

max. 1,5 W (24 V =)

Measuring range temp.

0..+50 °C

Accuracy temperature

±1 K (typ. at 21 °C)

Inputs

DI 1

1 input for NTC10K or floating contact

DI 3

1 input for floating contact

Control function

setpoint adjustment 0..+50 °C

Display

LCD 2,5“, 240x160 px, white backlighting

Functions

integrated PI-controller

Enclosure

PC, hardened acrylic glass with high scratch resistance

Protection

IP30 according to EN 60529

Connection electrical

Terminal 1..8

terminal block max. 1,5 mm²

Terminal 9..12

terminal block max. 1.0 mm²

Ambient condition

0..+50 °C, max. 85% rH non-condensing

Weight

195 g

Mounting

flush mounted with standard EU box (Ø=55 mm)

Diagnostics Menu

To access the diagnostics menu, select the header in the startscreen of the parameter menu, and press the ENTER key. Here

you will find various information, such as device type, software version, state of the inputs and outputs and controller state

(current manipulated variable).

Issue date: 24.11.2017 Page 3 / 8

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 · fax:-400 · www.thermokon.com · email@thermokon.de

JOY_Fancoil_EC_3AO_Modbus_Datasheet_v1.6.0+_en.docx © 2017

Mounting Advices

Plasterboard boxes shall be covered by wall paper or paint to avoid that the plasterboard box's front rim will be partially visible

underneath JOY.

Maybe consider using white plasterboard boxes (i.e. Kaiser 9063-77)

Connection Plan

1 Digital Input 3 7 24 V = (±10%) or 24 V ~ (±10%)

2 EC Fan (0..10 V) 8 -GND

3 Cooling (0..10 V) or 6-way valve 9 Digital Input 1 (or NTC10K)

4 Heating (0..10 V) or 6-way valve 10 GND DI 1

5 GND DI3 11 Modbus A

6 GND 12 Modbus B

Function Description - Buttons

On the touch surface, there are adjustment options for setpoint and fan speed regulation.

With power-button (5), the device can be set in standby mode by pressing the button (if keycard-switch is NOT used). If the

button is used as a occupancy button, the button must be pressed for at least 3s, in all other cases, a short actuation is sufficient.

In standby mode, the display and all outputs are switched off (controller deactivated). The frost and heat protection monitoring

remains active.

Modbus registers can still be read (e.g. room temperature).

The buttons (3) and (4) change

the setpoint in the range ± 3 ° C

(default setting, configurable).

The fan speed can be set by the

Buttons UP (1) and DOWN (2). 3

seconds without any interaction,

the display returns back to main

screen. While pressing of these

buttons, the white LED of the

Power-button (5) lights up for

visual feedback.

Page 4 / 8 Issue date: 24.11.2017

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 · fax:-400 · www.thermokon.com · email@thermokon.de

JOY_Fancoil_EC_3AO_Modbus_Datasheet_v1.6.0+_en.docx © 2017

Function Description –Controller/Fan stages

The room thermostat has a "PI controller" for heating and cooling.

6WV (PI-controller 0..10 V)

The usage of a 6-way valve is set via the configuration software. In this case the same manipulated variable is output at

terminals 3 and 4.

The manipulated variable is output as a proportional control signal at the output for the 6-way valve. The type of valve used is set

via the configuration software.

You can choose from 2..10 V / 2..10 V INV (Belimo), 0..10 V DN15 / DN15 INV, DN20 / DN20 INV (Sauter).

Fan stages

In automatic mode the fan speed is linked to the controller. The assignment of the fan stage to the control (heating / cooling, only

heating, only cooling) is freely selectable. To ensure that the fan motor starts reliably, a period of time can be configured in which

the fan starts with maximal value. Using one or more time channels, the fan control have to be set per timechannel and per

period. Via the touch surface the user has the option to override the settings of the device every time. When the next time

channel starts, the fan speed is set to the configured value. The fan is set to automatic mode when the user changes the

occupancy state (occupied↔unoccupied).

EC Fan automatic mode

The 0..10 V (0..100%) control of the fan is proportional to the calculated manipulated variable of the PI controller.

Example:

Calculated manipulated variable 65% → Fan control with 6,5 V.

Calculated manipulated variable 22% → Fan control with 2,2 V.

EC Fan manual

Up to 5 steps (steps) can be set using the configuration software. The set number of steps is divided linearly to the manipulated

variable of 0..100%.

Example:

Max. steps (stages) = 5

Stage 1 = 20%

Stage 2 = 40%

Stage 3 = 60%

Stage 4 = 80%

Stage 5 = 100%

Heating/ cooling with PI-controller (0..10 V)

The time response of the PI control loop depends on the control parameters xp for the proportional area and tn for the reset time

of the integral range. In case of an error variable, the P portion immediately changes the position value proportionally to the error

variable, while the integral portion takes effect after a certain time.

The resulting manipulated variable is output as an analogue 0..10 V signal directly to the outputs.

Proportional range Xp

The proportional band is the deviation in which controller emits 100% value. A small Xp leads to a stronger control action in case

of slight deviations, but increases the oscillation tendency.

Integral time Tn

The reset time Tn is the time which the I-component of the controller would require to produce the same positioning signal that

the P-component forms immediately once the control deviation is present. The effect of the I component decreases with

increasing reset time.

Minimum and maximum actuating variable

This setting defines a fixed minimum or maximum value of the actuating variable. The parameter "Mode selection actuating

variable" can be used to select whether the minimum actuating variable a) is retained until the controller changes its mode or b)

whether the actuating variable of the controller is output to the output only when the minimum actuating variable is exceeded.

Main screen/ Value display

The Display shows the measured value of the internal sensor. The value of an external sensor will be shown if connected and

configured accordingly. The room thermostat controls in this case according to the external sensor.

Max. steps (stages) = 3

Stage 1 = 33%

Stage 2 = 66%

Stage 3 = 100%

Issue date: 24.11.2017 Page 5 / 8

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 · fax:-400 · www.thermokon.com · email@thermokon.de

JOY_Fancoil_EC_3AO_Modbus_Datasheet_v1.6.0+_en.docx © 2017

Header Value display

Footer

Header

Current date and time will be displayed in the header. If enabled, ECO-mode status is indicated via symbol .

An attention symbol can be displayed in the header. This symbol has a higher priority than the ECO-mode symbol and is

prefixed instead of this.

Footer

Depending upon the heating or cooling mode, occupancy or window contact status, the corresponding symbols will be shown in

the footer. The symbol “active timechannel” will be shown only if active.

Symbols

Occupancy

Window contact/dew point

Heating/Cooling

Fan Speed

Active timechannel

….

Configuration

The setpoint of the Modbus version can be adjusted to any particular requirements or overwritten by a higher-level control.

Buttons

The configuration menu is activated by simultaneously pressing the buttons “up” (A), “left” (D) and “right” (B) for at least 3

seconds.

Page 6 / 8 Issue date: 24.11.2017

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 · fax:-400 · www.thermokon.com · email@thermokon.de

JOY_Fancoil_EC_3AO_Modbus_Datasheet_v1.6.0+_en.docx © 2017

Menu navigation on the touch-surface is performed by pressing the buttons “up” (A), “down” (C), “left” (D), “right” (B) or the power

button. Choose the desired parameter and press “right” (B) to open up the submenu. The menu will default after 30 seconds if no

button is pressed. To exit the menu select the header line and press “left” (D).

Menu → Time channels

Set point and timer can be set in this menu. Three different time channels with four periods of time are available. The Time

channels are prioritised. Channel 3 has the highest priority.

Choose the time channel and press “right” to enter the submenu. It is possible to select the total week as well as individual days

The selected parameter will be marked with the symbol

To edit the parameter of the selected timer, select “Periods” and press “right”.

ECO-mode is also available in the menu “section”, when selecting the dead zone increase from 2 °C to 10 °C. The adjustable

dead zone between the activation of heating or cooling modes enables an optimisation between comfort and energy saving.

The dead zone between heating and cooling in the ECO-mode will be set to the configured deadband range (see common

settings). (default 10.0 K)

Further information for the parameterisation of the time channels, please refer the detailed description of the JOY Modbus. (See

link under software)

Modbus parameter menu

The configuration menu is activated by simultaneously pressing the buttons “up” (A), “down” (C) for at least 5 seconds.

Issue date: 24.11.2017 Page 7 / 8

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 · fax:-400 · www.thermokon.com · email@thermokon.de

JOY_Fancoil_EC_3AO_Modbus_Datasheet_v1.6.0+_en.docx © 2017

Inputs

Up to 3 inputs are configurable for functions such as windows contact, dew point, occupancy, change-over or external sensor

option.

Sensor (NTC10K)

The value of an external sensor will be shown if connected and configured accordingly. In this case, the room thermostat

controls according to the external sensor.

Change-Over DI

Which controller is active depends on the state of the Change-Over contact. (Factory default: contact open heating controller

active, contact closed cooling controller active). The terminals 3 and 4 are used as outputs for heating rsp. cooling.

Change-Over Sensor

The Change-Over Sensor is used for switching between heating and cooling mode automatically. If the temperature is below 19

° C, the controller is in cooling mode. If it is above 28 ° C, it is a heating mode.

If an input is configured as a change-over, the room thermostat is automatically in 2-pipe operating mode and both outputs

(terminals 3 and 4) are used as outputs for heating rsp. cooling.

Window contact/Energy hold off

If a window contact is enabled via the digital input, the reference will switch to a setback set point (Heat SP/Cool SP).

Dewpoint

An active dewpoint contact locks the cooling controller.

Occupancy

If occupancy-function is active, the symbol will be displayed automatically. In state of “unoccupied” the heating set point is

reduced by 2K (default setting) rsp. the cooling set point raised by 2K.

Keycard-Switch

When the card is not inserted, the device is switched in sleep mode. Operation of the keys is locked, the display is switched off

and the controller adjusts to the nominal values of the "unoccupied"-State.

Application notice

SD-Card

Micro SD cards can be used to upload a new firmware or a new device configuration. With the PC configuration tool a

configuration file with extended parameter set can be created and uploaded via SD card. Only SD cards formatted in the FAT file

system can be used! NTFS and exFAT file systems are not supported.

Boot Loader

Because of an integrated bootloader a new application (update, upgrade) can be uploaded by means of a SD card. To insert the

SD card, the upper part must be removed. If the boot loader is activated, the ring illumination blinks in a 1s cycle, while display is

not triggered! After recognition of a SD card with a valid application the update process is started. Now, ring illumination blinks in

a 300ms cycle. After a successful update process (Duration approx. 2-3 minutes!) the new application is started

automatically. Afterwards, SD card shall be removed!

Software:

A detailed description of the parameter and the configuration software can be found using the following link.

The parameters for the display, set point, controller and the 6-way valve output configuration can only be

changed via the configuration software.

Address

Adjustable address (1-247)

Baud rate

9600Bd | 19200Bd | 38400Bd | 57600Bd

Parity

Non | odd | even

Page 8 / 8 Issue date: 24.11.2017

Thermokon Sensortechnik GmbH, Platanenweg 1, 35756 Mittenaar, Germany · tel: +49 2778 6960-0 · fax:-400 · www.thermokon.com · email@thermokon.de

JOY_Fancoil_EC_3AO_Modbus_Datasheet_v1.6.0+_en.docx © 2017

Dimensions (mm)

Accessories (optional)

Converter RS485 Modbus - USB Item No. 668293

Table of contents

Other Thermokon Thermostat manuals