Notes

1) When the Installer Set-Up Mode is initiated, only Category 1 ( 1) Set-Up Features are accessible.

Category 2 ( 2) Set-Up Features are accessed by pressing the PROG 2 key.

2) Remember to always press the INFO button to confirm that you want to store your new Installer Set-Up setting.

3) To exit the Installer Set-Up Mode move the CM67NG slider to the AUTO or MAN position (for CM61NG press the AUTO or MAN button).

This product has been designed with your environment in mind!

Please respect this by disposing of all packaging, used parts and eventually the product itself in an environmentally friendly manner.

Parameter

Optimisation enable

Minimum ON time

AM-PM/24h select

Accessory Module type

Reset time/temp program

Heat/Cool operation

Pump exercise feature enable

Cycle Rate

System Timing Master

Upper setpoint limit adjust

Lower setpoint limit adjust

Measurement offset adjust (temp)

Prop band width

Loss of Communications Instruction

Reset Installer Mode Parameters to

Defaults

Identifier

1:OP

2:Ot

3:Cl

4:At

5:rP

6:HC

8:PE

9:Cr

10:St

11:UL

12:LL

13:tO

15:Pb

16:LC

17:FS

Range

0(disable) /

1(enable)

1(1)5

0 (24h) / 1(12h)

{0,1,} 1

0(user prog) /

1(factory prog)

0(cool) /

1(heat)

0(disable) /

1(enable)

{3,6,9,12}

0 - standard operation of the room

unit

1 - room unit configured as master

21 (1) 30

5 (1) 16

-3.0 (0.1) 3.0

1.5 (0.1) 3.0

0(Relay Off)

1(Relay 20% on 80% off)

0(modified) / 1(factory)

Default

0 (Disabled)

1 min

0 (24h)

0 (no module)

0 (user prog)

1 (Heat)

0 (Disabled)

6 cph

0 (Standard opera-

tion)

30°C

5°C

0 K

1.5K

0 (Relay Off)

1 (factory)

Category

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

You must now press the PROG 2 key to enter the next section

4. INSTALLER SET-UP MODE TABLE

honeywell

Home Comfort & Systems

Honeywell Control Systems Ltd.

Newhouse Industrial Estate

Motherwell, ML1 5SB

Scotland

http://europe.hbc.honeywell.com

* Reset by pressing and holding the button

on the HC60NG for 15 seconds

B. INSTALLER SET-UP MODE (CONTINUED)

7. AUTOMATIC OPERATION

HC60NG receives the heat demand (0-100%) signal from one (or

more) CM61/67NG. The room unit will display the symbol whenever

more heat is required. Depending on the demand signal the HC60NG

will switch the heating device on to match the current requirements

of the system.

Green LED on - relay on

Green LED off - relay off

The green LED indicates status of the relay output.

8. TEMPORARY MANUAL OVERRIDE

Pressing the HC60NG button will override the current relay position. As

soon as next signal is received from the room unit the HC60NG will

return back to automatic operation as the automatic control has higher

priority than manual operation

9. COMMUNICATION LOSS

When HC60NG receiver does not receive the demand messages from

the units it is bound to for 1 hour, it will flag the communication loss

status to the user.

Red LED will be permanently ON - if no messages are received by

the HC60NG.

Red LED flashing at 2.5s on/2.5 sec off - if messages from one of the

room units is lost but the HC60NG still receives signals from others

units it is bound to.

After the communication loss status is detected, the HC60NG will

automatically enter the fail-safe mode.

The fail-safe mode operation depends on the HC60NG configuration

and its function in the system:

- HC60NG boiler controller: Fail-safe mode/0 configured in all room

units => relay OFF

Fail-safe mode/1 configured in any

of room units => relay cycling 20%

ON/80% OFF

- HC60NG zone controller Fail-safe mode/0 configured in the

zone room unit =>relay OFF

Fail-safe mode/1 configured in the

zone room unit => relay ON

When the HC60NG does not receive the system timing message

it will indicate the communication loss status (red LED flashing at

2.5s on/2.5 sec off) It will operate using the available heat demand

information. The system synchronisation may be lost and consequently

temperature control performance will become unsatisfactory. See sec-

tion C. TROUBLE SHOOTING GUIDE for possible cause and remedy.

For the set-up of the fail-safe mode see 6. FAIL-SAFE MODE SET-UP.

10. SYSTEM PARAMETERS CONFIGURATION

The key parameters of the boiler control algorithm are set centrally

at the unit configured as the system timing master.The following

parameters of the master unit will be used for boiler control:

2. SYSTEM TIMING MASTER SET-UP

One of the room units has to be configured as system timing master to

ensure efficient boiler operation. To configure room unit 1as system

timing master follow the procedure below:

1. Enter the installer’s mode of the room unit 1by moving the slider

to the OFF position (for CM61NG press the OFF button) and

pressing the PROG 3, 4 and buttons together

2. Press the PROG 2 button to enter the category 2 parameters.

Select parameter 10:St by pressing + or - button

3. Set the 10:St parameter value to 1 by pressing the TEMP or

button. Confirm the selected value by pressing the button

NOTE: There must be only one room unit configured as the timing

master into a system.

4.

Move the CM67NG slider to AUTO or MAN position (for

CM61NG press the AUTO or MAN button to exit the installer mode.

5. To check if the room unit 1is configured as the timing master

press the button twice. The unit will display the time and St

NOTE: If the St is not displayed repeat instructions above

6. Using the room unit 1configured as timing master, enter the time

master binding mode by moving the CM67NG slider to the OFF

position (for CM61NG by pressing the OFF button) and pressing

the TEMP , and PROG 6 buttons together. The unit will

display InSt St

7. To enter the binding mode, press and hold the push button of the

HC60NG zone controller 2for 5 sec (until the red LED starts

flashing at 0.5s on/0.5s off).

NOTE: It is not required to bind the room unit 1to the zone

controller 1as they are already factory bound.

8. Press the

button of the CM67/61NG master room unit to send

the timing binding signal. After successful binding operation the

red LED will be switched off If red LED still flashes push the

button again until binding is successful.

9. If you set-up a system with 3 or 4 zones, repeat steps 7 and 8 with

HC60NG zone controllers for zone 3 and 4

10. Exit the master timing binding mode by moving the slider to AUTO

or MAN position (for CM61NG by pressing the AUTO or MAN

button)

3. BINDING THE ROOM UNITS TO THE BOILER

CONTROLLER

To provide the heat demand signal from individual zones to the boiler,

each zone room unit has to be bound with the boiler controller

1. Install and wire-up the HC60NG boiler controller.The red LED will

flash 0.1s on/0.9s off.

NOTE: If it is not flashing as described above, press and hold the

push button for 15 sec to remove any stored binding data from

the memory.

2. Press and hold the push buttons of the boiler controller for 5 sec

to enter the binding mode. The red LED will start flashing at 0.5s

On/0.5 s Off. HC60NG is ready for binding

3. Move the slider of the CM67NG 1to OFF position (for

CM61NG 1press the OFF button). Press the TEMP ,

and PROG 1 button together. The CM67NG will display InSt

4. Press the

button to send the binding signal to the HC60NG boiler

controller. After successful binding operation the red LED will be

switched off. If red LED still flashes push the button again until

binding is successful.

5.

Move the CM67NG slider to AUTO or MAN position (for

CM61NG press the AUTO or MAN button to exit the binding mode.

6. Repeat steps 2 to 5 with each room unit ( 2, 3, 4) in the system.

NOTE: Before commencing installation make sure that the

hydronic layout of the heating system is suitable for zoning.

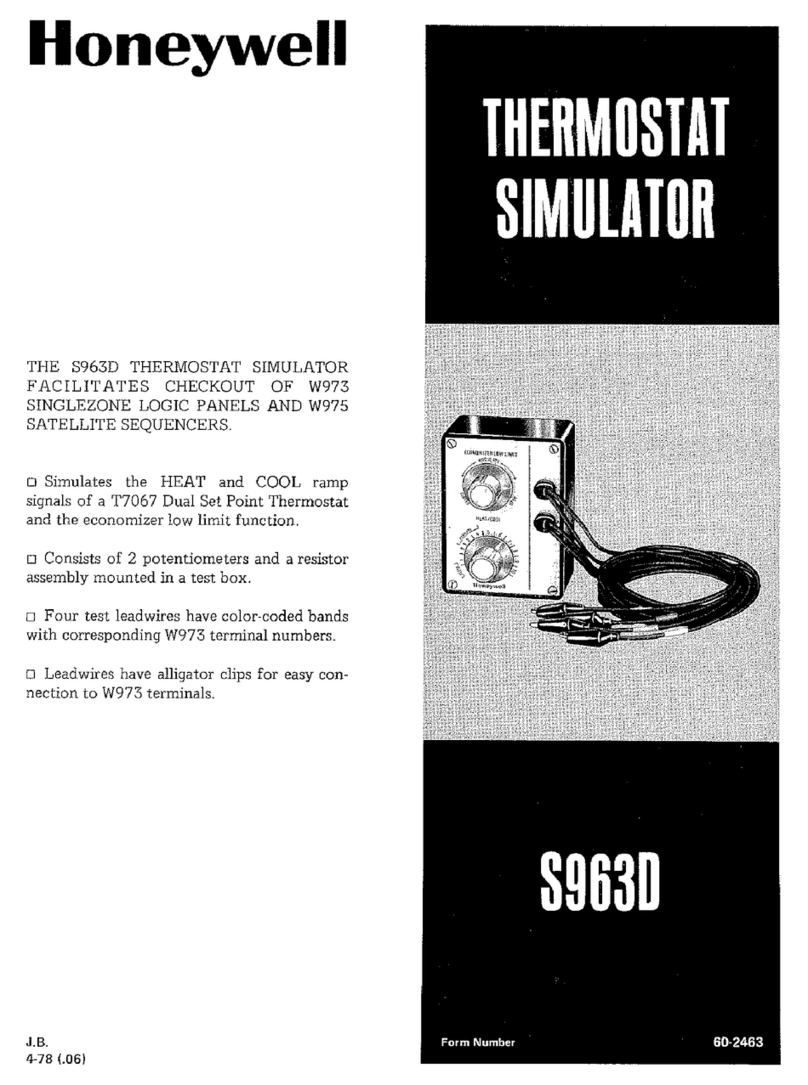

CM67/61NG is designed to be able to control multi-zone systems

where heat transfer to the individual zones is controlled by means of

zone valves or pumps (see Fig. 1).

D. MULTI-ZONE RF SYSTEM

4. LOCATING THE ROOM UNITS

To find proper locations for the room unit in each zone follow the

procedure below

1. Move the CM67NG slider into OFF position (for CM61NG push

the OFF button) and push the TEMP , and PROG 2 buttons

together to enter the RF communication test mode. The room unit

will display tESt

2. The room unit will start sending RF signals switching the green

LED of the HC60NG’s on and off every 5 seconds for 10 minutes.

NOTE: All the HC60NG relays will be off.

3. Review the RF Communication Check Table to establish which

HC60NG should react to the test signals of the room unit

4. Observing the room unit location guidelines (Fig. 9) find suitable

location for the room unit where RF communication is reliable.

5. The reliable communication is indicated when all appropriate

HC60NG’s (see RF COMMUNICATION CHECK TABLE) are

switching the green LED every 5 seconds.

6. Install the room unit in the selected location following CM67/

61NG Installation Guide (alternatively use the table stand).

7. Repeat the testing procedure with all the room units in the system.

5. RF COMMUNICATION CHECK TABLE

Zone 1

Zone 2

Zone 3

Zone 4

Room Unit in Test Mode

Room Unit 1, System

Timing Master

Room Unit 2

Room Unit 3

Room Unit 4

Responding Relay Boxes

All zone controllers, Boiler

controller

Zone controller 2, Boiler

controller

Zone controller 3, Boiler

controller

Zone controller 4, Boiler

controller

If no modifications to the values of these parameters are made the

default values apply (see part B. INSTALLER SET-UP MODE).

For detailed information on setting Installers parameters refer to part B.

INSTALLER SET-UP MODE.

NOTE: The minimum on time setting applies only to the boiler control-

ler. All HC60NG zone controllers work with a standard minimum on

time of 30 seconds.

Fig.2 Marking the room unit and the zone controller as a pair.

Fig.1 Multi-zone System Plan

6. FAIL-SAFE MODE SET-UP

The failsafe mode selected defines the HC60NG output relay status if

the RF communication is lost (e.g. when room unit stops communicat-

ing due to discharged batteries). The factory setting keeps the relay

permanently off when communications is lost. If the factory setting

needs to be changed follow the instructions below:

1. Move the CM67NG slider into OFF position (for CM61NG

press the OFF button). Press and hold the and PROG 3 & 4

buttons together.

2. Press the PROG 2 button to enter the category 2 parameters.

Select the parameter 16:LC by pressing +or -button.

3. Select the fail-safe mode by pressing TEMP or buttons

0 - when RF communication is lost the relay will be held in OFF

position

1 - when RF communication is lost the relay output will cycle at

20% on 80% off

IMPORTANT:

- To enable the frost protection when RF communication is lost

select the fail-safe mode 1

- For systems with separate frost protection thermostat or where

frost protection is not required select fail-safe mode 0

4. Confirm the selected value by pressing the button

5. Attach appropriate sticker to the HC60NG to indicate the selected

fail-safe mode.

NOTE: You can set fail-safe mode operation individually for each zone.

Parameter

- minimum on time:

- cycle rate

Factory Setting

default value 1 minute

default value 6 cycles

per hour

Range

range: 1-5

choice of 3, 6, 9 and

12 cycles per hour

NOTE: If you replace any of the components of the multi-zone control

system, it is recommended to follow all procedures described in Part. D

C. TROUBLE SHOOTING GUIDE

The HC60NG zone controllers operate zone valves or pumps. The

CM67/61NG room units located in every zone provide heat demand

signal for each zone controller. The HC60NG boiler controller operates

the boiler. It is collecting the demand signals from all room units to

make sure that the boiler delivers enough heat to satisfy every zone.

To set up a multi zone system you will need:

- one CM67NG or CM61NG system pack per zone in the installa-

tion. The system pack contains one room unit (transmitter) and one

zone controller (receiver)

- one HC60NG boiler controller

1. START-UP (max. 4 zones)

1. Mark the room units and relay boxes (zone controllers) from

system packs using 1, 2, 3, 4labels supplied (see Fig.2).

Leave the HC60NG boiler controller unmarked.

NOTE: It is important not to mismatch the pairs from the system

pack boxes as they are already pre-bound. Keeping them in pairs

will speed up system set-up. The HC60NG from the system packs

work as zone controllers (controlling the zone valves or zone

pumps), the HC60NG delivered separately will work as the boiler

controller (see Fig.1)

2. Install and wire up all the zone controllers following the installation

guidelines, zoning system plan (see Fig.1) and wiring diagrams.

NOTE: Do not connect power supply to the boiler controller.

3. Remove the insulation tabs from the room unit battery compart-

ments (see installation diagram 7)

4. To check the factory pre-set RF link between the room unit and

zone controller, move the CM67NG slider into OFF position (for

CM61NG press the OFF button) and press TEMP , and

PROG 2 buttons together for 3 sec.The unit will display tESt and

it will send test signals, The zone controller 1 will start switching

green LED on and off every 5 sec (the relay output will remain

off)

5. Exit the test mode by moving the slider into AUTO position (for

CM61NG press the AUTO button)

NOTE: If green LED is not switched on and off at specified

intervals, follow the procedure described in Part A. section 8.

BINDING.

6. Repeat steps 4 and 5 for every room unit and zone controller pair

in the system.

Symptom (Fault Message)

The room unit displays the

symbol but the relay does not

switch on

The HC60NG zone controller

does not react to setpoint

changes on the room unit

After binding procedure the red

LED is on and the green one is

flashing once every 3 sec

The red LED is on (Communica-

tion loss)

After procedure described in part

D. section 3.BINDING THE

ROOM UNITS TO THE BOILER

CONTROLLER the red LED is

on and the green one is flashing

twice every 3 sec.

After procedure described in part

D. section 2.SYSTEM TIMING

MASTER SET UP the red LED

is on and the green one is flash-

ing 3 times every 3 sec.

After procedure described in part

D. section 2.SYSTEM TIMING

MASTER SET UP the red LED

is on and the green one is flash-

ing 4 times every 3 sec.

The red LED is flashing 2.5 sec

on - 2.5 sec off (Communication

loss)

Possible Cause

This is normal operation. The room unit

sends only the demand signal (0-100%) to

the relay box. Depending on the demand

signal the relay box will switch the relay on

when required

The room unit and receiver are not bound.

Incorrect or incomplete binding procedure

Incorrect position of the room unit during

binding

The relay box receives no RF messages

from CM67/61NG:

RF signal is blocked due to wrong location

of the room unit

Room unit batteries are exhausted

An attempt was made to bind more than 4

room units with the boiler controller

An attempt was made to bind the HC60NG

with system timing message when no

demand binding information is present

An attempt was made to bind two system

timing masters with one receiver box

The relay box is missing signals from

one (or more) CM67/CM61NG but still

receives messages from other room units:

RF signal is blocked due to wrong location

of some room units in the system

Room unit batteries are exhausted

Remedy

Using TEMP button change the temperature setpoint by

a few degrees. The receiver should switch the relay on after

a few seconds delay

Reset* the HC60NG zone controller and follow the binding

procedure as described in part A. section 8 BINDING

Repeat the binding procedure

Repeat the binding procedure keeping approx. 1 m distance

between the HC60NG and CM61/67NG

Re-locate the room unit(s) following instructions in:

Par t A. section 2. LOCATING THE CM67/61 NG ROOM UNIT

or Part D. section 4.LOCATING THE ROOM UNITS

Replace batteries in the room unit

Reset* the HC60NG boiler controller, repeat the following

binding procedures:

Par t A. section 8.BINDING

Par t D. section 3. BINDING THE ROOM UNITS TO THE

BOILER CONTROLLER

Reset* HC60NG zone controller, repeat the following binding

procedures:

Par t A. section 8.BINDING

Par t D. section 2. SYSTEM TIMING MASTER SET UP

The above listed operations should be repeated ONLY for the

receiver which displayed the fault message

Make sure that only one room unit in the system is configured

as timing master. Reset all the HC60NG’s in the system.

Bind matching room units with the zone controllers (1 with 1,

2 with 2, …) as described in Part A, section 8.BINDING

Follow the instructions described in Part D. MULTI-ZONE RF

SYSTEM SET-UP

Relocate the room unit(s) following the instructions in:

Par t D. section 4.LOCATING THE ROOM UNITS

Replace batteries in the room unit

This part of the trouble shooting guide refers to single-zone and multi-zone systems

This part of the trouble shooting guide refers to multi-zone systems only

Zone 1

room unit

Zone 1

controller

Zone 2

room unit

Zone 2

controller

Zone 3

room unit

Zone 3

controller

Zone 4

room unit

Zone 4

controller

Boiler

controller

= Supply

= Return

NOTES:

- alternative control options for the zone controllers

- safety valves and balancing valves are not represented on the

zoning system plan

This product can be used in the following countries A, B, D, DK, E, F, FIN, HU, IRL, IT, LUX, N, NL, S, UK