Thermotron 3200 User manual

A Venturedyne, Ltd. Company

3200 Programmer/Controller

Operator Manual

Revision 2: May 12, 2010

This generic manual is intended for reference purposes only and is not intended to

be used to operate your equipment. For operating instructions and a description of

the features used on your specific control system, see the hard copy manual set for

your Thermotron product.

This manual provides the most current generic operating instructions for this

controller at the time of its revision date. Therefore this manual may not include

some recent software changes. This manual may also cover features that are not

available on your current controller. Examples within this manual are for typical

configurations that may not apply to the configuration of your control system.

This generic manual is not inten e to be use to operate your equipment.

For additional manuals, contact Thermotron Industries:

Thermotron Industries

291 Kollen Park Drive

Holland MI 4942 , USA

Phone: (616) 92-6550

Fax: (616) 9 -4549

www.thermotron.com

Therm-Alarm is a registered trademark of Thermotron Industries.

© Thermotron Industries

The information in this document is subject to change without notice. No part of this

document may be reproduced or transmitted in any form or by any means, electronic or

mechanical, without the express written permission of Thermotron Industries.

Thermotron Industries may have patents or pending patent applications, trademarks,

copyrights, or other intellectual property rights covering subject matter in this

document. The furnishing of this document does not give you license to these patents,

trademarks, copyrights, or other intellectual property except as expressly provided in

any written license agreement from Thermotron Industries.

All relevant issues have been considered in the preparation of this document. Should

you notice an omission or any questionable item in this document, please feel free to

contact the Thermotron Product Support group between 8:00 am and 4: 0 pm Eastern

Standard Time at (616) 92-6550.

Regardless of the above statements, Thermotron Industries assumes no responsibility

for any errors that may appear in this document nor for results obtained by the user as a

result of using this product.

Revision 0: August 14, 2009

Revision 1: February 25, 2010

Revision 2: May 12, 2010

3200 Programmer/Controller Operator Manual Table of Contents

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. i

Table of Contents

Section 1: Getting Starte

Introduction to the 200 ...............................................................................................................................................................1-1

Display module..................................................................................................................................................................................1-2

•Accessing other screens and functions......................................................................................................................1-2

200 basic functions........................................................................................................................................................................1-

•Control channels...............................................................................................................................................................1-3

•Chamber conditioning system signals.......................................................................................................................1-3

•Alarm output signals .......................................................................................................................................................1-3

•Auxiliary outputs...............................................................................................................................................................1-4

Running in manual mode..............................................................................................................................................................1-4

•Manual mode.....................................................................................................................................................................1-4

Running a program ........................................................................................................................................................................1-6

•Program mode...................................................................................................................................................................1-

•Edit from hold.....................................................................................................................................................................1-7

Chamber status..................................................................................................................................................................................1-8

Section 2: System Setup

Changing the temperature scale ................................................................................................................................................2-1

Changing the light timeout ..........................................................................................................................................................2-1

Enabling or disabling the key beep...........................................................................................................................................2-1

Changing the brightness ...............................................................................................................................................................2-2

Changing the contrast....................................................................................................................................................................2-2

Viewing the chamber model........................................................................................................................................................2-2

Viewing the software version.......................................................................................................................................................2-2

Adjusting standard control parameters...................................................................................................................................2-

•Proportional band parameters.....................................................................................................................................2-3

•Integral time parameters ...............................................................................................................................................2-3

•Tuning up the proportional band and integral time parameters ....................................................................2-4

Adjusting PTC control parameters.............................................................................................................................................2-7

•Gain parameters for PTC ...............................................................................................................................................2-7

•Integral time parameters for PTC ...............................................................................................................................2-7

•Offset parameters for PTC.............................................................................................................................................2-8

•Tuning up the PTC gain, integral time, and offset parameters........................................................................2-8

Setting process alarms................................................................................................................................................................. 2-12

Changing the access level or password................................................................................................................................ 2-1

Viewing computer interface settings..................................................................................................................................... 2-14

Table of Contents 3200 Programmer/Controller Operator Manual

ii This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

Configuring system events ........................................................................................................................................................ 2-14

•System event parameters defined............................................................................................................................ 2-14

•Setting up system events............................................................................................................................................. 2-15

•Viewing monitor channel readings .........................................................................................................................2-1

•Viewing diagnostic screens.........................................................................................................................................2-1

Section 3: Programming the 3200

Programmed cycling ....................................................................................................................................................................... -1

Creating or editing a new program........................................................................................................................................... -

Editing a program name................................................................................................................................................................ -5

Deleting a program.......................................................................................................................................................................... -6

Section 4: Therm-Alarm Functions

Introduction........................................................................................................................................................................................4-1

Therm-Alarm operating modes ..................................................................................................................................................4-2

Positioning the input thermocouple or analog sensor......................................................................................................4-2

Viewing the Therm-Alarm status................................................................................................................................................4-

Changing the Therm-Alarm settings.........................................................................................................................................4-4

•Alarm mute and reset mode functions......................................................................................................................4-5

•Muting or resetting the Therm-Alarm.......................................................................................................................4-5

Initializing the Therm-Alarm data ..............................................................................................................................................4-6

Calibrating a Therm-Alarm ...........................................................................................................................................................4-6

Section 5: CM2 Calibration

Calibrating Control Channels.......................................................................................................................................................5-1

Calibrating Monitor Channels......................................................................................................................................................5-1

Calibrating Analog Outputs..........................................................................................................................................................5-1

Appen ix A: Glossary

3200 Programmer/Controller Operator Manual Getting Starte

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. 1-1

Section 1: Getting Starte

This section provides the basic information you need to start using the 200. This includes an introduction

to the instrument, a brief hardware description, and instructions for operating in manual mode, running a

program, and checking the chamber status.

•For additional hardware information, see “ 200 basic functions” later in this section.

•For more detailed hardware information, see the CM2 Control Module Technical Manual.

•For information on 200 setup, see Section 2 of this manual.

•For information on programming the 200, see Section of this manual.

•For definitions of many of the terms used in this manual, see the glossary at the end of this manual.

Intro uction to the 3200

The 200 is a microprocessor-based programmer and controller. The programmer function allows you to

program temperature, temperature/humidity, or other types of tests and store them in program memory.

You can use these programs to operate the controller functions of the 200.

Most 200 programmer/controllers are configured for either single-channel operation (temperature only),

or dual-channel operation (temperature and humidity). If your 200 is configured for dual-channel

operation, it can operate as a temperature-only system or as a temperature/humidity system.

•Typically, channel 1 is dedicated to chamber air temperature using a dry bulb thermocouple. Channel

1 operates the chamber’s heating and cooling systems.

•Typically, channel 2 is dedicated to humidity using either a solid-state humidity sensor or a wet bulb

thermocouple. Channel 2 operates the chamber’s humidifying and dehumidifying systems.

•Channel may be configured for product temperature control (PTC). PTC is a heating and cooling

process that controls the process variable based on the product temperature rather than the test

space air temperature. OTE: Product temperature control and humidity cannot be run at the same

time.

Although the 200 can be configured for up to three programmable channels, for ease of use this manual

is based on the more common one- and two-channel configurations. Three-channel operation follows the

same basic principles described in this manual.

The 200 can be programmed and operated locally using the display screen, function keys, and keypad.

The 200 also can be programmed and operated from a host computer. For more information, refer to the

3200 Programmer/Controller Computer Interface Manual.

The controller functions operate the chamber and its attached equipment. Analog and transistor-transistor

logic (TTL) level signals control and monitor the system. The chamber’s conditioning systems, printers,

chart recorders, and solid-state relay devices are operated from the controller signals. Other analog

devices also can be monitored and operated.

Thermocouples can be mounted throughout the operating systems to feed diagnostic information back to

the controller.

Before operating the 200, several setup procedures must be completed. Most of the setup procedures

were performed at Thermotron; however, these procedures may need to be performed again if

requirements change. Refer to Section 2 for setup instructions.

Getting Starte 3200 Programmer/Controller Operator Manual

1-2 This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

Display mo ule

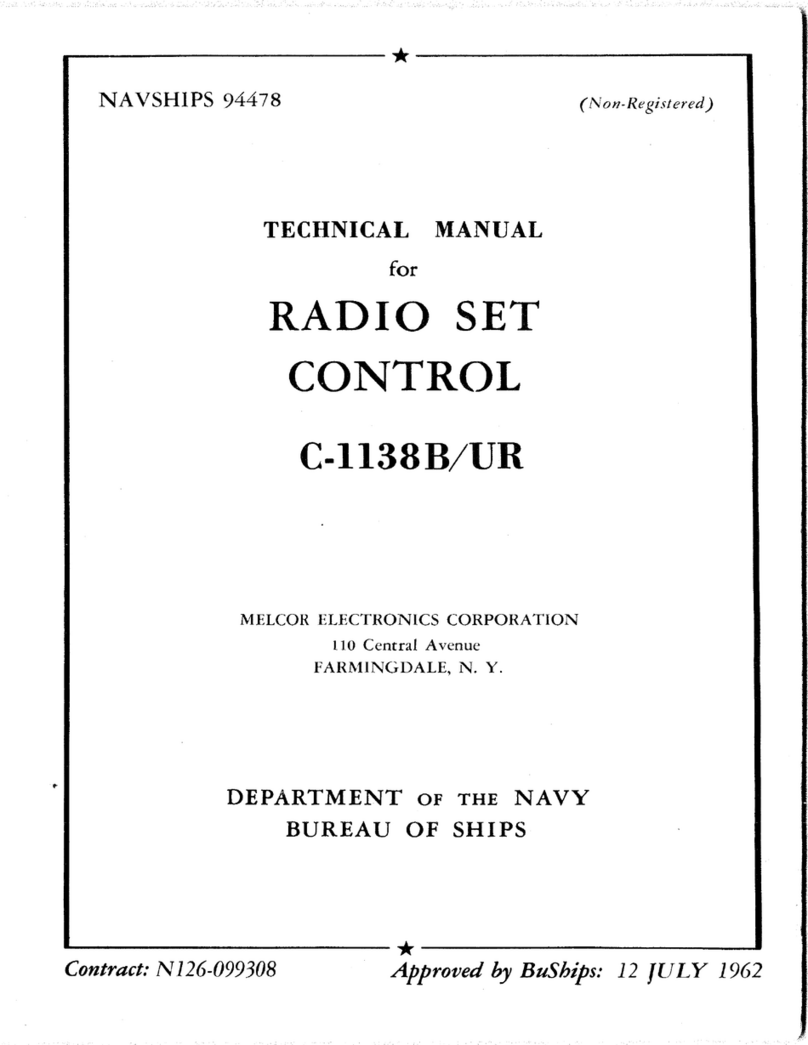

The 200 is operated using the 4-line by 20-character

display (illustrated to the right) and keypad.

Accessing other screens an functions

OTE: In this manual function keys are indicated in bold letters. For example, “Press RU . When the run

program screen appears, choose what program you would like to run.“

OTE: For CDS-5 chambers, enter 72776 (SETUP) on the numeric keypad to access the main menu.

For most 200 operations you start from the startup main screen (shown above) and use function keys to

access other screens and functions. To return to the startup main screen from any other screen, press the

ESC key repeatedly until the main screen is displayed.

•To display the cause of the last chamber stop, press STOP. OTE: Pressing STOP while a program is

running will stop the program.

•To turn the chamber light(s) on or off from any screen, press the ESC (LIGHT) function key and hold

for one second.

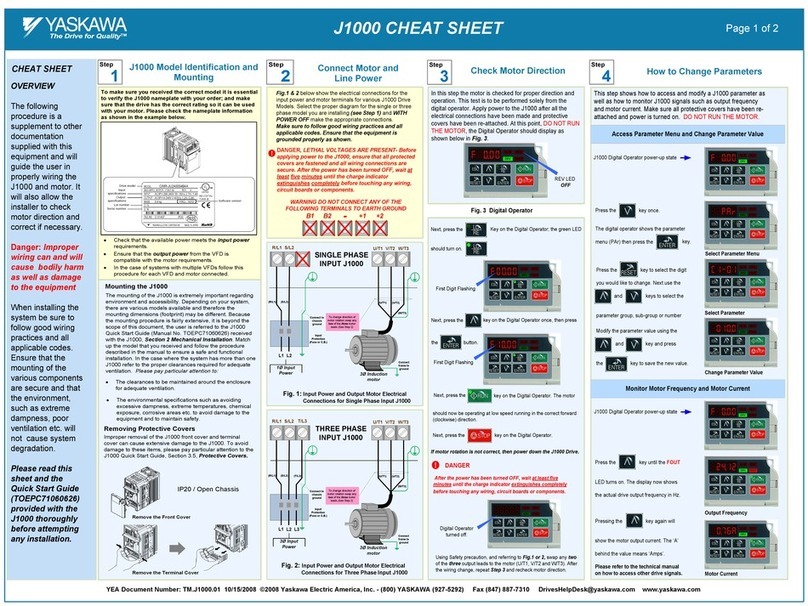

•If you try to access a function that is not available

at the current access level, this screen will appear:

For more information on access levels, see

“Changing the access level or password” in Section

2 of this manual.

3200 Programmer/Controller Operator Manual Getting Starte

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. 1-3

3200 basic functions

The following sections provide brief descriptions of some of the 200 functions.

Control channels

Control channels receive inputs from thermocouples and/or other sensing devices used to monitor the

environmental conditions inside the chamber’s test space. The 200 adjusts its control outputs based on

those inputs.

•Typically, channel 1 uses a thermocouple mounted in the chamber airflow to sense air temperature. Its

outputs control the heating and cooling systems.

•Typically, channel 2 uses a solid-state humidity sensor to monitor chamber humidity. The reading from

the sensor is used together with the reading from the channel 1 thermocouple to calculate chamber

humidity. The channel 2 outputs control the humidity system’s steam generator and dehumidify coil.

•Channel , if available, can sense temperature or linear inputs. These channels commonly are

configured for such options as product temperature control or altitude.

•Channels 5 through 8 can be programmed at the factory as constant control channels. Each channel

can be set at the factory to sense either temperature or linear inputs.

Chamber con itioning system signals

The chamber conditioning signals are used by the controller to operate chamber systems such as heating,

cooling, and humidity. These signals are dedicated to the system and are internally programmed.

•The system, refrigeration, and humidity enable outputs allow their respective systems to turn on.

•The heat and cool outputs control their systems. For example, the channel 1 cool output normally

operates the solenoids that regulate the flow of refrigerant into the chamber’s evaporator coil.

•The auxiliary cool output operates any auxiliary cooling system, such as liquid nitrogen (LN

2

) or carbon

dioxide (CO

2

).

Alarm output signals

The alarm output transistor-transistor logic (TTL) signals indicate when the chamber temperature or

humidity exceeds the programmed limits. Two types of alarms are available for each channel:

•Deviation alarms are activated when the chamber temperature, humidity, or other process variable is

outside the channel’s deviation alarm band. A deviation alarm band restricts how far the process

variable can be from set point. For example, a deviation alarm band of 5°C activates the alarm output

if the chamber temperature is more than 5°C from set point.

Deviation alarms can be set for each manual mode test or program interval. For more information, see

“Running in manual mode” below, or Section later in this manual.

•Process alarms are activated when the chamber temperature, humidity, or other process variable is

outside the process limits. The process alarm settings restrict the high and low limits of a test. A

process alarm stops the programmer/controller. For example, if the high process alarm limit is +125°C,

the alarm is activated if the temperature equals or exceeds +125°C.

Process alarms are a configuration setting that can be adjusted only in setup mode. For more

information, see Section 2 later in this manual.

Getting Starte 3200 Programmer/Controller Operator Manual

1-2 This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

Auxiliary outputs

Auxiliary outputs provide programmable TTL level outputs. There can be up to two groups of eight

auxiliary outputs. These outputs are programmed on and off during each program interval or during

manual mode operation. These outputs normally are used to program systems on and off. For information

on your chamber’s auxiliary outputs, see your chamber manual.

Running in manual mo e

Manual mode allows you to operate the 200 controller functions. Manual mode operates the chamber

using set point settings. You can enter manual mode when the system is in stop mode.

Manual mo e

1. From the main screen select option 2. Manual

Mode. The manual mode screen will appear:

2. Use the up and down arrow keys to cycle through the following screens.

. The following list describes the manual mode values displayed:

•Set Point: Enter the desired value for each active channel. When the ramp rate is not zero, the set

point will change toward this new value at the selected rate.

•Aux Grp1 and Aux Grp2 (auxiliary groups 1 and 2): Enter the numbers of the auxiliary relays

you want to activate. Auxiliaries are active only when the 200 is running. For more information on

auxiliary relays, see “Auxiliary outputs” earlier in this section.

3200 Programmer/Controller Operator Manual Getting Starte

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. 1-5

•Hum (humidity): Enables the optional humidity system. OTE: Humidity is disabled if product

temperature control (PTC) is enabled.

•PTC (product temperature control): Enables the optional PTC control method. OTE: PTC is

disabled if humidity is enabled.

•Control Parameters: For more information on parameter groups, see “Adjusting standard control

parameters” or “Adjusting PTC control parameters” in Section 2 of this manual.

•Throttle: Positive values indicate heating or humidifying; negative values indicate cooling or

dehumidifying.

•Deviation: Enter the value for how far you will allow the temperature or other process variable to

be from set point. The deviation setting will be monitored and the deviation alarm will be

activated if the value is exceeded. Enter a positive number only; the 200 will monitor both

positive and negative deviations.

4. To start running in manual mode using the settings entered above, press RU .

5. To stop manual mode operation, press STOP.

Getting Starte 3200 Programmer/Controller Operator Manual

1-2 This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

Running a program

The programmer function operates the 200 using programs. Each program consists of a group of

intervals. In each interval the controller cycles the chamber toward a final temperature and/or other

process variable in a specified amount of time. Once the interval is completed, the 200 either transitions

to the next interval or loops back to an earlier interval.

Once a program is entered into memory it can be run immediately. To create a program, see Section of

this manual.

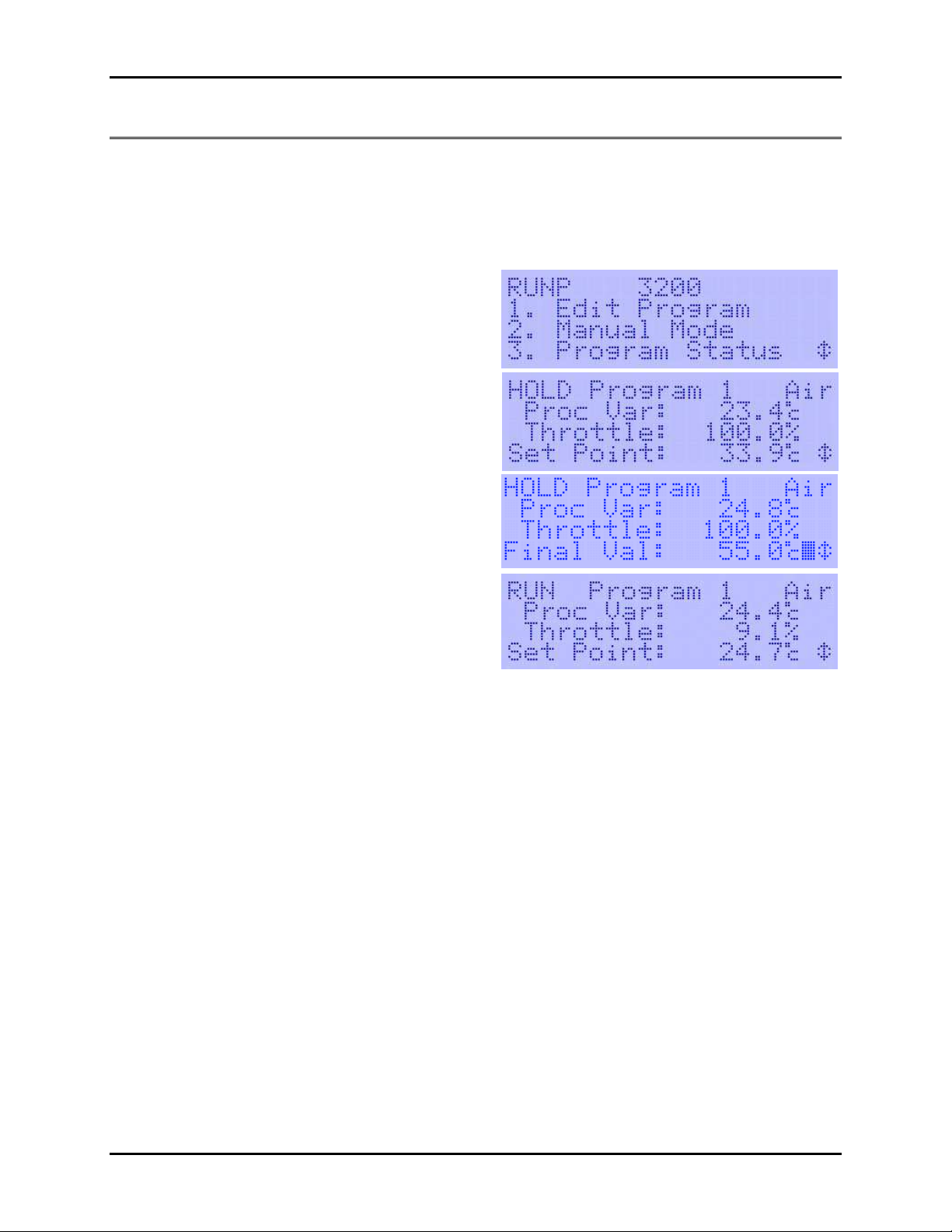

Program mo e

1. From any screen, press RU . ( OTE: The run

program screen will not appear when in program

edit mode or while a program is running.) The run

program screen will appear:

2. Select option 1 for program 1, interval 1. OTE: To

create a program, see Section of this manual.

. Select a starting interval. Then press the right

arrow key to run the selected program.

OTE: The start interval screen will only appear

when there is more than one interval created.

4. The 200 will enter run program mode and the

chamber status screen will appear:

For more information on the chamber status

screen, see “Chamber Status” later in this section.

5. To suspend the interval at its current settings,

press HOLD. The 200 will enter hold program

mode. From the top level menu, pressing the run

key, while RU P (run program) is displayed in the

top left corner, will display the message HOLD.

OTE: In hold program mode the 200 will maintain the chamber test space at the last set point.

6. To enter temporary values into the current interval, use the numeric keypad to enter a new value. For

additional information, go to step 4 of “Edit from hold” later in this section.

7. To resume running a suspended test, press RU .

8. To stop a running test, press STOP.

3200 Programmer/Controller Operator Manual Getting Starte

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. 1-7

E it from hol

Edit from hold allows you to place a running program in hold program mode and enter temporary values

into the current interval. Once the interval is run and completed, the temporary values are discarded. The

next time the interval is run, the original programmed values apply. OTE: In hold program mode the

200 will maintain the chamber test space at the last set point.

To operate in edit from hold mode, follow these steps:

1. While a program is running, go to the main screen

and select 3. Program Status.

2. Press the RU key. This will display the message

HOLD in the top left corner.

. Use the up and down arrow keys to select the

setting(s) to edit. For more detailed descriptions of

the settings, see Section of this manual.

OTE: In edit from hold mode only final values,

deviations, time left, auxiliaries, next interval, and

number of loops may be edited.

4. When all the settings are acceptable, press ESC. To

return to the main menu screen.

5. To resume running the current interval with the

settings entered in step above, press RU .

Getting Starte 3200 Programmer/Controller Operator Manual

1-2 This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

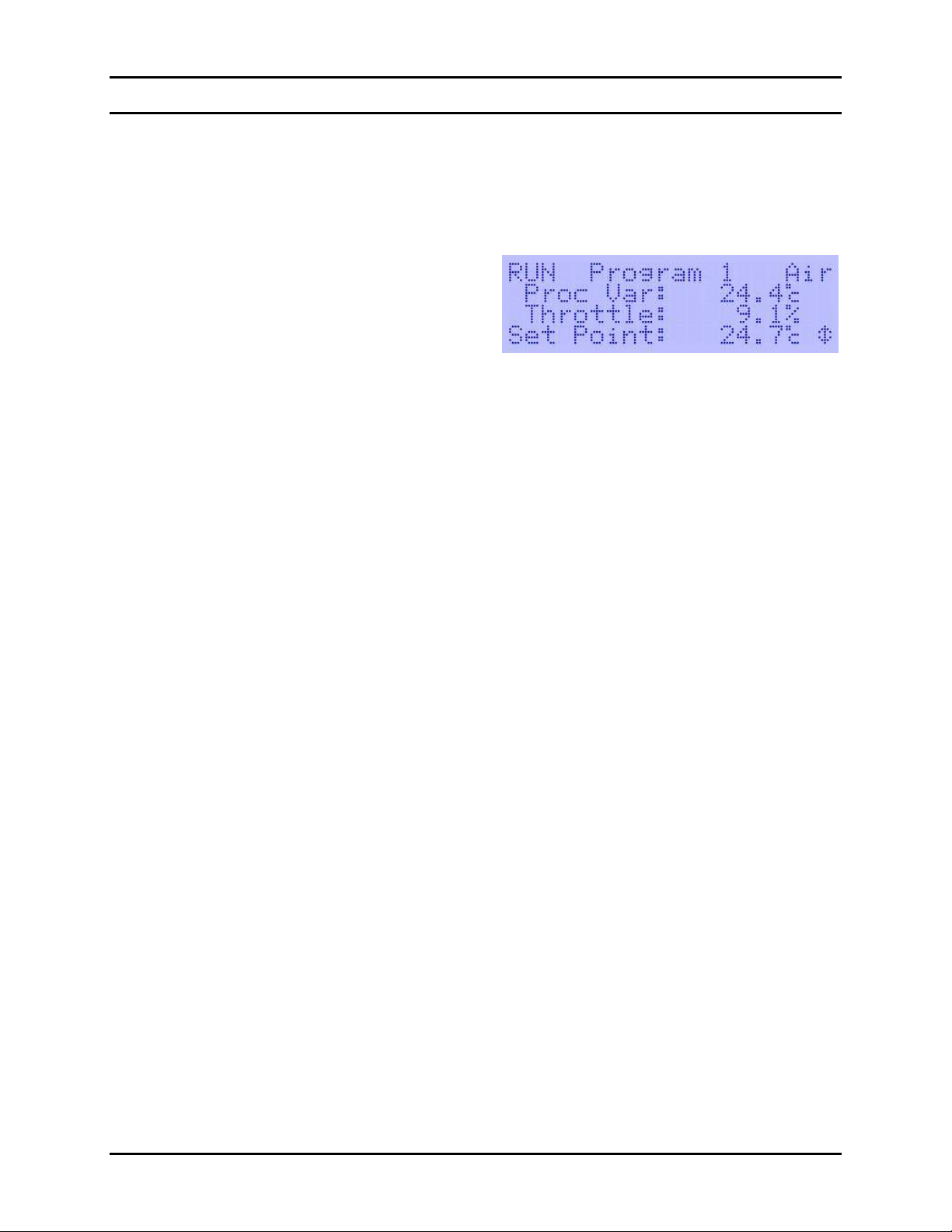

Chamber status

The program status screen allows you to view the current operating conditions of the chamber, such as set

points, process variables, and throttles.

OTE: The sample screen shows the display for a one-channel 200 configuration. The 200 can display

only one channel at a time.

1. From the main screen, select 3. Program Status.

The status screen will appear:

2. Use the up and down arrow keys to scroll through

the following status display values (for more

detailed descriptions of these values, see Section

of this manual):

•Throttle •Deviation

•Init Val: initial value •Current Interval

•Final Val: final value •ext Interval

•Time •Opt: options enabled

•Time Left •Process Var: process variable

•Aux Grp1 •Aux Grp2

3200 Programmer/Controller Operator Manual System Setup

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. 2-1

Section 2: System Setup

This section provides instructions for viewing or adjusting the following functions:

•Temperature scale •Process alarms •Monitor channels

•Access level and password •Brightness •Contrast

•Audible key beep •Computer interface setup •Light timeout

•Software version •System events •Control parameters

•Diagnostics •Chamber model

OTE: For CDS-5 chambers, enter 72776 (SETUP) on the numeric keypad to access the main menu.

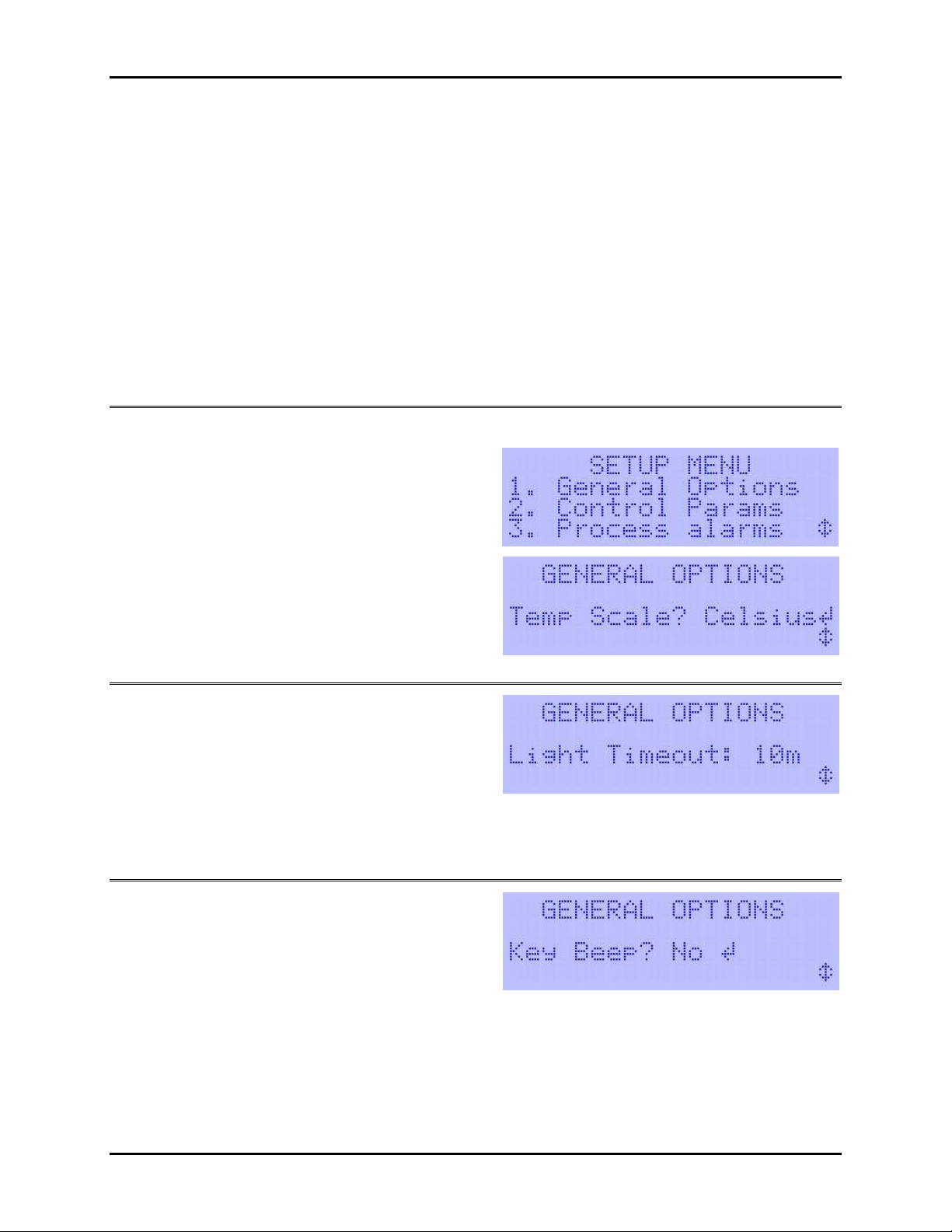

Changing the temperature scale

This setting changes the temperature scale for all displayed variables.

1. From the main screen, select 4. Setup. The setup

menu screen will appear:

2. Select 1. General Options. Use the up and down

arrow keys to cycle through the options.

. Press the E T key to toggle between Celsius and

Fahrenheit.

Changing the light timeout

1. From the main screen, select 4. Setup. The setup

menu screen will appear:

2. Select 1. General Options. Use the up and down

arrow keys to cycle through the options.

. Use the numeric keypad to enter the number of minutes before the light timeout is activated.

4. Press E T.

Enabling or isabling the key beep

1. From the main screen, select 4. Setup. This setup

menu screen will appear:

2. Select 1. General Options. Use the up and down

arrow keys to cycle through the options.

. Press the E T key to toggle between Yes and o.

System Setup 3200 Programmer/Controller Operator Manual

2-2 This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

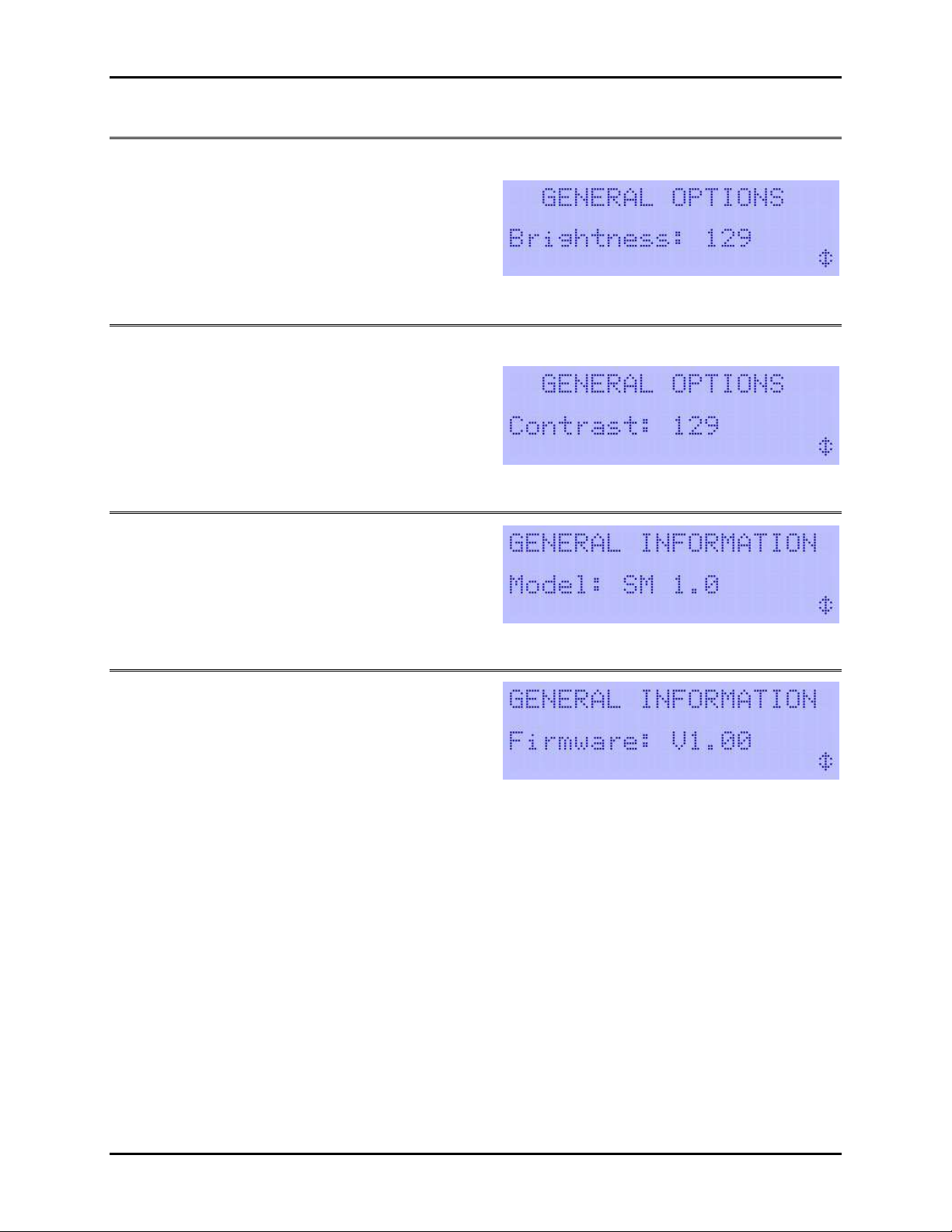

Changing the brightness

1. From the main screen, select 4. Setup. The setup menu screen will appear.

2. Select 1. General Options. Use the up and down

arrow keys to cycle through the options.

. Use the numeric keypad to enter the number for

the level of brightness. The range for brightness is

from 100 to 191.

Changing the contrast

1. From the main screen, select 4. Setup. The setup menu screen will appear.

2. Select 1. General Options. Use the up and down

arrow keys to cycle through the options.

. Use the numeric keypad to enter the number for

the contrast level. The range for contrast is from

120 to 150.

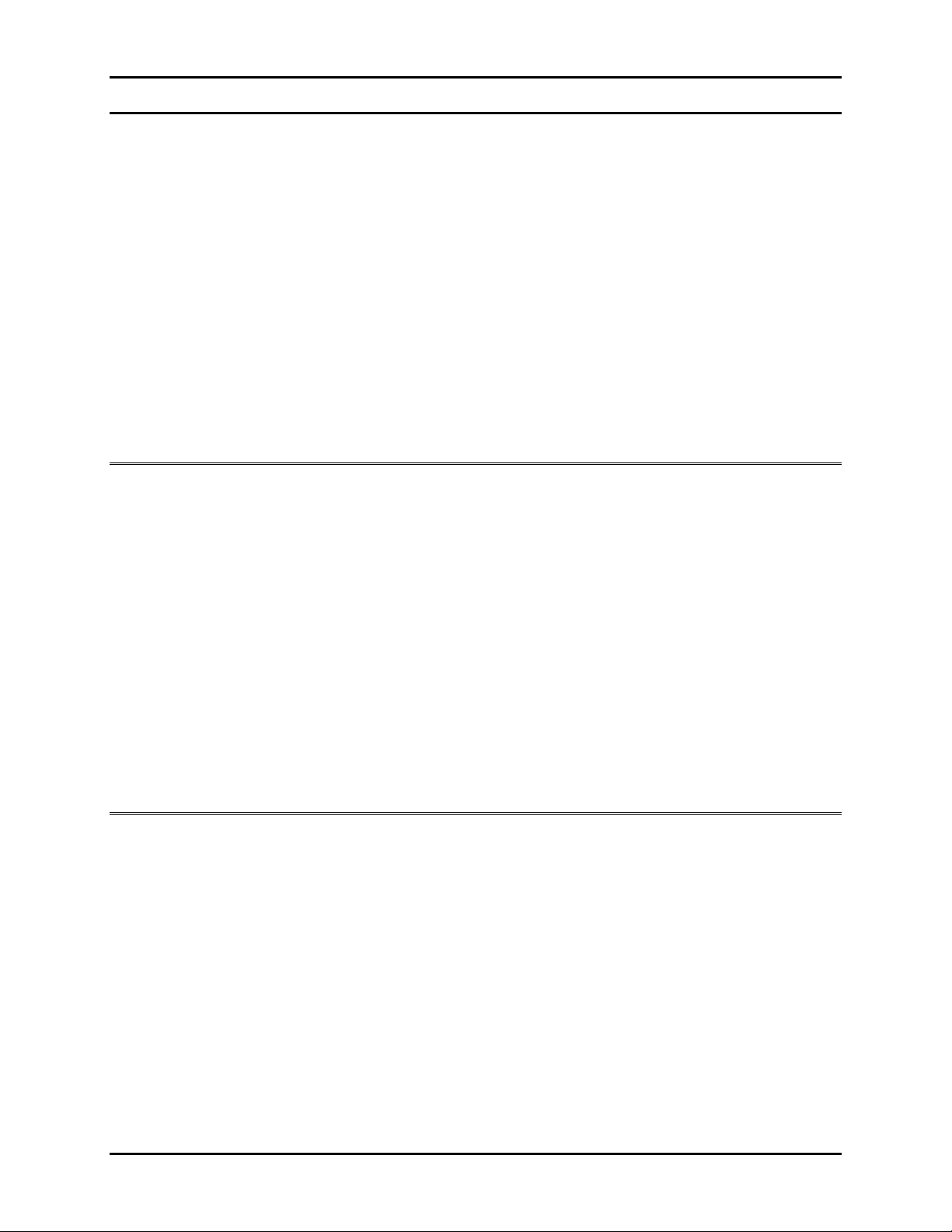

Viewing the chamber mo el

1. From the main screen, select 9. General Info.

2. From the general information screen use the up

and down arrow keys to cycle through the

information. From this screen you can see the

chamber model.

Viewing the software version

1. From the main screen, select 9. General Info.

2. From the general information screen use the up

and down arrow keys to cycle through the

information. From this screen you can see the

software version.

3200 Programmer/Controller Operator Manual System Setup

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. 2-3

A justing stan ar control parameters

CAUTIO : The 200 programmer/controller was factory-tuned and should not need to be re-tuned unless

the product requirements change enough to affect the performance of the chamber. Incorrect values

could damage your equipment and/or product.

OTE: Tuning the 200 control parameters is a time-consuming procedure that will take a minimum of

two to three hours to complete.

Control parameters adjust the performance of the chamber around the set point. As the chamber nears

the set point, the 200 adjusts the chamber throttles to provide a smooth ramp to the set point. To

prevent overshooting and oscillation around the final set point, the refrigeration, heating, and other

systems must be damped as they approach the set point. To maximize chamber performance, you must

also compensate for lag times.

The control parameters are tuned in manual mode. The same procedure is used to tune up each channel.

The adjustments are made to the proportional band and integral time parameters.

Proportional ban parameters

The proportional band parameters are a coarse adjustment (1 to 9,999 units) to the control algorithm.

These parameters set the proportional bandwidth around the set point for the control channel’s process

variable. As the process variable nears the set point, it enters the proportional band. Once inside the

proportional band, the throttle is backed off in proportion to the difference between the set point and the

current process variable. OTE: The proportional bands use the same units of measurement as the process

variable.

•Smaller proportional bands can result in faster transitions.

•If the proportional band is too large it can result in very slow transition times — the chamber may

never reach set point.

•If the proportional band is too small it can result in overshoot or oscillation around the set point.

•As a rule for the proportional band, smaller = faster response, larger = slower response. Generally,

you should adjust the proportional band to the smallest value possible without the process variable

excessively overshooting or oscillating around the set point.

Integral time parameters

The integral time parameter is a fine adjustment to the control algorithm. The integral time parameter is

used when the process variable nears the set point and the throttle is backing off. The integral time

parameter adjusts the throttle to take the droop out of the proportional band setting and allows the

chamber to reach the set point.

Droop is an effect, such as natural heat loss through the test space walls, that prevents the process

variable from reaching the final set point. The integral time parameter determines how quickly the throttle

will be adjusted to compensate for droop. Without an integral time entered, the process variable will not

reach or remain at the set point. OTE: The integral time parameter is programmable from 0 (integral off)

to 1,000 seconds.

•Longer integral times result in longer times to reach the set point.

•Shorter integral times result in shorter times to reach the set point.

System Setup 3200 Programmer/Controller Operator Manual

2-4 This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

•If the integral time is too short, the process variable will oscillate indefinitely when it reaches the set

point.

•As a rule for the integral time, shorter = faster response, longer = slower response. Generally,

shorter integral times mean shorter transition times.

Tuning up the proportional ban an integral time parameters

The proportional band and integral time parameters must be “tuned up” to produce an efficient,

controlled environmental test cycle. First you tune up the proportion band for quality control near set

point, then you tune up the integral time to achieve accuracy.

For the optimal combination of performance and quality, each control channel is tuned to be critically

damped. This occurs when the process variable overshoots the set point slightly and then oscillates

around the set point slightly until it stabilizes at the set point. This level of control becomes available only

with properly tuned proportional band and integral time parameters.

When tuning up chamber parameters with two or more control channels, tune up one channel at a time,

always tuning the proportional band parameters first. Additionally, each control channel’s reference

channel should be tuned up first. For example, for humidity operations, tune up the temperature channel

first because it is the reference channel for the humidity channel. The control stability of the temperature

channel directly affects the control stability of the humidity channel. OTE: For most chambers channel 1

is temperature and channel 2 is humidity.

Example starting parameters

Heat proportional band 20 Heat integral time 60

Cool proportional band 40 Cool integral time 90

Recor the original parameter settings

1. From the main screen, select 4. Setup.Then select

2. Control Params.Use the up and down arrow

keys to cycle through the values shown.

2. To edit, use the numeric keypad to enter a value.

Press E T.

. If needed, select the parameters screen for the channel you are tuning by pressing the right or left

arrow keys for Air, Hum, and PTC.

4. Write down the heat and cool proportional band (Prop Band) settings.

5. Use the up and down arrow keys to cycle through the values.

6. Write down the heat and cool integral time settings.

Obtain a performance baseline

7. Press ESC until the main menu screen appears.

8. Select 2. Manual Mode to edit the settings.

3200 Programmer/Controller Operator Manual System Setup

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. 2-5

9. Use the up and down arrow keys to select and edit the settings for the channel you are tuning:

a. Set the Deviation to 0.

b. Enter a new Set Point based on which parameters you are tuning, such as a heating set point for

tuning the heating parameters.

OTE: When tuning parameters, the heating parameters are usually tuned before the cooling

parameters. Normally you should select the set point based on the tests you are running.

c. Disable all unnecessary auxiliaries.

d. Make sure product temperature control (PTC) is disabled. OTE: If you are tuning the

temperature channel in a temperature-humidity system, disable humidity (HUM) for best results.

10. Press RU . The chamber will enter run manual mode.

11. Watch the process variable (Proc Var) for the channel you are tuning as it approaches set point and

then stabilizes for 10 to 15 minutes.

12. If the current parameter settings are correct, the process variable will overshoot the set point slightly

and then oscillate around the set point slightly until it stabilizes at the set point.

•If the process variable oscillates near the set point, the proportional band is too small.

•If the process variable takes too long to reach the set point, the proportional band is too large.

•If the process variable undershoots the set point slightly until it finally reaches the set point (if it

ever does), the integral time is too large.

•If the process variable overshoots the set point, the integral time is too small.

A just the setting

1 . To adjust the proportional band:

a. Change the set point (Set Point) to back the process variable away from the set point you will use

to tune the parameter.

b. From the main screen select 4. Setup, then select 2. Control Params (control parameters).

c. Change the heating or cooling proportional band (Heat/Cool Prop Band) for the channel you are

tuning.

14. Repeat steps 8 through 11 to see the effect of the new proportional band setting. The ideal

proportional band setting is obtained when the process variable stabilizes near set point (for example,

within ±2°C or ±2% RH). As it stabilizes, it oscillates in decreasing amounts until it droops just above or

below the set point. OTE: The integral time function will adjust the set point up or down to

compensate for this droop.

•If the process variable continues oscillating, you will need to increase the proportional band

setting just until the oscillation stops.

•If the process variable is not oscillating, you will need to decrease the proportional band setting

just until oscillation begins, then increase the setting until the oscillation stops.

System Setup 3200 Programmer/Controller Operator Manual

2-6 This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

15. If necessary, you can tune the current channel’s integral time parameter once you have tuned the

channel’s proportional band parameter.

a. Change the set point to back the process variable away from the set point you will use to tune the

parameter.

b. From the main screen select 4. Setup, then select 2. Control Params (control parameters).

c. Change the heating or cooling integral time (Heat/Cool Integral Time) for the channel you are

tuning.

16. To see the effect of the integral time setting, repeat steps 8 through 11. The ideal integral time setting

is obtained when the process variable equals the set point.

•If the process variable oscillates around the set point, you should increase the integral time.

•If the process variable takes too long to achieve the set point, you should decrease the integral

time.

Repeat as nee e

17. Once the first set of parameters (such as the heating parameters) have been tuned up, the other set of

parameters can be tuned up.

18. Once the parameters for the first channel have been tuned up, the next channel’s parameters can be

tuned up.

19. Once you have finished tuning up all the channels, record the parameter settings. Keep these values

on record with the 200 manual.

Summary

When adjusting the control parameters you should follow this general outline:

1. Run a heat-up test to see how the chamber controls. If necessary adjust the heat parameters.

2. Run a cool-down test to see how the chamber controls. If necessary adjust the cool parameters.

. Run a heat-up test to see the effect of the changes from step 1. If necessary adjust the heat

parameters again.

4. Run a cool-down test to see the effect of the change from step 2. If necessary adjust the cool

parameters again.

5. Continue to run alternating heat-up and cool-down tests, adjusting the heat and cool parameters as

needed to achieve the desired level of control.

3200 Programmer/Controller Operator Manual System Setup

Thermotron In ustries This generic manual is not inten e to be use to operate your equipment. 2-7

A justing PTC control parameters

CAUTIO : The 200 programmer/controller was factory-tuned and should not need to be re-tuned unless

the product requirements change enough to affect the performance of the chamber. Incorrect values

could damage your equipment and/or product.

OTE: Tuning the 200 control parameters is a time-consuming procedure that will take a minimum of

two to three hours to complete.

Control parameters adjust the performance of the chamber around the set point. As the chamber nears

the set point, the 200 adjusts the throttles to provide a smooth ramp to the set point. To prevent

overshooting and oscillation around the final set point, the refrigeration, heating, and other systems must

be damped as they approach the set point. To maximize chamber performance, you must also

compensate for lag times.

The product temperature control (PTC) control parameters are tuned in manual mode. The adjustments

are made to the gain, integral time, and offset parameters.

Gain parameters for PTC

The gain parameter is a coarse adjustment to the PTC control algorithm. The larger the gain, the longer

the 8200 will wait to start slowing down the throttle as the load temperature approaches the load setpoint.

maximum offset

gain = proportional band

For example, if the maximum offset is 10°C and the desired proportional band is 5°C, the gain would be

set to 10°C/5°C = 2.

The temperature channel will still perform using the air parameters, but the offset parameters control the

set point of the temperature channel in relation to the PTC channel’s set point. When a PTC program is

run, the temperature channel immediately cycles beyond the set point by the maximum offset. With the

chamber air at maximum offset, the product cycles toward the final set point at its maximum rate. The

temperature channel remains at the maximum offset above the PTC channel’s set point until the product

temperature enters the proportional band near final set point. The throttle of the temperature channel is

reduced in relation to the PTC channel until the final set point is reached.

The gain parameter is related to the time constant of the load. The greater the time constant of the load,

the more gain is required to change the temperature of the load. Increase the gain parameter for a faster

load response. Additionally, a higher gain causes the load to proportion into the set point when the

temperature is closer to the final set point.

As a rule for the gain setting, smaller = slower response, larger = faster response. Generally, you will

want the largest gain setting possible without the process variable excessively overshooting the set point.

Integral time parameters for PTC

The integral time parameter is a fine adjustment to the PTC control algorithm. The integral time parameter

is used when the process variable nears the set point and the throttle is backing off. The integral time

parameter adjusts the throttle to take the droop out of the proportional band setting and allows the

chamber to reach the set point.

System Setup 3200 Programmer/Controller Operator Manual

2-8 This generic manual is not inten e to be use to operate your equipment. Thermotron In ustries

Droop is an effect, such as natural heat loss through the test space walls, that prevents the process

variable from reaching the final set point. The integral time parameter determines how quickly the throttle

will be adjusted to compensate for droop. Without an integral time entered, the process variable will not

reach or remain at the set point. OTE: The integral time parameter is programmable from 0 (integral off)

to 1,000 seconds.

•Longer integral times result in longer times to reach the set point.

•Shorter integral times result in shorter times to reach the set point.

•If the integral time is too short, the process variable will oscillate when it reaches the set point and will

continue to oscillate indefinitely.

•As a rule for the integral time, shorter = faster response, longer = slower response. Generally,

shorter integral times mean shorter transition times.

Offset parameters for PTC

The offset is the number of degrees Celsius that the air temperature set point will be allowed to exceed

the load temperature set point when attempting to move the load temperature to the new load set point.

The offset allows the air temperature channel to overshoot the set point by up to ±100°C.

•Larger offsets can result in faster transitions.

•If the offset is too large it can result in overshoot, and may trip process alarms.

•As a rule for the offset, smaller = slower (less aggressive), larger = faster (more aggressive).

Generally, you should adjust the offset to the highest value possible without the process variable

excessively overshooting the set point.

The maximum offset should be programmed to allow the chamber air to overshoot the final value by an

amount that will not damage any portion of the load. For example, if the final set point is +100°C and the

load could be damaged by temperatures above +110°C, then the maximum heat offset should be +10°C.

CAUTIO : It is your responsibility to program the offset value correctly to avoid damaging any products

under test.

Tuning up the PTC gain, integral time, an offset parameters

The gain, integral time, and offset parameters must be “tuned up” to produce an efficient, controlled

environmental test cycle. First you tune up the gain parameter for quality control near set point, then you

tune up the integral time and offset parameters to achieve accuracy.

For the optimal combination of performance and quality, each control channel is tuned to be critically

damped. This occurs when the process variable overshoots the set point slightly and then oscillates

around the set point slightly until it stabilizes at the set point. This level of control becomes available only

with properly tuned PTC control parameters.

OTE: The PTC parameters should be tuned only after the air temperature control parameters have been

tuned, and only with a product load in the chamber.

Example starting parameters

Heat gain .0 Heat integral time 200 Heat offset 10

Cool gain .0 Cool integral time 400 Cool offset -10

Table of contents

Other Thermotron Controllers manuals

Popular Controllers manuals by other brands

Daikin

Daikin RoCon+ HP Series operating instructions

Zonet

Zonet ZUH2215V Quick installation guide

Allison Transmission

Allison Transmission 3000 Operator's manual

Leviton

Leviton Lumina RF Decora DL057-D0Z INSTALLATION AND QUICK START SHEET

LG

LG PQCSA001T0 Owners & installation manual

LOYTEC

LOYTEC L-DALI user manual