© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021857/01/21

Tel.

+49 551 79001-0 · Fax +49 551 79001-65 · [email protected]om ·www.thiesclima.com Seite 3 von 32 Table of Contents

1Available Models............................................................................................................. 4

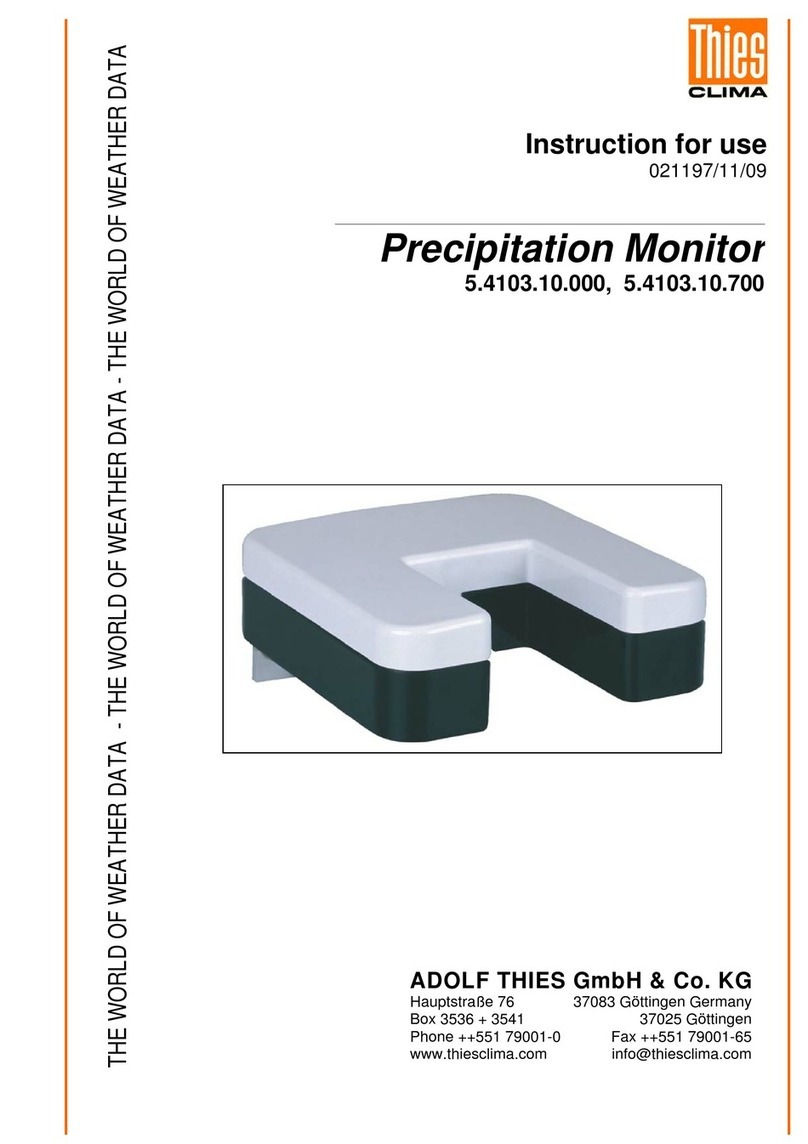

2Application...................................................................................................................... 5

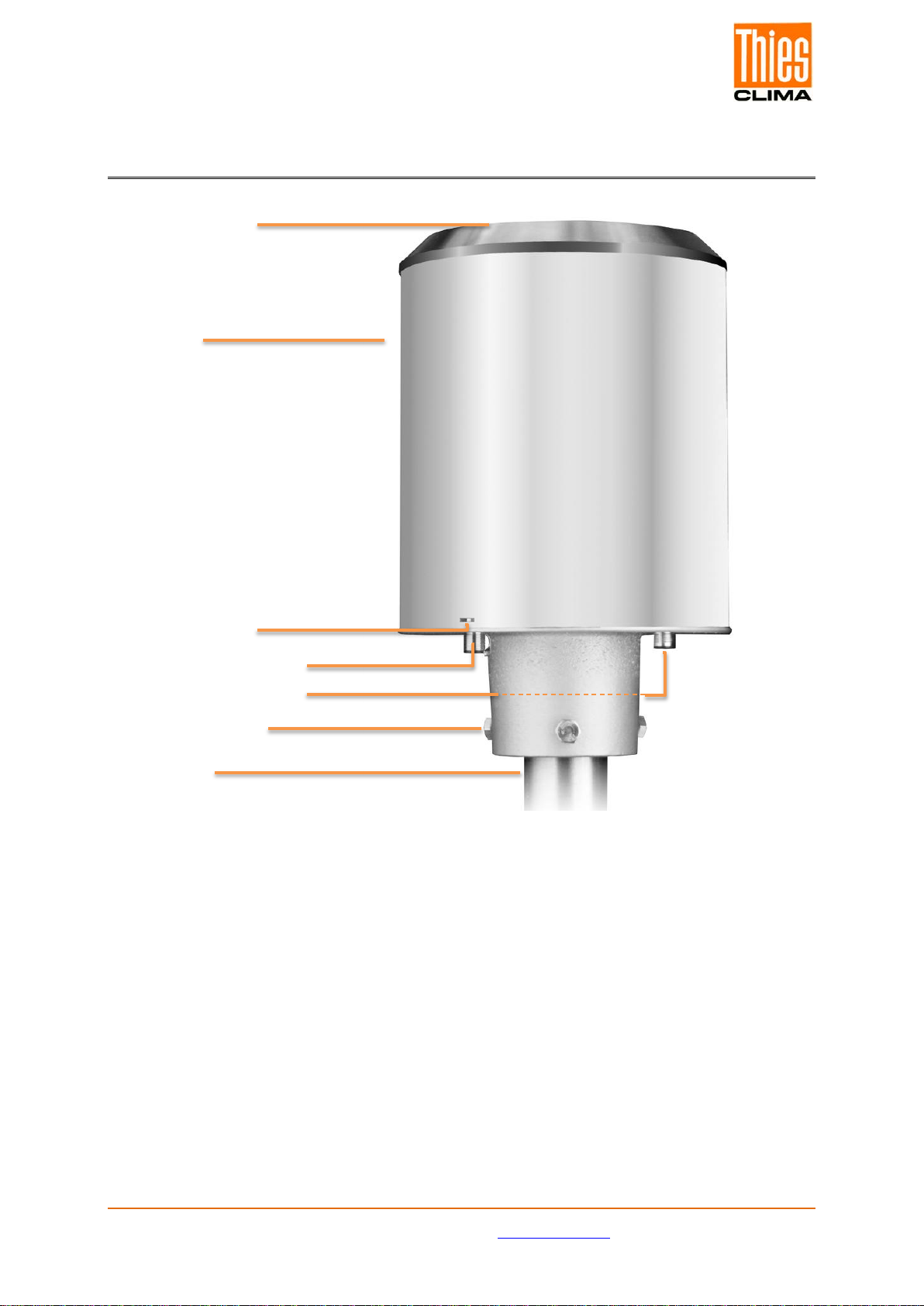

3Construction and Mode of Operation............................................................................... 6

3.1 Measured Values and Electrical Output.....................................................................7

3.2 Heating......................................................................................................................8

4Recommendations Side Selection / Standard Installation ............................................... 8

5Installation....................................................................................................................... 9

5.1 Mechanical Mounting.................................................................................................9

5.2 Electrical Mounting..................................................................................................15

5.3 Plug Mounting .........................................................................................................15

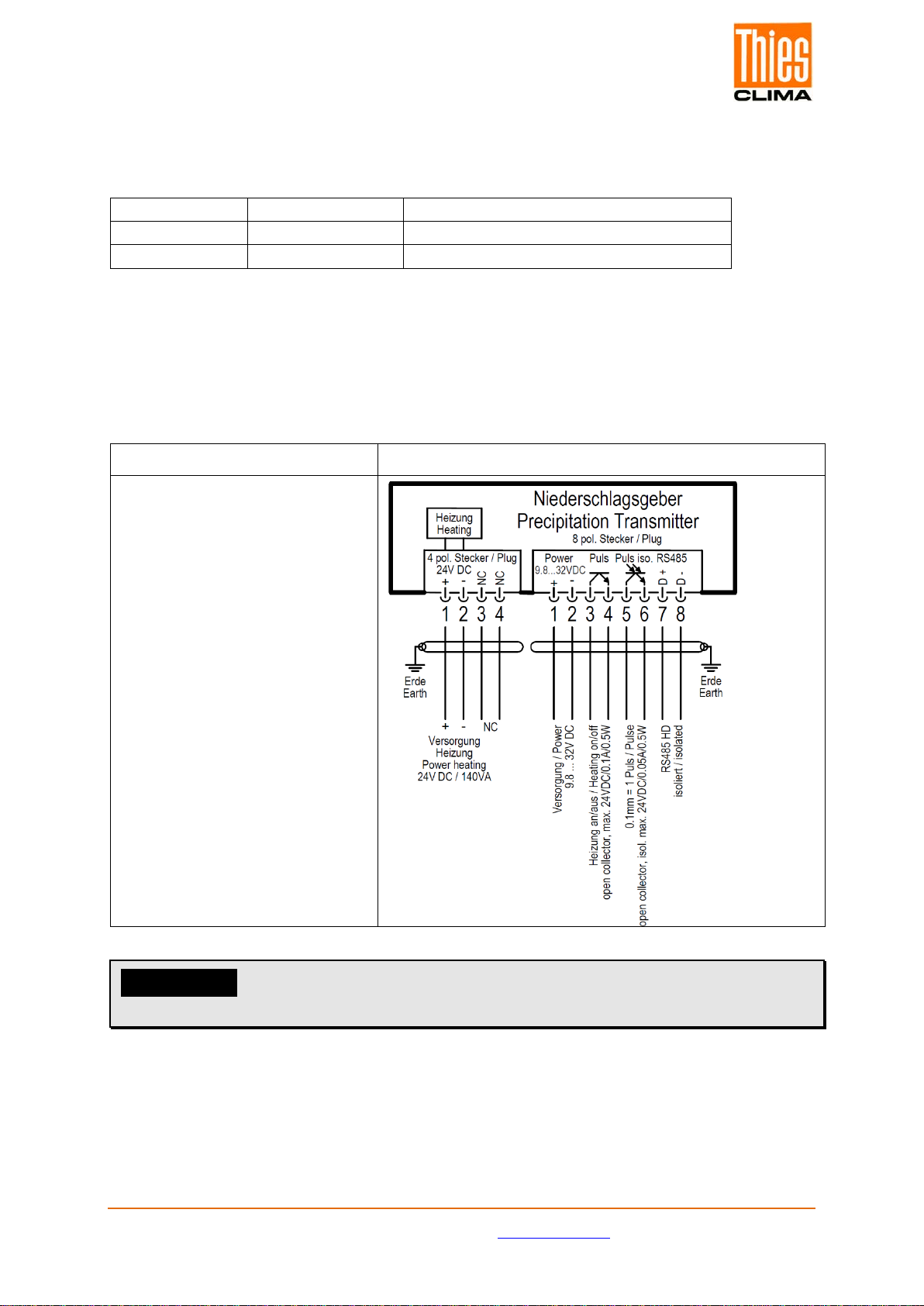

5.4 Power Connection and Signal Transmission............................................................16

5.4.1 Connection Order..............................................................................................17

Connections have to be carried out in the following order:............................................17

5.5 System Start............................................................................................................17

5.6 Interfaces ................................................................................................................18

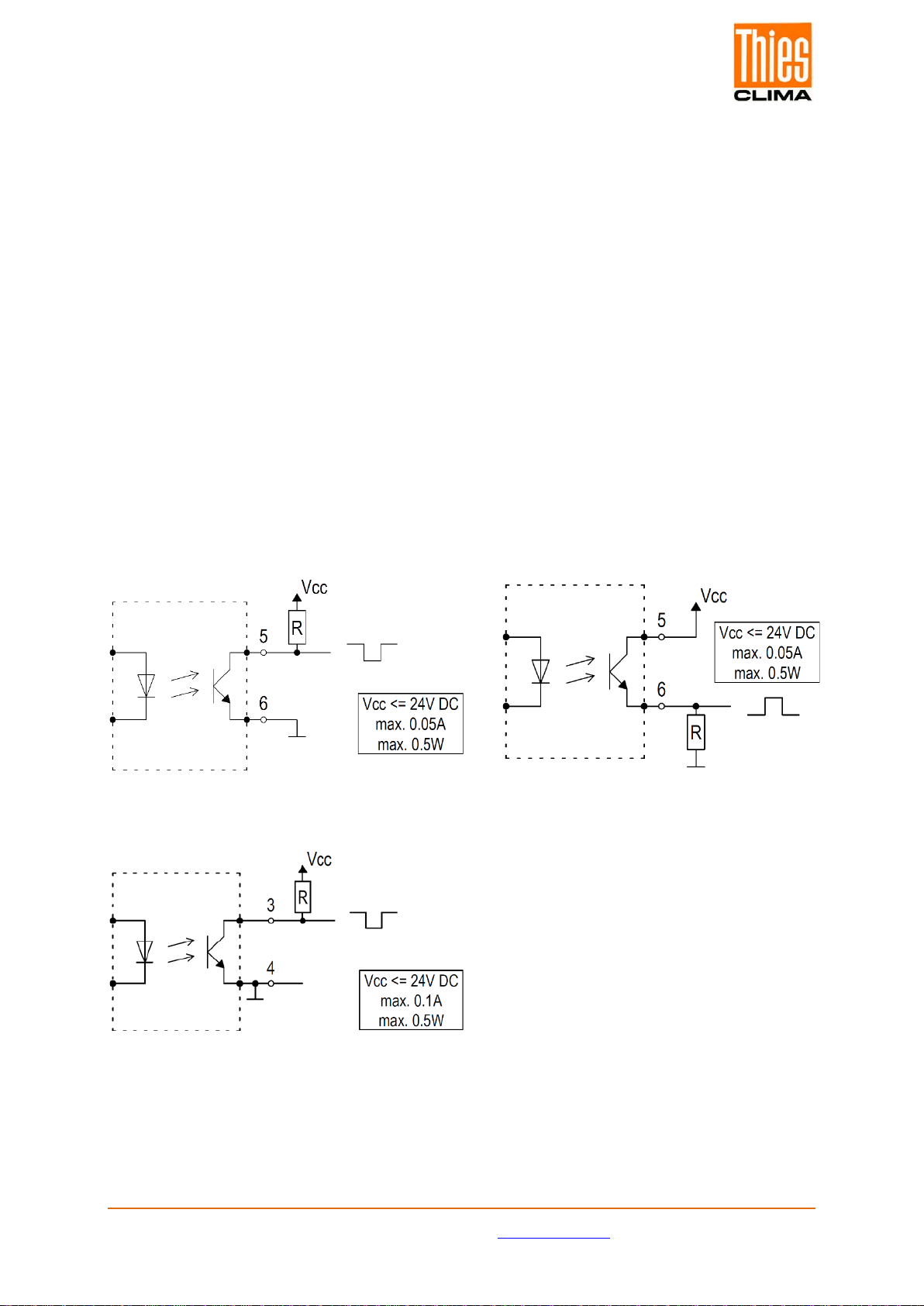

5.6.1 Examples for the Connection to the Optocoupler ..............................................18

5.7 Factory Setting ........................................................................................................19

6Serial Communication....................................................................................................19

6.1 RS485-Interface......................................................................................................19

6.2 ASCII-Protocol.........................................................................................................19

6.2.1 Overview over Commands................................................................................21

6.2.1.1 Command a................................................................................................21

6.2.1.2 Command e................................................................................................21

6.2.1.3 Command i.................................................................................................22

6.2.1.4 Command m...............................................................................................22

6.3 Command Interpreter MODBUS-RTU......................................................................22

6.3.1 Measured Values (Input Register).....................................................................23

6.3.2 Configuration Parameters .................................................................................23

6.3.3 Mapping Register Modbus ................................................................................24

6.3.4Sensor Status (error) Explanation.....................................................................24

6.3.5 Quantity of Precipitation....................................................................................24

6.4 Pulse Output............................................................................................................25

7Maintenance, Checks and Troubleshooting ...................................................................25

8Technical Data...............................................................................................................27

9Accessories (optional)....................................................................................................28

10 Dimension Diagram .......................................................................................................29

11 EC-Declaration of Conformity ........................................................................................30

List of Figures

Figure 1: Construction............................................................................................................6

Figure 2: Open the device....................................................................................................10

Figure 3: Inner parts and protective cylinder.........................................................................11

Figure 4: Installation of the collection vessel.........................................................................12

Figure 5: Re-assembly of the device ....................................................................................13

Figure 6: Dirt trap .................................................................................................................14

Figure 7: Examples for the Connection to the Optocoupler...................................................18

Figure 8: Dimension Diagram...............................................................................................29