Thies CLIMA Modbus User manual

Wind Direction Transmitter

>>First Class<<

Instruction for Use

4.3151.xx.401

- Device with digital output (MODBUS RTU), RS 485

- Wind velocity signal acquisition

Dok. No. 021887/12/20

T H E W O R L D O F W E A T H E R D A T A

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 2 - 34

Safety Instructions

•Before operating with or at the device/product, read through the operating instructions.

This manual contains instructions which should be followed on mounting, start-up, and operation.

A non-observance might cause:

- failure of important functions

- endangerment of persons by electrical or mechanical effect

- damage to objects

•Mounting

, electrical connection and wiring of the device/product must be carried out only by a qualified

technician who is familiar with and observes the engineering regulations, provisions and standards ap-

plicable in each case.

•Repairs and maintenance may only be carried out by trained staff or Adolf Thies GmbH & Co. KG.

Only components and spare parts supplied and/or recommended by Adolf Thies GmbH & Co. KG

should be used for repairs.

•Electrical devices/products must be mounted and wired only in a voltage-free state.

•Adolf Thies GmbH & Co KG guarantees proper functioning of the device/products provided that no

modifications have been made to the mechanics, electronics or software, and that the following points

are observed:

•All information, warnings and instructions for use included in these operating instructions must be

taken into account and observed as this is essential to ensure trouble-free operation and a safe condi-

tion of the measuring system / device / product.

•The device / product is designed for a specific application as described in these operating instructions.

•The device / product should be operated with the accessories and consumables supplied and/or rec-

ommended by Adolf Thies GmbH & Co KG .

•Recommendation: As it is possible that each measuring system / device / product may, under certain

conditions, and in rare cases, may also output erroneous measuring values, it is recommended using

redundant systems with plausibility checks for security-relevant applications.

Environment

•As a longstanding manufacturer of sensors Adolf Thies GmbH & Co KG is committed

to the objectives of environmental protection and is therefore willing to take back all

supplied products governed by the provisions of "ElektroG" (German Electrical and

Electronic Equipment Act) and to perform environmentally compatible disposal and

recycling. We are prepared to take back all Thies products concerned free of charge if

returned to Thies by our customers carriage-paid.

•Make sure you retain packaging for storage or transport of products. Should packag-

ing however no longer be required, please arrange for recycling as the packaging ma-

terials are designed to be recycled.

Documentation

•© Copyright Adolf Thies GmbH & Co KG, Göttingen / Germany

•Although these operating instructions have been drawn up with due care, Adolf Thies GmbH & Co

KG can accept no liability whatsoever for any technical and typographical errors or omissions in this

document that might remain.

•We can accept no liability whatsoever for any losses arising from the information contained in this doc-

ument.

•Subject to modification in terms of content.

•The device / product should not be passed on without the/these operating instructions.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 3 - 34

Table of contents

1Available Models...........................................................................................................4

2Application....................................................................................................................4

3Mode of Operation........................................................................................................5

4Recommendation Site Selection / Standard Installation................................................6

5Installation ....................................................................................................................6

5.1 Wind Vane Mounting.................................................................................................7

5.2 Mechanical Mounting and Alignment.........................................................................8

5.3 Electrical Mounting..................................................................................................10

5.3.1 Cable ................................................................................................................10

5.3.2 Cable Shield......................................................................................................10

5.3.3 Plug and Cable Mounting..................................................................................12

6Connecting Diagram...................................................................................................13

6.1 Example Connection Diagram.................................................................................14

7Serial Interface (RS485) .............................................................................................15

8Placing into Operation ................................................................................................15

9Serial Communication.................................................................................................15

10 Commands and Description........................................................................................16

10.1 Command BR..........................................................................................................17

10.2 Command CI...........................................................................................................17

10.3 Command FB..........................................................................................................18

10.4 Command ID...........................................................................................................18

10.5 Command KY..........................................................................................................18

10.6 Command MI...........................................................................................................19

10.7 Command OR .........................................................................................................19

10.8 Command RD..........................................................................................................19

10.9 Command RS..........................................................................................................20

10.10 Command SF..........................................................................................................20

10.11 Command SN..........................................................................................................20

10.12 Command SV..........................................................................................................21

10.13 Command TR..........................................................................................................21

10.14 Command TT ..........................................................................................................21

11 Command Interpreter MODBUS RTU.........................................................................22

11.1 Messwerte (Input Register)......................................................................................23

11.2 Commands (Holding Register).................................................................................24

12 Data Telegram............................................................................................................25

12.1 Telegram 3..............................................................................................................25

12.2 Telegram 4..............................................................................................................25

12.3 Telegram 5..............................................................................................................26

13 Maintenance...............................................................................................................26

14 Technical Data............................................................................................................27

15 Dimensional Drawing..................................................................................................29

16 Accessories................................................................................................................30

17 EC-Declaration of Conformity .....................................................................................32

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 4 - 34

Table overview

Table 1: Commands.............................................................................................................16

Table 2: MODBUS Frame ....................................................................................................22

Table 3: MODBUS Exceptions .............................................................................................22

Table 4: MODBUS Input Register.........................................................................................23

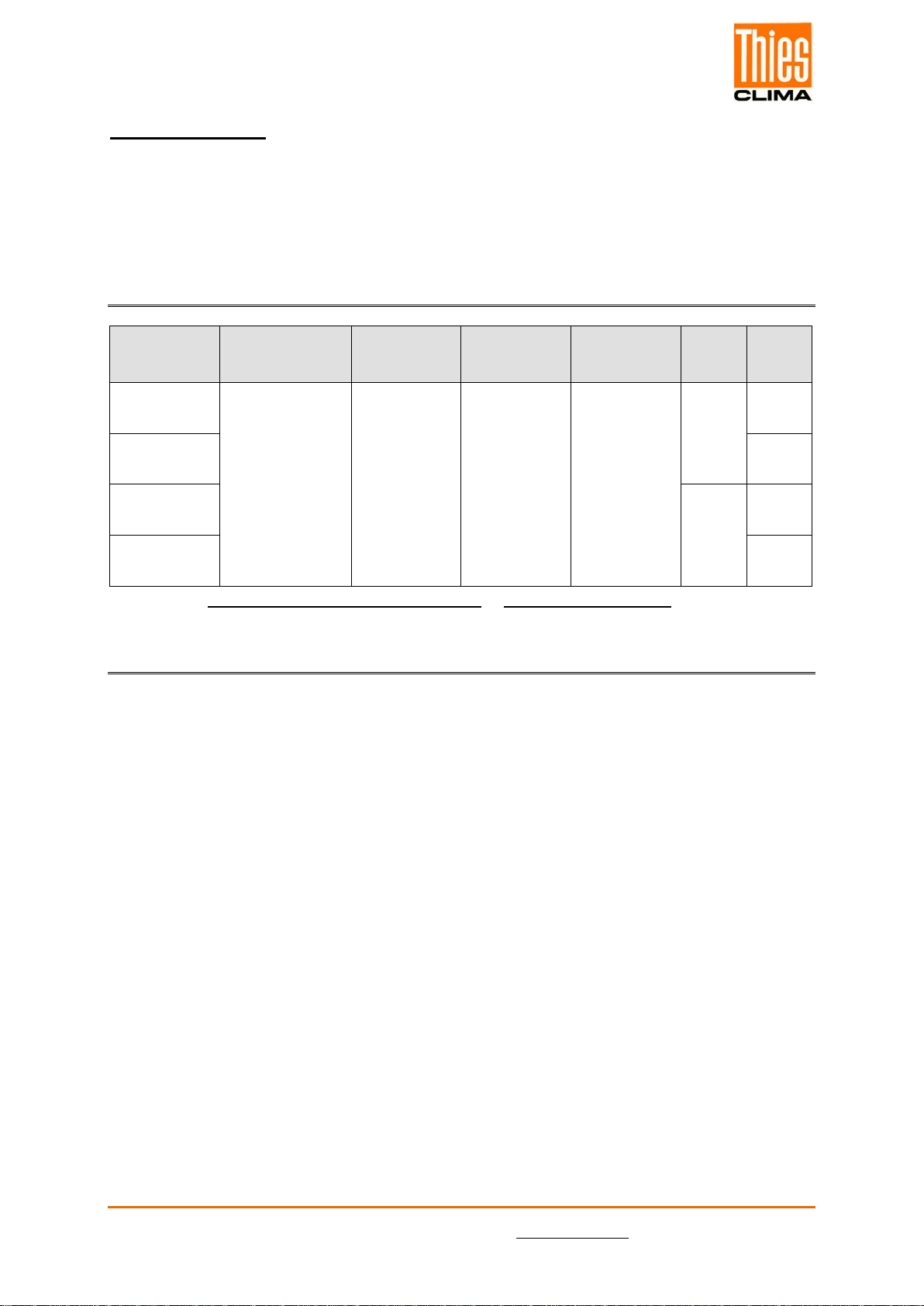

1 Available Models

*) see chapter 5.2 mechanical mounting and alignment or 15. dimensional drawing

2 Application

The wind direction transmitter serves for the detection of the horizontal wind direction in the

field of meteorology and the technology of environmental protection.

The measuring value is available in binary format on request as a serial data telegram via an

RS485 interface. The data telegram is able to operate, for e.g., wind displays, dataloggers,

process control systems.

The wind direction transmitter can also record the pulse signals from an anemometer and

can complete its serial data telegram by the parameter wind velocity.

Special characteristics:

•High level of measuring accuracy and resolution.

•High damping ratio at a small delay distance.

•Low starting threshold.

•Low current consumption (1,0mA @ 3,3 … 42V).

•Option for connecting an anemometer “First Class 4.335x.x0.000“.

•Data telegram additionally with wind velocity. (WV = 0,0462*f+0,21)

For wintertime use the wind direction transmitter (see chapter 1 models available) is optionally

equipped with an electronically regulated heating, which guarantees the smooth running of the

ball bearing, and prevents ice forming in the space between the external rotation parts.

Order - No.

Winddirection

Measuring range

Windvelocity

Input [Hz]

Interface /

Data output

Supply

Heating

South

bore*

4.3151.00.401

0 ... 360 ° 1082Hz

@ 50m/s

RS 485 /

Modbus RTU 3,3 … 42V DC

With Without

4.3151.01.401 With

4.3151.10.401 Without Without

4.3151.11.401 With

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 5 - 34

3 Mode of Operation

Wind direction

The dynamic characteristics of the wind vane is achieved by the aluminum lightweight con-

struction. The co-action of wind vane and balance weight results in a high damping ratio with

small delay distance as excellent characteristic of the complete vane.

The axis of the wind vane is running in ball bearings and carries a diametrically magnetized

magnet at the inner end. The angle position of the axis is scanned contact-free by a mag-

netic angle sensor (TMR-Sensor, Tunnel Magneto Resistance) through the position of the

magnet field. As the sensor is operated in magnetic saturation, effects by external magnetic

fields can almost be eliminated. The connected electronics calculates the angle position of

the axis and provides the respective serial output signal.

Note:

The wind direction is recorded 4 times per second.

Acquisition of Wind Velocity

Additionally to the wind direction acquisition the wind direction transmitter offers the option of

supplying the wind velocity signal from the Wind transmitter First Class 4.335x.x0.000. The

wind velocity signal is acquired and analyzed and is available in the output register along

with the acquired wind direction.

The measured frequency is converted into the wind speed using the following straight line

equation

= 0,0462 ∗ + 0,21 :ℎ

:

With frequency of 0Hz the wind speed is set to 0m / s.

Note:

The wind speed (frequency) is recorded by means of a period duration measurement (inter-

nal reference clock: 4MHz).

General

An AC- or DC-voltage of 24V is intended for the separate supply of the optional heating. In all

probability, the heating guarantees a trouble-free function of the Wind Direction Transmitter

First Class even under extreme meteorological icing-conditions.

The outer parts of the instrument are made of corrosion-resistant anodized aluminum and

stainless steel. Highly effective labyrinth gaskets and O-rings protect the sensitive parts in-

side the instrument against humidity and dust.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 6 - 34

4 Recommendation Site Selection / Standard Installation

In general wind measurement instruments should be able to detect the wind conditions of a

large area. In order to obtain comparable values when determining the surface wind, meas-

urements should be taken at a height of 10 meters over an even area with no obstacles. An

area with no obstacles means that the distance between the wind direction transmitter and an

obstacle should be at least 10 times the height of the obstacle (s. VDI 3786 Part 2). If it is not

possible to fulfill this condition then the wind direction transmitter should be set up a height

where local obstacles do not influence the measured values to any significant extent (approx.

6 … 10m above the obstacle). The wind direction transmitter should be set up in the center of

flat roofs and not on the edge in order to avoid any preferential directions.

5 Installation

Attention:

Storing, mounting and operation under weather conditions is permissible only

in vertical position, as otherwise water can get into the instrument.

Remark:

When using fastening adapters (angle, traverses, etc.) please take a possible effect on the

measurements by turbulences into consideration.

Caution:

The device may only be supplied with a power supply of the "Class 2, limited

power”.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 7 - 34

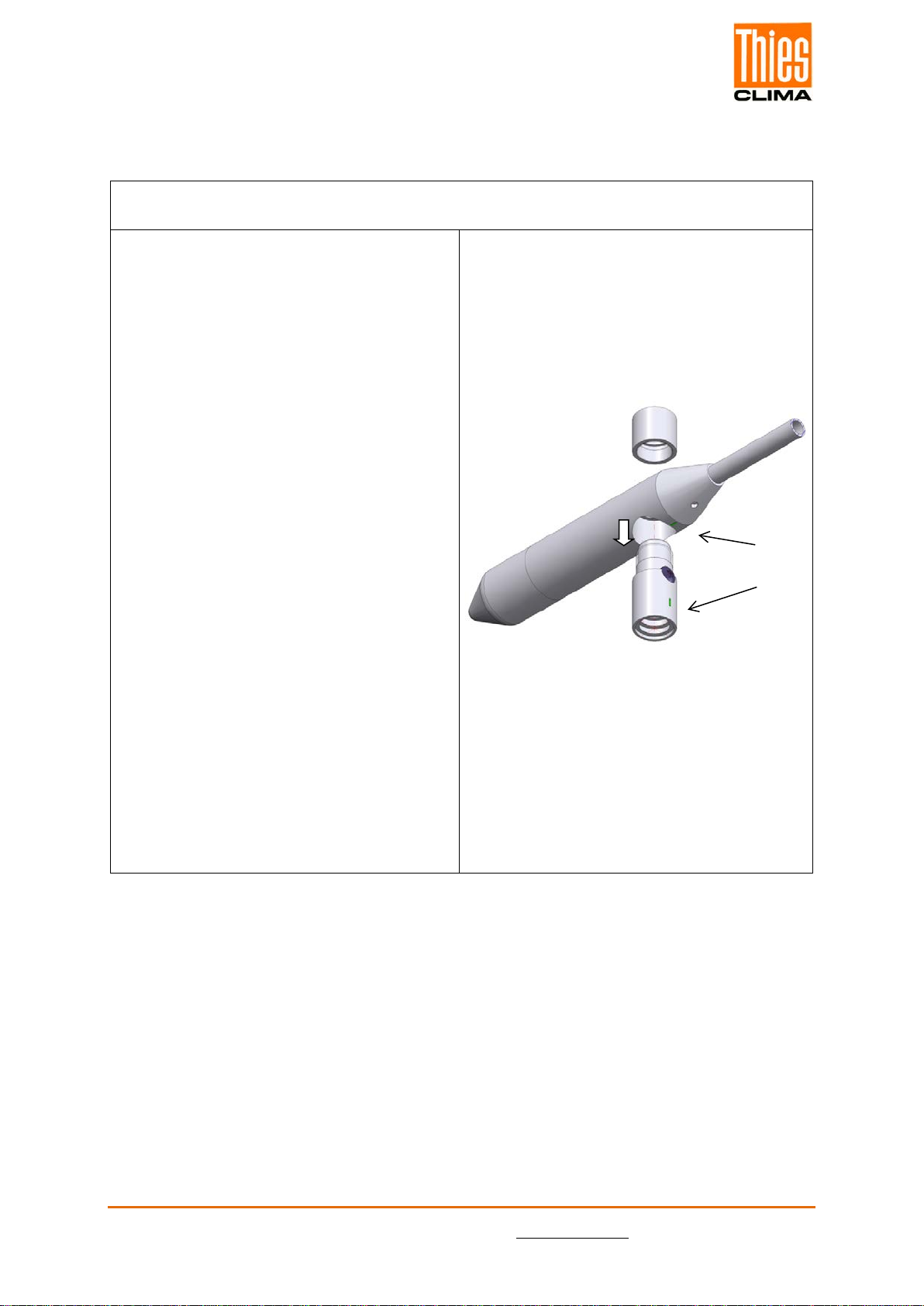

5.1 Wind Vane Mounting

Before the wind direction transmitter can be installed at its selected site, the wind vane

must be mounted on the housing.

Tool:

Not required.

Process

1. Remove wind transmitter shaft and

wind vane from the packing.

2. Remove capby left-hand rotation

of upper partof wind transmitter

shaft.

3. Put the wind vane onto the upper

part of the wind transmitter shaft.

Remark:

The longer part of the wind vane

blade must indicate upwards.

4. Keep hold of the wind vane by hand

to avoid twist movement, and turn

the upper part of the wind transmitter

shaft until the vane locks into the for-

cible control.

Remark:

The marking linesat the bottom of

wind vane counter weight, and at the

upper part of the wind transmitter

shaft, must be aligned.

5. Put the cap onto the thread, and

seize strongly by clockwise rotation

by hand ... ready

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 8 - 34

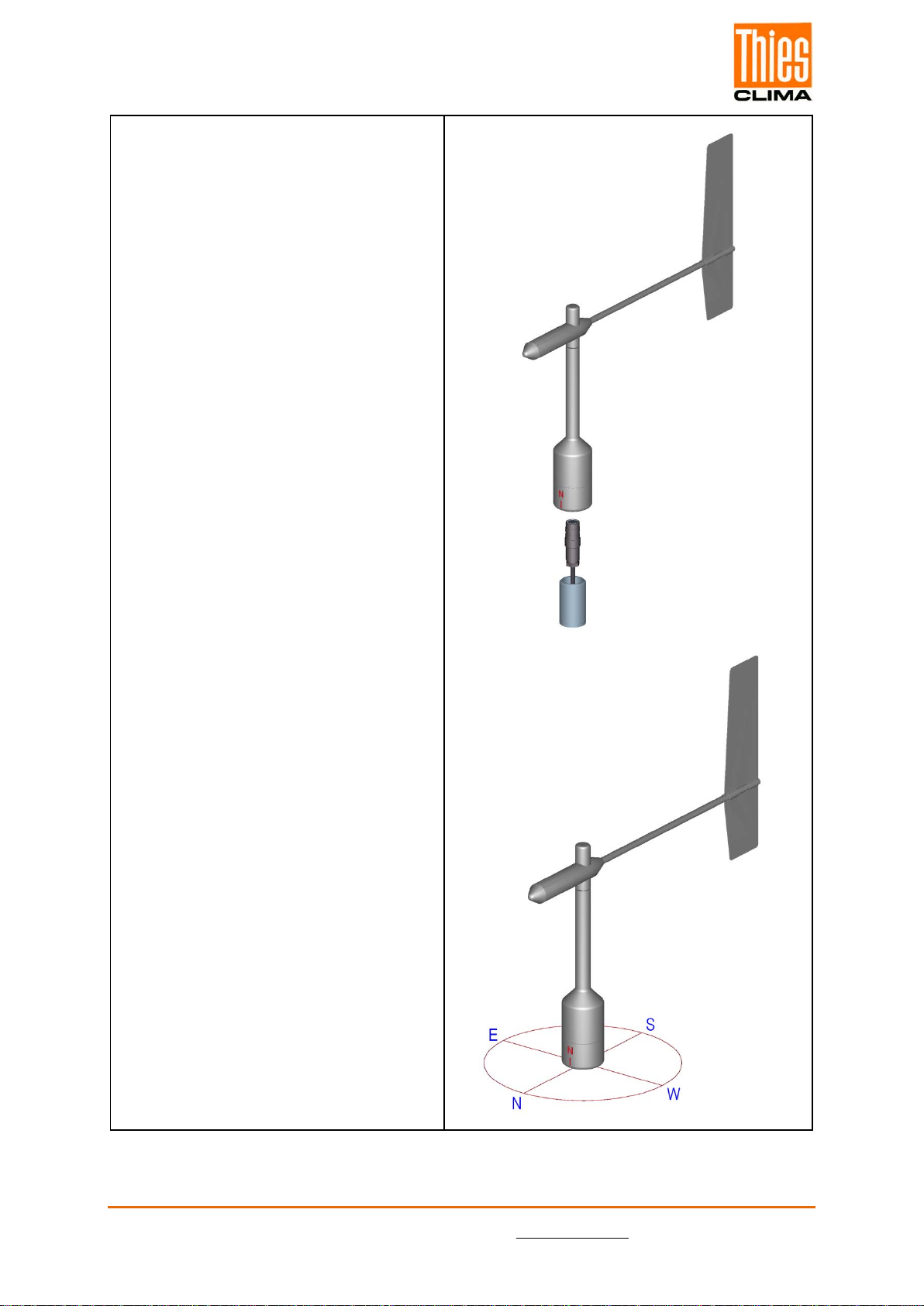

5.2 Mechanical Mounting and Alignment

Remark:

The wiring must be prepared so far, that plug and cable have been pushed through instru-

ment carrier, mast, traverse etc., and can be connected to the wind direction transmitter at

the moment of the “Mechanical Mounting”, described in the following (please refer to

chapter 5.3.).

The wind direction transmitter must be mounted on an instrument carrier, which is suited for

the measurement. For dimensions of wind direction transmitter please refer to chapter 15

Dimension diagram.

Suitable instrument carriers are masts, tubes, traverses, arms, adapters, adapters of POM

for isolated mounting, which correspond to the mounting dimensions of the wind transmit-

ter, and to the static requirements.

The inner diameter of the instrument carrier should be ≥ 20mm based on plug- and cable

feed-through.

If the north alignment is carried out by compass, please consider the local declination

(= deviation of direction of the magnetic needle from the true north), and local magnetic in-

terferences (e.g. hardware, electric cable).

For alignment aid and for easy changing / replacement without readjustment:

With the help of the north-ring (accessory 509619):

The optional north ring part. no. 509619 can be used to mount the wind transmitter. The

north ring serves as an alignment aid and for easy changing / replacement without having

to re-adjustment of the north direction of wind direction indicators. The north ring uses the

north borehole of the mast holder for this. See chapter 15 Dimension diagram.

With the help of the south borehole:

The south borehole is used for alignment in the north / south direction. It serves as an

alignment aid and for easy changing / replacement without readjustment. For north orienta-

tion using the south hole, you have to construct your mounting mast specifically. See chap-

ter 15 Dimension diagram.

When aligning the wind direction transmitter on a moving object (e.g. vehicle, wind wheel,

ship etc) please consider that the “north point” to be determined, might possibly be located

on the object.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 9 - 34

Tools:

Hexagon socket wrench size 3

(Allen key).

Procedure:

1. Push cable/ plug connector of the

wind direction transmitter through

the borehole of the mast, tube, arm

etc.

2. Put wind direction transmitter on

mast, tube, arm etc.

3. For the precise determination of

the wind direction the wind direc-

tion transmitter must be aligned

northwards (geographical north).

The north point (0 °) is at the point

where the output signal jumps from

the maximum value to the minimum

value.

4. Rotate north marking (I) at the

housing and wind vane axially one

above the other, acc. to figure.

5. Determine a prominent spot in the

surrounding area (tree, building

etc.) in northward direction, by

means of a compass.

6. Locate the prominent spot over

wind vane and balance weight of

the wind direction transmitter.

7. Align wind direction transmitter.

The north marking must indicate

the geographical north.

8. In case of conformity, safeguard

the wind direction transmitter by

two M6-Allen head screws.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 10 - 34

5.3 Electrical Mounting

5.3.1 Cable

Solder a shielded cable with diameter 7 … 8mm and a core cross-section of 0.5 ... 0.75mm²

to the enclosed coupling socket.

•The number of necessary wires is given in the connection diagram (chapter 7).

5.3.1.1 Cable Recommendation

No. of wires/ diameter / type / cable diameter

CABLE 8 x 0.5mm² LIYCY BLACK, UV- resistant, Ø 7.6mm

5.3.2 Cable Shield

The connection of the cable shield between sensor and data acquisition device should be se-

lected in way, that in case of over-voltages no equalizing currents will flow that might destroy

the electronic components.

The connection of the cable shield should depend on the selected isolated, or respectively,

non-isolated mounting of the sensors.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 11 - 34

5.3.2.1 Connecting Recommendation for the Cable Shield

Sensor Carrier Sensor Shielding / Ground Lightning Protection

1. Metallic measure-

ment mast, grounded Isolated mounting at

the measuring mast

(e.g. by non-metallic

brackets, holder etc.

or

by metallic brackets,

holder etc. with iso-

lated plastic adap-

tors).

Apply the cable shield

between sensor and

data acquisition device

(e.g. datalogger) both-

sided.

Ground data acquisi-

tion device.

Mount metallic lightning

protection rod on the

mast.

Alternatively:

Install separate lightning

protection rod beside

the measurement mast.

2. Metallic measure-

ment mast, grounded Non-isolated mount-

ing at the measure-

ment mast

(e.g. by metallic

brackets, holders

etc.).

Apply cable shield be-

tween sensor and data

acquisition device (e.g.

datalogger) only one-

sided at the acquisition

device..

Ground data acquisi-

tion device.

Mount metallic lightning

protection rod on the

mast in isolated condi-

tion, and ground light-

ning protection rod.

Alternatively:

Install separate lightning

protection rod beside

the measurement mast.

3. Metallic measure-

ment mast, not

grounded (mounted

in isolated condition,

e.g. on the attic)

Non-isolated mount-

ing at the measure-

ment mast.

(e.g. by metallic

brackets, holders

etc.).

Apply the cable shield

between sensor and

data acquisition device

(e.g. datalogger) both-

sided.

Ground data acquisi-

tion device.

Mount metallic lightning

protection rod on the

mast in isolated condi-

tion, and ground light-

ning protection rod.

Alternatively:

Install separate lightning

protection rod beside

the measurement mast.

4. Non-metallic measur-

ing mast (=isolated) Mounting at the

measurement mast.

(e.g. by metallic

brackets, holders

etc.).

Apply the cable shield

between sensor and

data acquisition device

(e.g. datalogger) both-

sided.

Ground data acquisi-

tion. device.

Mount metallic lightning

protection rod on the

mast, and ground light-

ning protection rod.

Alternatively:

Install separate lightning

protection rod beside

the measurement mast.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 12 - 34

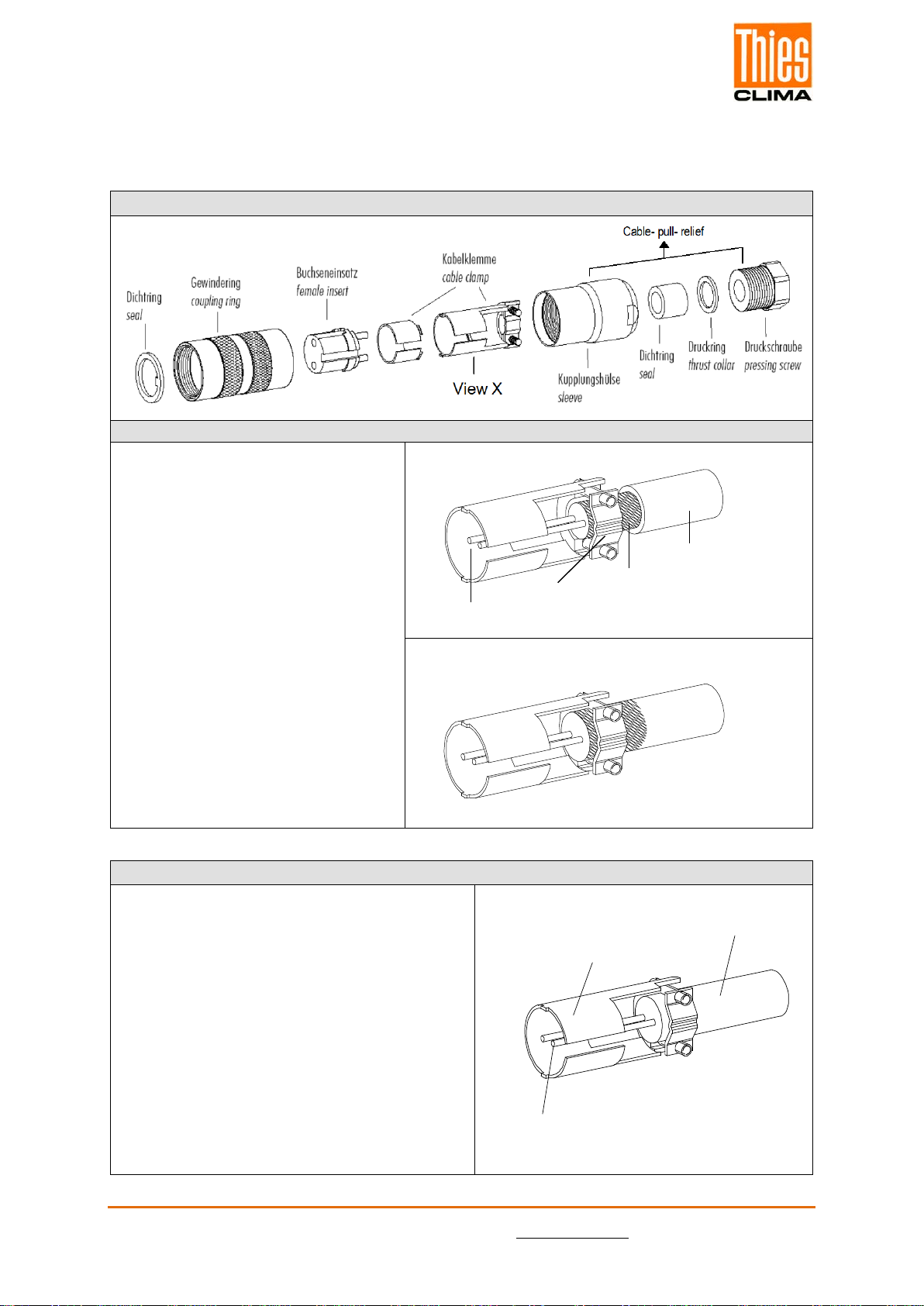

5.3.3 Plug and Cable Mounting

Coupling socket, Type: Binder, Serial 423, EMC with cable clamp

Cable connection: with cable shield

1. Stringing parts on cable acc. to

plan given above.

2. Stripping cable sheath 20mm

Cutting uncovered shield 15mm

Stripping wire 5mm.

Cable mounting 1:

Putting shrink hose or insolating

tape between wire and shield.

Cable mounting 2:

If cable diameter permits, put the

shield backward on the cable

sheath.

3. Soldering wire to the insert, posi-

tioning shield in cable clamp.

4. Screwing-on cable clamp.

5. Assembling remaining parts acc.

to upper plan.

6. Tightening pull-relief of cable by

screw-wrench (SW16 und 17).

Cable mounting 1

View X

wire

Cable clamp

shield

Cable shield

Cable mounting 2

View X

Cable connection:

without

cable shield

1. Stringing parts on cable acc. to plan given

above.

2. Stripping cable sheath 20mm.

3. Cutting uncovered shield 20mm.

4. Stripping wire 5mm.

5. Soldering wire to the insert.

6. Positioning shield in cable clamp.

7. Screwing-on cable clamp.

8. Assembling remaining parts acc. to upper

plan.

9. Tightening pull-relief of cable by screw-

wrench (SW16 und 17).

Cable clamp

Cable sheath

Wire

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 13 - 34

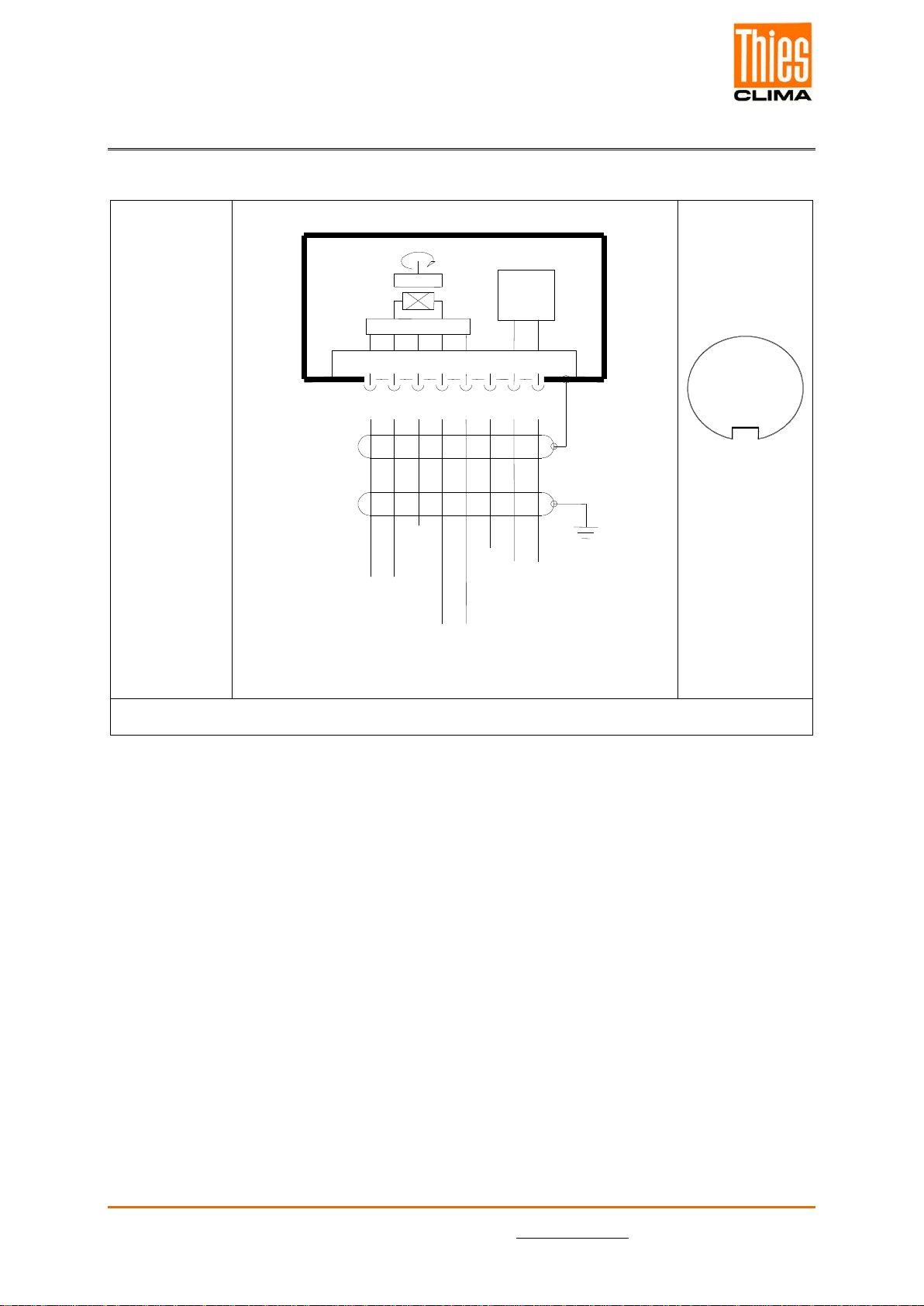

6 Connecting Diagram

Connection diagram acc. to chapter 5.3.2.1 no. 1, 3 and 4:

Order-No.

4.3151.0X.401

4.3151.1X.401*

3

4

Vers. / Power 3,3...42 VDC

8 pol. Binder Steckverb. / Plug

RS485 A

RS485 B

Digital Masse / Ground

2

1

N

S

Masse / Ground

5

6

7

Schirm

Shield

Erde / Earth

8

Versorgung / Power

Heizung / Heating

24 V AC / DC 25 W

Heizung

Heating

25 W

C P U

WG-Frequenz

View on the sol-

dered joint of

the counter plug

1

2

3

4

5

6

7

8

•*Order-no 4.3151.10.xxx (w/o heating) PIN 7 and 8 are not connected.

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 14 - 34

Pin

Name

Function

1 WV-frequency Input wind velocity

2 GND Supply ground

3

+Vcc

Supply 3.3 ... 42V DC

4

Serial B

RS 485 (B)

5 Serial A RS 485 (A)

6 DGND Digital ground / ground wind velocity

7 HZG Heating supply:

Voltage: 24V AC/DC

Power: 25W

8

*Order-no 4.3151.10.xxx (w/o heating) PIN 7 and 8 are not connected.

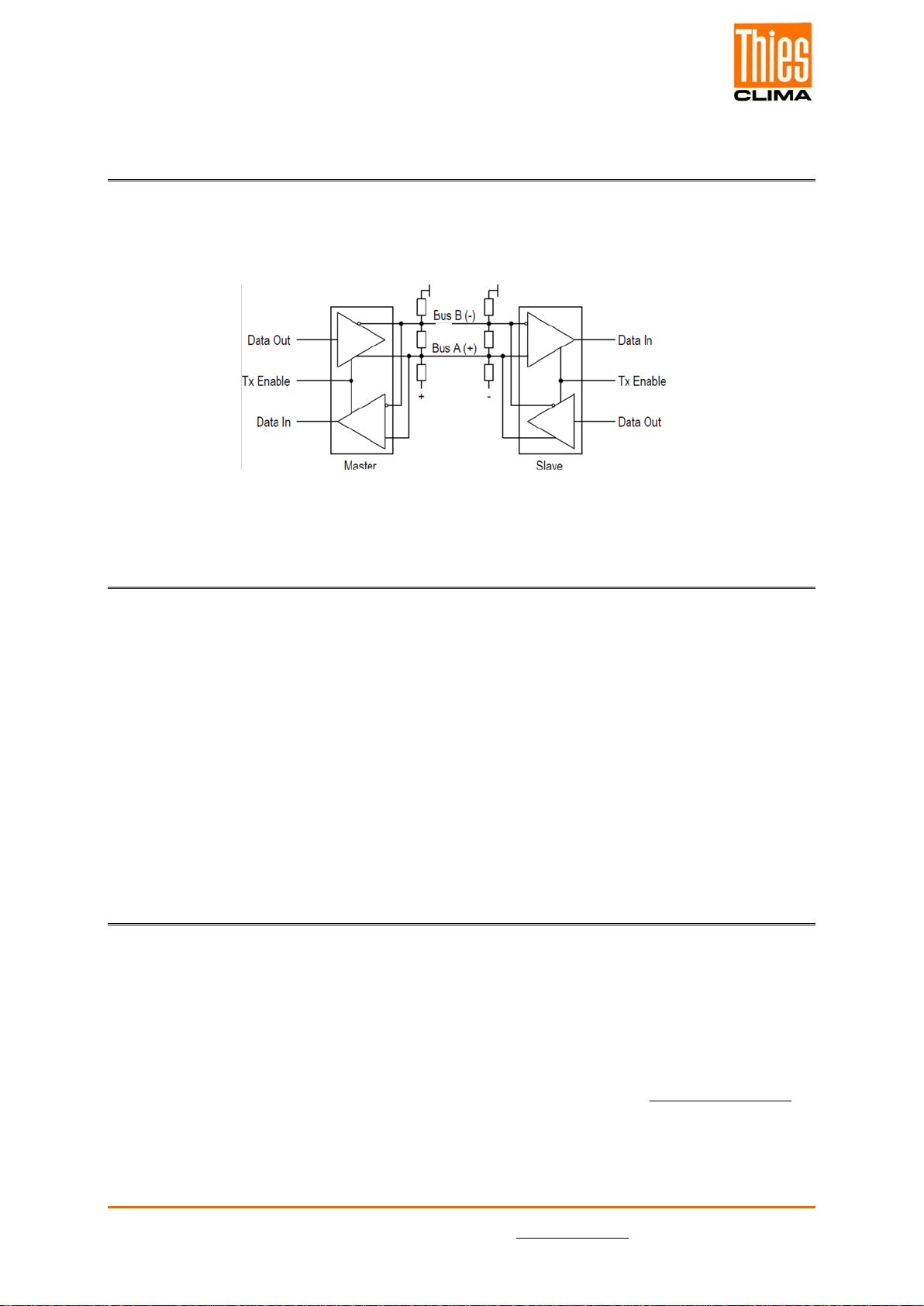

6.1 Example Connection Diagram

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 15 - 34

7 Serial Interface (RS485)

The wind direction transmitter has an RS485 interface, which is operated in half-duplex

mode. For a respective termination (terminating resistance) of the connecting cable must be

provided externally (no termination in the wind direction transmitter).

8 Placing into Operation

The wind direction transmitter is to be connected to a power supply and a RS485 interface,

as given in the connection diagram. With the connection of the supply voltage, and after a

delay of 5sec, the output of serial data starts automatically with the following setting/or the

MODBUS register are accessible:

Setting of interface:

Baud rate 9600 baud

Data bits 8 bit

Parity bit no

Stop bit 1

9 Serial Communication

The communication from the wind direction sensor has a command interpreter, which sup-

ports the following mode (see Command CI):

- MODBUS RTU

With the command interpreter can be read measurements and the behavior of the device can

be changed. This includes e.g. baud rate, framing, device ID and startup behavior.

In order to avoid an unwanted parameter adjustment some Commands (see Command list)

are secured by a password. This password must be sent before the actual command.

The wind direction sensor supports 1 password level.

•User-level (Password “1“).

Principle circuit diagram

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 16 - 34

Attention:

The password-protected commands are released until one of the following

conditions is met:

- switch the supply voltage

- the command 00KY0 <CR> is sent

The register addresses of the command interpreter in MODBUS-RTU mode according to the

supported commands are listed in Table 1.

10 Commands and Description

For the wind direction transmitter the following commands are available:

Command Initial value

factory setting MODBUS

Register-

adress

Description Password

read1/ write2

Command BR

5

40005

Set the baudrate

Without

User

Command CI

0

40013

Selection of the command inter-

preter

Without

User

Command FB

1

40001

Quick start mode

Without

User

Command ID

1 (MODBUS)

40003

Set wind sensor ID

Without

User

Command KY

0

40009

Key / Password

Without

Without

Command MI

10

40027

Averaging interval

Without

User

Command OR

100

-

Output interval

Without

User

Command RS

0

40021

Check reset source or perform

reset

Without

User

Command SF

0

40019

Frame format

Without

User

Command SN

0

40007

Serial number

Without

-

Command SV

-

45005

Software-version.

Without

-

Command TR

-

-

Telegram request

Without

Without

Command TT

0

-

Automatic telegram output

Without

User

Table 1: Commands

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 17 - 34

10.1Command BR

<id>BR<parameter><CR> Set the baudrate

Access: Read / write

Description: With command BR get/set the baudrate.

Parameter Description:

Parameter

Description

2

1200baud

3

2400baud

4

4800baud

5

9600baud

6

19200baud

7

38400baud

8

57600baud

Value range: 2 / 3 / 4 / 5 / 6 / 7 / 8

Initial value: 5

10.2 Command CI

<id>CI<parameter><CR> Selection of the command interpreter

Access: Read / write

Description: With Command CI get set the command interpreter.

Note:

If the identification number ID 0, switching to the MODBUS RTU interpreter is

not possible!

Parameter Description:

Parameter Description

1 MODBUS RTU

Value range: 0 bis 1

Initial value: 0

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 18 - 34

10.3 Command FB

<id>FB<parameter><CR> Quick start mode

Access: Read / write

Description: With command “FB“ get set the quick start mode

Parameter Description: 0: quick start modus off

1: quick start modus on

Value range: 0...1

Initial value: 1

10.4 Command ID

<id>ID<parameter><CR> Identification Number

Access: Read / write

Description: This command sets the slave address (MODBUS RTU Inter-

preter). Only if the 'id' contained in the command matches the

one set in the sensor will send a telegram. After the 'id' has

been changed, the device immediately reacts only to com-

mands with the new ID.

'id'.Parameter Description: 0 Broadcast Slave-Addresse (MODBUS RTU Interpreter)

Value range: 1 … 247 (MODBUS RTU Interpreter)

Initial value: 1 (MODBUS RTU Interpreter)

10.5 Command KY

<id>KY<parameter><CR> Key / Password

Access: Read / write

Description: With command “KY“ get set the value of the key / password. To

chance parameters, the required password must be set.

Parameter Description: 0 no password

1 key / password at user level

Value range: 0 / 1

Initial value: 0

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 19 - 34

10.6Command MI

<id>MI<parameter><CR> Averaging intervall

Access: Read / write

Description: With this command, the averaging interval for the sliding aver-

aging of the wind direction is set in seconds. The wind direction

is vectorially averaged with the unit vector (i.e., the magnitude

of the vector is 1).

Parameter Description: Averaging interval in seconds

Value range: 0...600

Initial value: 10

10.7 Command OR

<id>OR<parameter><CR> Output interval

Access: Read / write

Description: With command “OR” you set or query the output interval for the

automatic telegram output.

Parameter Description: Output interval in milliseconds

Value range: 100...60000

Initial value: 100

10.8Command RD

<id>RD<parameter><CR> Response delay

Access: Read / write

Description: With command “RD“ you set and query the response delay be-

tween receiving and command.

Parameter Description: Delay in milliseconds

Wertebereich: 0…50

Initialwert: 20

© Adolf Thies GmbH & Co. KG · Hauptstraße 76 · 37083 Göttingen · Germany 021887/12/20

Phone +49 551 79001-0 · Fax +49 551 79001-65 · inf[email protected] · www.thiesclima.com 20 - 34

10.9Command RS

<id>RS<parameter><CR> Reset

Access: Read / write

Description: Command “RS” queries the reset source (reading without pa-

rameter) or performs a reset (writing with any parameter).

The following reset sources can be output

Output

Meaning

POR

Power on reset

BODCORE

Brownout reset (µC core voltage)

BODVDD

Brownout reset (µC Vdd voltage)

EXT

External reset

WDT

Watchdog reset

SYST

System reset

Parameter Description: 1 Software Reset run

2 Watchdog Reset run

Value range: 1…2

Initial value: -

10.10 Command SF

<id>SF<parameter><CR> Frame format

Access: Read / write

Description: With command “SF“ set the frame format of the interface

Parameter Description: 0: 8N1 (8 data bits, no parity, 1 Stop bit)

1: 8N2 (8 data bits, no parity, 2 Stop bits)

2: 8E1 (8 data bits, straight parity, 1 Stop bit)

3: 8E2 (8 data bits, straight parity, 2 Stop bits)

4: 8O1 (8 data bits, uneven parity, 1 Stop bit)

5: 8O2 (8 data bits, uneven parity, 2 Stop bits)

Value range: 0…5

Initial value: 0

10.11 Command SN

<id>SN<CR> Serial number

Access: Reading

Description: With command “SN“ could read the serial number.

Parameter Description: -

Value range: -

Initial value: 0

This manual suits for next models

1

Table of contents

Other Thies CLIMA Transmitter manuals

Thies CLIMA

Thies CLIMA 5.4103.10.000 User manual

Thies CLIMA

Thies CLIMA 4.3120.22.012 User manual

Thies CLIMA

Thies CLIMA 4.3515.5 Series User manual

Thies CLIMA

Thies CLIMA 5.4041 1.00 Series User manual

Thies CLIMA

Thies CLIMA 4.3519 Series User manual

Thies CLIMA

Thies CLIMA 4.3515.30.000 User manual

Thies CLIMA

Thies CLIMA 4.3151.x0.400 Series User manual

Thies CLIMA

Thies CLIMA 4.3351.00.000 User manual