TxMiniBlock Transmitter

NOVUS AUTOMATION 2/2

3. Filtration Optimization: Filters the measurements ma e by the

transmitter eliminating interferences from the electrical system that fee s

the process.

4. Sensor Failure: Establishes the behavior of the output when problems are

presente by the sensor. When Minimum is selecte , the output current shifts

to < 4 mA ( own-scale), typically use in refrigeration. When Maximum is

selecte , if shifts to > 20 mA (up-scale), typically use for heating.

5. Zero orrection: Corrects minor errors presente by the transmitter, for

example, when the sensor is change . See item Operation in this manual.

6. Transmitter Information: In this fiel , there are ata that i entify the

transmitter. This information must be informe in any consultation with the

manufacturer.

7. Read onfiguration: When presse , this allows one to rea the

configuration on the transmitter connecte .

8. Send onfiguration: When presse , this allows one to sen the

configuration to the transmitter connecte .

Note: If, on the purchase or er, the user oes not efine a specific

configuration, the following configuration will be set:

•Pt100 sensor, range 0 to 100 °C, 0 °C zero correction.

•Filter to 60 Hz an maximum output for sensor failures.

4ME HANI AL INSTALLATION

The TxMiniBlock transmitter is suitable to be installe on hea s.

Figure 04 – Transmitter imensions

5ELE TRI AL INSTALLATION

Polyami e housing for the terminals.

Section of the wire: 0.14 a 1.0 mm².

Recommen e Torque: 0.8 Nm.

RE OMMENDATIONS FOR INSTALLATION

•Input signal con uctors shoul run away from power an contactor

wires, if possible, in groun e con uits.

•The instruments must be powere by a suitable network for

instrumentation.

•System failure shoul always be taken into account when esigning a

system to avoi irreversible amage to equipment or people. Installing

RC filters (47 Ω an 100 nF, in series) is strongly recommen e at

contactor coils or any other in uctors.

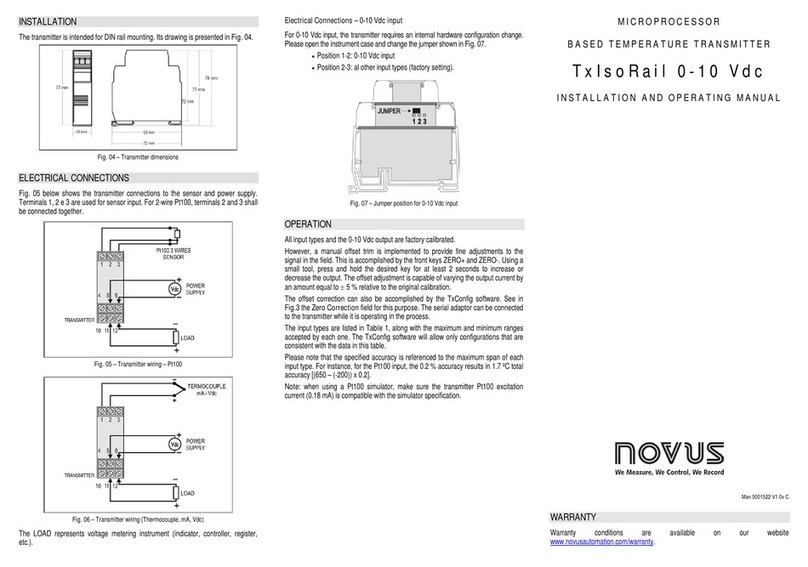

ELE TRI AL ONNE TIONS

Figure 05 below shows the transmitter wiring. Terminals 1, 2 an 3 are use

for sensor input. For 2-wire Pt100, terminals 2 an 3 shall be connecte

together. The LOAD represents the input shunt of an instrument measuring

the 4-20 mA current loop.

The figure below shows the electrical connections require . Terminals 1, 2

an 3 are use for the Pt100 input. For 2-wire Pt100, terminals 2 an 3 must

be interconnecte .

Figure 05 – Transmitter electrical connections – Pt100

The LOAD represents the input shunt of an instrument measuring the 4-20

mA current loop (in icator, controller, recor er, etc).

6OPERATION

The sensor input is factory calibrate . Recalibration in the fiel is not

recommen e , but it can be accomplishe through the TxConfig software.

Contact the factory for the calibration proce ure.

When necessary, fine a justments to the transmitter output current can be

accomplishe irectly at the transmitter. To o so, short circuit transmitter

terminals 1 an 4. After 2 secon s, the output current starts to increase

gra ually until it reaches 0.8 mA above the initial value. After reaching that

value, it rops to 0.8 mA below the initial value, increasing gra ually again.

The user must monitor the output current an open the circuit when the

current reaches the esire value.

The offset correction can also be accomplishe through the TxConfig

software. The TxConfig interface can be connecte to the transmitter while it

is operating in the process. See in Figure 03 the Zero orrection fiel in the

main screen of the TxConfig software.

The user must choose the sensor span most suitable to the application. The

maximum an minimum sensor spans are limite in the TxMiniBlock an in

the TxConfig software. The user can configure any value within those two

limits.

It is important to note that the accuracy of the transmitter is always base on

the maximum range of the Pt100 sensor, regar less of the configure span. .

Example:

•Pt100 maximum span = 850 °C; 0.2% accuracy.

•Maximum error = 1.7 °C (0.2 % e 850 °C)

The error is the same no matter if total span is use (-200 to 650 °C) or a

narrower user- efine span is use , like 0 to 100 °C.

Note: When using a Pt100 simulator, make sure the TxMiniBlock’s Pt100

excitation current (0.20 mA) is compatible with the simulator specification.

7WARRANTY

The manufacturer assures the owner of the equipment, i entifie by the

purchase invoice, a twelve-month warranty as follows:

•The warranty perio starts from the ate the invoice was issue by the

manufacturer.

•Within the warranty perio , the labor an components use for the

repair are free of charge

•For any repairs, sen the equipment, along with the repair invoices, to

the manufacturer’s a ress. Costs an risks of transportation, roun

trip, will be the owner’s responsibility.

•Even uring the warranty perio , the repair of efects cause by

mechanical shock or exposure to unsuitable con itions of temperature

an humi ity will be charge .