THIES 4.3811.00.000 User manual

THE WORLD OF WEATHER DATA - THE WORLD OF WEATHER DATA - THE WORLD OF WEATHER DATA

Ultrasonic Anemometer 2

D

4.3811.00.000

Software version V2.00 or higher Status: 10/2006

Operating Instructions

021511/10/06

ADOLF THIES GmbH & Co. KG

Hauptstraße 76 37083 Göttingen Germany

Box 3536 + 3541 37025 Göttingen

Phone ++551 79001-0 Fax ++551 79001-65

4.3811.00.000_US-Anemometer-DSP_eng.doc 2 - 26 021511/10/06

Contents

1Application ................................................................................................................................. 4

2Mode of Operation ..................................................................................................................... 4

2.1 Measuring principle: Wind velocity and direction ................................................................ 5

2.2 Measuring principle: Acoustic virtual temperature............................................................... 6

3Preparation for Operation / Installation ...................................................................................... 6

3.1 Selection of installation site ................................................................................................. 7

3.2 Installation of anemometer .................................................................................................. 7

3.3 Alignment to north ............................................................................................................... 7

3.4 Cables, cable preparation, connector installation................................................................ 7

3.5 Connector pin assignment................................................................................................... 9

4Maintenance .............................................................................................................................. 9

5Calibration................................................................................................................................10

6Warranty .................................................................................................................................. 10

7Functional Description ............................................................................................................. 11

7.1 Serial communication ........................................................................................................ 11

7.1.1 General telegram structure ......................................................................................... 12

7.1.2 Return values of ULTRASONIC.................................................................................. 13

7.1.3 Access mode .............................................................................................................. 13

7.1.4 Device ID .................................................................................................................... 14

7.1.5 Bus mode.................................................................................................................... 14

7.2 Data acquisition................................................................................................................. 14

7.2.1 Averaging.................................................................................................................... 14

7.3 Serial data output .............................................................................................................. 15

7.3.1 Data enquiry ............................................................................................................... 15

7.3.2 Fixed telegram formats ............................................................................................... 15

00005 ............................................................................................................................................. 15

7.4 Generation of check sum .................................................................................................. 16

7.5 Status information ............................................................................................................. 16

7.5.1 Definition of status byte version 1............................................................................... 16

7.5.2 Structure of status byte version 1 ............................................................................... 16

7.5.3 Definition of temperature difference in status byte ..................................................... 17

7.5.4 Definition of averaging memory used ......................................................................... 17

7.6 Behaviour in fault conditions ............................................................................................. 17

7.7 Heating control .................................................................................................................. 17

7.8 Output of all system parameters ....................................................................................... 18

7.9 Enquiry about software version ......................................................................................... 18

7.10 Forcing a restart ................................................................................................................ 18

7.11 Bootloader ......................................................................................................................... 18

7.12 Online Help........................................................................................................................ 18

8Configuration of Ultrasonic Anemometer by Customer............................................................ 19

9Command List, Short ............................................................................................................... 20

10 Predefined Data Telegram.................................................................................................... 22

4.3811.00.000_US-Anemometer-DSP_eng.doc 3 - 26 021511/10/06

11 Technical Data...................................................................................................................... 23

12 Dimension Drawing .............................................................................................................. 25

13 Accessories (available as optional features) ........................................................................ 25

Fig.

Fig. 1: Connector assembly.............................................................................................................. 8

Table

Table 1: Return values with incorrect interpretation of command .................................................. 13

Table 2: Access key for different command levels ......................................................................... 13

Table 3: List of predefined data telegrams ..................................................................................... 15

4.3811.00.000_US-Anemometer-DSP_eng.doc 4 - 26 021511/10/06

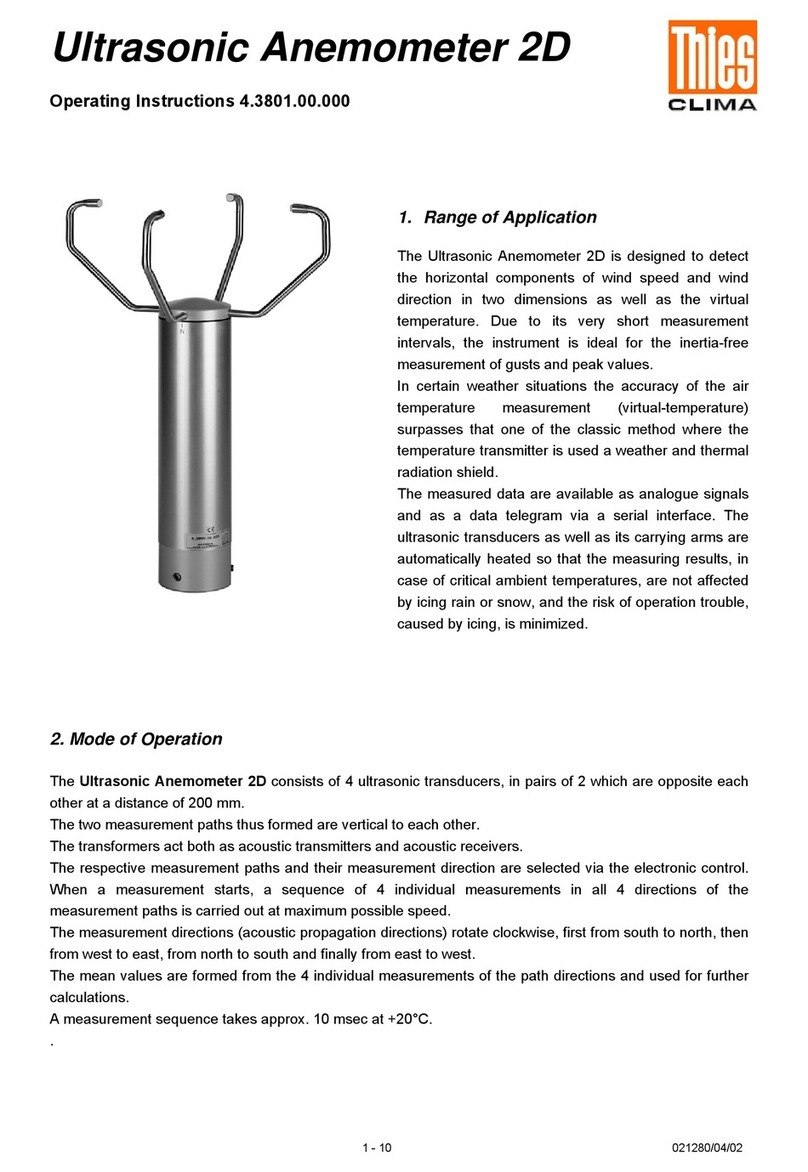

1 Application

The Ultrasonic Anemometer 2D is used to detect the horizontal components of wind velocity and

wind direction as well as the virtual temperature in 2 dimensions.

Due to the measuring principle the instrument is ideal for inertia-free measurement of gusts and

peak values.

The level of accuracy achieved when measuring the air temperature (virtual temperature)

surpasses that of classical methods, in which the temperature sensors are used with weather and

radiation protection, following correction of the influence of damp occurring with certain weather

situations.

Output of the measured values is digital. An RS485 in half duplex mode is available for serial

communication.

Serial output of the data is as a sliding mean.

The sensor arms are automatically heated if necessary with critical ambient temperatures. This also

ensures functionality with snowfall and sleet and minimises the risk of malfunctions due to icing-up.

The model No. 4.3811.00.000 has additional protection from mechanical stresses such as ice

fracture and attack by birds by means of metal encapsulated ultrasonic transformers.

These Operating Instructions relate to the device version 4.3811.00.000. They describe possible

applications and settings.

The Ultrasonic Anemometer 2D is factory-set. Identification for the factory setting is via the order

No. and "Factory Setting".

Order number and setting

see supplementary sheet "Factory Setting"

In addition, the default settings for device version 4.3811.00.000 are marked in "grey" in these

Operating Instructions.

2 Mode of Operation

The Ultrasonic Anemometer 2D consists of 4 ultrasonic transformers, in pairs of two facing each

other at a distance of 200 mm. The two resulting measurement paths are vertical to each other.

The transformers function both as acoustic transmitters and receivers.

The electronic control system is used to select the respective measurement path and its measuring

direction. When a measurement starts, a sequence of 4 individual measurements is performed in

all 4 directions of the measurement paths at maximum speed.

The measuring directions (sound propagation directions) rotate clockwise, first from south to north,

then from west to east, from north to south and finally from east to west.

The mean values are worked out from the 4 individual measurements of the path directions and

used to make further calculations..

The time required for a measuring sequence is approx. 2.5 msec at +20°C at the maximum

measuring speed.

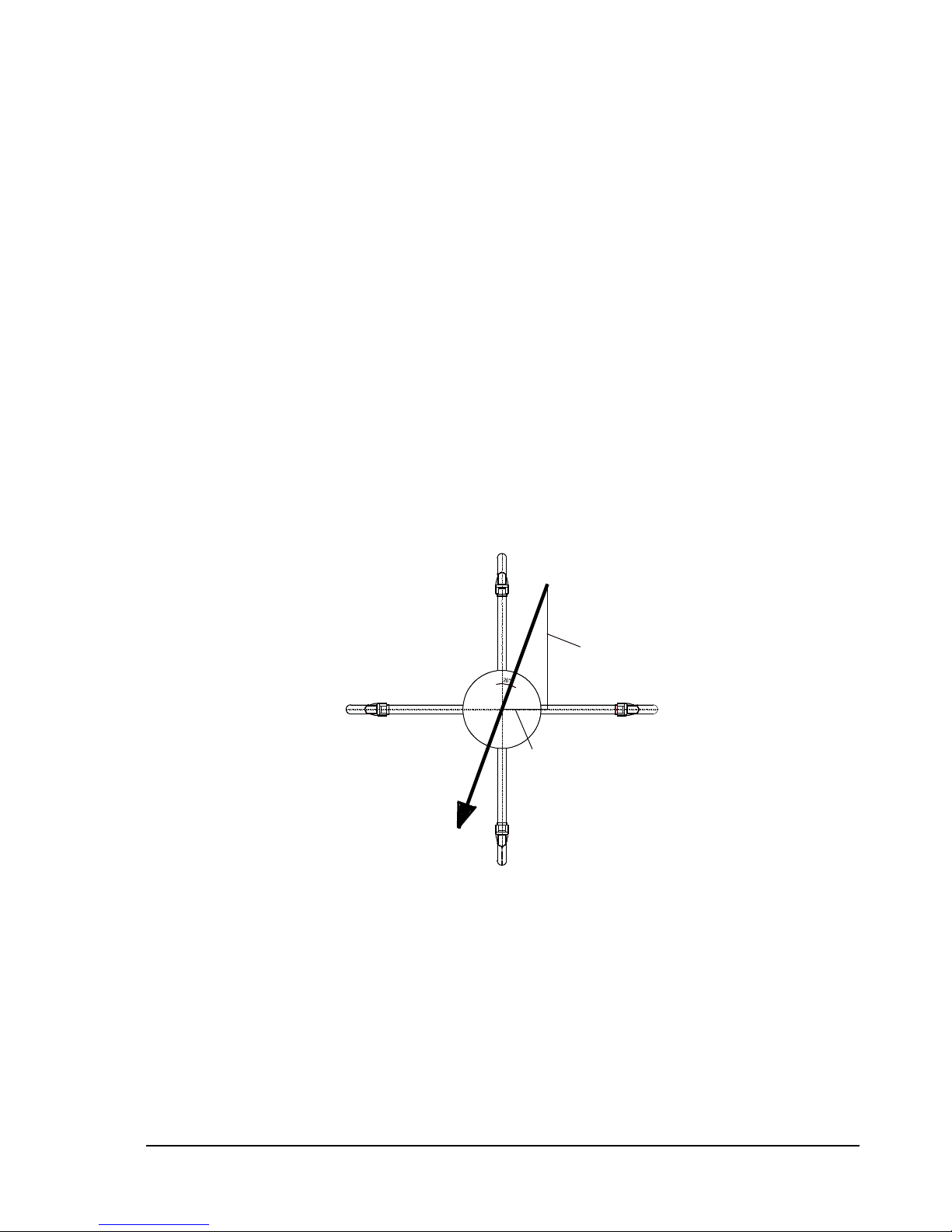

2.1 Measuring principle: Wind velocity and direction

The speed of propagation of the sound in calm air is superposed by the velocity components of an

air flow in the direction of the wind.

A wind velocity component in the propagation direction of the sound supports the speed of

propagation; i.e. it increases it while a wind velocity component against the propagation direction

reduces the speed of propagation.

The propagation speed resulting from superposition leads to different propagation times of the

sound at different wind velocities and directions over a fixed measurement path.

As the speed of sound greatly depends on the temperature of the air, the propagation time of the

sound is measured on each of the two measurement paths in both directions. This rules out the

influence of temperature on the measurement result.

By combining the two measurement paths which are at right angles to each other, the

measurement results of the sum and the angle of the wind velocity vector are obtained in the form

of perpendicular components.

After the perpendicular velocity components have been measured, they are then converted to polar

coordinates by the µprocessor of the anemometer and output as a sum and angle of wind velocity.

Wind from NNE

Y-component

X-component

E

N

W

S

4.3811.00.000_US-Anemometer-DSP_eng.doc 5 - 26 021511/10/06

4.3811.00.000_US-Anemometer-DSP_eng.doc 6 - 26 021511/10/06

2.2 Measuring principle: Acoustic virtual temperature

The speed of propagation of the sound depends on the absolute temperature of the air via a root

function although it is more or less independent of the air pressure and only depends on the air

humidity to a minor extent. We can thus make use of these physical properties for temperature

measurement of air with a known and constant chemical composition.

Here we measure gas temperature without the indirect step of thermal coupling involving this gas to

a sensor.

The advantages of this measuring method are firstly an inertia-free reaction to the actual gas

temperature, and secondly, the avoidance of measuring errors such as those that occur for

example when a solid-state temperature sensor is heated by radiation.

Due to the low dependence of the speed of propagation of the sound on the air humidity level the

"acoustic virtual temperature" relates to dry air (0% humidity) under the same pressure conditions

as those actually measured.

The deviation of the measured "acoustic virtual temperature" from the real air temperature shows

linear dependence on the absolute humidity level of the air.

The amount of water vapour in the air proportionately increases the speed of the sound as H2O

molecules only have around half the mass of the other air molecules (O2and N2).

The increase in the speed of the sound results in an apparent (virtual) increase in the measured

temperature of humid air in comparison to dry air of the same temperature.

The deviation of the measured virtual temperature of humid air from the real air temperature can be

corrected for instance according to the following relationship if the absolute humidity is known:

Tr= Tv– 0.135 K * m3 / g * a

where Tris the real air temperature, Tvthe measured acoustic virtual temperature and athe

absolute humidity in grammes H2O per m3air.

With an air temperature of 20°C the virtual temperature is around 2 K too high with 100% rel.

humidity.

3 Preparation for Operation / Installation

Attention:

The working position of the anemometer is vertical (sensor

arms "above", connector "below").

During installation, de-installation, transport or maintenance of

the anemometer it must be ensured that no water gets into the

shaft or connector of the anemometer.

When using a lightning rod it must be borne in mind that it

should always be installed less than 45° to a measurement

path; otherwise there will be deviations in the measured values.

4.3811.00.000_US-Anemometer-DSP_eng.doc 7 - 26 021511/10/06

3.1 Selection of installation site

As already described, the ultrasonic anemometer transmits sound packages required to measure

the propagation speed. If these sound packages meet surfaces that reflect sound, they are thrown

back as an echo and can may result in incorrect measurements under unfavourable conditions.

It is therefore advisable to install the ultrasonic anemometer at a minimum distance of 1 metre to

objects in the measuring level.

In general, wind meters should register wind conditions over a wide area. To obtain comparable

values when measuring the ground wind, measurement should be performed at a height of 10

metres above even and undisrupted terrain. Undisrupted terrain means that the distance between

the wind transmitter and the obstruction should be at least ten times the height of the obstruction (s.

VDI 3786). If it is not possible to comply with this provision, the wind meter should be installed at a

height at which measured values are influenced by obstructions located in the vicinity to the least

possible extent (approx. 6-10 m above the interference level). On flat roofs the anemometer should

be installed in the middle of the roof and not at the edge to thus avoid any preferential directions.

3.2 Installation of anemometer

Proper installation of the ultrasonic anemometer is carried out using a tube socket R1½" (Ø 48.3

mm) and 50 mm in length The inside diameter of the tube socket must be at least 40 mm as the

ultrasonic anemometer is electrically connected to the connector (s. Accessories: connecting cable,

compl.) from below. After connection the ultrasonic anemometer is fitted on the tube or mast

socket. The arm of the sonic transformer marked red must be aligned to north. This allows a

bearing to be taken from an object located to the north, e.g. a building or special geographical

feature, using the sonic transformers of the north / south measurement path.

The instrument is fixed to the shaft with the four Allen screws (AF 4 mm).

3.3 Alignment to north

To align the anemometer, the arm of the sonic transformer marked red must point to north

(true north). To do so, select a conspicuous feature of the landscape to the north or south with a

compass and turn the mast or anemometer until the opposing arms are aligned in this direction.

The user can also position himself to the north or south at an appropriate distance while another

person turns the anemometer or mast as commanded until the relevant pair of sensor arms are

aligned.

It is recommended using a telescope for this process.

When aligning the instrument to north using a compass, the magnetic variation (= deviation in

direction of compass needle from true north) and local magnetic fields (e.g. iron parts, electric

cables) should be taken into account.

3.4 Cables, cable preparation, connector installation

A prepared connecting cable can be supplied for the ultrasonic anemometer (see Accessories).

If the user wants to procure the cable himself, the cable must have the following properties:

8 cores; 0.5 to 0.75 mm² core cross-section for supply; min. 0.14 mm² core cross-section for data

communications ; max. 8 mm cable diameter, resistant to ultraviolet rays, overall shielding.

The coupling socket (mating connector) is included in the scope of supply. This is placed in the

bottom of the box for shipment.

The pin assignment can be found in these Operating Instructions: see under 3.5 pin assignment.

The cable shield should be connected with the cable clamp.

Coupling socket 507550 (Binder, series 432), EMC with cable clamp

View X

Cable strain relief

Cable assembly 1

1. String parts onto cable according to

diagram above.

2. Strip off cable sheath 20 mm

Shorten exposed shield by 15 mm

Strip off litz wire 5mm.

Cable assembly 1

Fit shrink tube or insulating tape

between litz wire and shield.

Cable assembly 2

Position shield to rear on

cable sheath if cable diameter

permits.

3. Solder litz wire to female insert,

position shield in cable clamp.

4. Screw on cable clamp.

5. Assemble other parts according to

diagram above.

6. Securely tighten cable strain relief

with spanner (AF16 and 17).

Cable assembly 2

Vi

e

w X

Cable sheath

Shield

Cable clamp

Litz wire

Vi

e

w X

Fig. 1: Connector assembly

4.3811.00.000_US-Anemometer-DSP_eng.doc 8 - 26 021511/10/06

3.5 Connector pin assignment

Note:

- The exact functional assignment can be found in the supplementary sheet

"Factory Setting".

- Pins 1 to 6 (inclusive) are electrically isolated from the supply voltage

and the housing.

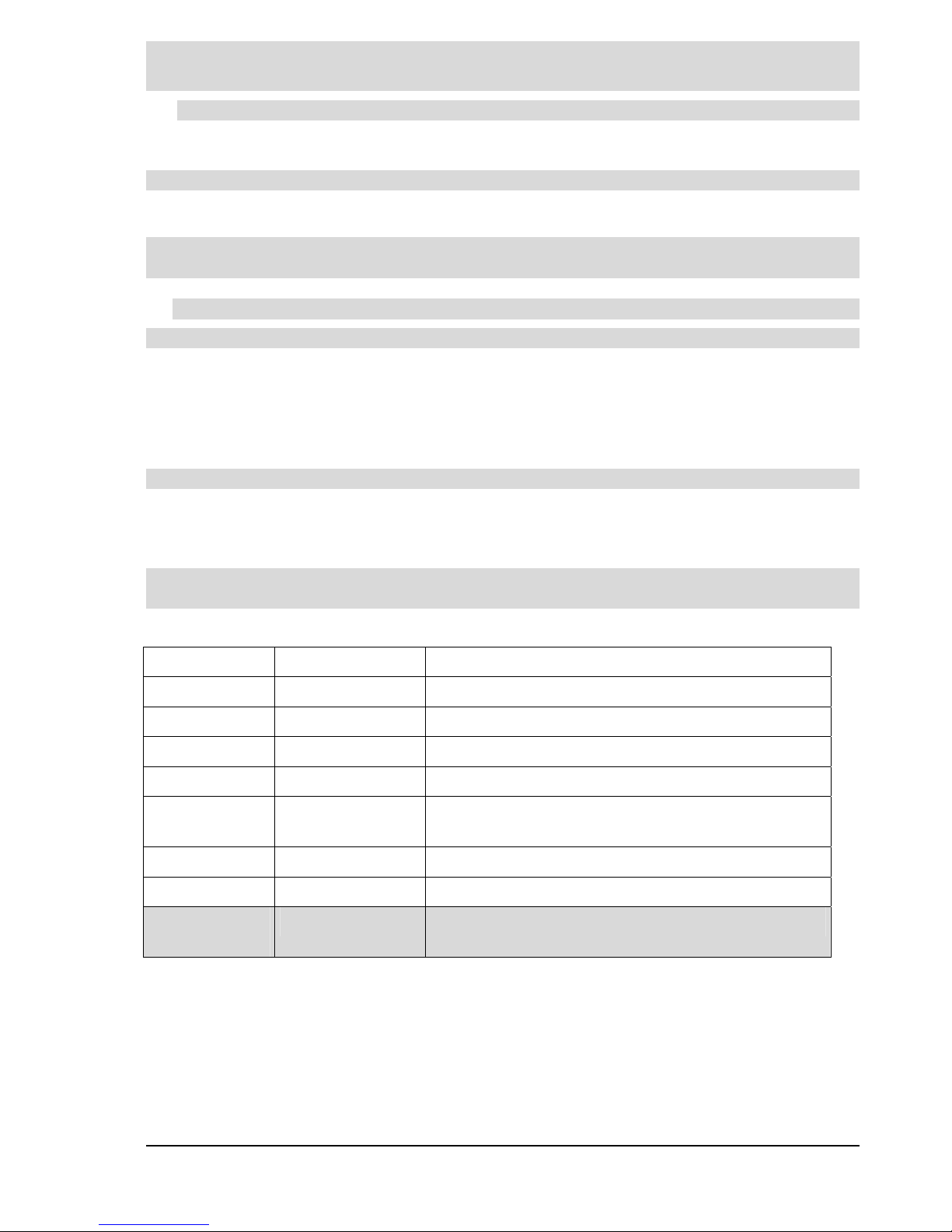

Pin No. Function Comment View of solder terminal

of coupling socket

1 Selection device ID (Low active), Bit 0 Pull up 1mA internal

2 Selection device ID (Low active), Bit 2 Pull up 10 KΩinternal

3 TX−/ RX−(Z) RS 485 / RS 422 Serial interface

4 Selection device ID (Low active), Bit 1 Pull up 1mA internal

5 TX+ / RX+ (Y) RS 485 / RS 422 Serial interface

6 GND Serial interface

7 Supply 20−28 VAC, nom. 24 VAC No-load voltage 32 VAC

8 Supply 20−28 VAC, nom. 24 VAC No-load voltage 32 VAC

Shield

1

2

3

4

5

6

78

4 Maintenance

As the device does not have moving parts, i.e. is not subject to wear during operation, no servicing

is required.

Attention:

During storage, installation, de-installation, transport or

maintenance of the anemometer it must be ensured that no

water gets into the shaft or connector of the anemometer.

4.3811.00.000_US-Anemometer-DSP_eng.doc 9 - 26 021511/10/06

4.3811.00.000_US-Anemometer-DSP_eng.doc 10 - 26 021511/10/06

5 Calibration

The ultrasonic anemometer does not contain any adjustable components such as electrical or

mechanical trimming elements. All components and materials used show invariant behaviour in

terms of time. This means that no regular calibration is required due to ageing. Errors in measured

values are only caused by mechanical deformation of the transformer arms and associated

changes in measurement path lengths.

The acoustic virtual temperature can be used to check the measurement path length. A change of

0.17% in the measurement path length and thus a measuring error of 0.17% for the wind velocity

corresponds to a deviation in the virtual temperature of 1 K at 20°C. With a 6 K temperature

deviation there is thus a measuring error of approx. 1% for the wind velocity.

Important:

Mechanical deformation of the measuring arms results in

errors in the measured values, which involve the output of

error telegrams / error signals to the analog interfaces.

In the event of any change in the measurement paths of the anemometer the manufacturer should

be consulted regarding recalibration.

6 Warranty

Damage caused by improper handling or external influences, e.g. lightning, do not fall under the

warranty provisions. The warranty entitlement expires if the device is opened.

Important:

The ultrasonic anemometer must be returned in the original

packaging as the warranty entitlement otherwise expires with

mechanical damage, e.g. deformation of measuring arms.

4.3811.00.000_US-Anemometer-DSP_eng.doc 11 - 26 021511/10/06

7 Functional Description

The functioning of the ULTRASONIC anemometer is described below. Due to the internal structure

certain functions depend on other functions. Such dependency is described in each case. For

example, in half duplex mode independent telegram output is not permissible. There are also

restrictions regarding the functional definition of the cable connector. This is due to the double

assignment of individual PINs.

7.1 Serial communication

The ULTRASONIC provides an RS485 interface for serial communication. It can be operated either

in full or half duplex mode and at different baud rates.

A standard terminal program is used for communication with the ULTRASONIC. With a Windows-

based operating system Hyper Terminal is included in the scope of supply.

It has to be subsequently installed if required.

The ULTRASONIC does not contain any pull-up or pull-down resistors or a wave terminating

resistor.

When starting the ULTRASONIC, the communications parameters are output to the serial interface.

Output takes place at 9600.8N1. The baud rate, the duplex modus and the ID are output:

Example:

THIES ULTRASONIC

!00BR00006

!00DM00000

The ULTRASONIC starts with ID 0, a baud rate of 19200.8N1 and half duplex mode.

4.3811.00.000_US-Anemometer-DSP_eng.doc 12 - 26 021511/10/06

7.1.1 General telegram structure

For serial communication the ULTRASONIC has a fixed telegram format which also permits

communication in bus mode. It has the following form:

NNBB<cr> <cr> stands for Carriage Return (Enter key)

for a data enquiry or

NNBBPPPPP<cr> <cr> stands for Carriage Return (Enter key)

for a parameter change.

The individual letters have the following meaning:

NN: Two-position ID of the ULTRASONIC. It can be selected in the range 00 to 99. The

presetting of the ID is '00'.

PPPPP: If a new parameter is to be set, the parameter is changed with a 5-position value. The

parameter is always right-justified; i.e. it thus has to be padded from the left with zeros.

Example:

Telegram No. 4 is to be interrogated. The relevant command is:

00TR00004<cr> <cr> stands for Carriage Return (Enter key)

The prerequisite is that the ULTRSONIC ID has the value '0'.

Example:

With the command

00BR<cr> <cr> stands for Carriage Return (Enter key)

the data record selected for the baud rate is returned.

!00BR00006

Note:

The input buffer of the ULTRASONIC can be emptied by transmitting Carriage

Return <CR>. If the ULTRASONIC possibly has invalid characters in the input

buffer, the input buffer can be processed by transmitting Carriage Return. In this

case it is recommended transmitting a Carriage Return at the beginning of a

telegram, e.g.:

<cr>00BR<cr> <cr> stands for Carriage Return (Enter key)

4.3811.00.000_US-Anemometer-DSP_eng.doc 13 - 26 021511/10/06

7.1.2 Return values of ULTRASONIC

After a valid command has been input, the ULTRASONIC sends acknowledgement, e.g.

acceptance of the parameter or output of a data telegram.

For a standard command the response starts with a '!', followed by the ID and the parameter value.

If the input command is TR or TT, the ULTRASONIC transmits a data telegram as the response.

If the command cannot be processed for a certain reason, the device transmits a telegram with the

error code 'CE' (Command Error). The meanings of the values for CE are summarised in Table 1:

Return values with incorrect interpretation of command:

Value output in CE telegram Meaning

8 Incorrect access key

16 Parameter not in valid range

4 or 32 Violation regarding parameters of other commands

Table 1: Return values with incorrect interpretation of command

7.1.3 Access mode

For configuration the ULTRASONIC has a set of commands which determine behaviour in terms of

the propagation time. The commands are broken down into three levels:

• interrogation mode

• user mode

• configuration mode

Interrogation mode:

This mode includes commands which do not influence the parameters of the ULTRASONIC. They

include for example output of the system status and interrogation of the data telegram TR.

User mode:

This mode includes commands which alter the behaviour of the ULTRASONIC. These parameters

can be changed by the user. The system behaviour of the device is altered with these commands.

This group of commands includes e.g. settings for data transmission and averaging.

Configuration mode:

This mode includes commands which were set when adjustment of the device was performed at

the factory. They can be equated with calibration. These parameters must not be changed.

To distinguish between commands of the three groups when parameterising the ULTRASONIC the

device is equipped with an access key KY. Inputting of this key accesses the individual levels.

Access to commands at a higher level includes access to commands at a lower level.

Access key Response from ULTRASONIC Command level

00KY00000 WRITE PROTECTED

!00KY00000

Interrogation mode (preset)

00KY00001 USER ACCESS

!00KY00001

User mode

00KY00234 CONFIG ACCESS

!00KY00234

Configuration mode

Table 2: Access key for different command levels

4.3811.00.000_US-Anemometer-DSP_eng.doc 14 - 26 021511/10/06

After the access key has been changed, the ULTRASONIC transmits a response which contains

not only the parameter input but also the access mode.

After parameters have been changed with the key '00001' or '00234', the ULTRASONIC must be

reset to the locked state with the command 00KY00000.

Example:

00KY00001

USER ACCESS Response from ULTRASONIC

!00KY00001 Response from ULTRASONIC

00AV00005 Change in averaging time

00KY00000

WRITE PROTECTEDResponse from ULTRASONIC

!00KY00000 Response from ULTRASONIC

7.1.4 Device ID

The device ID specifies the address to which the ULTRASONIC is to respond during serial

communication. The ID is determined on startup via the external signals at PIN 1, PIN 4 and PIN 2

(ADIO). The device ID lies in the range from 0..7. Every telegram from the ULTRASONIC starts

with the device ID. Under certain conditions this provides for bus mode, see 7.1.5 Bus mode.

On interrogation the device ID 99 is a generic ID. If this ID is used on interrogation, devices transmit

a response, regardless of the ID selected.

7.1.5 Bus mode

The concept of ID-based communication allows ULTRASONICs to be operated in a bus system.

In bus mode there are no restrictions on parameterisability and program upload. A station can also

be provided with a new program in bus mode for a specific purpose. With an update the program

update must be performed for every ULTRASONIC.

7.2 Data acquisition

The main function of the ULTRASONIC firmware is data acquisition and preparation. For data

acquisition sound impulses are transmitted by the sensors in a clockwise direction and received by

the sensor opposite. The propagation time measured is a measure of the velocity. A measuring

cycle is complete when every sensor has performed transmit and receive once. The complete data

record is then time-stamped and passed on to the next level. After the plausibility check the

individual components are calculated and written to the averaging buffer (see 7.2.1 Averaging).

For a resulting wind velocity < 0.1m/s the wind direction and wind velocity are set to zero. The wind

direction 0° is reserved for no wind. If the wind direction is equal to zero with WV > 0.1m/s, the

interface outputs 360°.

The last valid instantaneous value of the wind velocity is always used as the output value for this

criterion.

7.2.1 Averaging

Given the high data acquisition rate averaging is recommended in most cases. The averaging

period is set to 1 second with this device version.

It is a basic rule that only valid values are written to the averaging puffer. The size of the buffer is

not determined by the number of data records but by the difference in the time stamp between the

first and last data record. As a result any missing measured values do not influence the averaging

result. The content level of the averaging buffer is shown in the status value of the ULTRASONIC.

4.3811.00.000_US-Anemometer-DSP_eng.doc 15 - 26 021511/10/06

The Ultrasonic incorporates two different practical procedures for averaging:

• one procedure for generating vectorial mean values

and

• one procedure for generating scalar mean values

"Vectorial averaging" is set in this device version.

7.3 Serial data output

The transmission of data via the RS485 interface is known as serial data output. Two modes are

available for data transmission:

• independent transmission of data

• transmission of data via interrogation telegram

This device version only transmits data on request.

7.3.1 Data enquiry

The command TR is used for data enquiry via the ULTRASONIC. The command has no access

protection. After processing the command the device sends back the appropriate response

telegram. The time between the last character in the request telegram and the first character in the

data telegram is < 0.5ms.

The response to a data enquiry is delayed by 5ms in this device version.

7.3.2 Fixed telegram formats

For telegram output several predefined telegrams are available for independent output and data

request.

The detailed structure is described in 10 Predefined Data Telegram. A reference list of telegram

formats can be found in Table 3: List of predefined data telegrams.

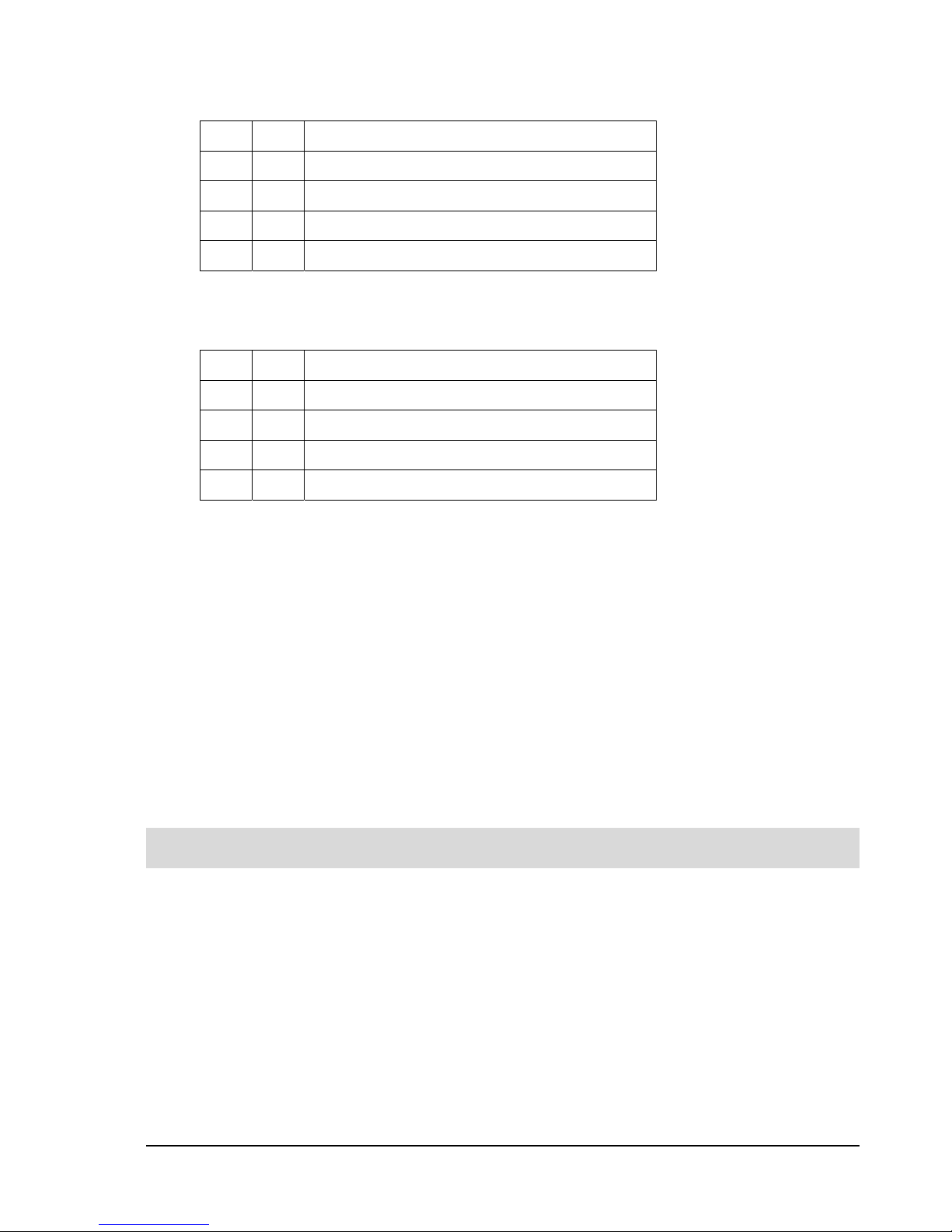

Telegram name Telegram number Telegram structure

VD 00001 (STX)gg.g ddd*cc(CR)(ETX)

VDT 00002 (STX)gg.g ddd ttt.t ss*cc(CR)(ETX)

V4DT 00003 (STX)ggg.g ddd ttt.t v ss*cc(CR)(ETX)

NMEA V 2.0 00004 $WIMWV,ddd.d,R,ggg.g,v,A*xx(CR)(LF)

Standard

deviation 00005

(STX)iigg.g hhh.h ddd eee ttt.t uuu.u ss*cc(CR)(ETX)

User-specific 00006 The user-specific telegram is output

Vx, Vy 00007 (STX)aaa.a;bbb.b;ttt.t;ss;cc(CR)(ETX)

VDT Version 1

(GAMESA)

00009 !iigggdddttttwf(CR)

Table 3: List of predefined data telegrams

4.3811.00.000_US-Anemometer-DSP_eng.doc 16 - 26 021511/10/06

Where

g: wind velocity

h: standard deviation of wind velocity

d: wind direction

e: standard deviation of wind direction

t: temperature

u: standard deviation of temperature

s: status byte

c: check sum (EXOR link)

v: identifier for scaling of wind velocity (K, N, M, S = km/h, Knots, m/s, mph)

a: wind velocity in X-direction (east -> west)

b: wind velocity in Y-direction (north -> south)

w: status byte version 1

f: check sum version 1

i: device ID

7.4 Generation of check sum

The check sum is the result of the bytewise EXOR link of the bytes output in the telegram.

With the resulting check byte high and low nibble (4 bit) are EXOR linked and output as an ASCII

value.

7.5 Status information

7.5.1 Definition of status byte version 1

The status byte contains information about the current system status.

The information includes the occurrence of an error with the acquisition of measured values,

possible decalibration, e.g. caused by a change in the measurement path length due to deformation

of the measuring arms and the operating status of the device heating.

7.5.2 Structure of status byte version 1

Bit 0 0 = data valid 1 = data invalid

Bit 1 Temperature difference between X and Y measurement path (LSB)

Bit 2 Temperature difference between X and Y measurement path (MSB)

Bit 3 Averaging memory used (LSB)

Bit 4 Averaging memory used (MSB)

Bit 5 Measuring range exceeded (counter overflow)

Bit 6 Reserved (always one)

Bit 7 0 = heating off 1 = heating on

4.3811.00.000_US-Anemometer-DSP_eng.doc 17 - 26 021511/10/06

7.5.3 Definition of temperature difference in status byte

Bit 2 Bit 1 Temperature difference x to y path in Kelvin

0 0 0.0 K to 3.1 K

0 1 3.2 K to 6.3 K

1 0 6.4 K to 7.9 K

1 1 ≥8.0 K →invalid measurement

7.5.4 Definition of averaging memory used

Bit 4 Bit 3 Averaging memory used

0 0 Averaging memory content level > 80%

0 1 Averaging memory content level > 66%

1 0 Averaging memory content level > 33%

1 1 Averaging memory empty

7.6 Behaviour in fault conditions

The ULTRASONIC is equipped with a highly effective internal fault detection and correction system.

This allows it to detect incorrect measured values using the history and to discard them.

It cannot however be ruled out that the ULTRASONIC will get into a situation in which the

acquisition of new data is impossible. In this case the error bits are set in the status values and a

defined value possibly output at the analog outputs.

It is a basic rule that the measured values output are always valid and can be interpreted by the

target system (unless a specific error telegram is output in the case of error). However, what may

happen in the case of error is that the data become 'too old', i.e. are not updated over a certain time

and freeze. In this case the error bits are set in the status byte. If a special error telegram is defined

with a serial telegram, this is output.

This device version outputs an error in the status byte if no new data can be determined for

approx.10 seconds.

7.7 Heating control

To prevent the device from freezing the ULTRASONIC is equipped with built-in heating for the

sensor arms. In standard mode the heating is controlled by the system status. If control of the

heating is software-set, the heating system will switch on under the following conditions:

Acoustic virtual temperature < 2°C

Continuous measuring error > 3sec

4.3811.00.000_US-Anemometer-DSP_eng.doc 18 - 26 021511/10/06

The heating system switches off after another 10sec when:

Acoustic virtual temperature> 7°C

No error in acquisition of measured values

7.8 Output of all system parameters

Most parameters of the ULTRASONIC are stored internally in an EEPROM. The command SS can

be used to output all stored parameters.

Before amending parameters it is recommended making a backup copy of existing settings and

storing them in a text file.

7.9 Enquiry about software version

The command SV is used to enquire about the software version.

7.10 Forcing a restart

The command RS can be used to force a restart of the ULTRASONIC. The commands

00KY00001<cr>

00RS00001 <cr>

will restart the ULTRASONIC after approx. 3sec.

7.11 Bootloader

Whenever the ULTRASONIC is restarted, the device first starts a bootloader. The function of the

program is to start program upload. For this a specific program containing the new firmware must

be started at a connected PC. After identification the program upload then starts automatically. If

the bootloader does not know its remote station, the ULTRASONIC firmware starts.

7.12 Online Help

For a short description of commands the ULTRASONIC contains an Online Help which provides

information about individual commands. The Help text for the command is returned by inputting the

command and a '?'.

If the command

00?? <cr> <cr> stands for Carriage Return (Enter key)

is input, the ULTRASONIC will list all commands with the relevant Help.

Example:

Help with setting the baud rate is to be called up. With the command

00BR?<cr> <cr> stands for Carriage Return (Enter key)

the ULTRASONIC provides the following response:

BR: Set / get Baudrate

4.3811.00.000_US-Anemometer-DSP_eng.doc 19 - 26 021511/10/06

0 -> reserved 10 -> 1200 7E1

1 -> reserved 11 -> 1200 7E1

2 -> 1200 8N1 12 -> 4800 7E1

3 -> 2400 8N1 13 -> 9600 7E1

4 -> 4800 8N1 14 -> 19200 7E1

5 -> 9600 8N1 15 -> 38400 7E1

6 -> 19200 8N1 16 -> 57600 7E1

7 -> 38400 8N1 17 ->115200 7E1

8 -> 57600 8N1

9 ->115200 8N1

8 Configuration of Ultrasonic Anemometer by Customer

The Ultrasonic Anemometer 2D is factory-set prior to delivery to the customer.

Setting is described in the supplementary sheet "Factory Setting".

It is possible for the customer to alter the factory setting of the Ultrasonic Anemometer 2D or to

adapt it to new requirements. Here it should be borne in mind that with a change in settings, the

order number allocated at the factory can then no longer help with identification.

These Operating Instructions relate to the device version 4.3811.00.000.

For the adjustment of settings we recommend you consult the General Operating Instructions for

THIES ULTRASONIC. This describes all available settings.

Recommendation:

After performing configuration please amend the supplementary sheet "Factory Setting" and send

in to the manufacturer in the event of maintenance or repair.

4.3811.00.000_US-Anemometer-DSP_eng.doc 20 - 26 021511/10/06

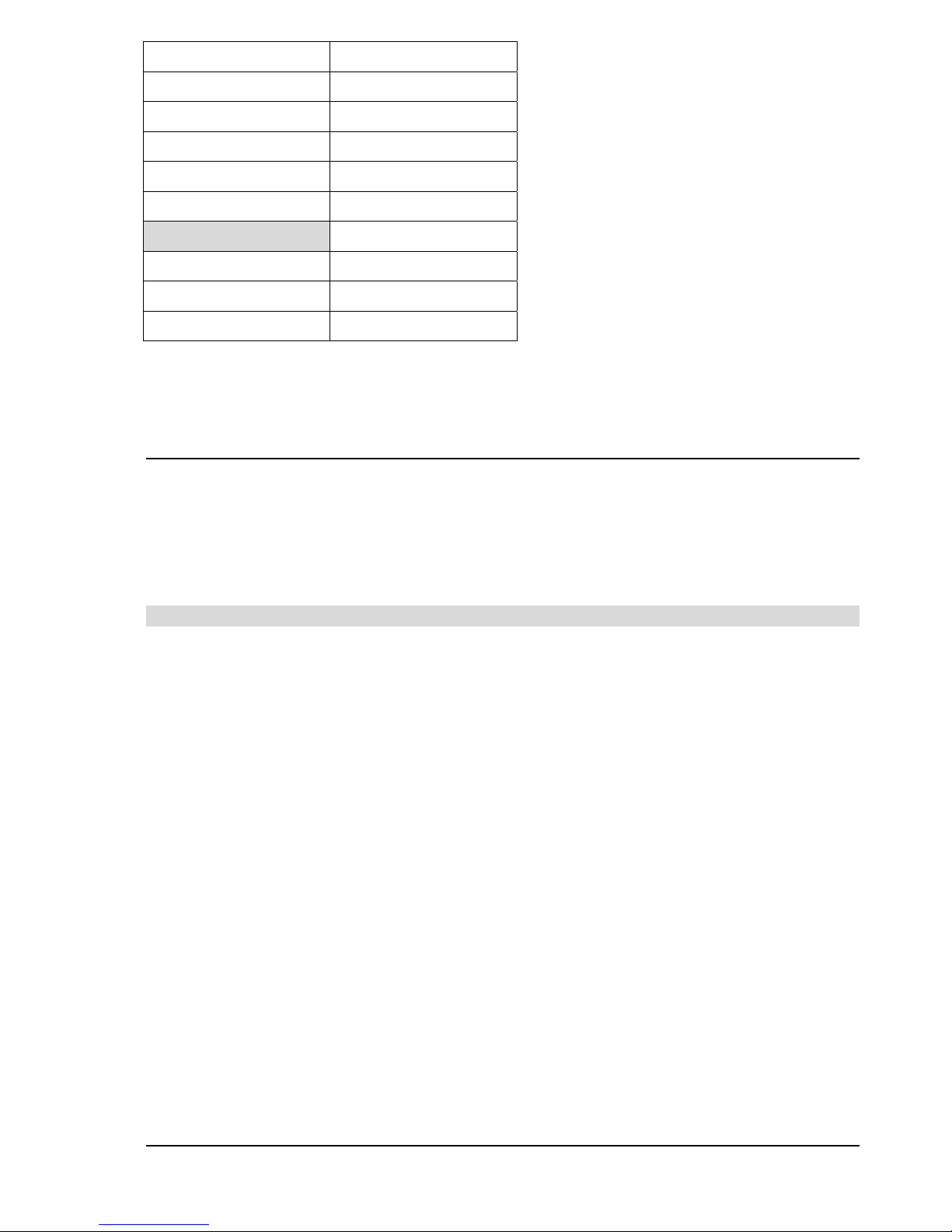

9 Command List, Short

Command Description

<id>AA<para5> Functions for PIN WV/RXD-(Analog channel A)

<id>AB<para5> Functions for PIN WD/RXD+ (Analog channel B)

<id>AC<para5> Functions for PIN ADIO (Analog channel C)

<id>AM<para5> Selection of averaging method (Average mode)

<id>AN<para5> Analog output mode (Analog output)

<id>AO<para5> Scaling of analog wind direction output (Angle output)

<id>AR<para5> Scaling of analog wind velocity output (Analog range)

<id>AT<para5> Testing of analog inputs/outputs (Analog test)

<id>AV<para5> Averaging time (Average)

<id>AU<para5> Update of analog inputs

<id>AY<para5> Scaling of minimum value for analog input PIN WV/RXD-

<id>AZ<para5> Scaling of maximum value for analog input PIN WV/RXD-

<id>BH<para5> Selects the Bavaria Hesse measuring instrument addresses

<id>BR<para5> Select baud rate (Baud rate)

<id>BX<para5> Select baud rate (Baud rate extension)

<id>BY<para5> Scaling of minimum value for analog input PIN WV/RXD+

<id>BZ<para5> Scaling of maximum value for analog input PIN WV/RXD+

<id>CI<para5> Selects command interpreter (Command interpreter)

<id>CY<para5> Scaling of minimum value for analog input PIN ADIO

<id>CZ<para5> Scaling of maximum value for analog input PIN ADIO

<id>DA<para5> Data request in Bavaria Hesse command interpreter

<id>DE<para5> Standard deviation (Deviation)

<id>DF<para5> Set initial values (Default values)

<id>DM<para5> Duplex mode

<id>EI<para5> Analog value in case of error (Error inversion)

<id>FB<para5> Fast boot

<id>HT<para5> Heating control (Heating)

<id>ID<para5> ULTRASONIC ID

<id>KY<para5> Access mode (Key)

<id>MA>>para5> Automatic adjustment of measured value acquisition (Measurement automation)

<id>MD>>para5> Measuring interval (Measurement delay)

Table of contents

Other THIES Measuring Instrument manuals