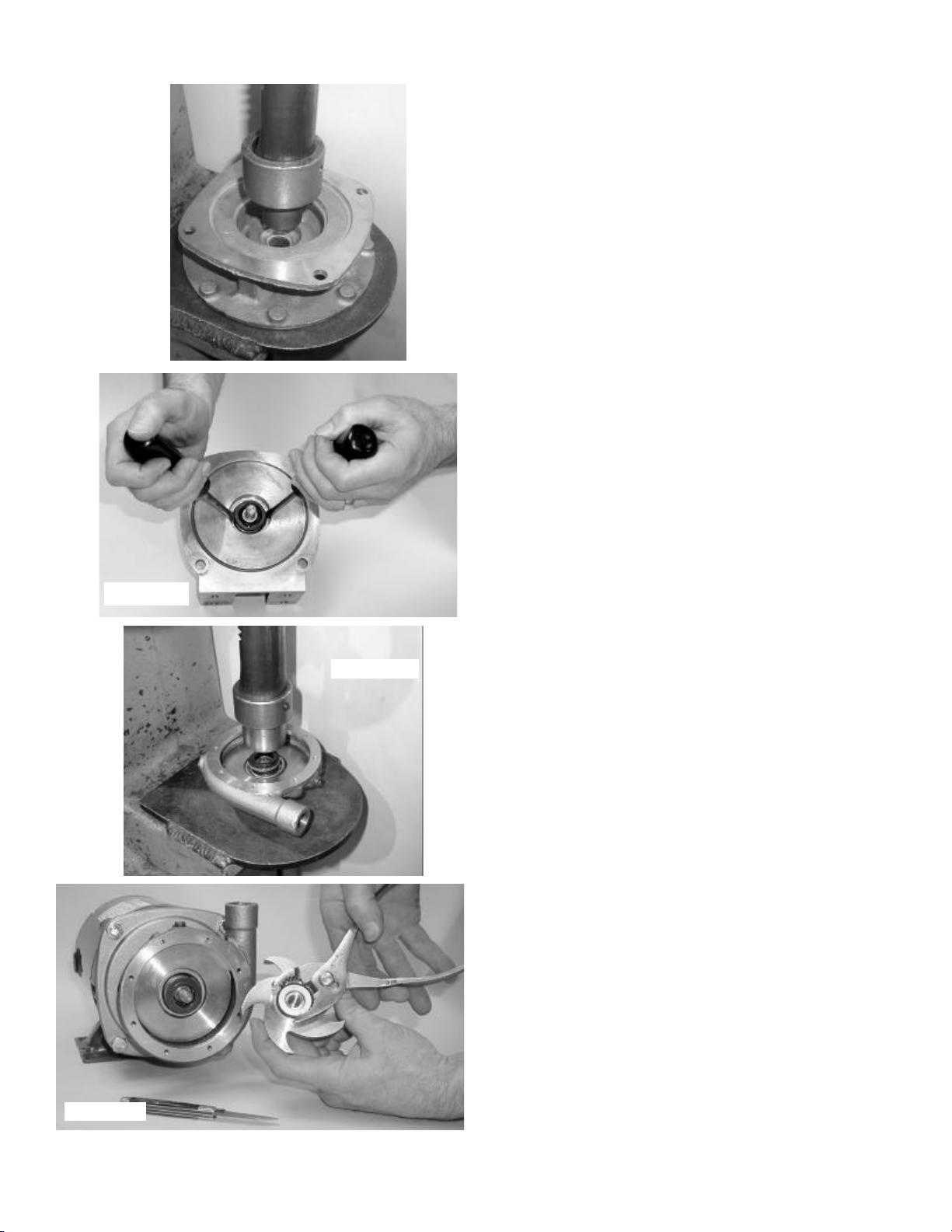

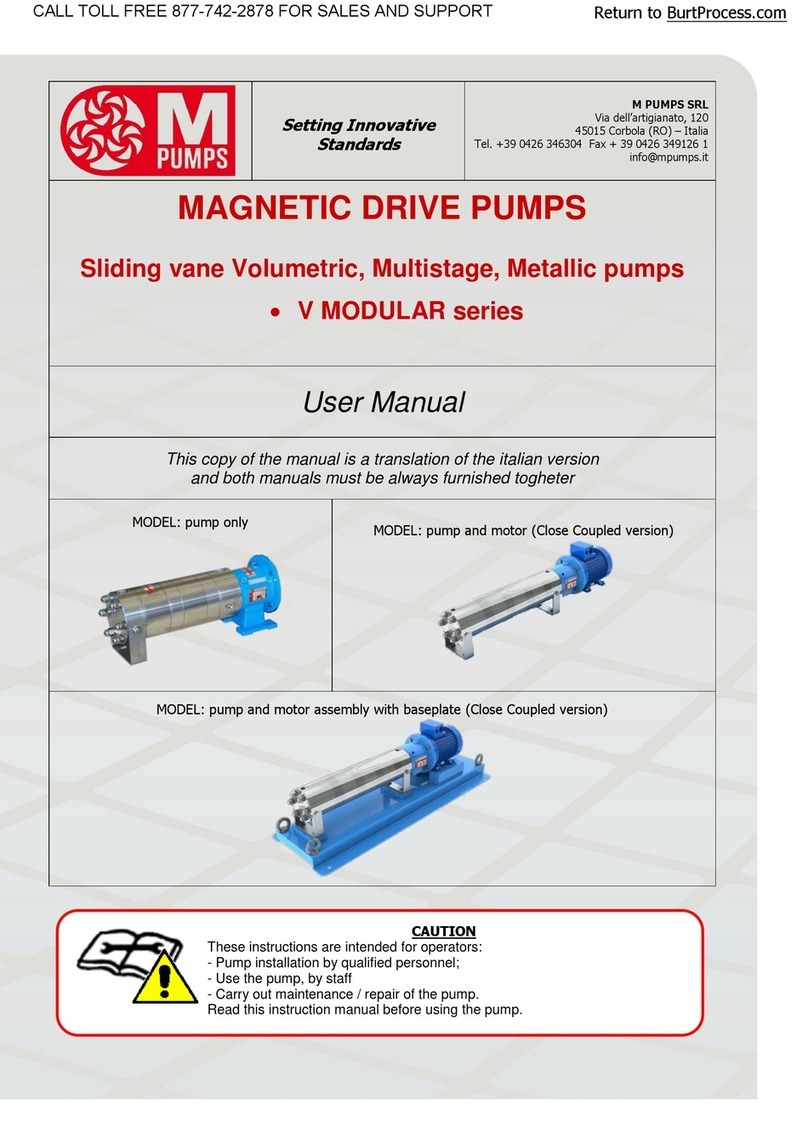

4. Press Seal from Pump Body or from the Pump

Casting Containing the Seal

(SEE FIGURE 3) The seal is a press fit in the pump body

or adapter. To press out, place body flange down on flat sur-

face exposing motor or bracket end of seal. Press seal

through into impeller chamber - DO NOT attempt to press in

other direction as seal has a seating flange. Clean the bore

in the pump body from which seal was removed. Remove all

hardened residue. Do not gouge or damage seal bore. (SEE

FIGURE 4) On some pedestal pump models (70P & 800B),

it is not possible to press out the seal without first pressing

out the shaft and bearing assembly. In such cases, it is pos-

sible to collapse and pry out the seal while leaving the shaft

and bearing assembly in position.

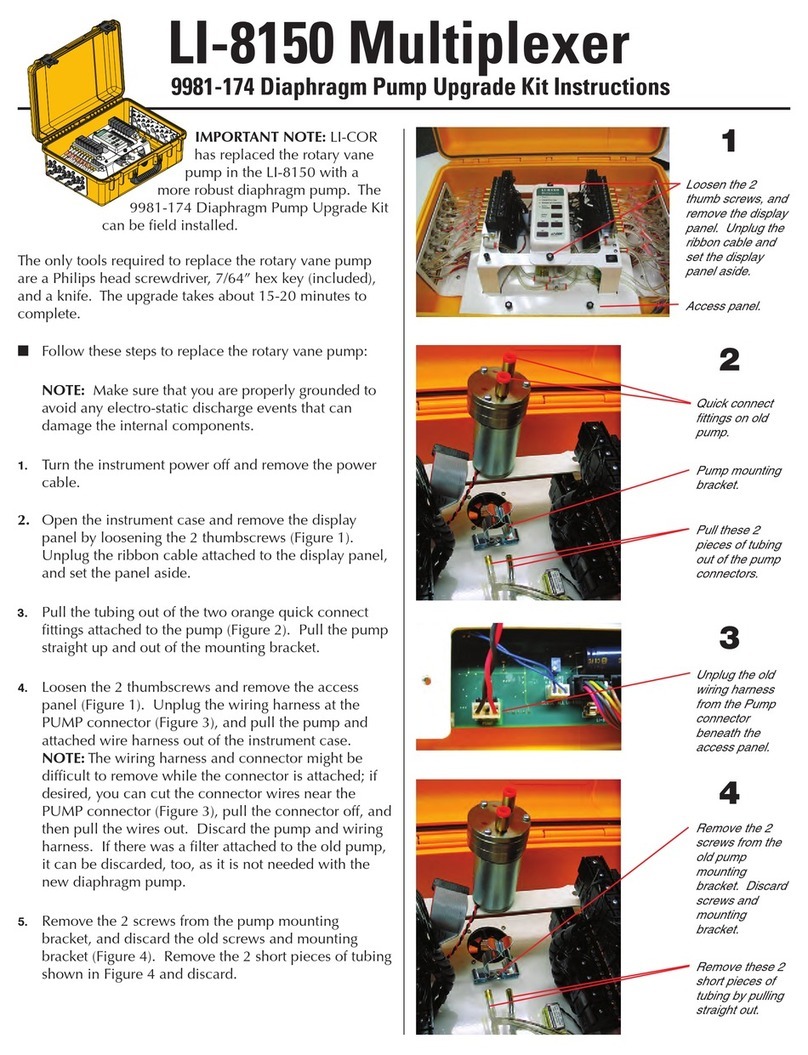

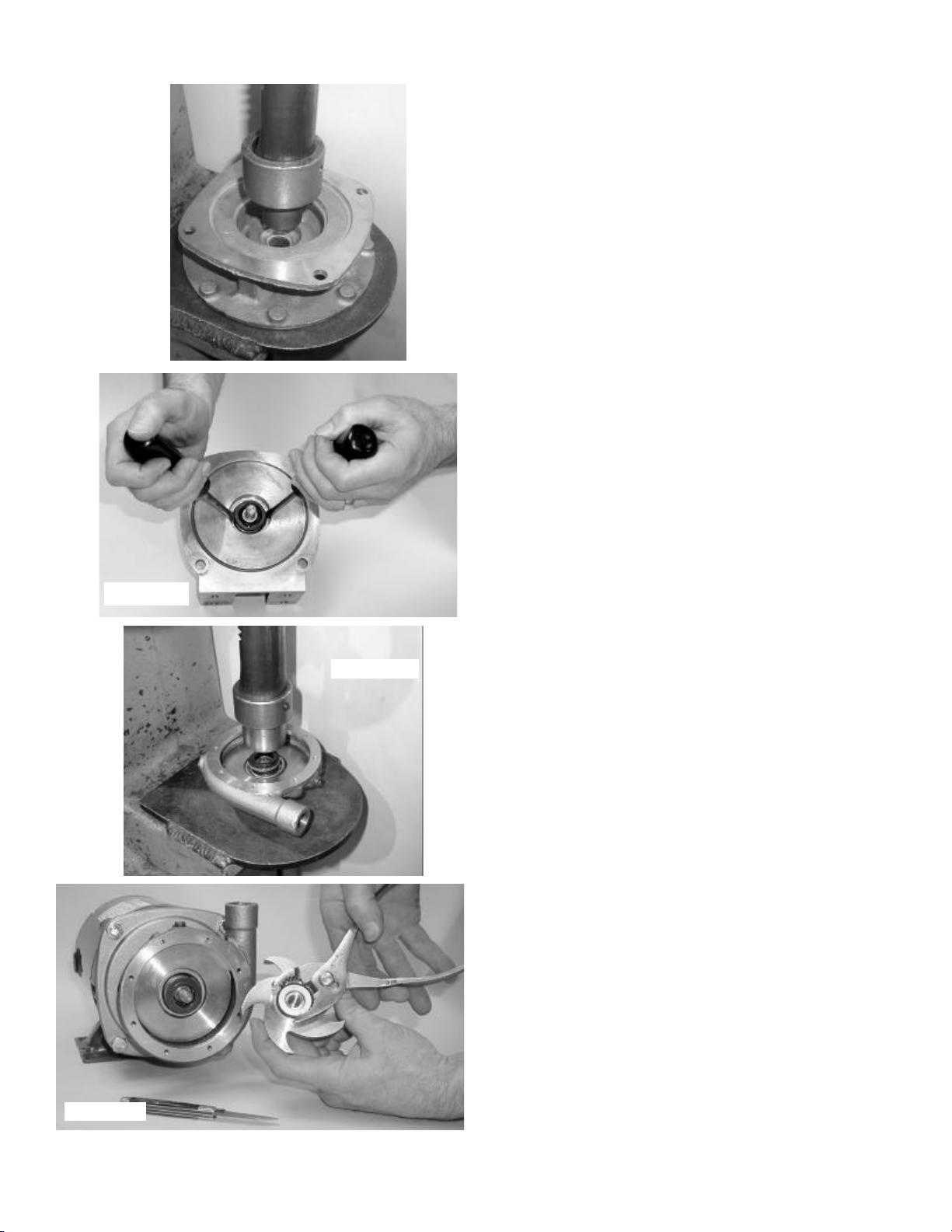

5. Press New Seal into Pump Body

( SEE FIGURE 5) Coat bore with Permatex #2®, Teflon®

paste, Locktite 620®, or equivalent sealer to press-in. Use

bushing type pusher to press and press only on metal flange

of seal DO NOT press on spring loaded carbon face. DO

NOT damage of scratch lapped carbon face. A scratched sur-

face will cause seal to leak.

6. Remove Seal Wear Face from Impeller

(SEE FIGURE 6) If lapped wear face projects above

impeller, use pliers to pry out. If wear face does not project,

use knife or sharp instrument to pry out.

7. Install New Seal Wear Face

Coat wear face (and seal seat) with liquid soap and push

into impeller chamber with finger pressure. DO NOT dam-

age or scratch wear face surface.

8. Reinstall Pump Parts

Reinstall pump parts to motor adapter or to motor and

pedestal bracket or adapter in reverse order as follows:

1. Slide pump body on motor adapter or bolt

pedestal bracket or adapter to motor.

2. Thread impeller onto shaft. Be sure to replace any

spacer shims used originally for impeller

positioning.

3. Clamp pump body to motor adapter by single

draw down bolt. A rotating clearance should remain

between body or cover and impeller.

4. Reinstall gasket, o-ring and pump cover.

9. Check for Impeller Interference

Check that the impeller does not interfere with pump

body or cover by rotating impeller by hand or jogging the

motor. Metallic noise is a sign of interference. To eliminate

interference noise, reposition the impeller to better center it

in the body chamber and provide rotating clearance. Do this

by adding or removing spacer shims onto motor shaft.

315-437-0361 or 800-448-1668 Fax: 315-463-9561 web: www.oberdorfer-pumps.com

12/2001

FIGURE 4

FIGURE 5

FIGURE 6

FIGURE 3

Marketing/Advertising/Maintenance Manuals/Cent. Seal replace/centrifugal seal replacement.qxd