I-FEEDER MXD User manual

1-rEEDER Global

MXD INSTRUCTIONS

•

Installation and operating instructions

YOUR LEADER IN DOSING TECHNOLOGY

GENERAL DESCRIPTION

MXD pumps are heavy duty, precision, electric diaphragm positive displacement pumps.

This dosing pump consists of one main gearbox with dosing head. This unit

forms the main drive of the dosing pump. What makes the MXD pump special

is the capability to add as many extras dosing units to the drive unit. This allows volumes from

10 liters per hour up to any volume imaginable. Each of these dosing units can be independently

regulated by means of a positive adjustment caliper.

Dosing units can be designed in such a manner that several different volumes

or products can be dosed or the total volume can be increased. Increased dosing units allow

higher permissible operating pressure, higher level of precision dosing & greater flexibility in the

products being dosed into the injection line. When four ( 4 ) injection units are combined, it is

possible to obtain straight line dosing, instead of

the pulsed flow usually found with positive displacement dosing pumps. Dosing

units can be added at a later stage as required or at the point of manufacture.

Dosing pumps are also upgradeable in volume as required.

I-FEEDER MXD dosing pumps are manufactured with materials that can

resist most chemicals products, even acids. They are designed for all sorts of processes where

it is necessary to dose a product into a hydraulic network,

such as: food, textile, chemical industry, water treatments, etc. (See materials

in Technical Features). In case there is any doubt about compatibility of

materials with the products to be used please contact I-FEEDER GLOBAL Technical Service.

Each injection unit can be controlled independantly with no need to stop operation when

adjusting the pump volume.

The original packing is prepared so that carriage and storing of the product do

not cause any damage to the product, as long as this is done far from heat

sources and in dry, ventilated spaces.

A. General

A1 Introduction

These installation and operating instructions contain all the

information required for starting up and handling the MXD-D

dosing pump.

If you require further information or if any problems arise, which

are not described in detail in this manual, please contact the

nearest I-Feeder company.

A2 Service documentation

If you have any questions, pleas e contact the nearest I-Feeder

company or service workshop.

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

SAFETY RULES

To avoid personal or enviromental damages and to guarantee a proper

operation of the equipment, the staff in charge of the installation, set up and

maintenance of the equipment must follow the instructions of this manual,

specially those recommendations and warnings explicitly detailed. In addition,

specific instructions for the chemical products to be dosed should be followed.

CONTENTS

Pg

A General 3

A1 Introduction 3

A2 Service documentation 3

1. General Information 4

1.1 Applications 4

1.2 Warranty 4

2. Safety 4

2.1 Identification of safety instructions 4

2.2 Qualification and training 4

2.3 Risks 4

2.4 Safety conscious 4

2.5 Safety instructions 4

2.6 Safety for maintenance, inspection and installation 4

2.7 Unauthorised modification and manufacture 4

3. Type Key 5

B Technical data 6

4. Pump Performance 6

4.1 Accuracy 6

4.2 Performance 6

4.3 Suction heights 6

C Dimensions 7

5. Installation 8

5.1 General 8

5.2 Electrical Connection 8

6 Commissioning 8

6.1 Checks before start-up 8

6.2 Start-up 8

6.3 Switching on/ off 8

7 Installation tips 8

8 Tube/ Pipe lines 8

8.1 General 8

8.2 Connecting suction & Discharge lines 8

8.3 Suction 9

8.4 Injection 9

8.5 Dosing Flow 9

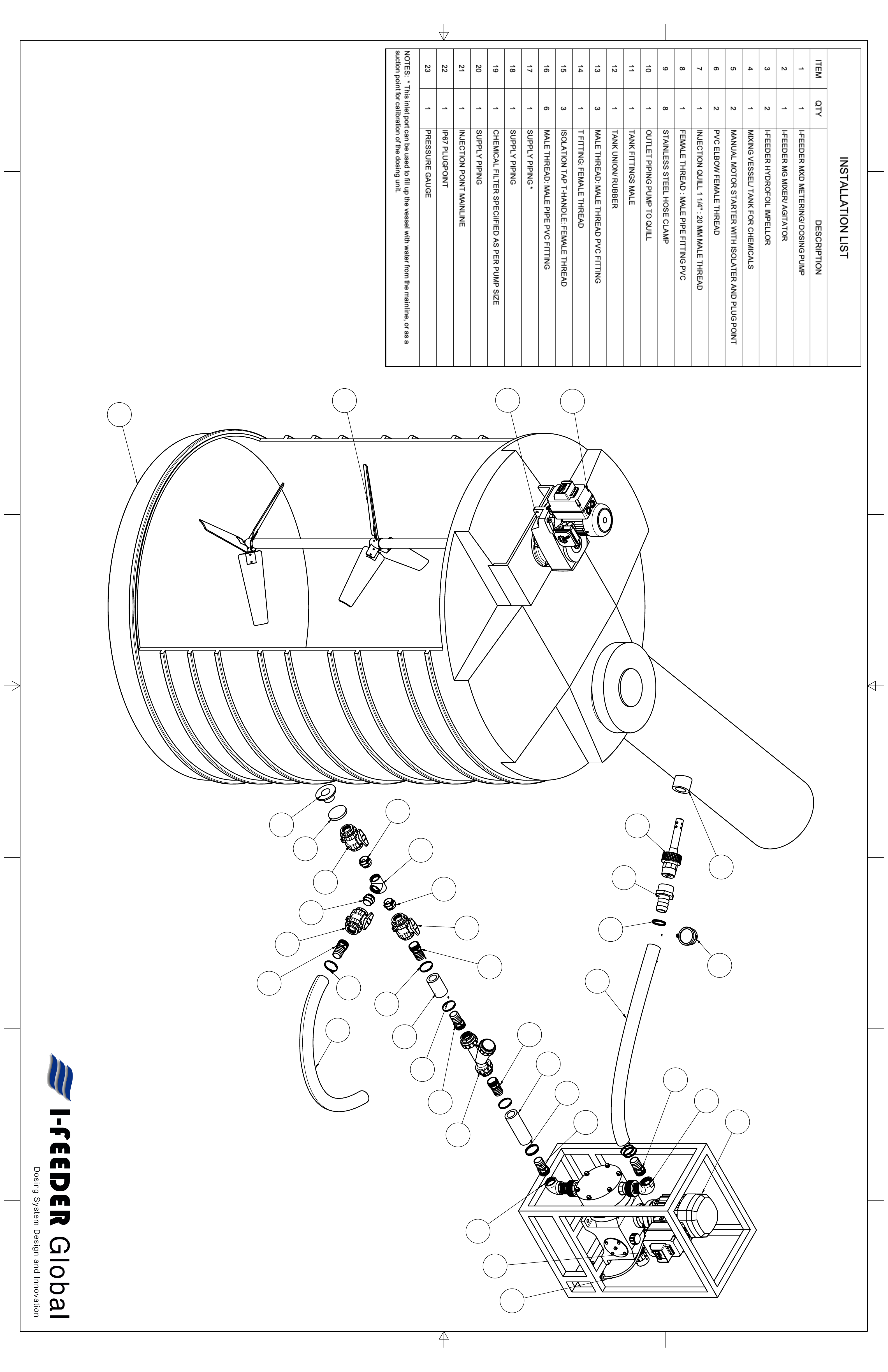

D Installation drawing 10

9 Maintenance 11

9.1 General notes 11

9.2 Replacing the diaphragm 11

9.3 Periodical maintenance 11

10 Transport & Storage 11

10.1 Delivery 11

10.2 Intermediate storage 11

10.3 Unpacking 11

10.4 Return 11

11 Fault finding chart 12

12 Dosing curves 13

E Parts list 14

F Warranty 15

1. General information

1.1 Applications

The MXD-D pump is suitable for liquid, non-abrasive and non-

inflammable media strictly in acco rdance with the instructions in

this manual.

1.2 Warranty

Warranty in accordance with our general terms of sale and

delivery is only valid

• if the pump is used in accordance with the information within

this manual.

• if the pump is not dismantled or incorrectly handled.

• if repairs are carried out by authorised and qualified

personnel.

• if original spare parts are used for repairs.

2. Safety

This manual contains general inst ructions that must be observed

during installation, operation and maintenance of the pump. This

manual must therefore be read by the installation engineer and the

relevant qualified personnel/operators prior to installation and start-

up, and must be available at the installation location of the pump at

all times.

It is not only the general safety instructions given in this "Safety"

section that must be observed, but also all the specific safety

instructions given in other sections.

2.1 Identification of safety instructions in this manual

If the safety instructions or other advice in this manual are not

observed, it may result in personal injury or malfunction and

damage to the pump. The safety instructions and other advice are

identified by the following symbols:

Information provided directly on the pump, e.g. labelling of fluid

connections, must be observed and must be maintained in a

readable condition at all times.

2.2 Qualification and training of personnel

The personnel responsible for the operation, maintenance,

inspection and installation must be appropriately qualified for these

tasks. Areas of responsibility, levels of authority and the

supervision of the personnel must be precisely defined by the

operator.

If the personnel do not have the necessary knowledge, the

necessary training and instruction must be given. If necessary,

training can be performed by the manufacturer/supplier at the

request of the operator of the pump. It is the responsibility of the

operator to make sure that the contents of this manual are

understood by the personnel.

2.3 Risks when safety instructions are not observed

Non-observance of the safety instructions may have dangerous

consequences for the personnel, the environment and the pump.

If the safety instructions are not observed, all rights to claims for

damages may be lost.

Non-observance of the safety instructions may lead to the

following hazards:

• failure of important functions of the pump/system

• failure of specified methods for maintenance

• harm to humans from exposure to electrical, mechanical and

chemical influences

• damage to the environment from leakage of harmful

substances.

2.4 Safety-conscious working

The safety instructions in this manual, applicable national health

and safety regulations and any operator internal working,

operating and safety regulations must be observed.

2.5 Safety instructions for the operator/user

Hazardous hot or cold parts on the pump must be protected to

prevent accidental contact.

Leakages of dangerous substances (e.g. hot, toxic) must be

disposed of in a way that is not harmful to the personnel or the

environment. Legal regulations must be observed.

Damage caused by electrical energy must be prevented.

2.6 Safety instructions for maintenance, inspection

and installation work

The operator must ensure that all maintenance, inspection and

installation work is carried out by authorised and qualified

personnel, who have been adequately trained by reading this

manual.

All work on the pump should only be carried out when the pump is

stopped. The procedure described in this manual for stopping the

pump must be observed.

Pumps or pump units which are used for media that are harmful

to health must be decontaminated.

All safety and protective equipment must be immediately

restarted or put into operation once work is complete.

Observe the points described in the initial start-up section prior to

subsequent start-up.

2.7 Unauthorised modification and manufacture of

spare parts

Modification or changes to the pump are only permitted following

agreement with the manufacturer. Original spare parts and

accessories authorized by the manufacturer are safe to use. Using

other parts can result in liability for any resulting consequences.

Warning

Other applications or the operation of pumps in

ambient and operating conditions, which are not

approved, are considered improper and are not

permitted. Irriquip CC accepts no liability

for any damage resulting from incorrect use.

Warning

If these safety instructions are not observed,

it may result in personal injury!

Caution

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment!

Note Notes or instructions that make the job easier

and ensure safe operation.

Warning

Electrical connections must only be carried out

by qualified personnel!

The pump housing must only be opened by

personnel authorised by I-FEEDER!

3 Type key

MXD XX X X X X X X X X X X X

Type range Motor variant

Model number E0 PTC motor for frequency control

Maximum counter-pressure [bar] E1 Motor type 400 V,

Control variant E2 Motor type 220 V,

B Standard - manual control Mains plug

AR* Analog/pulse control

4-20 mA control X no plug

Connection, suction/discharge

VSD Variable speed control

4 Tubed

6 Cemented

Dosing head variant

PP Polypropylene

PV PVDF (polyvinylidene fluoride)

PVC Polyvinyl chloride

SS Stainless steel, SUS 316

PV-R PVDF + integrated relief valve

PVC-R PVC + integrated relief valve

8 Threaded, male

Valve type

1 Standard valve

3 0.05 bar suction opening pressure

0.8 bar discharge opening pressure

Gasket material

E EPDM 4 Spring-loaded, discharge side only

0.8 bar opening pressure

5 Valve for abrasive media

T PTFE

Supply voltage

Valve ball material G 230 V, 50/60 Hz

G Glass

C Ceramic

E380 V, 50/60 Hz

SS Stainless steel

Control panel position

X no control panel

PROTECTION:IP-55

TECHNICAL :

4 Pump performance

4.1 Accuracy

• Dosing flow fluctuation: ± 1.5 % within the control range 1:10

• Linearity deviation: ± 4 % of the full-scale value. Adjustment

from max. to min. stroke length, within the control range 1:5.

Applies to:

• water as dosing medium

• fully deaerated dosing head

• measurement according to IRRIQUIP factory standard

no. 0027/0813

• standard pump version.

4.2 Performance

Applies to:

• maximum counter-pressure

• water as dosing medium

• flooded suction 0.5 mWC

• fully deaerated dosing head

• three-phase 400 V motor.

4.3 Suction heights ( See chart below )

4.3.1 Media with a viscosity similar to water

Applies to:

• counter-pressure of 1.5 to 10 bar

• non-degassing and non-abrasive media

• temperature of 20 °C

• stroke length 100 %.

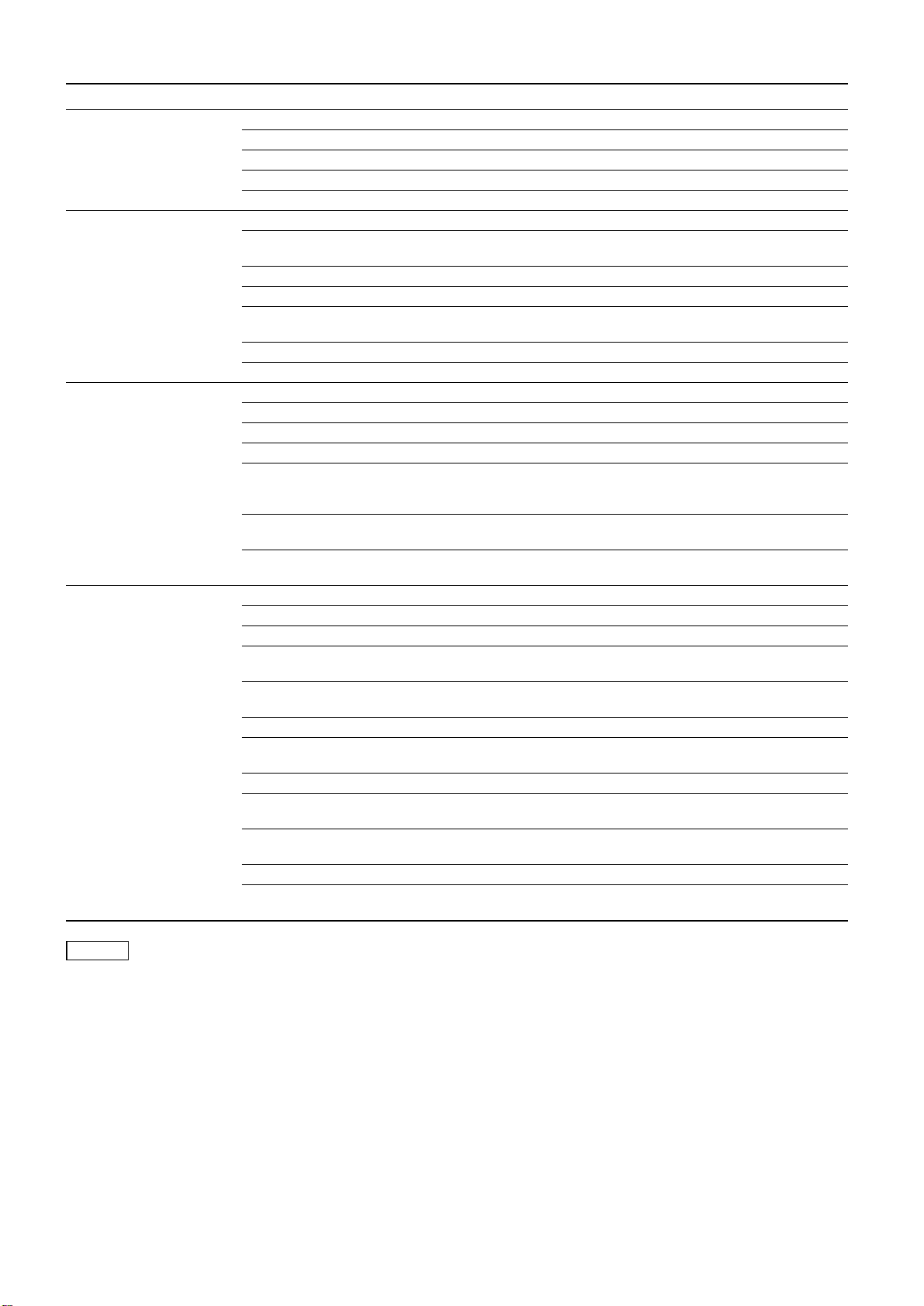

Pump type

50 Hz 60 Hz Maximum length of

suction line

[m]

Suction height*

[mWC]

Intake height**

[mWC]

Suction height*

[mWC]

Intake height**

[mWC]

MXD 82S 4 3 4 3 4

MXD 23S 4 3 4 3 4

MXD 63S 3 2 3 2 3

MXD 53S 2 1 2 1 2

MXD 14S 2 1 2 1 2

MXD 20S 1 1 1 1 2

MXD 16S 1 1 1 1 2

* Suction line and dosing head filled ( continuous operation )

** Suction line and dosing head not filled.

M o d e l - M X D 8 2 S 2 3 S 6 3 S 5 3 S 1 4 S 2 0 S 1 6 S

M a x . d i s c h a r g e v o l u m e ( lph )5 0 1 0 0 2 0 0 3 0 0 6 0 0 9 0 0 1 2 0 0

M a x . d i s c h a r g e p r e s s u r e ( Bar ) 1 0 1 0 7 10 10 8 6

S t r o k e l e n g t h ( m m )

S t r o k e s p e r m i n u t e 3 6 3 6 3 6 5 8 1 1 6 1 7 4 2 3 2

C o n n e c t i o n t y p e / a p e r t u r e K 1 5 A

T r a n s f e r r a b l e v i s c o s i t y( mPa * s )

T r a n s f e r r a b l e t e m p e r a t u r e ( ° C )

P o w e r

S t a n d a r d m o t o r P o l e s 2

P o w e r ( k W ) 0 ,3 7 0 , 5 5 0 ,7 5 1 ,1 1 ,1

P u m p p a i n t c o l o r

W e i g h t ( k g ) 2 6 2 6 2 9 2 9 2 9 3 2 3 2

M a t e r i a l / T y p e P T S S T S V E C P E C

P u m p H e a d P P S U S 3 0 4 P V C P P

D i a p h r a g m P T F E P T F E E P D M E P D M

C h e c k B a l l S U S 3 0 4 S U S 3 0 4 C E R A M C E R A M

J o i n t P P S U S 3 0 4 P V C P P

O - r i n g N E O V IT O N N E O N E O

1 2 ,5

H a m m e r t o n e B l u e

S t a i n l e s s s t e e l c h e c k b a l l: 3 0 0 0 m P a * s

S t a i n l e s s s t e e l / P V D F : 0 - 6 0 ° c - N O F R E E Z I N G A L L O W E D

2 2 0 V ( s i n g l e - p h a s e ) o r 3 8 0 V ( t h r e e - p h a s e )

4

K 2 5 A

0 ,2 5

L i q u i d E n d M a t e r i a l s

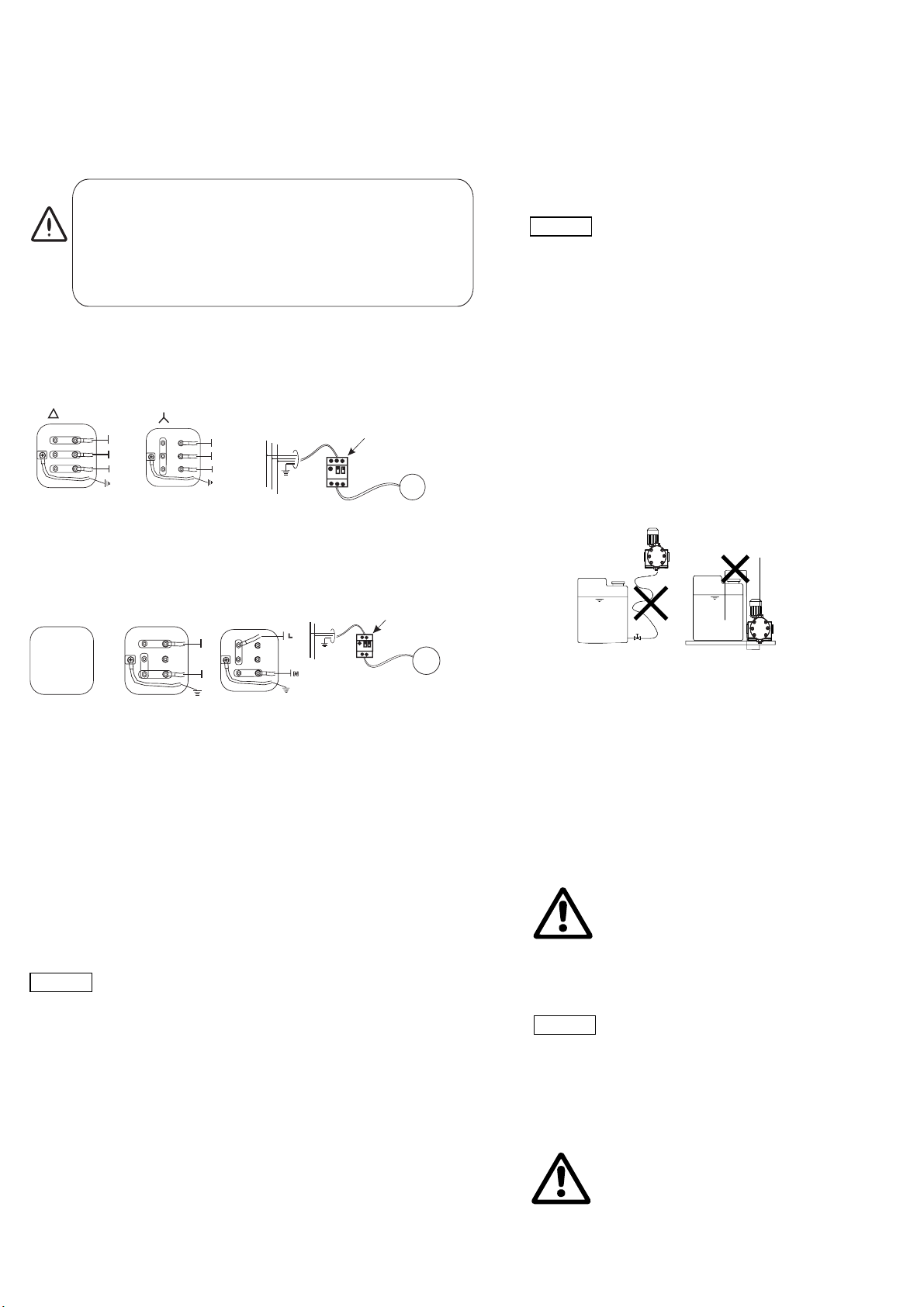

The electric protection of the motor must be installed and adjusted

following its nominal instensity (overloaded switch disjuntor). (See

wiring).

A disconnection overload must be installed in case of emergency.

The equipment must be protected to avoid untimely sudden starts.

ON

OFFOFF

DOL Starter with overload

U

V

W

THREE-PHASE CONNECTION (50/60 Hz)

To work at 230 V we will plug the motor in delta

To work at 400 V it will be a star connection.

V1

W1

U1

230 V 400 V

V1

W1

U1

ON

OFF

DOL Starter with overload

L

SINGLE PHASE CONNECTION

N

To work at 230 V single-phase at 50 Hz we will connect directly the motor wire

to the adequate protection. To work at 60 Hz we will connect the connection box

plates as shown in the drawing.

N

L

115 VAC (60 Hz) 230 VAC (60 Hz)

230 VAC (50 Hz)

WIRE

INCLUDED

M

M

5 INSTALLATION

5.1 GENERAL

To install this pump it is advisable to choose places protected from water,

away from heat sources and air renewal.

Place the pump vertically over a rigid surface to achieve proper distribution

of lubrication. Anticipate spaces needed for maintenance and installation.

6. Commissioning

6.1 Checks before start-up

• Check that the rated voltage stated on the pump nameplate

corresponds to the local conditions!

• Check that all connections are secure and tighten,

if necessary.

• Check that the dosing head sc rews are tightened with the

specified torque and tighten, if necessary.

• Check that all electrical connections are correct.

6.2 Start-up

1. Open the deaeration valve , if installed, in the discharge line, or

relieve the pressure on the discharge side so that the medium

can run out without a counter-pressure.

2. Switch on the power supply.

3. Set the stroke-length adjustment knob to 100 %.

4. Leave the pump running until the dosed medium is free of air

bubbles.

5. Close the deaeration valve, if installed.

– The pump is now ready for operation.

Caution

After initial start-up and after each time the

diaphragm is changed, tighten the dosing head

screws.

After approximately 6-10 operating hours or two

days, cross-tighten the dosing head screws

using a torque wrench.

Maximum torque: 6 Nm.

Functional principle

• Reciprocating displacement pump with electric motor and

mechanical diaphragm control.

• The rotation of the motor is transformed into the reciprocating

movement of the dosing diaphragm by the eccentric and the

tappet.

• The dosing flow can be set by adjusting the stroke length of the

tappet.

6.3 Switching on/off

• To start the pump, switch on the power supply.

• To stop the pump, switch off the power supply.

Caution

Before switching on the pump, check that it is

installed correctly.

7 Installation tips

• For easy de-aeration of the dosing head, install a ball valve

with bypass line (back to the dosing tank) immediately after

the discharge valve.

• In the case of long discharge lines, install a non-return valve in

the discharge line.

• When installing the suction line, observe the following:

– Keep the suction line as short as possible. Prevent it from

becoming tangled.

– If necessary, use swept bends instead of elbows.

– Always route the suction line up towards the suction valve.

– Avoid loops which may cause air bubbles.

• For media with a tendency to sedimentation, install the suction

line with filter so that the suction valve remains a few millimetres

above the possible level of sedimentation.

8.Tube / pipe lines

8.1 General

8.2 Connecting the suction and discharge lines

• Connect the suction line to the suction valve.

– Install the suction line in the tank so that the foot valve

remains 25 to 30 mm above the bottom of the tank or the

possible level of sedimentation.

• Connect the discharge line to the discharge valve.

Caution

Warning

Only use the prescribed line types!

All lines must be free from strain!

Avoid loops and buckles in the tubes!

Keep the suction line as short as possible to

avoid cavitation!

If necessary, use swept bends instead of elbows.

Observe the chemical manufacturer's safety

instructions when handling chemicals!

Make sure that the pump is suitable for the actual

dosing medium!

The flow must run in the opposite direction to

gravity!

The resistance of the parts that come into contact

with the media depends on the media, media

temperature and operating pressure. Ensure that

parts in contact with the media are chemically

resistant to the dosing medium under operating

conditions!

Warning

All lines must be free from strain!

Only use the prescribed line types!

8.3 SUCTION

It is essential to fit in the suction of the dosing liquid the filter of 500 mesh.

Couple the suction pipe to the lower connecter of the cylinder, putting the mesh filter inbetween.

The sediment at the bottom of the tank must never be suctioned, to avoid suction of undiluted parts.

The piping must be stiff enough so that it does not lose its shape when there is suction.

To help suction the piping must be as short as possible, the pipe diameter must be at least 40 mm.

For pipes of over 3 m, diameter must be increased.

8.4 INJECTION

Fix the check valve supplied with the pump at the input of the water network, as

shown in the drawing, and couple the injection hose to the upper connecter of

the cylinder.

The pipe diameter will have to be the same as the valve diameter. For pipes over

15m length the diameter shall be increased. Do never insert a shutoff valve.

8.5 DOSING FLOW

Through the micrometic regulator adjust the dosing flow from 0 to 100 % depending

on the wished value. A regulation inferior than 10% is not advisable.

In order to check the dosing flow:

1.- Prime the pump immersing the

suction pipe in graduated receptacle ( A )

2.- Mark in the receptacle the liquid level.

3.- Start up the pump and pour a

known volume (V) of measured liquid

in a second receptacle ( B).

4.- Measure the time (t) that goes

between the start up of the pump and

the precise instant in which the liquid

reaches the level of the mark of

receptacle A.

5.- The dosed flow corresponds to:

Q(l/h) = V (liters) / t (seconds) x 3600

A

B

A

1

B

C

D

A

B

C

D

2345678

12345678

4

2

5

3

11

12

15

13

14

13

15

16

9

13

15

16

9

18

9

16

19

16

7

8

9

10

1

16

5

6

6

16

9

20

17

21

22

23

10. Transport and storage

10.1 Delivery

The MXD type dosing pumps are supplied in different packaging,

depending on pump type and the overall delivery. For transport

and intermediate storage, use the correct packaging to protect the

pump against damage.

10.2 Intermediate storage

• Permissible storage temperature: –20 °C to +50 °C.

• Permissible air humidity: max. relative humidity: 92 %

(non-condensing).

10.3 Unpacking

Retain the packaging for future storage or return, or dispose of

the packaging in accordance with local regulations.

10.4 Return

Return the pump in its original packaging or equivalent.

The pump must be thoroughly cleaned before it is returned or

stored. It is essential that there are no traces of toxic or

hazardous media remaining on the pump.

Before returning the pump to Irriquip for service, the

safety declaration at the end of these instructions must be filled in

by authorised personnel and at tached to the pump in a visible

position.

If Irriquip or agent is requested to service the pump, it must be

ensured that the pump is free from substances that can be

injurious to health or toxic. If the pump has been used for such

substances, the pump must be cleaned before it is returned.

If proper cleaning is not possible, all relevant information about the

chemical must be provided.

If the above is not fulfilled, Irriquip can refuse to accept

the pump for service. Costs of returning the pump are paid by the

customer.

The safety declaration can be found at the end of these instructions.

Caution

Do not throw or drop the pump.

Store the pump in a dry and cool place.

Store the pump in upright position so that the

gear oil cannot leak out.

Do not use the protective packaging as transport

packaging.

Observe the permissible storage temperature!

Caution

Irriquip accepts no liability for damage

caused by incorrect transportation or missing or

unsuitable packaging of the pump!

Caution

If a pump has been used for a medium which is

injurious to health or toxic, the pump will be

classified as contaminated.

Caution

The replacement of the supply cable must be

carried out by an authorised Irriquip service

workshop.

9. Maintenance

9.1 General notes

Warning

When dosing dangerous media, observe the

corresponding safety precautions!

Risk of chemical burns!

Wear protective clothing (gloves and goggles

when working on the dosing head, connections

or lines!

Do not allow any chemicals to leak from the

pump. Collect and dispose of all chemicals

correctly!

Warning

The pump housing must only be opened by

personnel authorised by Irriquip!

Repairs must only be carried out by authorised

and qualified personnel!

Switch off the pump and disconnect it from the

power supply before carrying out maintenance

work and repairs!

Replacing the diaphragm

1. Loosen the six dosing head screws.

2. Remove the dosing head.

3. Turn the fan blades until the diaphragm reaches the front dead

centre (the diaphragm detaches itself from the diaphragm

flange).

4. Unscrew the diaphragm by manually turning it counter-

clockwise.

5. Check the parts and replace by new ones, if necessary.

6. Screw in the new diaphragm completely. Then turn it back until

the holes in the diaphragm and the flange coincide.

7. Turn the fan blades until the diaphragm reaches the bottom

dead centre (the diaphragm is pulled onto the diaphragm

flange).

8. Refit the dosing head carefully and cross-tighten the screws.

Maximum torque: 6 Nm.

9. Deaerate and start the dosing pump.

Before any maintenance operation we will check:

That the pump is stopped and disconnected from the electric

supply.

There is no pressure neither inside the head nor in the impulsion

pipe. It is advisable to empty the head before opening it.

The staff in charge of the maintenance will use the adequate

protection means in order to manipulate the dosed liquid.

PERIODICAL MAINTENANCE:

Change oil after the first 500 hours. Next changes will be every 2000 hours

(minimum once a year).

Check the diaphragm every 3 months or 1000 hours.

Check the suction filter before and after operation..

Check the valves every 3 months or 1000 hours.

It is advisable to periodically clean the dosing unit, letting clean water flow through it

(we can make it coincide with the emptying of the tank), to eliminate precipitated

rests that can remain in the inner part of the cylinder or in suction / impulsion pipes.

If we are using highly corrosive liquids it is advisable to double the frequency

of checkings.

OIL: Take off re-filling lid and fill the pump with the provided oil:

320 GRADED OIL. If the pump has several boxes oil must be

filled into all boxes.

Approximate oil capacity: 1 liter per gearbox.

When carrying, keep upright.

CHECKING THE HYDRAULIC CIRCUIT: Check that all valves are

opened and that escapes from priming valves derive the liquid to a

proper receptacle.

ROTARY DIRECTION: Start up the pump to check that the rotary

direction coincides with the one shown by the arrow. To change rotary

direction invert two phases in the motor terminals box.

CHECKING OF PUMP: Check visually/auditorilly the proper working

of the pump.

11. Fault finding chart

Fault Cause Remedy

1. Dosing pump does not

run.

a) Not connected to the power supply. Connect the power supply cable.

b) Incorrect supply voltage. Replace the dosing pump.

c) Electrical failure. Return the pump for repair.

d) The empty indication has responded. Remove the cause.

e) The diaphragm leakage detection has responded. Replace the diaphragm.

2. Dosing pump does not

suck in.

a) Leaking suction line. Replace or seal the suction line.

b) Cross-section of the suction line too small or

suction line too long. Check with I-Feeder specification.

c) Clogged suction line. Rinse or replace the suction line.

d) Foot valve covered by sediment. S u s p e n d the suction line from a higher position.

e) Buckled suction line. I n s t a l l t h e suction line correctly. Check for

damage.

f) Crystalline deposits in the valves. Clean the valves.

g) Diaphragm broken or diaphragm tappet torn out. Replace the diaphragm.

3. Dosing pump does not

dose.

a) Air in the suction line and dosing head. Wait, until the pump has deaerated.

b) Stroke-length adjustment knob set to zero. Turn the adjustment knob in the "+" direction.

c) Viscosity or density of medium too high. Check the installation.

d) Crystalline deposits in the valves. Clean the valves.

e) Valves not correctly assembled. Assemble the inner valve parts in the right order

and check and possibly correct the flow

direction.

f) Injection point blocked. Check and possibly correct the flow direction

(injection unit), or remove the obstruction.

g) Incorrect installation of lines and peripheral

equipment.

Check the lines for free passage and correct

installation.

4. Dosing flow of the pump

is inaccurate.

a) Dosing head not fully deaerated. Repeat the deareation.

b) Degassing medium. Check the installation.

c) Parts of the valves covered in dirt or incrusted. Clean the valves.

d) Zero point misadjusted. Adjust the zero point to the actual counter-

pressure.

e) Counter-pressure fluctuations. Install a pressure-loading valve and a pulsation

damper.

f) Suction height fluctuations. Keep the suction level constant.

g) Siphon effect (inlet pressure higher than counter-

pressure). Install a pressure-loading valve.

h) Leaking or porous suction line or discharge line. Replace the suction line or discharge line.

i) Parts in contact with the medium are not resistant

to it. Replace with resistant materials.

j) Dosing diaphragm worn (incipient tears). Replace the diaphragm. Also observe the

maintenance instructions.

k) Supply voltage fluctuations. Decrease the counter-pressure of the pump.

l) Variation of the dosing medium (density,

viscosity).

Check the concentration. Use an agitator,

if necessary.

Caution For further error signals for the control unit, refer to the relevant section.

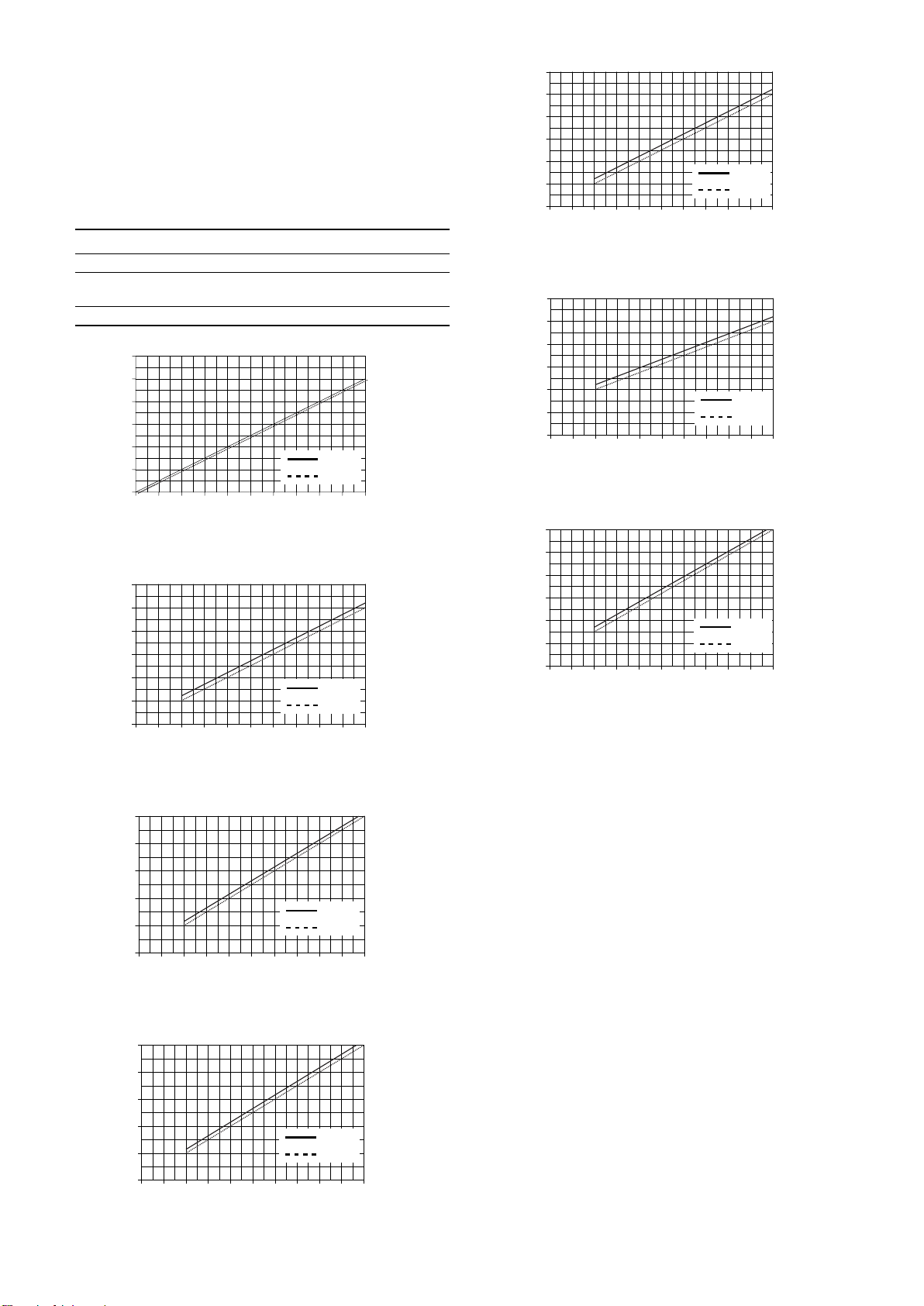

12. Dosing curves

The dosing curves on the following pages are trend curves.

They apply to:

• performance of simple pump (the flow rate is doubled for the

double pump)

• water as dosing medium

• suction line with foot valve, 0.5 m flooded suction

• zero point of pump Q0 for specified pressure, see table below

• standard pump version.

MXD-82S (50 Hz)

MXD-23S (50 Hz)

MXD - 63S (50 Hz)

MXD - 53S (50 Hz)

MXD-14S ( 50 Hz )

MXD - 20S ( 50 Hz )

Abbreviation Description

Q Dosing flow

Q0

Zero point of the pump

The pumps are calibrated so that Q is 0 at 2 bar.

h Stroke length

0

10

20

30

40

50

60

0 10 20 30 40 50 60 70 80 90 100

h [%]

Q [l/h]

2bar

10bar

2 bar

10 bar

0

20

40

60

80

100

0 10 20 30 40 50 60 70 80 90 100

h [%]

Q [l/h]

10bar

3bar

2 bar

10 bar

0

40

80

120

160

200

0 10 20 30 40 50 60 70 80 90 100

h [%]

Q [l/h]

3bar

10bar

2 bar

8.5 bar

0

60

120

180

240

300

0 10 20 30 40 50 60 70 80 90 100

h [%]

Q [l/h]

10bar

2 bar

10 bar

0

120

240

360

480

600

720

0 10 20 30 40 50 60 70 80 90 100

h [%]

Q [l/h]

3bar

2 bar

10 bar

0

180

360

540

720

900

1080

0 10 20 30 40 50 60 70 80 90 100

h [%]

Q [l/h]

16bar

2 bar

8 Bar

0

200

400

600

800

1000

1200

0 10 20 30 40 50 60 70 80 90 100

h [%]

Q [l/h]

3bar

10bar

2 bar

6 bar

MXD - 16S ( 50 Hz )

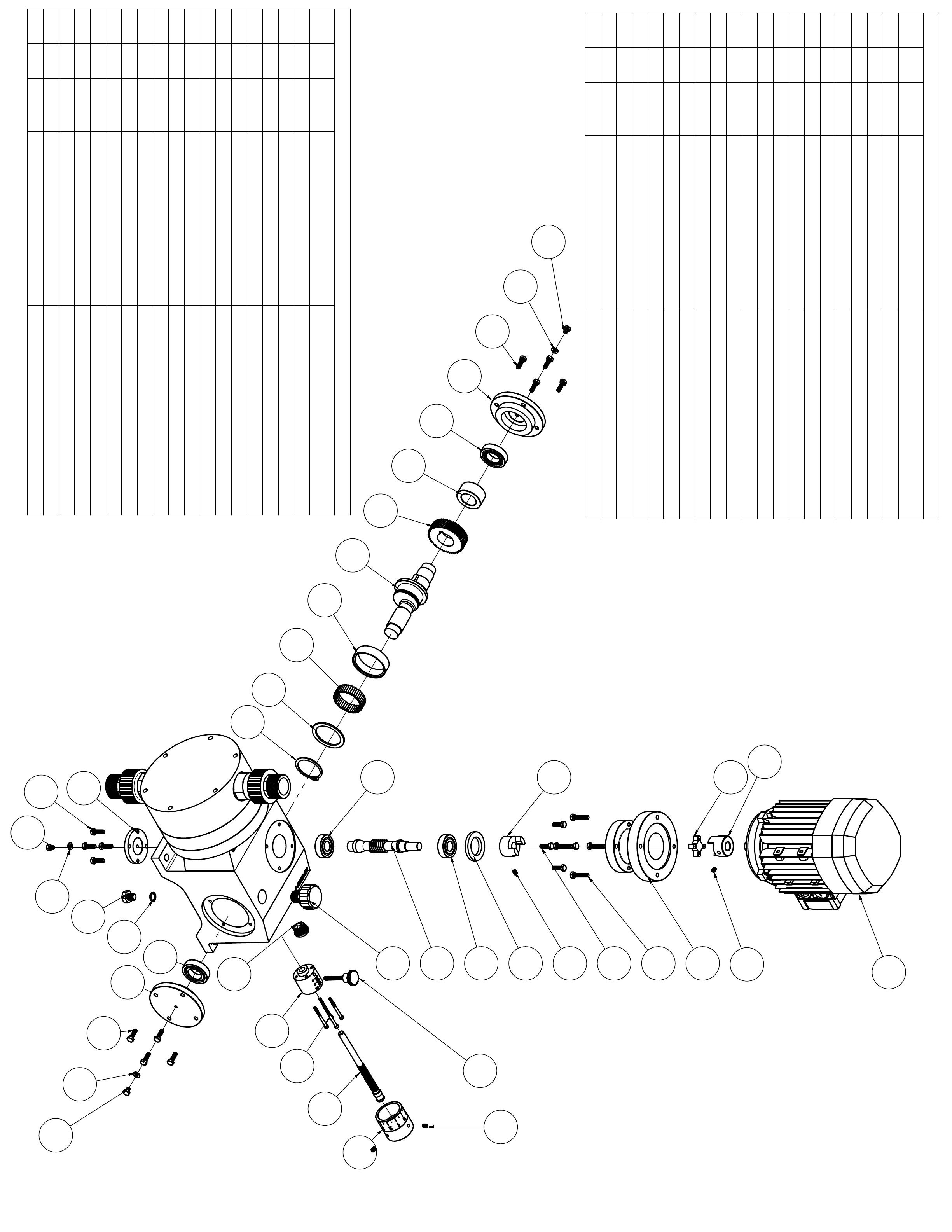

PARTS LIST

ITEM QTY PART

NUMBER PART NAME DESCRIPTION

1 3 K-34 BOLT M6:8 BOLT M6 X 8 STAINLESS STEEL

2 3 K-37 COPPER WASHER COPPER WASHER M6

3 16 K-33 BOLT M6:20 BOLT M6 X 20 MM STAINLESS STEEL

4 2 K-14 BEARING CAP MXD BEARING CAP MXD GEARBOX

5 2 K-44 BEARING MAIN SHAFT 6005 BEARING MAIN SHAFT

6 1 K-29 MAIN SHAFT SPACER MAIN SHAFT SPACER

7 1 K-22A WORM GEAR MAIN DRIVE GEAR

8 1 K-26 MAIN SHAFT ECCENTRIC CAM MAIN SHAFT

9 1 K-27 ECCENTRIC BEARING BUSH ECCENTRIC CAM ROLLER BEARING BUSH

10 1 K-31 ECCENTRIC BEARING ECCENTRIC CAM ROLLER BEARING

11 1 K-28 ECCENTRIC CAM RETAINING RING ECCENTRIC CAM BEARING RETAINING RING

12 1 K-30 ECCENTRIC CAM CIRCLIP MAIN SHAFT BEARING CIRCLIP 40,5

13 1 K-41 BOTTOM CAP BOTTOM RETAINING CAP STEEL

14 1 K-19 OIL DRAIN PLUG OIL DRAINING PLUG M12

15 1 K-19A OIL DRAIN WASHER OIL DRAIN COPPER WASHER M12

16 1 K-21 LEVEL INDICATOR HYDRAULIC PLUG LEVEL INDICATOR 1/2 "

17 1 K-47 ADJUSTMENT COARSE ADJUSTMENT HOLDER COARSE

18 4 K-36 CAPSCREW M4:45 CAPSCREW M4 X 45 STAINLESS STEEL

19 1 K-48 ADJUSTMENT SHAFT ADJUSTMENT SHAFT

20 1 K-49 ADJUSTMENT CONTROL NUMERICAL ADJUSTMENT CONTROL

PARTS LIST

ITEM QTY PART

NUMBER PART NAME DESCRIPTION

21 4 K-45 GRUBSCREW M6:8 GRUBSCREW M6 X 8 STAINLESS STEEL

22 1 K-52 SETSCREW M6:45 STAINLESS SETSCREW M6X50

23 1 K-20 OIL BREATHER CAP HYDRAULIC BREATHER CAP 1/2"

24 1 K-22 WORM SHAFT WORM GEAR SHAFT

25 2 K-42 BEARING WORM SHAFT 6203 BEARING WORM SHAFT

26 1 K-12 RETAINER STAINLESS STEEL RETAINER 32555

27 4 K-53 BOLT M6:35 BOLT M6 X 35 STAINLESS STEEL

28 1 K-40 MOTOR FLANGE MOTOR FLANGE STEEL 71:80

29 1 MF-AC380 AC ELECTRIC MOTOR ELECTRIC MOTOR 380V B34

30 2 K-38 DRIVE COUPLING SPIDER COUPLING LO70

31 1 K-37 LO70 COUPLING RUBBER SPIDER COUPLING RUBBER LO70

32 2 K-01 1ST JOINT 1 1/4" 1ST JOINT 1 1/4" PP

33 1 K-10A BACKING RING BACKING RING PP

34 1 K-23 MAIN FLANGE MAIN FLANGE LARGE

35 1 K-10 LARGE PUMP HEAD 190 LARGE PUMP HEAD PP 190 MM

36 1 MX-GB MXD GEARBOX MXD GEARBOX

37 2 K-02 VALVE MAIN VALVE 1 1/4"

38 2 K-07 UNION NUT UNION NUT PP 1 1/4"

29

21

30

31

28

27

3

21

30

26

25

25

21

17

18

19

20

5

4

3

2

1

15

14

13

1

2

3

4

5

6

7

8

9

10

11

24

22

16

23

12

32

1

Parts List

Item Qty Part Number Part Name Description

1 6 K-11 Head Bolt M8 x 120 Head Bolt Stainless Steel

2 6 K-11B Head Bolt Split Washer M8 Head Bolt Split Washer SUS

3 6 K-11A Head Bolt Flat Washer M8 Head Bolt Flat Washer SUS

41 K-10 Pumphead MXD Large Pump Head PP

5 4 K-05 O-Ring Valve 1 1/4" O-Ring Valve 1 1/4" EPDM

6 2 K-02 Valve Main Valve 1 1/4"

72K-03S Checkball 22 SUS Stainless Steel Check Ball 7/8"

8 2 K-04 Ballcage 1 1/4" Ballcage 1 1/4" PP

9 2 K-07 Union Nut Union Nut PP 1 1/4"

10 2 K-01 1st Joint 1 1/4" 1st Joint 1 1/4" PP

11 1 K-18E Diaphragm 140 140 mm Diaphragm

12 1 K-13 Diaphragm Connector Diaphragm Connector SUS

13 1 K-10A Backing Ring Backing Ring PP

14 4K-35 Capscrew M8:30 Capscrew Headflange M8x30

15 1 K-15 Oil Seal Piston OIl Seal 15307 for Piston

16 1 K-23 Main Flange Main Flange Large

17 1 K-16 Cap Screw M5:16 Capscrew for Piston Flange m5x16

18 1 K-24 Spring Steel Spring

19 1 K-25 Piston Shaft Piston Shaft

20 1 MX-GB MXD Gearbox MXD Gearbox

20

19

18

17

16

15

14

13

12

11

4

5

6

7

8

5

9

10

3

2

1

5

6

8

7

5

9

10

Sales date and shop stamp

SERIAL #

MODEL

14. WARRANTY

IRRIQUIP CC Warrants the product specified in this document for a period of 1 year from

the purchase date. This warranty obligation is limited to the free replacement of the

damaged parts due to any material or manufacture defect. This warranty does not

include periodic maintenance and damage resulting from misuse.

The equipment must be sent to a I-Feeder Service Center with prepaid transport

charges, and will be sent back with transport charges for customer’s account.

The warranty document with sales date and shop stamp, or an invoice copy must be

sent with the equipment.

IRRIQUIP CC can not be held liable for any loss of crop or product due to breakage.

WESTERN CAPE

TEL: +27 21 9135942

SOUTH AFRICA

CELL #: +27834579991

Table of contents

Popular Water Pump manuals by other brands

Pentair

Pentair INTELLIFLO VSF Series quick start guide

MYERS

MYERS SP75 Series Installation, Operation & Parts Manual

dosatron

dosatron D14MZ5VAFII manual

Vito Agro

Vito Agro VIBSMAL1000 instruction manual

Wilo

Wilo Star-Z 20/7 EM Installation and operating instructions

Novatech

Novatech 38888 instruction sheet