THOMPSON PUMP J1939 User manual

Product Manual

Pump Display & Control Panel

J1939 Engines

Part Number: C4F-G8352-AS

Revision: 2.2

Application: Full Feature Pump Panel

______________________________________________________________________________________________________________________________________

- 1 -

TABLE OF CONTENTS

PRIOR TO STARTING ENGINE……………………………………………………………………….……………….………………….…………...8

REQUIRED SETTINGS FOR OPERATION

MANUAL OPERATION SETTINGS

AUTOMATIC OPERATION SETTINGS

MANUAL THROTTLE SETTINGS…………………………………………………………………………………………………...……………….10

STANDARD VERNIER UP AND DOWN THROTTLE

MULTISTATE THROTTLE

AUTOMATIC THROTTLE SETTINGS……………………………………………………………………………………….…………………….11

SINGLE SPEED (PROFILE) THROTTLE

LINEAR THROTTLE

LEVEL OR PRESSURE MAINTAIN THROTTLE

PANEL OPERATION…………….…………………………………………………………………………………….……………………………….……….17

MANUAL OPERATION

AUTO START/STOP OPERATION

SLEEP MODE

MODULE CONNECTORS…………………………………………………………………………………………………….……………………………..18

PRIMARY 14 PIN MODULE CONNECTOR

SECONDARY 23PIN CONNECTOR

PANEL CONNECTOR……...………………………………………………...……………………………………………….……………………..………….20

21 PIN ENGINE HARNESS CONNECTOR

31 PIN ACCESSORY CONNECTOR

ENGINE ALARMS, CODES AND MESSAGES………………………………………………………………………………........………...23

ENGINE ECU ALARMS/DE-RATE/SHUT DOWNS

PANEL ALARM ANNUNCIATION AND CODE READER

ALARM HORN SILENCE

PANEL INDICATION LAMPS

ACTIVE AND STORED ENGINE ECU CODES

CONTROL PANEL SPECIFIC ALARMS AND SHUT DOWNS…………………………………………….…………..……….25

CONTROL PANEL ANALOG AND DIGITAL INPUTS……………………….…...………………………………………………..…26

ANALOG INPUT FUNCTIONS

DIGITAL FUNCTIONS

CONTROL PANEL RELAY OUTPUTS ……………………………………………………………………..….…………………...................…..28

RELAY FUNCTIONS, POLARITY & INITIAL STATE

PANEL TO ENGINE ECU COMMUNICATIONS…..…………….……………………………………………………………….…….31

BATTERY RECHARGE MONITOR………………………………………….……………………………………………………………..….…....32

MODBUS CONFIGURATION………………………………………….……………………………………………………………………..….…....32

- 2 -

CLUTCH CONFIGURATION………………………………………….………………………………………………………………………..….…....33

CLOCK SETUP………………………………………….………………………………………………………………………………………………..….……...36

EMISSION MONITORING ………………………………………………………………………………………………...……………………………37

SCHEDULER SET-UP………………………………………………………………………………………….……………….………………….…………...3

SETTING THE REAL TIME CLOCK

DISPLAYING DATE AND TIME IN AUTO MODE

SETTING UP THE WEEKLY SCHEDULER

RUNNING ON THE WEEKLY SCHEDULER

MENU SYSTEM……………………………………………………………………………………………..……………………………………………….……40

MENU ACCESS, EXIT AND NAVIGATION

VIEWING MENUS

CONFIGURATION MENUS

- 3 -

PRIOR TO STARTING ENGINE

Prior to starting the engine, fully complete the Parameter Configuration menu, select the

required START/STOP and THROTTLE settings. Reference the tables below to determine the

appropriate operating modes. Details on each setting are provided on the following pages.

PARAMETER CONFIGURATION

Critical features to pump operation are to be selected and configured in this menu. These items

include Fuel Level, Voltage Source, Hour meter, Transducer Settings (Application, Inlet Pressure

and Outlet Pressure) and Flow Rate. Choose the parameter to be configured by pressing the enter

button (placing brackets) and using the up and down arrow buttons. Once the correct parameter

appears press enter to select. Press the up arrow keys to configure the chosen parameter.

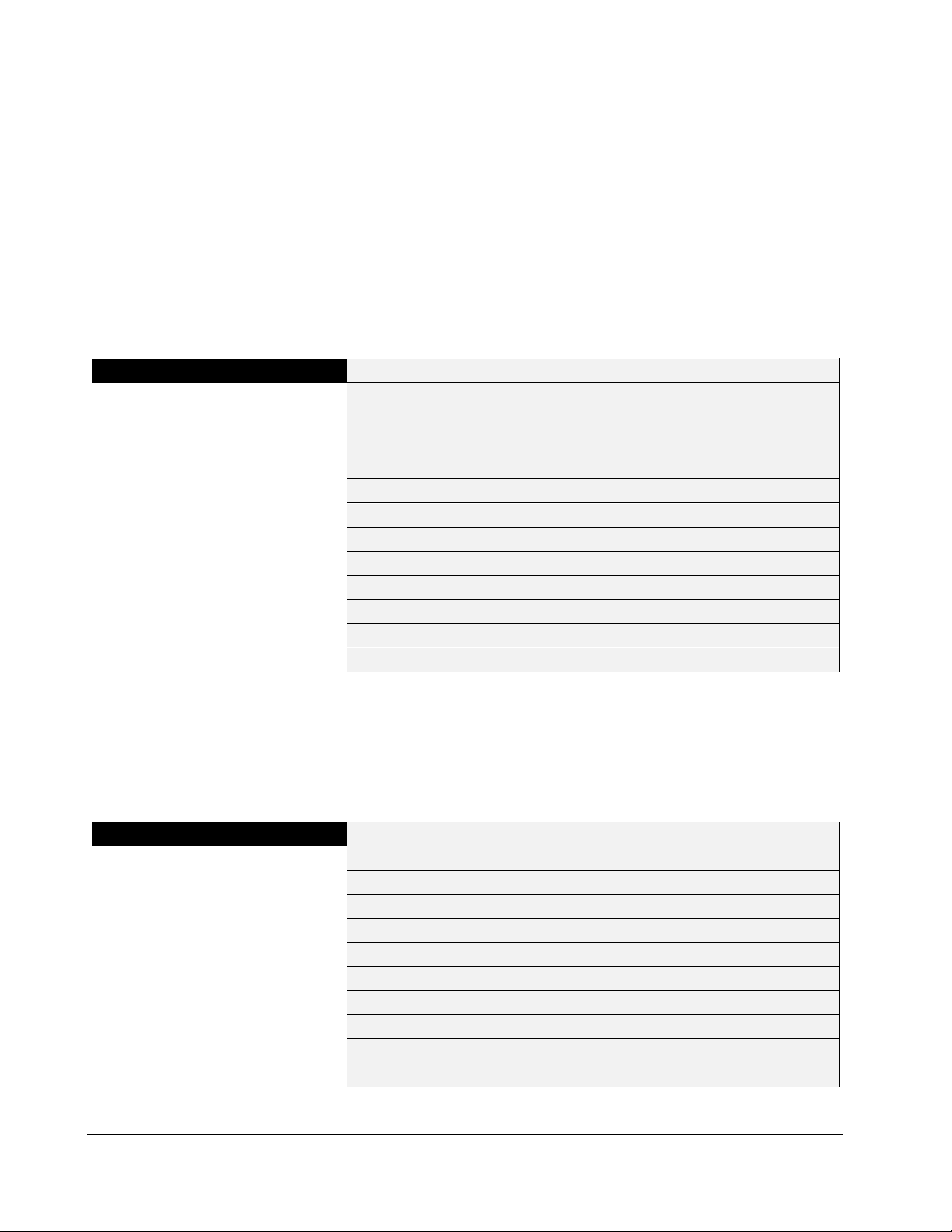

MANUAL OPERATION SETTINGS

AUTOMATIC OPERATION SETTINGS (Key in Auto Position)

Start/Stop Mode Available

Floats (single or dual)

Transducer

A fail safe float backup option is available for pressure and level modes should the

pressure or level transducer fail to operate.

Start/Stop Mode Available

Manual Key Start

Throttle Mode Available

Throttle Description

TSC Vernier

UP and DOWN via panel buttons

(set min and max speeds)

Multistate

UP and DOWN via panel buttons

(up to four separate operating speeds)

Throttle Mode Available

Throttle Description

Single Speed

Select warm up, prime, operating and cool down speeds

Linear

Engine speed adjusts between selected min and max speeds in relation

to selected min and max level or pressures

Target

Engine speed adjusts to maintain selected level or pressure

- 4 -

FAIL SAFE FLOAT START/STOP

An optional fail safe float can also be used as a backup to the transducer. To enable the failsafe float:

In the Auto Operations Menu

1) set Failsafe Float to “ON”

2) set the Failsafe Speed to “Desired engine speed if fail safe float is tripped”

3) set the Failsafe Float Time Delay for “the minimum amount of time the engine runs if the

failsafe float is tripped”

DUAL FLOAT BACK-UP OPERATION

An optional dual float back-up operation is available when utilizing the application transducer for the

pump start/stop. To enable this function:

In the Auto Operations Menu

1) set Start/Stop Input to “Transducer & Floats”

2) set the Dual Float Speed to “Desired engine speed if dual float is tripped”

In this mode, when the level reaches the dual float trip point, indicating transducer failure, the pump

will continue to run in a single speed mode under standard dual float operation.

- 5 -

MANUAL THROTTLE SETTINGS

The following bolded settings are required for manual throttle operation in the Throttle

Configuration menu.

VERNIER THROTTLE (DEFAULT)

Vernier throttle is standard up and down throttle between the minimum and maximum selections.

The ramp rate is the rate of acceleration in RPM’s per second. The control panel uses J1939 throttle,

also called “torque speed control” or TSC1.

Throttle Configuration Menu

Throttle Type - Throttle Type Selection (Default = Vernier)

TSC Mode Selection (Default=Primary)

TSC Min Speed Selection (Preset by pump specification)

TSC Max Speed Selection (Preset by pump specification)

TSC Bump Speed (Default = 20 rpm)

TSC Ramp Rate Selection (Default = 100 rpm/sec)

Throttle Curve Selection

Multistate Speed 1 Selection

Multistate Speed 2 Selection

Multistate Speed 3 Selection

Multistate Speed 4 Selection

TSC Absolute Minimum Speed (Preset to pump specification)

TSC Absolute Maximum Speed (Preset by pump specification)

MULTISTATE THROTTLE

Multistate throttle provides for one, two, three or four specific operating speeds. Pressing the up and

down buttons adjusts engine speed between the selected multistate speed selections.

Throttle Configuration Menu

Throttle Type - Throttle Type Selection (Select Multistate)

E-Throttle Mode Selection

TSC Mode Selection

TSC Min Speed Selection (Preset by pump specification)

TSC Max Speed Selection (Preset by pump specification)

TSC Ramp Rate Selection (Default = 100 rpm/sec)

Throttle Curve Selection

Multistate Speed 1 Selection

Multistate Speed 2 Selection

Multistate Speed 3 Selection

Multistate Speed 4 Selection

- 6 -

AUTOMATIC THROTTLE SETTINGS

The following auto start/stop throttle options are available for when the key is placed in the AUTO

position:

SINGLE SPEED (PROFILE) THROTTLE

Single speed allows the engine to run according to a predetermined speed profile. Select the desired

engine speed for the following:

1) Warm Up Speed

2) Prime Speed (Optional)

3) Operating Speed

4) Cool Down Speed

Maximum Speed

Minimum Speed

Prime Speed

Warm up Speed

Operating Speed

Cool Down Speed

- 7 -

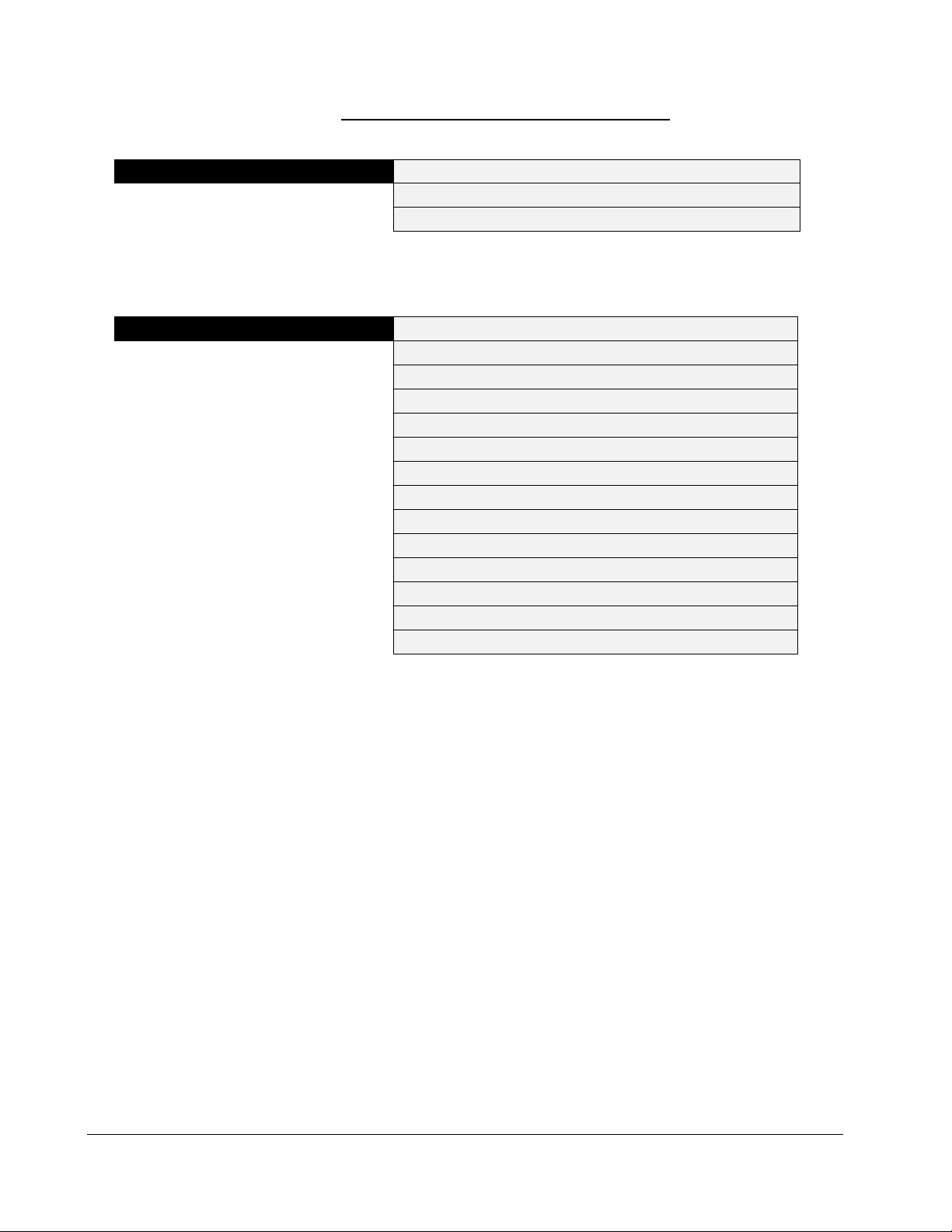

For single speed operation, the highlighted menu settings are required.

Auto Operation Settings Menu

Start/Stop Input (Floats, Transducer)

Throttle Mode (Single Speed, Linear, Target)

Operate Speed (Select Operating Speed)

Auto Start Configuration Menu

Auto Start Delay (Default = 10 seconds)

Pre Heat Time (Default = 0 seconds)

Crank Time (Default = 10 seconds)

Crank Rest Time (Default = 10 seconds)

Warm Up Speed (Default = 800 rpm)

Warm Up Time (Default = 10 seconds)

Prime Speed (Default = 800 rpm)

Prime Time (Default = 0 seconds)

Cool Down Speed (Default = 800 rpm)

Cool Down Time (Default = 10 seconds)

Crank Cycles (Default = 5)

Fault Bypass Period (Default = 10 seconds)

Crank Hold Delay (Default = 0)

Crank Release Speed (Default = 400 rpm)

If any auto start configuration settings are not required (such as warm up speed), set the time to 0:00

seconds for that parameter.

- 8 -

LINEAR THROTTLE

With linear throttle, the minimum and maximum engine speeds and the corresponding minimum and

maximum level or pressures are selected. Engine speed adjusts according to the linear relationship as

shown below.

Example: Level Transducer (0 to 200-inch range)

Minimum Speed = 1000 rpm

Maximum Speed = 2000 rpm

Minimum Speed Level = 50 inches

Maximum Speed Level = 150 inches

Operation

If level = 50 inches, engine speed = 1000 rpm

If level = 100 inches, engine speed = 1500 rpm

If level = 150 inches, engine speed = 2000 rpm

Linear throttle can be combined with any of the automatic engine start/stop modes. If any automatic

speeds settings are not required (such as warm up), set the time delay to 0:00 seconds for that

parameter.

- 9 -

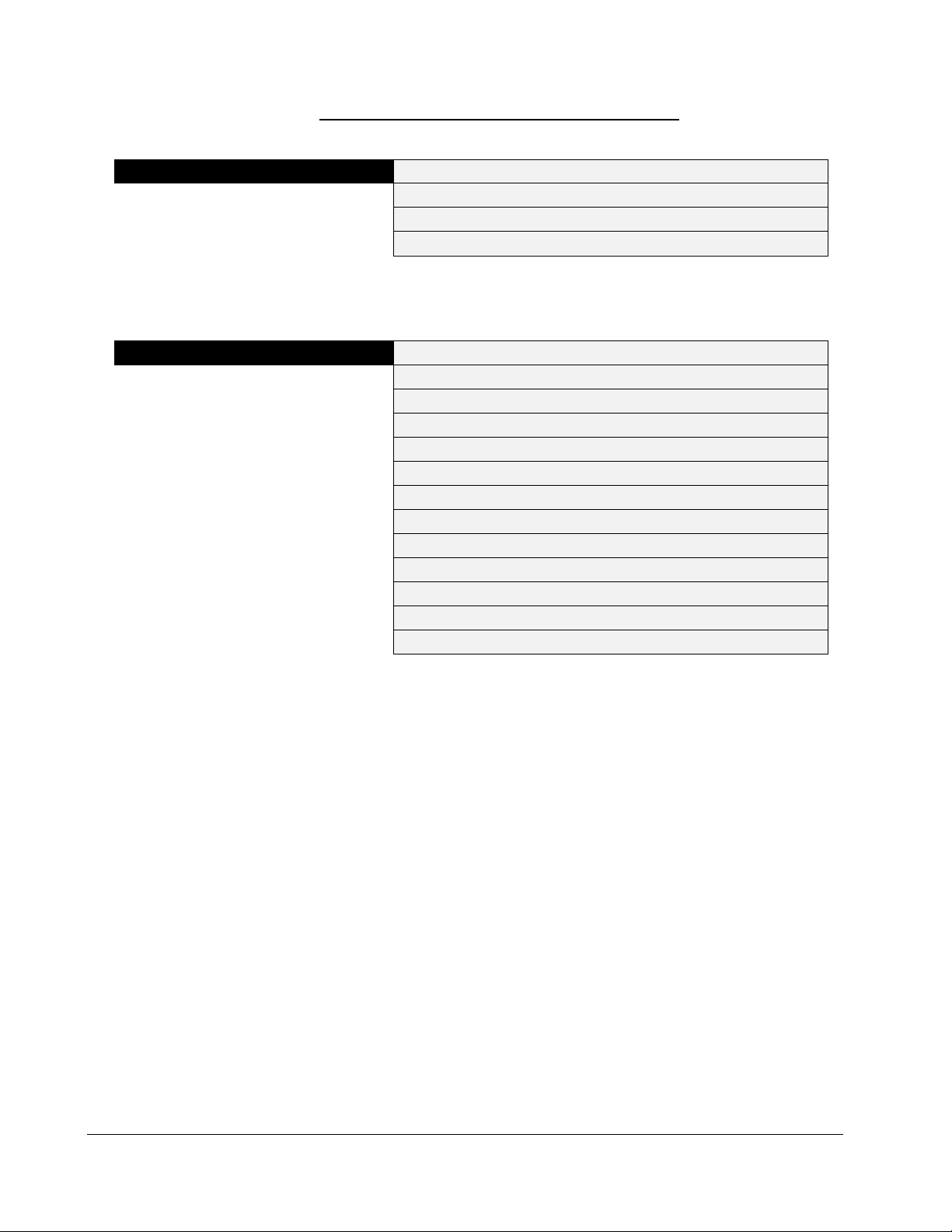

For linear throttle operation, the highlighted menu settings are required.

Auto Operation Settings Menu

Start/Stop Input (Floats, Transducer)

Fail Safe Float (On, Off)

Fail Safe Speed (Default = 2400 rpm)

Fail Safe Off Delay (Default = 0:00 seconds)

Auto Start Configuration Menu

Auto Start Delay (Default = 10 seconds)

Pre Heat Time (Default = 0 seconds)

Crank Time (Default = 10 seconds)

Crank Rest Time (Default = 10 seconds)

Warm Up Speed (Default = 800 rpm)

Warm Up Time (Default = 10 seconds)

Prime Speed (Default = 800 rpm)

Prime Time (Default = 0 seconds)

Cool Down Speed (Default = 650 rpm)

Cool Down Time (Default = 10 seconds)

Crank Cycles (Default = 5)

Fault Bypass Period (Default = 10 seconds)

Crank Hold Delay (Default = 0)

If any auto start configuration settings are not required (such as warm up speed), set the time to 0:00

seconds for that parameter.

- 10 -

LEVEL/PRESSURE MAINTAIN THROTTLE

With level or pressure maintain throttle, engine speed adjusts to maintain the selected level or

pressure.

Example: Pressure Transducer (0 to 50 psi range)

Target Pressure = 30 psi

Minimum Speed = 1000 rpm

Maximum Speed = 2000 rpm

Operation

If pressure = 20 psi, engine speed increases up to 2000 rpm until 30 psi is reached

If pressure = 40 psi, engine speed decreases down to 1000 rpm until 30 psi is reached

If pressure = 30 psi, engine speed holds

The throttle response time can be increased or decreased by adjusting the “Gain Trim Setting” in the

Auto Operations Settings menu.

Level or pressure maintain throttle can be combined with any of the automatic engine start/stop

modes. If any automatic speeds settings are not required (such as warm up), set the time delay to

0:00 seconds for that parameter.

For level/pressure maintain operation, the highlighted menu settings are required.

Auto Operation Settings Menu

Start/Stop Input (Floats, Transducer)

Fail Safe Float (On, Off)

Fail Safe Speed (Default = 2400 rpm)

Fail Safe Off Delay (Default = 0:00 seconds)

- 11 -

Auto Start Configuration Menu

Auto Start Delay (Default = 10 seconds)

Pre Heat Time (Default = 0 seconds)

Crank Time (Default = 10 seconds)

Crank Rest Time (Default = 10 seconds)

Warm Up Speed (Default = 800 rpm)

Warm Up Time (Default = 10 seconds)

Prime Speed (Default = 800 rpm)

Prime Time (Default = 0 seconds)

Cool Down Speed (Default = 650 rpm)

Cool Down Time (Default = 10 seconds)

Crank Cycles (Default = 5)

Fault Bypass Period (Default = 10 seconds)

Crank Hold Delay (Default = 0)

If any auto start configuration settings are not required (such as warm up speed), set the time to 0:00

seconds for that parameter.

- 12 -

PANEL OPERATION

MANUAL OPERATION

1) Engine Start - Turn key to CRANK position

2) Engine Stop - Turn key to OFF position

3) Engine Throttle - Push up and down buttons

Throttle operation based on manual throttle settings.

Note: If your engine is equipped with a Diesel Exhaust Fluid (DEF) tank and the engine’s ECU is

broadcasting the level, the control module will display the % DEF Fluid by alternating the value with in

the Engine Hours location (Lower Right) on the display.

Engine Running

Six Up Display

(Typical)

Engine Running

Six Up Display with DEF

Level when present

- 13 -

AUTO START/STOP OPERATION

1) Engine Start - Turn key to AUTO position

Engine start/stop based on auto start/stop settings. Panel display shows “Auto Start ARMED”

message.

2) Engine Throttle

Throttle operation based on auto throttle settings.

- 14 -

SLEEP MODE

To minimize current draw, the panel goes into a sleep mode two minutes after being set in auto

mode. In sleep mode, the display goes blank and the red lamp blinks once every ten seconds. The

engine ECU is also turned off.

Upon receiving a signal from a float or transducer, the panel wakes up, the display turns back on and

normal operation commences.

Pushing any of the four buttons wakes up the panel and turns the display on. It will return to sleep

mode after a two-minute period.

For service purposes, to keep engine ECU powered, access the menu system. The engine ECU remains

on when the menu system is active.

Red LED blinks

once every 10

seconds

- 15 -

MODULE CONNECTORS

Primary Connector

14 Pin

Secondary Connector

23 Pin

- 16 -

PRIMARY CONNECTOR (14 Pin)

Pin

Function

Pin

Function

1

Fuel Solenoid/ECU Signal

8

J1939 Low

2

Start & Alarm Signal

9

Battery Positive

3

Alarm

10

Key Auto Detect

4

Battery Positive

11

Battery Positive

5

Crank Signal

12

Battery Negative

6

Battery Positive

13

Fuel Level Sender Input

7

J1939 High

14

High Float Input

SECONDARY CONNECTOR (23 Pin)

Pin

Function

Pin

Function

Pin

Function

1

Output Relay #5 N/O

9

Relays # 5 & 6 Common

16

Output Relay #6 N/O

2

10

17

DI #2 Low Float

3

APP Transducer Input

11

Inlet Pressure Input

18

Digital Input #3

4

Outlet Pressure Input

12

Flow Rate Input

19

Digital Input #4

5

13

MODBUS

20

Digital Input #5

6

Digital Input #8

14

MODBUS

21

Digital Input #6

7

Digital Input #9

15

Relays # 7 & 8 Common

22

Digital Input #7

8

Output Relay #7 N/O

23

Output Relay #8 N/O

CAUTION:

Maximum current draw for signal circuits is 5 amps

CAUTION:

Maximum current draw relay output circuits is 5 amps

- 17 -

PANEL CONNECTORS

1. Engine Harness Connector –Deutsch 21 pin (HDP24-24-21PE)

2. Accessory Connector –Deutsch 31 pin (HDP-24-24-31PE)

31 Pin Accessory Connector

Pin

Function

1

High Water Alarm

7

Common Alarm

8

Over Crank Output (Fail to Start)

9

Common for Pins 1 & 16 (RY 5 & 6)

12

Flow Rate Input

13

Modbus A

14

Modbus B

15

Common for Pins 8 & 23 (RY 7 & 8)

16

Unit in Auto Output

17

Start Alarm Output

18

High Water Alarm Input

19

Auto Start Inhibit Input

20

Fuel Leak Input

21

Low Fuel Input

22

Digital Input #7

23

Engine Run Output

25

Fuel Level Sender Input

30

Battery Positive (Switched B+)

31

Battery Negative

21 Pin Engine Harness Connector

Pin

Function

B

Battery Positive

E

Battery Negative

G

Key On Power

D

Crank Signal

V

J1939 High

U

J1939 Low

J

Alternator Excite

L

Analog Throttle Emulator

M

Analog Throttle Emulator

C

Analog Throttle Emulator

R

Digital Throttle Emulator

S

Digital Throttle Emulator

Accessory

Connector (31 Pin)

Engine Harness

Connector (21 Pin)

CAUTION:

Maximum current draw for relay

output circuits is 5 amps

- 18 -

Sensor Inputs

4-Pin Float Connector

Pin

Function

1

High Float Input

2

Low Float Input

3

High Float Common

4

Low Float Common

4-Pin Level Transducer

Pin

Function

1

4-20 mA Signal

2

Battery Positive

3

Battery Negative

4

N/A

4-Pin Pressure Transducer

Pin

Function

1

4-20 mA Signal

2

Battery Positive

3

Battery Negative

4

N/A

4-Pin Suction Transducer

Pin

Function

1

4-20 mA Signal

2

Battery Positive

3

Battery Negative

4

N/A

- 19 -

PUMP MONITORING AND SAFETY

The following menus must be configured prior to the utilization of suction and discharge pressures for

pump monitoring:

Pump Safety Configuration

Inlet Pressure Check (Off, Always, Run)

Low Inlet Pressure Pre Alarm

Low Inlet Pressure Alarm

High Inlet Pressure Pre Alarm

High Inlet Pressure Alarm

Inlet Pressure Delay

Inlet Pressure Hysteresis

Outlet Pressure Check (Off, Always, Run)

Low Outlet Pressure Pre Alarm

Low Outlet Pressure Alarm

High Outlet Pressure Pre Alarm

High Outlet Pressure Alarm

Outlet Pressure Delay

Outlet Pressure Hysteresis

For Display of Inlet and outlet pressures, enter the Module Configuration Menu and turn on

Suction/Discharge

Other manuals for J1939

1

This manual suits for next models

1

Table of contents