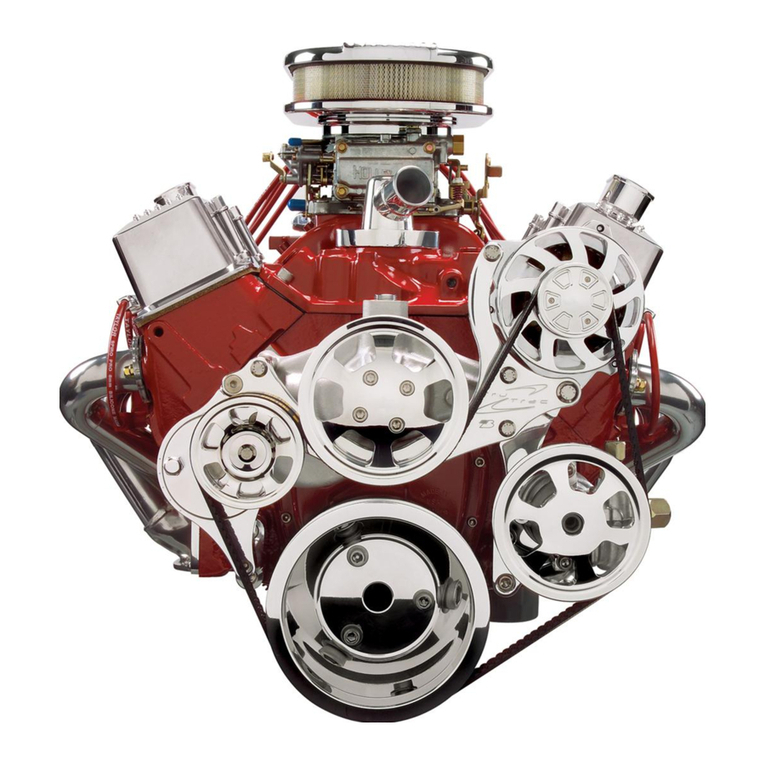

Billet Specialties Tru Trac # 13805 User manual

Small Block Chrysler

Installation Manual

For Systems without A/C

#13805 / #13825

Billet Specialties, Inc.

500 Shawmut Avenue.

La Grange, Illinois 60526

Tech Line (708) 588-0505

Fax (708) 588-7181

Required Tools & Materials

Anti-seize Compound

RTV Silicone

Permatex Hylomar® (Gasket Dressing)

Gasket Scraper

Scotch-Brite®Pad

3/8-16 Thread Chaser* & Holder

*Thread chasers are available at your local

parts store and are different from a thread

cutting tap.

PLEASE READ ALL INSTRUCTIONS BEFORE INSTALLING ANY

COMPONENTS OF THE TRU TRAC SERPENTINE SYSTEM

5/32” Allen

7/32" Allen

1/4" Allen

5/16" Allen

5/8” Box End Wrench

11/16” Box End Wrench

3/4” Box End Wrench

Socket Wrench & Extension

3/8" 12-point socket

10mm 12-point socket

12mm 12-point Socket

Tech Line: 708.588.0505

Fax: 708.588.7181

www.billetspecialties.com

TECH TIP:

Billet Specialties recommends the use of Anti-Seize on all

fasteners to prevent thread lock-up.

5/16-18 x 2-3/4" Socket Head Cap Screw

Power Steering Pump To Bracket

x2

3/8-16 x 3/4" Socket Head Cap Screw

Power Steering Bracket To Alternator Bracket

x2

5/16" Lock Washer

x2

Skin Board #1 - Packaged With Power Steering Pump

Skin Board #2 - Packaged With Water Pump

7/8" Spacer Nut x4

1-11/32" Spacer Nut x2

2-3/8" Spacer Nut x1

3/8-16 Zinc Coated

Hex Nuts

(Discard After Use)

x2

3/8-16 x 2-1/2" Block Mounting Stud x2

3/8-16 x 5-1/2" Block Mounting Stud x4

Prepping The Block

Disconnect battery and remove all existing accessory drive brackets &

components from motor.

Remove water pump and mechanical fuel pump, scrape away any

existing gasket material with a gasket scraper and dress surface with a

Scotch Brite® pad.

Remove the timing bolt on the passenger side of the motor just below the

fuel pump.

Note: If you wish to replace the timing cover gaskets and seals now is the time to do so.

Fel-Pro makes a timing cover gasket set P/N TCS 6563-1 that covers all of them.

THIS KIT IS NOT DESIGNED FOR USE WITH A

MECHANICAL FUEL PUMP

3/8-16 x 1-1/4" Block Mounting Stud x1

3-1/2" Spacer Nut x1

3/8-16 x 3/4" 12-Point Cap Screw

Tensioner Pulley

x1

8mm-1.25 x 25mm 12-Point Cap Screw

Bridge Bracket

x1

3/8-16 x 1-1/2" 12-Point Cap Screw

Water Pump To Block

x1

3/8-16 x 1-3/4" 12-Point Cap Screw

Idler Pulleys

x3

10mm-1.25 x 70mm 12-Point Cap Screw

Alternator - Lower Bolt

x1

3/8-16 x 2-3/4" Button Head Cap Screw

Timing Cover To Block

x1

3/8-16 x 1" Flat Head Cap Screw

Thru Bridge Bracket Into Spacer Nuts

x6

5/16-18 x 3/4" Flat Head Cap Screw

Thru Bridge Bracket Into Tensioner

x3

3/8-16 x 1-1/4" Socket Head Cap Screw

Tensioner Bracket Assembly

x2

3/8-16 x 1" Socket Head Cap Screw

Thru back Of Tensioner Bracket To

Tensioner Spacer Nut

x1

5/16-18 x 1" Socket Set Screw

Tensioner Assembly

x1

5/16-18 x 3/4" Socket Head Cap Screw

Water Pump Pulley

x4

5/16-18 x 1" Socket Head Cap Screw

Crank Pulley

x6

5/16" Belleville Washer

x6

Skin Board #3 - Packaged In Main Box

Serpentine Belt

Goodyear Poly-V 6-Rib Serpentine Belt - 66" #4060660 (with power steering)

Goodyear Poly-V 6-Rib Serpentine Belt - 63.5" #4060635 (without power steering)

3/8-16 x 3/4" Button Head Cap Screw

Fuel Pump Block-Off

x2

Packaged With Fuel Pump Block-Off

www.billetspecialties.com

www.billetspecialties.com

7

Figure 1: Install Fuel Pump Block-Off

A] Sparingly apply RTV silicone to the timing cover surface and gasket.

Attach the fuel pump block off with the two 3/8-16 x 3/4” button head

cap screws and tighten rmly.

B] Thread the 3/8-16 x 2-3/4” button head cap screw into the timing cover

by the fuel pump block off and tighten rmly.

Figure 2: Install Block Mounting Studs

Apply RTV silicone to one end of the four 3/8-16 x 5-1/2” threaded studs

and the two 3/8-16 x 2-1/2” threaded studs.

A] Thread the silicone side of the 5-1/2” studs into the upper four holes in

the timing cover.

Important! Leave 2-7/16” of thread exposed from the timing cover face.

B] Thread the silicone side of the two 2-1/2” studs into the bottom two

holes of the timing cover.

Important! Leave 2” of thread exposed.

Double-check your lengths.

The studs can easily be tightened by threading two 3/16” zinc coated

nuts (supplied) onto the stud and tighten them against each other to act

as a drive nut (discard after use).

*Example

A

B

2-7/16" From Timing Cover 2" From Timing Cover

A B

www.billetspecialties.com

www.billetspecialties.com

9

Figure 3: Install Water Pump

Coat both sides of water pump gasket with Permatex Hylomar gasket

dressing. Install gasket over studs.

A] Slide the water pump over the studs and into position. Apply anti-seize

to the threads of the 3/8-16 x 1-1/2” 12-point ARP cap screw and thread

into top water pump hole, nger tighten.

Apply anti-seize to the exposed threads on the remaining studs.

B] Finish by threading the two 1-11/32” spacer nuts to the bottom two

studs and nger tighten.

Figure 4: Install Tensioner Bracket

Apply anti-seize to the two 3/8-16 x 1-1/4” socket head cap screws.

A&B] Assemble front and rear tensioner bracket halves together with the

two 3/8” cap screws and tighten rmly.

C] Place completed bracket on passenger-side of water pump and se-

cure with two 7/8” spacer nuts and nger tighten.

D] Apply Loc-Tite to one end of the 3/8-16 x 1-1/4” threaded stud and

thread it into the 3-1/2” long spacer nut until it bottoms out.

E] Apply anti-seize to the remaining exposed threads and install the

3-1/2” spacer nut into the tensioner bracket using the top open hole.

Tighten rmly.

A

B

A

B

D

C

E

www.billetspecialties.com

www.billetspecialties.com

11

FOR KITS WITHOUT POWER STEERING – SKIP TO STEP B

Figure 5: Install Alternator & Power Steering Bracket

A] Apply anti-seize to the two 3/8-16 x 3/4” socket head cap screws.

Assemble power steering bracket to the back of the alternator bracket

and tighten rmly.

B] Place alternator bracket on driver side water pump and secure with

two 7/8” spacer nuts.

Tighten all water pump spacer nuts at this time rmly in a cross pattern,

make sure bracket fasteners are also tightened rmly.

Now is a good time to install the

barbed ttings in the water pump.

Figure 6: Install Bridge Bracket

Apply anti-seize to the six 3/8-16 x 1" at head cap screws.

Place bridge bracket to motor and align mount holes with the six water

pump spacer nuts.

Thread the 3/8” at head screws through the bridge bracket and into the

water pump spacer nuts, nger tighten only.

A B

1

2

3

45

6

www.billetspecialties.com

www.billetspecialties.com

13

Figure 7: Install Tensioner

A] Apply Loc-Tite to one end of the 5/16-18 x 1” socket set screw and

thread into the back of the tensioner body, nger tighten.

B] Apply anti-seize to the remaining exposed threads of the setscrew.

Thread the 2-3/8” long spacer nut onto the stud and tighten rmly.

ABC

D

E

Figure 8: Install Tensioner Continued

Apply anti-seize to the threads of the three 5/16-18 x 3/4” at head cap

screws and the 3/8-16 x 1” socket head cap screw.

C&D] Place tensioner assembly between the tensioner bracket and the

bridge bracket. Thread two 5/16” athead cap screws through the bridge

bracket and into the tensioner body, nger tighten. Thread the third

5/16-18 x 3/4” at head cap screw through the bridge bracket and into

the 3-1/2” spacer nut, nger tighten.

E] Thread the 3/8” socket head cap screw through the back of the

tensioner bracket and into the tensioner spacer nut, tighten rmly.

www.billetspecialties.com

www.billetspecialties.com

15

FOR KITS WITHOUT POWER STEERING – CONTINUE TO FIGURE 11

Figure 10: Install Power Steering Pump With Pulley

Apply anti-seize to the threads of the two 5/16-18 x 2-3/4” socket head

cap screws.

Place power steering pump with pulley on bracket and align.

Thread the two 5/16-18 x 2-3/4” cap screws with 5/16” lock washers

through the power steering pump mount bosses and into the power

steering bracket, tighten rmly 26ft/lbs.

Figure 9: Install Alternator

Apply anti-seize to the 8mm-1.25 x 25mm ARP 12-point cap screw and the

10mm-1.25 x 70mm ARP 12-point cap screw.

A] Place alternator between bridge bracket and alternator bracket, align

alternator bosses with the bridge bracket. Thread the 10mm ARP 12-point

cap screw through the bottom bridge bracket hole and alternator into

the alternator bracket, nger tighten.

B] Thread the 8mm ARP 12-point cap screw through the bridge bracket

and into the top alternator boss.

Tighten all fasteners rmly at this time: All ARP 12-point fasteners and at

head bridge bracket screws.

A

B

www.billetspecialties.com

www.billetspecialties.com

17

Figure 11: Install Crankshaft Pulley

Apply Loc-Tite to the threads of the six 5/16-18 x 1” socket head

cap screws.

A] Place crankshaft pulley on damper and align holes.

B&C] Thread the 5/16” cap screws with a Belleville washer

(cup side towards pulley) through the pulley and into the crankshaft,

tighten rmly 26ft/lbs.

Figure 12: Install Water Pump Pulley

Apply Loc-Tite to the threads of the four 5/16-18 x 3/4” socket head cap

screws.

Place water pump pulley on water pump and align holes.

Thread the 5/16” cap screws through the pulley and into the water pump

ange, tighten rmly 26 ft/lbs.

A B

C

www.billetspecialties.com

www.billetspecialties.com

19

Figure 13: Install Idler Pulleys

Apply Loc-Tite to the threads of the three 3/8-16 x 1-3/4” ARP 12-point cap

screws.

A] AC Delete Idler Pulley: Thread a 3/8” ARP 12-point cap screw with

aluminum washer through the large idler pulley and pulley boss into the

bridge bracket and tighten rmly 46ft/lb.

B&C] Small Idler Pulleys: Thread the second 3/8” ARP 12-point cap screw

through the small idler pulley-cover, pulley and pulley boss into the bridge

bracket and tighten rmly, 46ft/lb. Repeat for other side.

A B

C

Figure 15: Install Belt &

Tensioner Pulley

A] Apply anti-seize to one

3/8-16 x 3/4” ARP 12-point cap

screw.

Route serpentine belt as shown

below - minus tensioner pulley.

Place a 5/8” box end wrench

on tensioner.

B] Align belt onto pulley and pull up

on wrench to release tension until

tensioner pulley slips onto

tensioner shaft.

Slowly return wrench to starting

position to apply tension to belt.

C] Remove wrench and install the

3/8-16 x 3/4” ARP 12-point cap

screw with thrust washer onto pulley

and tighten rmly (46 ft/lbs).

A

B

C

With Power Steering Without Power Stering

Billet Specialties, Inc.

500 Shawmut Avenue

La Grange, Illinois 60526

Tech Line 708.588.0505

Fax 708.588.7181

www.billetspecialties.com

#13805/ #13825

This manual suits for next models

1

Other Billet Specialties Engine manuals

Popular Engine manuals by other brands

MINN KOTA

MINN KOTA RIPTIDE POWERDRIVE owner's manual

SEW-Eurodrive

SEW-Eurodrive CMP40 Revision

Lowrance

Lowrance Ghost Series installation manual

DLE

DLE DLE55RA user manual

Briggs & Stratton

Briggs & Stratton 133200 Series Operating & maintenance instructions

Perkins

Perkins 1206F-E70TTA Operation and Maintenance Instructional Manual