Thomson Power Systems Marathon MEC 20 Service manual

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110

Telefax (604) 888-3381 E-Mail: info@thomsontechnology.com www.thomsontechnology.com

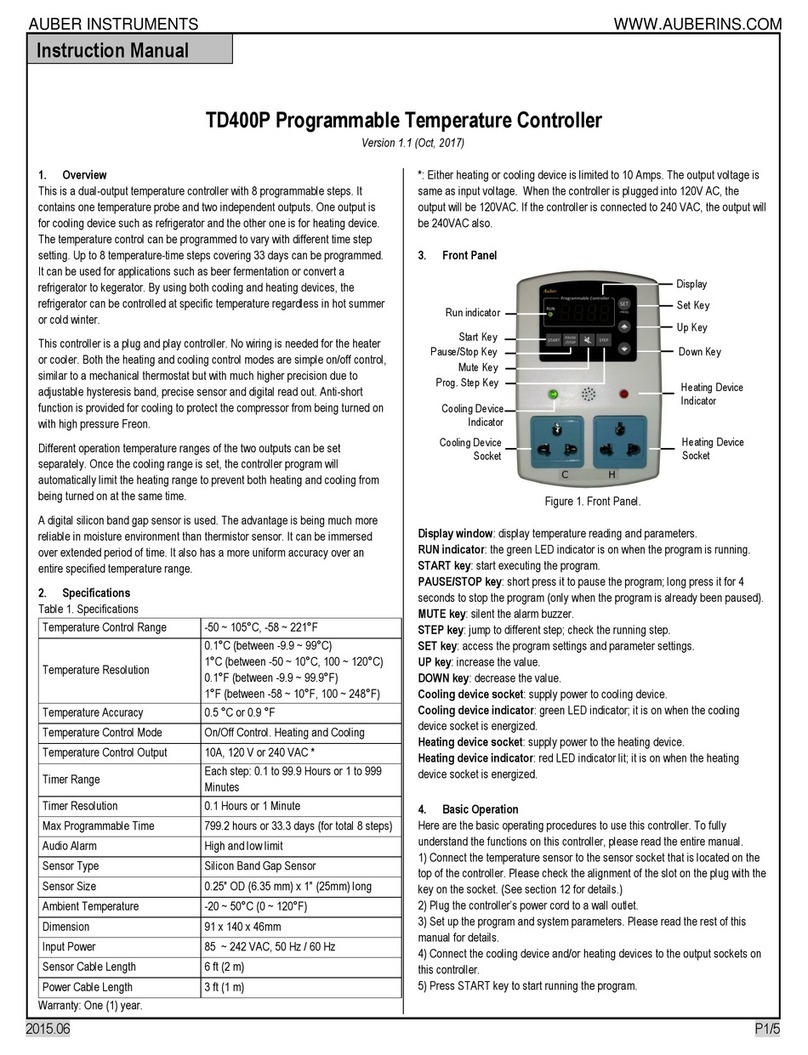

MEC 20

MICROPROCESSOR

ENGINE/GENERATOR CONTROLLER

(WITH REMOTE COMMUNICATION, EXPANSION OUTPUT MODULE &

EAP 110 REMOTE ANNUNCIATOR OPTIONS)

INSTALLATION, OPERATING &

SERVICE MANUAL

Software Version 1.81

PM047 Rev 12 03/03/04

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 Thomson Power Systems

CONTENTS

1. INTRODUCTION 1

1.1. PRODUCT REVISION HISTORY 1

1.2. GENERAL DESCRIPTION 3

2. INSTALLATION 5

2.1. GENERAL INFORMATION 5

2.2. BATTERY SUPPLY INPUT 5

2.3. SPEED SENSING INPUT 6

2.4. DC VOLTAGE INPUTS 7

2.5. AC VOLTAGE INPUT 7

2.6. AC CURRENT INPUT 8

2.7. OUTPUTS 9

2.8. EXTERNAL PANEL CONTROL WIRING 9

2.9. REMOTE START CONTACT FIELD WIRING 10

2.10. REMOTE COMMUNICATION WIRING 10

2.11. EXPANSION OUTPUT MODULE LOCATION/INSTALLATION 11

2.12. MEC MOUNTING LOCATION/INSTALLATION 12

2.13. FACEPLATE MOUNTING DIMENSIONS 13

2.14. MEC 20 ASSEMBLY - SIDE VIEW 13

2.15. DIELECTRIC TESTING 14

3. DESCRIPTION 15

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 Thomson Power Systems

3.1. LEXAN FACEPLATE 15

3.2. PRINTED CIRCUIT BOARD 17

4. FAULT CIRCUIT DESCRIPTIONS 19

4.1. MEC 20 FUNCTIONAL BLOCK DIAGRAM 20

4.2. INTERNAL FAULT CIRCUITS 21

4.3. DIGITAL FAULT INPUT CIRCUITS 22

4.4. ANALOG FAULT INPUT CIRCUITS 24

5. CONTROL OUTPUT CONTACT DESCRIPTIONS 29

5.1. RUN, CRANK, COMMON FAIL OUTPUT CONTACTS 29

5.2. PROGRAMMABLE OUTPUT CONTACTS 30

6. REMOTE COMMUNICATION OPTION 34

7. EXPANSION OUTPUT MODULE OPTION 38

8. EAP 110 REMOTE ANNUNCIATOR OPTION 41

9. OPERATING INSTRUCTIONS 42

9.1. MEC 20 POWER-UP OPERATION SEQUENCE 42

9.2. MEC 20 DISPLAY MENUS 42

9.3. SEQUENCE OF OPERATION 50

9.4. CONTROL PUSH-BUTTONS 57

10. PROGRAMMING INSTRUCTIONS 59

10.1. SECURITY PASSWORDS 59

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 Thomson Power Systems

10.2. BASIC PROGRAMMING OPERATION 60

10.3. MAIN PROGRAMMING MENU 61

10.4. ANALOG FAULT PROGRAMMING MENU 69

10.5. DIGITAL FAULT PROGRAMMING MENU 70

10.6. CALIBRATION MENU 72

11. PROGRAMMING SHEETS 83

11.1. SUMMARY CONFIGURATION DATA SHEET 83

11.2. MAIN CONFIGURATION 84

11.3. ANALOG FAULT PROGRAMMING MENU 87

11.4. DIGITAL FAULT PROGRAMMING MENU 88

11.5. CALIBRATION MENU 89

12. SPECIFICATIONS 90

13. CONNECTION DIAGRAM 91

14. TROUBLE SHOOTING 92

15. NOTES 95

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 1Thomson Power Systems

1. INTRODUCTION

1.1. PRODUCT REVISION HISTORY

The following information provides an historical summary of changes made to this

product since the original release.

1.1.1. Software Version

1.81 03/03/04 Changed Oil Pressure Sender Manufacturer requiring revised

pressure/resistance calibration data

New Oil Pressure Sender Thomson p/n-003654, Manufacturer-

Datcon, p/n 102227.

Discontinued Oil Pressure Sender Thomson p/n-000772,

Manufacturer- Isspro, p/n R9279C

Note: The oil pressure senders are not interchangeable with the

software versions.

1.8 02/09/09 Added Programmable Output Feature “EPS Supplying Load”

Added Digital Input Feature “No-Load Test”

Added New Digital Fault Names

Basin Rupture

ATS in Bypass

Fuel Leak

Vent Damper Fail

High Fuel Level

Low Fuel Press

Bat Charger Fail

Fail to Sync

HighIntkManfTemp

Added Independent Programming features for AMF Outputs

Added references for EAP 110 Remote Annunciator

Misc. Display & Menu changes

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 2Thomson Power Systems

1.7 02/02/15 Key changes implemented as follows:

•Auto Mains Failure (AMF) logic with new timers, control outputs

and display features

•Line to Neutral AC Voltage Display on 3 Phase 4 Wire Systems

(neutral connection required)

•

Analog Shutdown Capability from Oil Pressure and

Temperature Senders

•Expanded oil pressure operation up to 150 PSI (was 100 PSI)

•Single Point Calibration for Oil Pressure/engine temperature

sender inputs (simplified calibration, field calibration is now

mandatory)

•Programmable Output features now expanded to map to every

available fault circuit

Add new Programmable Output features Engine Ready & Engine

Run (Fuel)

There were also minor changes that are reflected in the manual.

1.6 01/07/18

Added Ready to load programmable output and new Isspro Oil

Pressure sender curves; increased standard digital & analog fault

features.

1.5 00/09/20 Added kVA metering.

1.4 99/12/09 Added new digital faults labels and blank selections.

1.3 98/02/09 New version with communication features, expansion relay module

capability, deletion of “horn” programming, deletion of cooldown

shutdown programmability, deletion of “common fail”

programmability and revised password number.

1.2 97/06/04 Original version.

1.1.2. Operating & Service Manual Version

Rev 12 03/03/04 Changed Oil pressure/resistance calibration data and new software

version 1.81.

Rev 11 02/09/09 Added descriptive information for new software version 1.8

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 3Thomson Power Systems

Rev 10 02/02/15 Added descriptive information for new software version 1.7

Rev 9 01/10/17 Clarification of faults required for C282 or NFPA 110.

Rev 8 01/07/18 Addition of “Static Precaution”; deletion of calibration jumpers to

requiring external calibration resistors/potentiometers; standard

fault circuits increase from 12 to 28; Ready status changes to

“Ready to Load”; changes in temperature and pressure calibrations;

extended temperature ratings.

Rev 7 00/12/01 Minor text changes.

Rev 6 00/10/06 Added KVA metering feature.

Rev 5 00/04/06 Changes made to digital fault labels.

Rev 4 99/02/01 Remote communication wiring changes

; multiple controllers that

can be connected changes from 5 to 10.

Rev 3 98/05/08 Corrected minor errors.

Rev 2 98/02/18 New version with communication features; expansion relay module

capability and revised password number.

Rev 1 98/01/22 Corrected minor errors.

Rev 0 97/06/04 Original release.

Contact Thomson Technology, to obtain applicable instruction manuals. Soft copy of

most current version is available at www.thomsontechnology.com.

1.2. GENERAL DESCRIPTION

The Thomson Technology MEC 20 Microprocessor-based Engine/Generator Controller

utilizes the latest advancements in microprocessor design technology for the control and

monitoring of engine-generator sets. The MEC 20 provides a comprehensive array of

operational, protection and display features for automatically controlling an

engine/generator set. All standard and optional features of the MEC 20 are configurable

from the front panel LCD display and are security password protected. The LCD display

screen prompts are in plain English, providing a user-friendly operator interface with

many display options available. The microprocessor design provides high accuracy for

all voltage monitoring, current monitoring and timing functions as well as providing many

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 4Thomson Power Systems

standard features which were previously only available as expensive add-on optional

features.

The MEC 20 provides the following advanced features:

•Up to 28 alarm/shutdown fault circuits utilizing analog and digital inputs.

•Standard model meets or exceeds CSA C282, NFPA 110 Level 1 generator set

control requirements.

•RS 422 remote communication port.

•Expansion output module communication port for individual output fault contact

capability.

•Backlit LCD display screen with alpha-numeric readout for display and programming.

•Digital 3-phase voltage, 3-phase current, KVA and frequency metering for generator

output.

•Non-volatile memory retains logic and set points if control power is lost.

•Direct 3-phase voltage sensing inputs on generator supply from 120Vac up to

600Vac (nominal).

•Security password-protected programming levels.

•Self diagnostic features continuously verify processing, I/O and memory circuits.

•Superior EMI/RFI noise immunity and surge performance features as per IEEE

C62.41 requirements.

•Dual microprocessor design provides independent speed sensing circuitry for higher

performance.

CAUTION

contents subject to damage by

STATIC ELECTRICITY

This equipment contains static-sensitive parts. Please observe the following anti-static

precautions at all times when handling this equipment. Failure to observe these

precautions may cause equipment failure and/or damage.

•Discharge body static charge before handling the equipment (contact a

grounded surface and maintain contact while handling the equipment, a

grounded wrist strap can/should also be utilized).

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 5Thomson Power Systems

•Do not touch any components on the printed circuit board with your

hands or any other conductive equipment.

•Do not place the equipment on or near materials such as Styrofoam,

plastic and vinyl. Place the equipment on grounded surfaces and only

use an anti-static bag for transporting the equipment.

2. INSTALLATION

2.1. GENERAL INFORMATION

NOTE:

Installations should be done according to all

applicable electrical regulation codes as

required.

The following installation guidelines are provided for general information only

pertaining to typical site installations. For specific site installation information,

consult Thomson Technology as required. Note: Factory installations of TTI

supplied control panels that have been tested and proven may deviate from

these recommendations.

CAUTION!!!

All installation and/or service work performed must be done by qualified

personnel only. Failure to do so may cause personal injury or death.

2.2. BATTERY SUPPLY INPUT

The MEC 20 can operate on any battery supply from 10 to 30 volts DC. The

battery DC negative or common conductor must be grounded to the main

generator-set frame ground. The MEC 20 is internally protected by a solid state

type fuse that protects it from inadvertent shorts on the output terminals. The

solid state fuse will automatically reset when the overcurrent condition is

removed. Wiring from the engine cranking battery to the control panel should

conform to the following guidelines to avoid possible controller malfunction

and/or damage.

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 6Thomson Power Systems

2.2.1. Avoid wiring from the engine starter terminals - wiring should go directly

from the battery terminals to the engine control panel (to avoid voltage

drop in the starter cables and starter motor commutator noise). Note:

Unit mounted control panels with short wiring runs may utilize

connections from the starter terminals provided that the specific

application is tested satisfactorily.

CAUTION!!!

The battery charger must be turned off before battery cables are

removed from the battery (i.e. for servicing). Failure to do so may

subject the control panel to an overvoltage condition in which

damage may result.

2.2.2. Wiring from battery to engine control panel should be two - #14 AWG

(2.5mm2) wires (i.e. do not use the engine block as one of the common

conductors).

2.2.3. Under noisy environments (i.e. gas engines with high voltage ignitions,

etc.), wiring from battery should be a twisted pair of #14 AWG (2.5mm2)

wires.

2.3. SPEED SENSING INPUT

Field wiring of the speed sensing signal wires should conform to the following

guidelines to avoid possible controller malfunction and/or damage:

2.3.1. Wiring from magnetic pickup must utilize a 2 conductor shielded/twisted

cable. The drain (shield) wire must be connected at the control panel end

only.

2.3.2. Magnetic pickup voltage at cranking speed must be greater than 3.0VAC.

At nominal speed, magnetic pickup voltage should be between 3.0 and

5VAC.

2.3.3. A single dedicated magnetic pickup is recommended for connection to

the speed sensing input terminals. Note: One common magnetic pickup

may be utilized for the system provided specific test measurements are

done with the equipment installed (i.e. mag pickup voltage levels meet

the required levels).

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 7Thomson Power Systems

2.4. DC VOLTAGE INPUTS

All DC voltage inputs to the MEC 20 are optically isolated and filtered for

protection from noise spikes and transients Input wiring must be routed so that it

is not near electrically "noisy" wiring such as ignition, starter wires or main AC

power conductors. All contacts must be “dry” (i.e. non-powered) and one side

must be connected to the common DC negative conductor.

2.5. AC VOLTAGE INPUT

The MEC 20 can accept direct AC voltage input from 120-600Vac (nominal).

Note: Direct input voltage sensing can only be used when the generator utilizes

a single phase 3 wire or 3 phase, 4 wire distribution system with a solidly

grounded neutral conductor. For 3 phase 3 wire systems (i.e. no neutral) or high

voltage systems, potential transformers must be used. Refer to FIGURES #1 - 4

for voltage sensing connections. To display generator line to neutral voltage in a

3 phase 4 wire system, the neutral must be connected as shown.

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 8Thomson Power Systems

GRD

MEC 20

FIGURE #1

3Ø, 4W 208/380/480/600VAC DIRECT SENSING

SOLIDLY GROUNDED NEUTRAL SYSTEM

VOLTAGE INPUTS

600VAC L-L, 347VAC L-N

380VAC L-L, 220VAC L-N

480VAC L-L, 277VAC L-N

208VAC L-L, 120VAC L-N

VA

VB

VC

VN

GRD

BA C N

GEN.

GRD

ABC

N

GRD

MEC 20

FIGURE #2

1Ø, 3W 120/240VAC DIRECT SENSING

SOLIDLY GROUNDED NEUTRAL SYSTEM

VOLTAGE INPUTS

240VAC L-L, 120VAC L-N

Note: L1 and L2 phase

voltages must be 120Vac

when referenced to common

neutral. (Delta connected

generators required PTs as per

figure#3 & no phase C PT)

VA

VB

VC

VN

GRD

L2L1 N

GEN.

GRD

L1 L2

N

No Connection

GRD

MEC 20

FIGURE #3

3Ø, 4W WYE PT's

SECONDARY PT VOLTAGE

208VAC L-L, 120VAC L-N

120VAC L-L, 69VAC L-N

VA

VB

VC

VN

GRD

BA C N

GEN.

N

120

120

120

GRD

ABC

GRD

MEC 20

FIGURE #4

3Ø, 3W DELTA PT's

SECONDARY PT VOLTAGE

120VAC L-L

(NO NEUTRAL)

VA

VB

VC

VN

GRD

120

120

GRD

BA C

GEN.

ABC

N

No Connection

G:\ENGINEER\PRODUCTS\MEC20\MEC20_08.VSD REV. 2 02/02/22

2.6. AC CURRENT INPUT

Current transformers (CT’s) must be used to supply the MEC 20 current inputs.

CT polarity is not critical for correct circuit operation. Note: The CT secondary

common conductors must be externally grounded for correct operation. CT’s

must be rated for a minimum of 1.5VA output at the specified accuracy.

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 9Thomson Power Systems

CAUTION!!!

When installing or performing any service work on CT circuits, always de-

energize the system before proceeding with any work. Never open circuit

an energized CT as extreme high voltages may result which may cause

serious injury or death.

2.7. OUTPUTS

All outputs from the MEC 20 are relay driven contacts. Relay contacts have a

10A/240Vac resistive, 8A/24Vdc (3 Amp inductive 0.4pf), rating and are isolated

Form A & Form C types. Interposing relays are recommended between the MEC

20 outputs and end devices to prevent internal damage due to possible

excessive current draw and/or damage should an external fault occur. Note:

These outputs will require external overcurrent protection (Maximum 10 Amp).

The use of AC or DC operated solenoids or relays in control systems can

sometimes cause high voltage spikes on the DC power supply, which may cause

electronic devices to fail. Transient suppression devices are recommended for

all inductive devices sharing wiring or if physically located near engine/generator

control panels. For DC operated relays or solenoids, use a suitably rated

counter EMF Diode (or commonly known as “freewheeling” diode). For AC

operated relays or solenoids, use a suitably rated metal oxide varistor (MOV) or

capacitor/resistor suppressor.

2.8. EXTERNAL PANEL CONTROL WIRING

As a minimum, all control wiring shall conform to the local regulatory authority on

electrical installations. Specific wire sizes for typical circuits⊄(of distances up to

100ft (30m)⊇) are as follows:

2.8.1. Battery Control Power #14 AWG (2.5mm2)

2.8.2. Engine Alarm/Shutdown Contacts #16 AWG (1.5mm2)

2.8.3. Remote Start Contact for Transfer Switch #14 AWG (2.5mm2)

2.8.4. Crank & Preheat Output Wiring #14 AWG (2.5mm2) (To pilot

relays)

2.8.5. Speed Sensing Wiring #16 AWG (1.5mm2) 2

Conductor Shielded Cable

2.8.6. Metering Voltage Inputs #16 AWG (1.5mm2)

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 10 Thomson Power Systems

2.8.7. Metering Current Inputs (from CT’s) #14 AWG (2.5mm2)

⊇For distances exceeding 100 Ft. (30m) consult TTI.

⊄For unit mounted control panels, wire sizes may be reduced to the next

smallest wire size available.

2.9. REMOTE START CONTACT FIELD WIRING

Field wiring of a remote start contact from a transfer switch to a control panel

should conform to the following guidelines to avoid possible controller

malfunction and/or damage.

2.9.1. Remote start contact wires (2 - #14 AWG (2.5mm2) should be run in a

separate conduit.

2.9.2. Avoid wiring near AC power cables to prevent pick-up of induced

voltages.

2.9.3. An interposing relay may be required if field wiring distance is excessively

long (i.e. greater than 100 feet (30m) and/or if a remote contact has a

resistance of greater than 5.0 ohms.

2.9.4. The remote start contact must be voltage free (i.e. dry contact). The use

of a “powered” contact will damage the engine controller.

2.10. REMOTE COMMUNICATION WIRING

All interconnecting wiring to/from the MEC 20 engine/generator controller

communication port shall utilize #22 AWG (min.) 8 conductor, twisted, shielded

cable with RJ45 connectors. The drain (shield) wire must be connected at the

MEC 20 controller end only. Refer to Section 6 for further information.

Communication cable from the controllers’ com port must be suitably routed to

protect it from sources of electrical interference. Guidelines for protection

against possible electrical interference are as follows:

•Use high quality, 8 conductor shielded cable only with drain wire

grounded at the controller end only.

•Route the communication cable at least 3 M (10”) away from sources of

electrical noise such as variable speed motor drives, high voltage power

conductors, UPS systems, transformers, rectifiers etc.

•Use separate, dedicated conduit runs for all communication cables. Do

not tightly bundle communication cables together in the conduit. Conduit

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 11 Thomson Power Systems

should be ferromagnetic type near sources of possible electrical

interference. The entire length of conduit should be grounded to building

earth ground.

•When communication cables must cross over low or high voltage AC

power conductors, the communication cables must cross at right angles

and not in parallel with the conductors.

For additional information on protection against electrical interference, contact

TTI factory.

2.11. EXPANSION OUTPUT MODULE LOCATION/INSTALLATION

The expansion module(s) are to be mounted inside a control panel using four

screws with stand-offs provided. The expansion module must be mounted within

300 metres (1000 feet) wiring distance from the MEC 20 using an 8 conductor

shielded cable provided with the module. The communication cable must not be

bundled together with other control wiring inside the panel. Mounting dimensions

for the expansion output module are shown in FIGURE #5.

7.62 mm

137.16 mm

152.4 mm

152.4 mm

7.62 mm

137.16 mm

4 HOLES

4.75 MM

DIAMETER

(3/16" DRILL)

FIGURE #5

: MEC 20 EXPANSION MODULE MOUNTING DIMENSIONS

G:\ENGINEER\PRODUCTS\MEC20\MEC20_14.VSD

DRAWING SCALE .75:1

0.00 mm

0.00 mm

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 12 Thomson Power Systems

2.12. MEC MOUNTING LOCATION/INSTALLATION

The MEC 20 Engine-generator controller is designed for mounting directly onto a

control panel door. Considerations should be given for the following:

•The controller should be installed in a dirt free, dry location away from

extreme heat sources.

•The LCD window should be installed at an optimum height for operator

viewing.

•Adequate space should be provided around the rear of the MEC 20 circuit

board for control wiring.

•Verify that the intended AC voltage input to the controller does not exceed

the maximum allowable level on the control panel door as per the applicable

control panel certification standard.

The MEC 20 controller can be installed onto a door of a control panel using one

of the following methods:

•The first method requires a special door cutout for the LCD display and

LED’s as shown in FIGURE #6. This mounting method requires the lexan

faceplate to be mounted directly onto the door of the control panel. The

controller must be disassembled to mount on the door, then re-assembled.

Refer to FIGURE #7 for correct assembly location of all parts.

•The second method of controller mounting requires a factory supplied

adapter faceplate as shown in FIGURE #8. This method only requires a

single large rectangular hole to be cut out of the door as shown in FIGURE

#9.

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 13 Thomson Power Systems

2.13. FACEPLATE MOUNTING DIMENSIONS

268 mm.

126 mm.126 mm.

166 mm.

49 mm.49 mm.

24 mm.24 mm.

75 mm.75 mm.

OUTLINE OF PRINTED CIRCUIT

BOARD UNDER PANEL DOOR

4 HOLES

4 mm. DIAMETER

(3/16" DRILL)

33 mm.

41 mm.

7 mm.

16.5 mm.

20 mm. 32 mm.

80 mm.

8 mm.8 mm.

TOP

CUTOUT

9 HOLES

6 mm. DIAMETER

(1/4" DRILL)

C

C

G:\ENGINEER\PRODUCTS\MEC20_07.VSD

FIGURE #6

2.14. MEC 20 ASSEMBLY - SIDE VIEW

PANEL DOOR

MEC 20 PCB

MEC 20 REAR COVER

#8-32 × 3/8" MACHINE SCREW

# 8-32 INTERNAL TOOTH LOCK WASHER

1.25" ALLUMINUM STANDOFF (HEX)

#8-32 THREAD

#8-32 INTERNAL TOOTH LOCK WASHER

1/2" NYLON SPACER

(#8-32 CLEARANCE

UNTHREADED)

PEM STUD

#8-32 × 1"

G:\ENGINEER\PRODUCTS\MEC20_09.VSD Rev. 0 97/06/02

REARFRONT

HIGH VOLTAGE

MYLAR BARRIER

(mounts on bottom

right hand corner, as

viewed from rear)

FIGURE #7

MEC 20 MICROPROCESSOR ENGINE/GENERATOR CONTROLLER

PM047 Rev 12 03/03/04 14 Thomson Power Systems

Notes:1. Ensure that all lockwashers are installed as shown above.

2. The high voltage mylar barrier (P/N TMW;10805;1) must be installed as shown

when the MEC 20 is installed onto the door of a control panel.

3. When the MEC 20 is installed on a door without 1” PEM studs, 1” machine

screws must be used.

11.5 in

7.5 in

TOP

C

C

CUTOUT

9 HOLES

1/4" DIAMETER

4 STUDS #8/32 1/4"

1/4"

FIGURE #8: ADAPTER FACEPLATE

G:\ENGINEER\PRODUCTS\MEC20_11.VSD Rev. 1 00/07/13

5.5 in

3.5 in

C

C

FIGURE #9:DOOR CUTOUT FOR ADAPTER FACEPLATE

10.875 in

6.875 in

2.15. DIELECTRIC TESTING

Do not perform any high voltage dielectric testing on the control panel with the

MEC 20 connected in the circuit as serious damage will occur to the controller.

All AC control fuses connected to the MEC 20 must be removed if high voltage

dielectric testing is performed on the control panel.

Table of contents

Popular Controllers manuals by other brands

Honeywell

Honeywell Experion 8 Series technical information

Johnson Controls

Johnson Controls Metasys VMA1610 installation instructions

Eurotops

Eurotops Profi-Partner 44670 instruction manual

ABB

ABB ACS 800 Series Hardware manual

HORNER

HORNER RCC972 user manual

CDI

CDI 197-0001 Installation and troubleshooting guide