THOR GE559-N Owner's manual

Thor Gas Salamander

Installation and Operation Instructions

Model: GE559-N GE559-P

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For Warranty

Service and/or parts, this information is required.

Model Number Serial Number Date Purchased

WARNING: For your safety, do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliances. Keep the area free and clear of

combustible.

WARNING :Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury, or death. Read the installation operating and maintenance

instructions thoroughly before installing, or servicing this equipment.

WARNING:Instructions must be posted in a prominent location. All safety precautions

must be taken in the event the user smells gas. Safety information can be obtained from

your local gas supplier.

15 Badgally Road, Campbelltown

NSW 2560

Thor after sales/service: 1300 225 960

Contents

Introduction

............................................................................................. 2

Specifications

........................................................................................... 3

General

Pack Contents

Gas Supply Requirements

Dimensions

................................................................................................ 4

Installation

................................................................................................ 5-9

Installation Requirements

Unpacking

Location

Clearances

Assembly

Gas Connection

Commissioning

Operation

...................................................................................................10-11

Operation Guide

Description of Controls

Lighting the Main Burner

Main burner air supply

Cleaning and Maintenance

............................................................................12

Initial cleaning

Daily Cleaning

Weekly Cleaning

Vent system

Stainless steel surface

Adjustments……………………………………………………………………………………………13

Trouble Shooting

.........................................................................................14

Replacement parts ……

........................................................................……..14

Explosion Drawing

..............................................................................……..15-16

Spare Parts List

..........................................................................................17-18

2

Introduction

We are confident that you will be delighted with your Thor Gas Salamander, and it will become a most

valued appliance in your commercial kitchen.

To ensure you receive the utmost benefit from your new Gas Salamander, there are two important things

you can do.

Firstly

:

Please read the instruction book carefully and follow the directions given. The time taken will be well

spent.

Secondly

:

If you are unsure of any aspect of the installation, instructions or performance of your appliance,

contact your dealer promptly. In many cases a phone call could answer your question.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS APPLIANCE.

WARNING:

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS ARE TO BE POSTED IN A PROMINENT

LOCATION. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING THE LOCAL GAS SUPPLIER.

WARNING:

GREAT CARE MUST BE TAKEN BY THE OPERATOR TO USE THE EQUIPMENT SAFELY TO GUARD IT AGAINST RISK OF

FIRE.

•

THE APPLIANCE MUST NOT BE LEFT ON UNATTENDED.

•

IT IS RECOMMENDED THAT A REGULAR INSPECTION IS MADE EVERY TWO MONTHS BY AN AUTHORISED

SERVICE PERSON TO ENSURE CORRECT AND SAFE OPERATION OF YOUR APPLIANCE IS MAINTAINED.

•

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPOURS OR LIQUIDS IN THE VICINITY OF THIS

OR ANY OTHER APPLIANCE.

•

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

CAUTION:

THIS APPLIANCE IS;

•

FOR PROFESSIONAL USE

A FULL UNDERSTANDING OF THIS MANUAL IS REQUIRED BEFORE USING THIS PRODUCT

•

INSTALLATION TO BE CARRIED OUT BY AUTHORISED INSTALLERS, SERVICING AND GAS CONVERSION

OPERATIONS.

•

COMPONENTS HAVING ADJUSTMENTS PROTECTED BY THE MANUFACTURER SHOULD NOT BE ADJUSTED BY

THE USER/OPERATOR.

•

DO NOT OPERATE THE APPLIANCE WITHOUT THE LEGS SUPPLIED FITTED.

3

Specifications

General

Commercial gas salamander.

Pack Contents

The following is included:

Thor Gas Salamander

1pcs racks

4pcs Feet (optional)

Instruction Manual

Wall Mounting Bracket, including:

-2 x 25mm Black Plastic Spacer.

-2 x 3/8” Bolts/Nuts

-6x 30mm Screw Tox.

-6 x ST4.9x30 screws

Gas Supply

Requirements

Natural Gas

Propane

ULPG

GE559-N

GE559-P

GE559-P

Single burner Heat Input

16MJ/Hr

16 MJ/Hr

16 MJ/Hr

Heat Total

32 MJ/Hr

32 MJ/Hr

32 MJ/Hr

Burner Operating

1.0 kPa

2.75 kPa

2.75kPa

Minimum inlet supply

pressure

1.13 kPa

2.75 kPa

2.75 kPa

Gas Connection

¾” BSP Male

¾” BSP Male

¾” BSP Male

The burner operating pressure is to be measured at the gas control valve outlet test point with two burner

operating at ‘High’ setting. The operating pressure is ex-factory set, through the appliance regulator and should

not to be adjusted, However the pressure must be checked during installation to confirm adequate supply

pressure is available. (Test point for checking gas pressure is located by removing right side panel. Turn gas

supply off before removing test point screw.)

Minimum input of burner: 13MJ for LPG, 13MJ for NG

4

Dimensions

Dimensions for Gas Salamander

Minimum clearance from grease filter - minimum 600mm - Refer AS/NZS5601 - Gas

Installations

Note: Gas Salamander rack can carry a load of up to: 15KG (33 lbf)

5

Installation

Installation Requirements

NOTE:

•

It is most important that this appliance is installed correctly and that operation is correct before

use. Installation shall comply with local gas, health and safety requirements.

•

This appliance shall be installed with sufficient ventilation to prevent the occurrence of

unacceptable concentrations of substances harmful to health.

•

The appliance is to be installed under a grease filter in accordance with AS/NZS5601 -

Gas Installations.

Our Gas Salamanders are designed to provide years of satisfactory service and correct installation is essential

to achieve the best performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in accordance

with relevant National / Local codes covering gas and fire safety.

This product is intended for commercial use only, not for household use.

The installation must conform with local codes, or in the absence of local codes, with AS/NZS5601- Gas

Installations

Installations must be carried out by authorised persons only. Failure to install equipment to the relevant

codes and manufacturer’s specifications shown in this section will void the warranty.

Components having adjustments protected by the manufacturer are only to be adjusted by an authorized

service agent. They are not to be adjusted by the installation person.

Step 1: Unpacking

Step 2a: Install the Legs (option)

A set of four legs is packed with units ordered with legs.

A threaded leg pad is fastened to the base frame at each corner. Each leg has a corresponding mating thread.

The leg can be adjusted to overcome a slightly uneven floor.

1. Raise unit sufficiently to allow leg pads and legs to be attached. For safety, “shore up” and support the unit

with an adequate blocking arrangement strong enough to support the load.

2. Attach the four leg pads to the bottom of the range using the lock washers and machine screws. The

mounting holes are pre-drilled and threaded.

3. Screw the legs into the holes in the centers of the leg pads.

4. Lower unit gently onto a level surface. Never drop or allow the unit to fall.

5. Use a level to make sure that the range surface is level. The legs can be screwed in or out to lower or raise

each corner of the range.

6. The appliance is to be secured to the bench to ensure it does not move when the appliance is used.

7. Go on to installation Step 3.

IMMEDIATELY INSPECT FOR DAMAGE

Check equipment and parts for damage.

Report any damage immediately to the carrier and distributor within 24 hours.

Report any deficiencies to the distributor who supplied the appliance within 24 hours.

6

Installation (continued)

Assembly

NOTE:

•

This appliance is assembled before delivery except feet and rack.

•

This appliance is fitted with adjustable feet to enable the appliance to be positioned securely and

level. This should be carried out on completion of the gas connection. Refer to the ‘Gas

Connection’ section.

•

IM will be stated that the appliance shall be installed in such a way that side body surfaces are

not accessible in the installed position.

Step 3: Location

1. Installation must allow for a sufficient flow of fresh air for the combustion air supply.

2. Installation must include adequate ventilation and exhaust means, to prevent dangerous build-up

of combustion products.

3. Any gas burning appliance requires adequate clearance and ventilation for optimum and trouble-free

operation. The minimum installation clearances shown below are to be adhered to.

4. Position the appliance in its approximate working position. In accordance with AS/NZS5601 - Gas

Installations.

5. All air for burner combustion is supplied from underneath the unit. The legs must always be fitted

and no obstructions placed on the underside or around the base of the unit, as obstructions will

cause incorrect operation and / or failure of the appliance.

6. Components having adjustments protected by manufacturer are only allowed to be adjusted by an

authorized service agent. They are not to be adjusted by the installation person.

7. Do not place any equipment on top of the appliance.

8. The unit should be mounted under an extraction hood incompliance with all local regulations.

In the event that the unit is not mounted under an extraction hood, the installer must

ensure that all regulations are met and that there is an unobstructed minimum distance of

750mm from the top surface of the unit to the ceiling, which must be of non-combustible

material.

NOTE: Do not obstruct or block the appliance’s flue. Never directly connect a ventilation

system to the appliance’s flue outlet.

7

Installation (continued)

Clearances

NOTE: Only non-combustible materials can be used in close proximity to this appliance.

Combustible

Surface

Non Combustible

Surface

Left / Right Hand Side

Rear

Top Clearance to:

-Extraction Hood

-Grease Arresting Filter**

-Ceiling***

100mm

50mm

25mm*

30mm

200mm

600mm

750mm

* We recommend allowing a clearance of 100 mm on either side of the

appliance to allow access to the side panels for servicing purposes.

** Using the wall mounting accessories provided with this appliance.

*** Top clearances can be reduced where local fire protection system is provided,

if allowed by the local regulations.

CEILING

GREASE ARRESTING FILTER

EXTRACTION HOOD

200mm

400mm

750mm

Side Clearance of 100mm

for any obstruction

100mm

(must be non-combustible material)

600mm

8

Installation (Continued)

Wall Mounting (To Non-Combustible Wall Only)

1. Fix the wall mounting bracket to the wall

with six screws, in such a position that the

top of the bracket is level and at least 945

mm (38”) above any surface beneath the

unit. This will ensure that the bottom of the

Salamander is at least 600 mm (24”) above

any surface. Refer to Fig. 1 as an example.

2. Fit the two black plastic spacers to the top

rear corners of the unit. Leave them

unscrewed by approximately 5 mm. Refer to

Fig. 2 (A).

3. Fit the two adjusting screws / bolts into the

nut inserts at the bottom rear corners of the

unit. These should protrude approximately 30

mm from the rear of the Salamander. Refer

to Fig. 2 (B).

4. Lift the Salamander onto the wall bracket,

lining up the black plastic spacers on the

salamander with the mounting notches in the

bracket. Refer to Fig. 3.

5. Lower the Salamander onto the mounting

bracket. Refer to Fig. 4.

6. Tighten the black spacers securely and adjust

the leveling screws / bolts to ensure that the

unit is level. Refer to Fig. 4.

Fig. 1

Screws

945mm

600mm

5mm

Fig. 2

30mm

B

A

Fig. 3

Fig. 4

9

Gas Connection

NOTE: ALL GAS FITTING MUST ONLY BE CARRIED OUT BY AN AUTHORISED PERSON.

1. The Gas Salamanders do not require an electrical connection, as they function totally on the gas

supply only.

2. It is essential that the gas supply is correct for the appliance to be installed and that

adequate supply pressure and volume are available. The following checks should

therefore be made before installation:-

a. Gas Type required for the appliance is shown in the rating label. Check that this is correct for

the gas supply the appliance is being installed for. The gas conversion procedure is detailed

in this manual.

b. Supply Pressure required for this appliance is shown in the ‘Gas supply requirements’ section

of this manual. Check the gas supply to ensure adequate supply pressure exists.

c. Input Rate of this appliance is stated on the Rating label .The input rate should be checked

against the available gas supply line capacity. Particular note should be taken if the appliance is

being added to an existing installation.

NOTE: It is important that adequately sized piping runs directly to the connection joint on the

appliance with as few tees and elbows as possible to give maximum supply volume.

NOTE: Ensure the regulator is converted to the correct gas type that the appliance will operate on. The

regulator outlet pressure is fixed ex-factory for the gas type .

3. Correctly locate the appliance into its final operating position and using a spirit level, adjust

the legs so that the unit is level and at the correct height.

4. Connect the gas supply to the appliance through the regulator. A suitable jointing compound

which resists the breakdown action of propane must be used on every gas line connection,

unless compression fittings are used.

5. Check all gas connections for leakages.

WARNING:

DO NOT USE A NAKED FLAME TO CHECK FOR GAS LEAKAGES.

6. Check that the gas operating pressure.

7. Turn off the mains gas supply and bleed the gas out of the appliance gas lines.

8. Turn on the gas supply and the appliance.

9. Verify the operating pressure remains correct.

Commissioning

1. Before leaving the new installation;

a. Check the following functions in accordance with the operating instructions specified in the

‘Operation’ section of this manual.

•

Light the Main Burner.

•

Turning 'Off' the Main Burner

b. Ensure that the operator has been instructed in the areas of correct lighting, operation, and

shutdown procedure for the appliance.

2. This manual must be kept by the owner for future reference and a record of the Date of Purchase,

Date of Installation and the Serial Number of the Appliance must be recorded and kept with this

manual. (These details can be found on the Rating label, refer to the ‘Gas Connection’ section).

NOTE: If for some reason it is not possible to get the appliance to operate correctly, shut off the gas

supply and contact the supplier of this appliance.

10

Operation

Operation Guide

CAUTION:

•

THIS APPLIANCE IS FOR PROFESSIONAL USE AND IS ONLY TO BE USED BY QUALIFIED PEOPLE.

•

ONLY QUALIFIED SERVICE PERSONS ARE TO CARRY OUT INSTALLATION, SERVICING OR GAS CONVERSION

OPERATIONS.

•

COMPONENTS HAVING ADJUSTMENTS PROTECTED (E.G. PAINT SEALED) BY THE MANUFACTURER SHOULD NOT

BE ADJUSTED BY THE USER/OPERATOR.

1. The Gas Salamanders have been designed to provide simplicity of operation and 100% safety

protection.

2. Improper operation is therefore almost impossible, however bad operation practices can reduce the

life of the gas salamander and produce a poor quality product. To use this appliance correctly

please read the following sections carefully:-

Lighting the Burners.

Turning off the Burners

1. Lighting the Burners

Flame Failure Protection is incorporated for each burner by way of a thermo-electric system which will

shut off the gas supply to that burner in the event that the burner goes out, so that un-burnt gas is not

expelled.

1. Select the burner required, depress and turn the corresponding gas control knob anti-

clockwise to the 'HIGH' flame position.

2. With the gas control knob depressed, manually light the burner. (It will be take about 1

minute to clear the air in pipe during initial use)

3. Release the gas control knob after approximately 10-20 seconds after lighting the burner.

4. Low flame can be achieved by depressing the gas control knob and rotating fully anti-

clockwise to the ‘LOW' flame position.

5. To achieve simmer control, depress the gas control knob and rotate between the ‘HIGH’

and ‘LOW’ positions to achieve the temperature required.

2. Turning 'OFF' the Main Burners / Pilots

1. To turn off the main burner, rotate the gas control knob clockwise to the stop position. Then

rotate the gas control knob clockwise to ‘I’position with the knob depressed, the main burner

will extinguish.

11

Operation (Continued)

CAUTION

The space between the legs at the bottom admits combustion air. DO NOT BLOCK THIS SPACE.

Do not permit fans to blow directly at the unit. Wherever possible, avoid open windows next to the

units' sides or back. Avoid wall type fans which create air cross-currents within a room.

It is also necessary that sufficient air should be allowed to enter the room to compensate for the

amount of air removed by any ventilating system. Otherwise, a subnormal atmospheric pressure

will occur, affecting operation and causing undesirable working conditions.

A properly designed and installed hood will act as the heart of the ventilating system for the room

or area in which the unit is installed, and will leave the unit independent of changing draft

conditions.

All valves must be checked and lubricated periodically. This must be done by an authorized service

representative in your area.

Note:

Please wait at least 15 seconds to restart the main burners to maintain the best function of the

thermostat valve after turning off the main burners.

IMPORTANT

Should any abnormal operation like;

- ignition problems,

- abnormal burner flame,

- burner control problems,

- partial or full loss of burner flame in normal operation, be noticed, the appliance requires IMMEDIATE

service by a qualified service person and should not be used until such service is carried out.

12

Cleaning and Maintenance

INITIAL CLEANING:

Prior to operating your new salamander, thoroughly wash the exterior with a mild detergent or

soap solution. Do not use abrasive cleaners, since this might damage the cabinet finish. If the

stainless steel surfaces become discolored, scrub by rubbing only in the direction of the finished

grain.

When the salamander is first heated, it will smoke until oil used in manufacturing, preservation and

dust from storage and shipping are burned off. An hour at "max." on all burners is usually sufficient.

DAILY CLEANING:

Remove, empty, and clean grease drawers and dirt trays.

Clean griddle drain chutes.

VENT SYSTEM

At least twice a year the unit venting system should be examined and cleaned.

Following daily and periodic maintenance procedures will enhance long life for your equipment. Climatic

conditions (such as salt air) may require more thorough and frequent cleaning or the life of the

equipment could be adversely affected.

STAINLESS STEEL SURFACES

1. To remove normal dirt, grease and product residue from stainless steel that operates at LOW temperature,

use ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with

a clean cloth.

2. To remove grease and food splatter, or condensed vapors, which have BAKED on the equipment, apply

cleanser to a damp cloth or sponge and rub cleanser on the mental in the direction of the polishing lines will

not mar the finish of the stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt deposits

which do not respond to the above procedure can usually be removed by rubbing the surface with SCOTCH-

BRITE sourcing pads or STAINLESS sourcing pads. DO NOT USE ORDINARY STEEL WOOL, as any particles

left on the surface will rust and further spoil the appearance of the finish. NEVER USE A WIRE BRUSH,

STEEL SOURCING PADS (EXCEPT STAINLESS), SCRAPPER, FILE OR OTHER STEEL TOOLS. Surfaces which

are marred collect dirt more rapidly and become more difficult to clean. Marring also increases the possibility

of corrosive attack. Refinishing may then be required.

To remove heat tint- Darkened areas sometimes appear on stainless steel surfaces where the area has

been subjected to excessive heat. These darkened areas are caused by thickening of the protective surface

of the stainless steel and are not harmful. Heat tint can normally be removed by the foregoing, but tint

which does not respond to this procedure calls for a vigorous scouring in the direction of the polish lines,

using SCOTCH-BRITE sourcing pads or a STANILESS sourcing pad in combination with a powered cleanser.

Heat tint action may be lessened by not applying, or by reducing heat to equipment during slack periods.

Do not waste gas and abuse equipment by leaving all burners “FULL ON”, if not required. During idling

periods, adjust burner valves to keep top warm. Re-adjust burner valves as required for periods of heavy

loads.

NOTE:

Let the unit and the oil in the drip tray cool down first before performing any maintenance or

cleaning activities.

•

If the gas Salamander usage is very high, we recommend that the weekly cleaning procedure is

carried out on a more frequent basis.

•

Ensure that protective gloves are worn during the cleaning process.

•

DO NOT use harsh abrasive detergents, strong solvents or caustic detergents as they will damage

the grate and burners.

•

DO NOT use water on the cooking grid while they are still hot as warping may occur.

Allow these items castings to cool and remove for cleaning.

•

Parts protected by the manufacturer or his agent are not to be adjusted by the installer, unless the

installer is an authorized service agent

13

Adjustments

Warning: Adjustments and service work may only be performed by a qualified

technician who is experienced in, and knowledgeable with, the operation of

commercial cooking equipment. However, to assure your confidence, contact

your authorized service agency for reliable service, dependable advice and other

assistance, and of genuine factory parts.

In case of problems in operation at initial installation, check type of gas and manifold pressure and compare

information listed on the serial plate.

CONVERTING FROM ONE GAS TYPE TO ANOTHER

1. Shut-off the main isolation valve and follow the lock-out/tag-out procedure.

2. Remove the left side panel and right side panel.

3. Replace the burner injectors. See the parts list or Gas Specification Table below.

4. Adjust the gas supply pressure, and convert the gas regulator.

5. Change rating label, warning label,

GAS SPECIFICATION TABLE

Natural Gas

Propane

ULPG

GE559-N

GE559-P

GE559-P

Single burner Heat

Input

16MJ/Hr

16 MJ/Hr

16 MJ/Hr

Heat Total

32 MJ/Hr

32 MJ/Hr

32 MJ/Hr

Burner Operating

1.0 kPa

2.75 kPa

2.75kPa

Supply Pressure

1.13 kPa

2.75 kPa

2.75 kPa

Gas Connection

¾” BSP Male

¾” BSP Male

¾” BSP Male

Burner Injector

Orifice#

#185

#109

Set-up of converter

Low

Flame

Size

Ø 0.65mm

Ø 0.65mm

Adjustment

Only if necessary

Only if necessary

CAUTION: Please replace the corresponding warning label that shows the gas

type operated when the qualified person will convert to another gas in order not

to cause death or injury or damage.

14

TROUBLESHOOTING

Consult the following table:

Problem

Cause

Remedy

Burners in the unit will

not turn “ON”

Main gas supply to unit is “OFF”

Ensure that the main gas supply to the unit is

“ON”

Not enough gas pressure.

Ensure that the gas line has enough gas

pressure. Ensure that the gas tanks are not

empty.

Clogged or blocked burner injector

orifice.

Call your authorized service agent.

Thermocouple connection to the

gas valve is loose or too tight.

Call your authorized service agent.

Faulty thermocouple.

Call your authorized service agent.

Faulty gas valve.

Call your authorized service agent.

Only one burner will not

turn “ON”

Clogged or blocked burner injector

orifice.

Call your authorized service agent.

Thermocouple connection to the

gas valve is loose or too tight.

Call your authorized service agent.

Faulty thermocouple.

Call your authorized service agent.

Faulty gas valve.

Call your authorized service agent.

Two burners produce

excessive carbon

deposits

Incorrect gas type supplied to unit.

Ensure that the gas type supplied to the unit

is correct based on the rating label. Refer to

the Gas Specification on Page 13.

Only one burner in a unit

produce excessive

carbon deposits.

Incorrect injector orifice installed.

Ensure that a correct injector orifice is

installed on the unit. Refer to Gas

Specification Table on Page 13 of this manual

Flame comes out from

the flue.

Incorrect gas type supplied to unit.

Ensure that the gas type supplied to the unit

is correct based on the rating label. Refer to

the Gas Specification on Page 13.

Incorrect injector orifice installed.

Ensure that a correct injector orifice is

installed on the unit. Refer to Gas

Specification Table on Page 13 of this manual

Flashback or backfire –

when the flame burns

near the injector and

with a sound like a blow

torch.

Crack on the burner ceramic.

Call your authorized service agent.

Replacement Parts

IMPORTA

N

T

:

Only

g

enu

i

n

e

authorized

rep

l

a

c

ement

p

art

s

should be used for the servicing and repair of

t

h

is

appl

ian

c

e

.

The instructions supplied with the parts should be followed when

rep

l

acing components.

For further information and servicing instructions, contact your nearest authorized service branch

.

When ordering replacement parts, please quote the part number and the description listing below. If the

part required is not listed below, request the part by description and quote model number and serial number

which is shown on the rating plate.

15

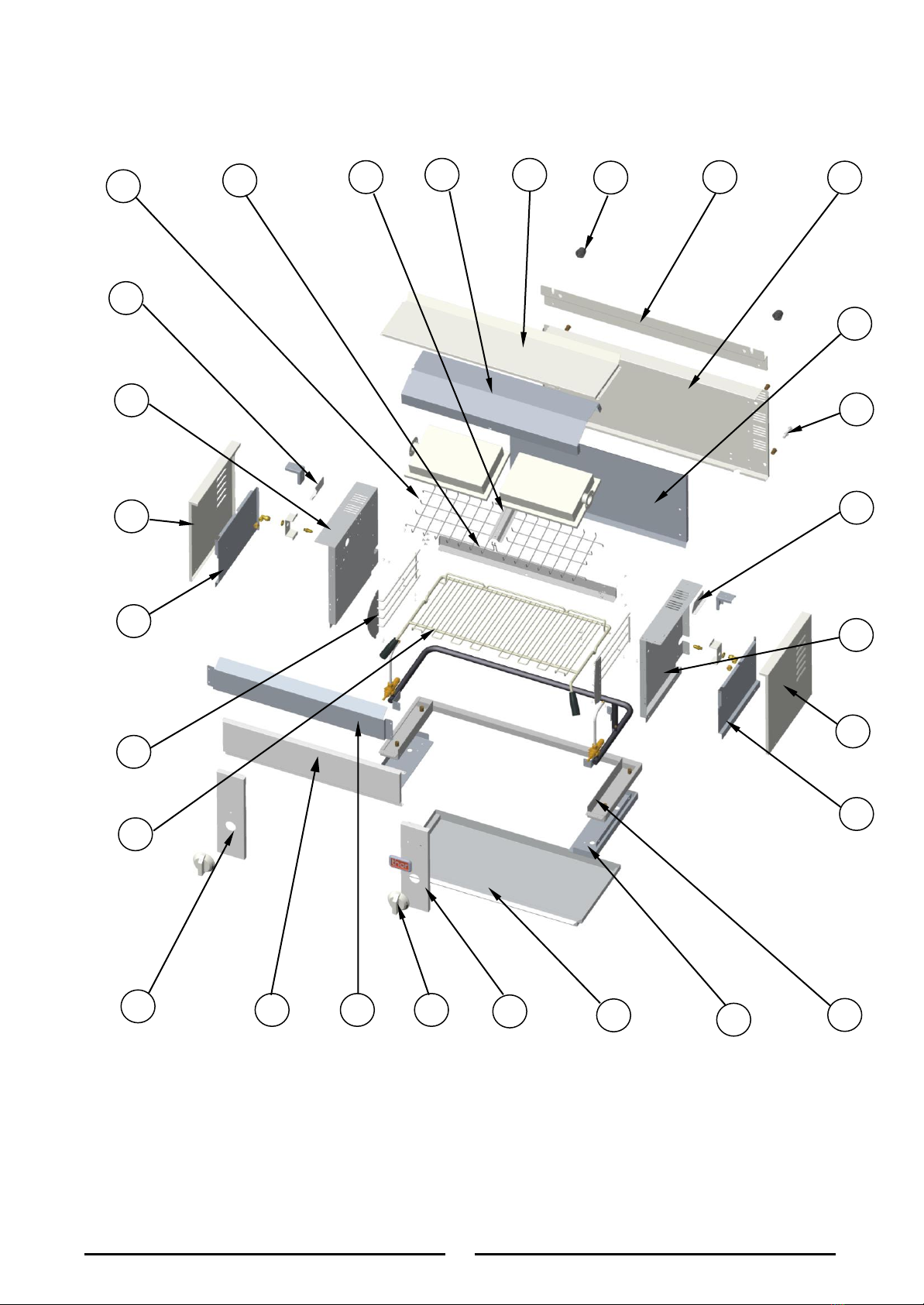

Explosion drawing

28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

20

21

23

22

25

26

27

19

24

16

Explosion drawing(Continued)

29

30

31

32

33

34

35

36

17

Spare Parts List

NO.

DESCRIPTION

Part No

CODE

GE559-P

GE559-N

1

Rack

01.11.1062056

1

1

2

Rack support

01.02.1005371

2

2

3

Left insulation

01.15.1066413

1

1

4

Side panel-l

01.05.1029292

1

1

5

Left inner panel

01.15.1066420

1

1

6

Upper left plate

01.05.1029296

1

1

7

Burner protect

01.03.1015100

2

2

8

Upper inner2

01.15.1066419

1

1

9

Burner protect connector

01.05.1029298

1

1

10

Upper inner1

01.15.1066418

1

1

11

Top cover

01.05.1029295

1

1

12

Feet1

02.12.1165053

2

2

13

Back hold plate

01.15.1066412

1

1

14

Back panel

01.15.1066415

1

1

15

Back inner plate

01.15.1066417

1

1

16

Feet2

01.02.1005381

2

2

17

Upper right plate

01.05.1029297

1

1

18

Right inner panel

01.15.1066421

1

1

19

Right insulation plate

01.15.1066414

1

1

20

Side panel-l

01.05.1030294

1

1

21

Support assembly

01.09.1050453

1

1

22

Side bottom

01.05.1029291

2

2

23

Oil tray

01.05.1029290

1

1

24

Control panel-r

01.05.1030295

1

1

25

Knob

06.05.1472202

2

2

18

Spare Parts List

NO.

DESCRIPTION

Part No

CODE

GE559-P

GE559-N

26

Front insulation

01.15.1066416

1

1

27

Front cover

01.05.1029294

1

1

28

Control panel-l

01.05.1029293

1

1

29

Main pipe assembly

06.05.1472745

2

2

30

L-connector

01.18.1067451

2

2

31

Main burner injector/Orifice

(for Natural Gas) - #185

01.20.1068670

2

Main burner injector/Orifice

(for LPG) - #109

01.20.1068671

2

32

Infrared burner

01.03.1015139

2

2

33

Safety Gas Valve

01.20.1068572

2

2

34

Thermocouple

03.11.1250034

2

2

35

Manifold assembly

01.24.1070916

1

1

36

Regulator

01.22.1069526

1

1

15 Badgally Road, Campbelltown

NSW 2560

Thor after sales/service: 1300 225 960

V1.Rev4 12-20

This manual suits for next models

1

Table of contents

Other THOR Grill manuals

Popular Grill manuals by other brands

Weber

Weber SMOKEY JOE PREMIUM owner's guide

Nexgrill

Nexgrill 820-0015 manual

Lotus

Lotus CWK-74ET Instructions for installation and use

all-clad

all-clad PG715850 owner's guide

George Foreman

George Foreman RPGV3801BK SERIES use and care manual

Lang

Lang PB-24 Installation, operation, concept training, maintenance, & troubleshooting