THORAIR AM190001 User manual

L G R D E H U M I D I F I E R S

A M 1 9 0 0 0 1

A M 1 9 0 0 0 2

insulation, and con- tents, and maintain a healthy level of humidity. Using the LGR2200 may also prevent

secondary damage caused by high humidity.

WARNINGS

•Always store, transport, and use the unit in a horizontal position. If the unit is ever placed in a

vertical position, return it to the horizontal position and let it stand for at least 30 minutes before

turning it on.

•Do not move or carry the Dehumidifier while it is operating. When the Dehumidifier is operating,

the powerful airflow can cause unpredictable movement.

•NEVER allow children to play with or around the Dehumidifier.

•Do not alter or modify your Dehumidifier in any way. Use only authorized replacement parts .

Modifications or use of unauthorized parts could create a hazard and will void your warranty.

•Insert three prong-plug on power cord into a matching electrically grounded outlet. Do not use

adapter. Never cut off third prong.

•The Dehumidifier should never be operated near water as it will create a risk of serious injury from

electrical shock.

•Handle unit with care to avoid causing damage or injury.

•The Dehumidifier should always be operated on a flat surface. Do not operate where unit could fall,

or on slippery surfaces, as this could increase the chance of injury, fire, or electrical shock.

•Do not use the Dehumidifier near combustible gas, or hot air as unit could melt and cause a fire or

electrical hazard.

•Do not take the Dehumidifier apart or repair it unless you are qualified to do so. Never repair or

service unit while Dehumidifier is plugged in.

•Make sure the air intake and outlet are free from all materials and away from obstructions, as any

restrictions may cause the Dehumidifier to overheat and cause a shock or fire hazard.

•Unplug the Dehumidifier before performing any service or changing filters

•Do not stack more than 2 units high in order to avoid a tipping hazard – falling equipment can

cause bodily harm.

•Keep away from open flames and heat sources.

•Do not use or store where vapors from gasoline, sol- vents, thinners or other flammable materials

may be present.

POSITONING LGR2200/2500

For best results, operate your dehumidifiers in an enclosed area. Close all doors and windows that open

to the outside to maximize water removal efficiency. Place your dehumidifier away from obstructions,

and keep it away from anything that could block airflow into and out of the unit.

SET DRAIN HOSE

The LGR2200/2500 condensate pump connects to a plastic drainage hose. This hose is equipped with a

quick- connect fitting for quick attachment to the provided 25 ft. (7.5 m) drain hose. Unwrap the entire

hose and place the unattached end in a sink, drain, bucket or outdoors – anywhere that water can drain

out safely. If you use a bucket or other container for water collection, check it regularly to prevent

overflows.

NOTICE: Uncoil and straighten the entire drain hose. Do not leave any part of the hose coiled and do not

place the end of the hose higher than 20 ft. (6 m) above the bottom of the unit. Also check for kinks or

other obstructions that might restrict the flow of water. Obstructions may cause a water backup and

result in overflows.

PLUG THE UNIT

The LGR2200/2500 should be plugged into a 125volt outlet rated for at least 10 amps. Always plug the

cord firmly into the unit first, and then plug the other end into a suitable outlet.

Startup display and normal display modes

When unit is first plugged in to AC power, the control panel display will briefly cycle through a series of

readouts. This is part of the unit’s self-diagnosis procedure and no user intervention is required.

CONTROL PANEL

ON/OFF

Press and release to turn unit on or off.

MENU

Press to select next item in menu. Menu item will show in display.

SET

Press to toggle or select values in menu displayed

PUMP

Press and release to start purge.

IN

Shows Temp & humidity of the inlet

OUT

Shows Temp & humidity of the outlet

Cool

Shows Temp @ condenser

COMP A

Shows Current of the compressor

Runtime

Shows Job hours & life hours

STATE

Shows the state of the dehumidifier

HUMIDISTAT SETTING

The default operating mode keeps the dehumidifier running at its maximum capacity. This is ideal for

most restoration application. To control humidity at a specific level, described below:

1) Press MENU once, and screen shows as FIG A, Press SET until the screen shows as FIG B, an arrow

point the Moisture,

FIG A

FIG B

2) Press SET to adjust the target Moisture, Each press of the button increases the setting by 5%

increments, cycling through 90%RH and starting again at 40%RH.

3) Press MENU until the screen back to the main Menu.

TEMPERATURE SETTING

To change unit of temperature, described below:

1) Press MENU only once, and screen shows as FIG C, Press SET until the screen shows as FIG D, an

arrow point the Moisture,

2) Press SET to select Fahrenheit or Centigrade scale

FIG C

FIG D

AFTER THE JOB

To reduce the possibility of drips when moving the unit, follow these additional steps to ensure that all

water is removed from the unit.

NOTICE: To ensure the condensate tank empties completely while purging, make sure the unit is

positioned horizontally on a flat surface.

1) Gently rock the machine to ensure any water remaining on interior surfaces falls into the sump

area.

2) Press the PUMP key. When the purge cycle is complete, turn the unit off.

3) Remove the external drain hose, drain it carefully, coil it and secure it with one of the Velcro

straps provided on the side of the unit.

4) Unplug power cord from power supply and from base of the machine, coil neatly, coil it and

secure it with one of the Velcro straps provided on the side of the unit.

TRANSPORTATION AND STORAGE

NOTICE: Handle the unit carefully. Do not drop, throw, or place the unit where it could fall. Rough

treatment can damage this equipment and may create a hazardous condition or void warranty.

•Do not expose the control panel to moisture, snow or rain.

•Protect from freezing.

•Store and transport securely to avoid any damaging impact to internal parts.

•Secure during transport to prevent sliding and possible injury to vehicle occupants.

MAINTENANCE SCHEDULE

WARNING! ELECTRIC SHOCK HAZARD. Unplug unit before cleaning or servicing.

WARNING: Risk of dust and contaminants exposure. Use of respirator mask and gloves is recommended.

If unit has been exposed to potentially dangerous contaminant, clean thoroughly and sanitize before

reuse.

NOTICE: The unit is fitted with sensitive electronic sensors. Protect the sensors and their lead wires from

damage and do not expose them to water or cleaning solution.

Before each use Inspect the electrical cord for damage. Look for fraying, cuts, etc. Replace the cord if

you find any damage.

Inspect, vacuum or replace filter. The LGR2200/2500 is provided with a 3M™ HAF High Air Flow .HAF

filters may be vacuumed clean and reused up to three times before replacement. Use a HEPA vacuum

and brush tool to remove any dust or de- bris. Do not use compressed air or expose the filter to any

liquids, as may damage the filter.

Monthly Inspect coils. Clean when dust accumulation is visible. In normal use, dust can accumulate and

can restrict airflow, reducing performance and causing the unit to overheat. Use a vacuum cleaner with

a brush tool and a soft cloth to remove any debris. Take care not to damage any interior components.

To maintain appearance, wipe interior and exterior surfaces with a damp cloth. For deep cleaning and a

lasting, protective shine, use an automotive interior cleaner.

Clean pump check valve and basin If the unit displays the message “STATE PUMP”, which means

the pump may be blocked, check valve and pump basin may need to be cleaned. Remove grills and cover.

Remove screws from pump base and lift out pump. Wipe out pump basin with a damp cloth. Inspect the

pump base for build-up of debris and clean if needed. Unthread barbed fitting with check valve and rinse

fitting and check valve with clean water. Reinstall check valve into barbed fitting and install the barbed

fitting into pump. Do not overtighten. Reinstall pump on base. Reinstall cover and grills.

Clean coils With the cover removed, inspect both coils. If excessive dust and debris is present, vacuum

thoroughly and/or clean with coil cleaner.

LGR2200/2500 SPECIFICATIONS

MODEL

LGR2200

LGR2500

Power Input

110 Volts, 60 Hz

110 Volts, 60 Hz

Compressor Power

3/4HP @Aham

1HP @Aham

Motor Rating:

1/3 hp

1/3hp

Current:

7 amps

7.5amps

Water Removal

125Pints/Day (71L) @ 90F/90%

80Pints/Day (45L) @ 80F/60%

135Pints/Day (71L) @ 90F/90%

85Pints/Day (45L) @ 80F/60%

CFM:

250-500

300-550CFM

Weight

36.5Kg

42Kg

Size

24x14x21inch

26*22*37inch

Certifications:

ETL

ETL

Specifications are subject to change without notice.

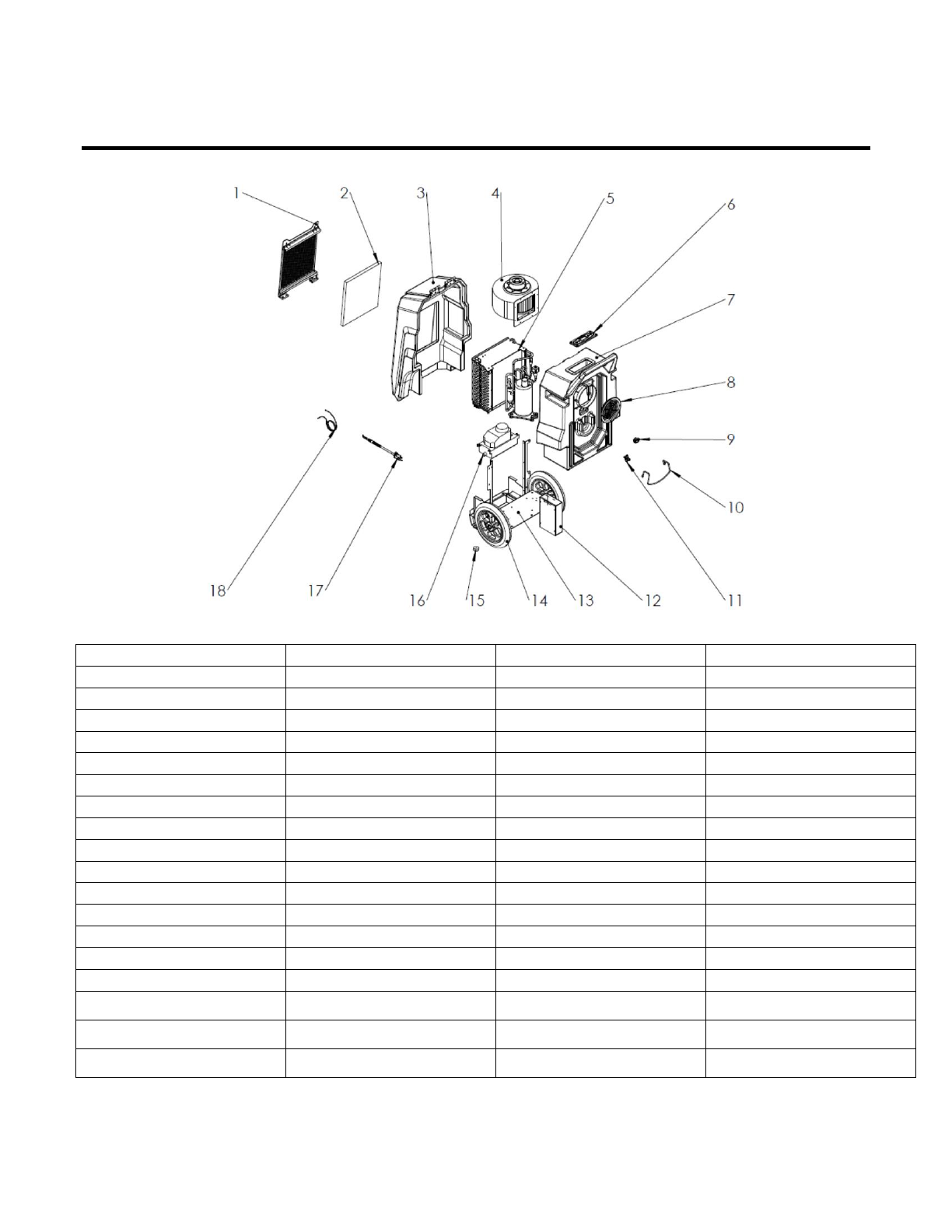

LGR2200/2500 PARTS LIST

Ref

Part Number

Description

Qty Req

1

LGR2201

Inlet Grill

1

2

LGR2202

3M HAF Filter

1

3

LGR2203

Water Pump

1

4

LGR2204

Condens

1

5

LGR2205

Airflow Guide

1

6

LGR2206

1/3 HP Motor

1

7

LGR2207

Motor Support

1

8

LGR2208

Motor Seal Panel

1

9

LGR2209

Switch Panel

1

10

LGR2210

Fan Inlet Cover

1

11

LGR2211

Outlet Grill

1

12

LGR2212

Fan

1

13

LGR2213

Control Box

1

14

LGR2214

Compressor Base

1

15

LGR2215

Down Housing

1

16

LGR2216

Up Housing

1

16

LGR2217

Quick Pipe connector

1

17

LGR2218

Handle

2

LGR2500 PARTS LIST

Ref

Part Number

Description

Qty Req

1

LGR2501

Inlet Grill

1

2

LGR2502

Filter

1

3

LGR2503

Inlet Housing

1

4

LGR2504

Fan Motor

1

5

LGR2505

Compressor

1

6

LGR2506

Control Panel

1

7

LGR2507

Outlet Housing

1

8

LGR2508

Outlet Grill

1

9

LGR2509

Cord Connector

1

10

LGR2510

Bracket

1

11

LGR2511

Water Connector

1

12

LGR2512

Control Box

1

13

LGR2513

Base

1

14

LGR2514

Wheel

2

15

LGR2515

Rubber

2

16

LGR2516

Pump

1

16

LGR2517

Cord

1

17

LGR2518

Drain Hose

1

SYSTEM MESSAGES

The LGR2200/2500 control system constantly monitors internal operating conditions. If the system detects a

problem, it will state the ERROR code at the after the STATE row, instead RUN/OFF. If the display

shows an ER message, first unplug the unit and then plug it back in. This will usually reset the electronics,

and the unit will begin operating normally. If the error message reappears, refer to the explanation and

solution shown below.

C O N T R O L P A N E L

M E S S A G E

E X P L A N A T I O N A N D S O L U T I O N

STATE:COMP

Compressor may do not work, Check compressor cable for proper connection , if

contact service center

STATE: MOIS

Check inlet Temp/RH sensor for proper connection. If error persists, contact service.

STATE: TEMP 1

Check inlet Temp/RH sensor for proper connection. If error persists, contact service.

STATE: TEMP 2

Check outlet Temp/RH sensor for proper connection. If error persists, contact service.

STATE: PUMP

Check for obstructions in drain hose. If clogged, remove hose from unit and blow hose

out with compressed air. Inspect and clean the pump check valve and pump basin.

TROUBLE SHOOTING

Water drips out

when moving unit

Unit was unplugged before

purging was complete.

Purge unit before moving. See “At the End of the

Job,” p. 4.

Unit does not

operate

Unit not switched on.

No power to machine.

Switch unit on.

Plug in unit; check power cord connection at wall

outlet and at base of unit.

Unit operating, but

room not dry

Not enough time to dry. Poor

air movement in room.

Excessive moist air infiltration.

Allow more time for drying.

Increase air movement with air movers. Seal off area

to reduce infiltration.

Unit collects too

little water

Room air is dry.

Room temperature is too low.

Filter is clogged.

Coils are clogged.

Confirm humidity level with hygrometer. Increase

room temperature.

Check filter. Clean or replace as necessary. Check

coils. Clean as necessary.

Unit stop working

after few hours

The setted humidity is less than

the environment humidity

Decrease the setted humidity according to the

HUMIDISTAT SETTING process

Thank you for purchasing this product. Please read the instructions carefully and follow all warnings.

All products are manufactured to be easy to use and provide years of worry free service when the

recommendations in this manual are followed.

This manual suits for next models

3

Table of contents