THORNADO TH-WP30A User manual

TH-WP30A TH-WP40AE

TH-WB80 TH-CP20V TH-CP30V

WATER PUMP

Owner’s Manual

· 1 ·

PREFACE

Thank you for choosing a water pump of our company.

Please keep the owner’s manual for reference.

This manual should be considered a permanent part of the water pump

and should remain with the water pump if it is resold.

The manual instructs the user how to operate the water pump including

before operation to get the best results. If a problem should arise or if you

have any questions about the pump, consult an authorized dealer of our

company.

All information and diagrams of this manual are provided in accordance

with the newest products at the publishing time. If revision or any other

change is made in respect of the information descried in this manual,

making it a little different from the product's actual status,our company

will explain it.Our company reserves the right to make changes at any

time without notice and without incurring any obligation. No part of

this publication may be reproduced without written permission of our

company.

· 2 ·

CONTENTS

CONTENTS

1. SAFETY …………………………………………………………… 3

2. COMPONENT IDENTIFICATION ……………………………… 7

3. CONTROL SYSTEM …………………………………………… 14

4. PRE-OPERATION INSPECTION ……………………………… 17

5. OPERATION …………………………………………………… 22

6. STARTING THE ENGINE ……………………………………… 26

7. STOPPING THE ENGINE ……………………………………… 29

8. MAINTENANCE ……………………………………………… 31

9. STORAGE ……………………………………………………… 36

10. TROUBLESHOOTING ……………………………………… 37

11. ELECTRIC DIAGRAM ……………………………………… 39

12. SPECIFICATION ……………………………………………… 40

· 3 ·

1. SAFETY

Our company's water pump is designed to give safe and reliable service

if operated according to instructions. Read and understand the Owner’s

Manual before operating the water pump. Failure to do so could result in

personal injury or equipment damage.

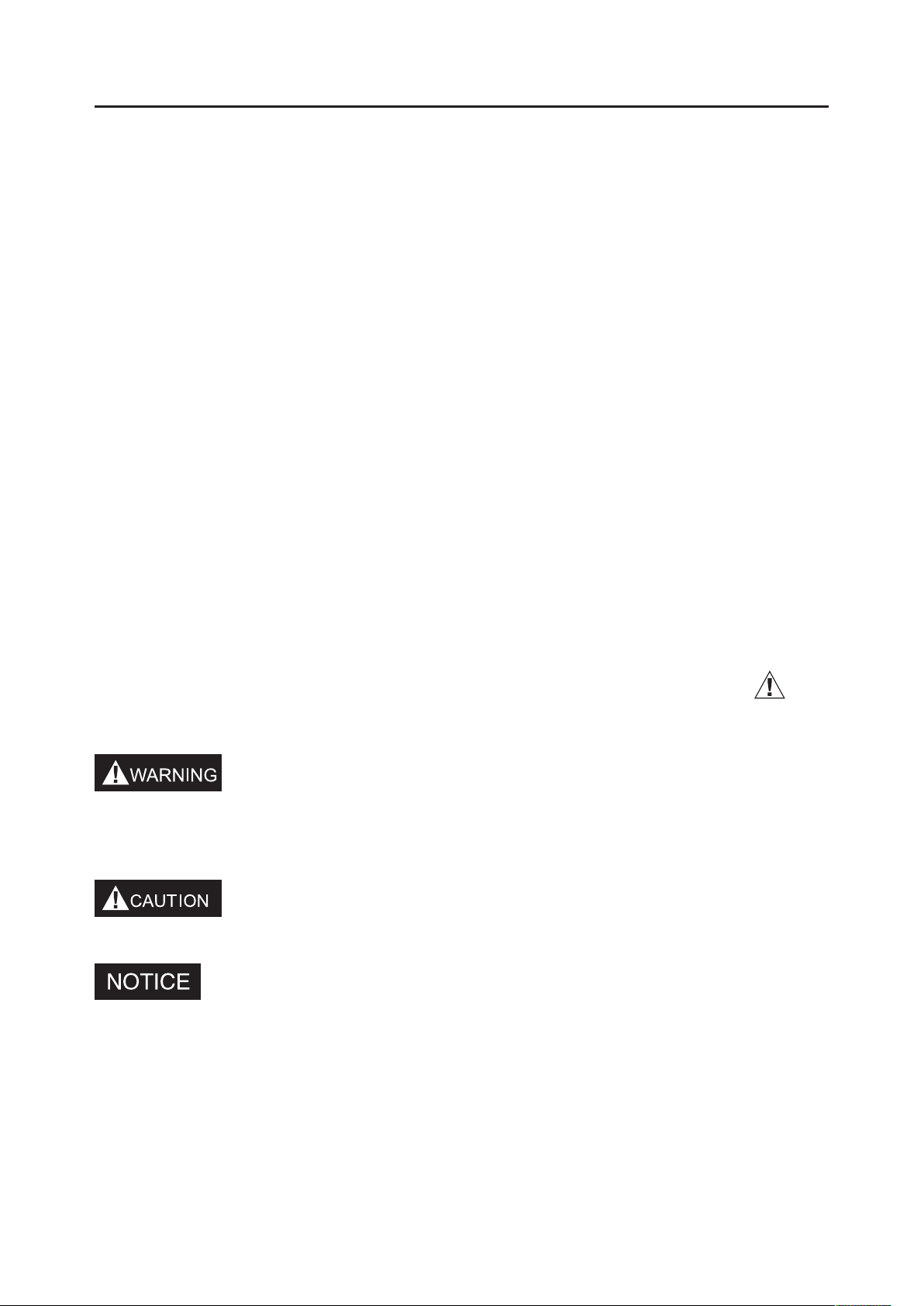

Safety Messages

Your safety and the safety of others are very important. We have provided

important safety messages in this manual and on water pump and engine.

Please read these messages carefully.

Safety label - on the water pump and engine.

A safety message - alerts you to potential hazards that could hurt you or

others. Each safety message is preceded by a safety alert symbol and

one of three words: WARNING, CAUTION, or NOTICE. These mean:

You CAN be KILLED or SERIOUSLY HURT if you don’t follow

instructions.

You CAN be HURT if you don’t follow instructions.

Your water pump or other property could be damaged if you don’t follow

instructions.

SAFETY

· 4 ·

1) Safety Instruction

Clean water pump and high pressure pump are only designed for

pumping clean water.

Sewage pump has the apability of transmiting soft solids within the

diameter of 25.4mm

Chemical pumps is used for transmission of weak acid and base (PH4-

11), high ignition temperature liquid and sea water.

Mud pump is suitable for pumping dirt water with up to 50% solid

sewerge,Capactiy up to diameter of 25.4mm.

To prevent fire hazards and to provide adequate ventilation, keep the

pump at least 1 meter away from each of the building walls and other

equipment during operation. Do not place flammable objects close to

transportation.

The muffler becomes very hot during operation and remains hot for a

it is hot. Let the engine cool before storing the water pump indoors.

and fuel storage area.

Place the pump on a firm, level surface. If the pump is tilted or

overturned, fuel spillage may result.

Refuel in a well-ventilated area with the engine stopped, and in places

for refueling or storing gasoline. If spilling occurs, immediately clean it.

After refueling, cover the fuel tank well and screw it down.

Exhaust contains poisonous carbon monoxide gas that can build up to

dangerous levels in closed areas. Breathing carbon monoxide can cause

unconsciousness or death.

Don’t screw off the plug while the engine is running to avoid damaging

SAFETY

· 5 ·

the equipment and hurting the persons.

Children and pets must be kept away from the area of operation due to a

possibility of burns from the hot engine components.

The machine is forbidden to be operated in a potentially explosive

atmosphere.

2) Safety Label

SAFETY

· 6 ·

SAFETY

· 7 ·

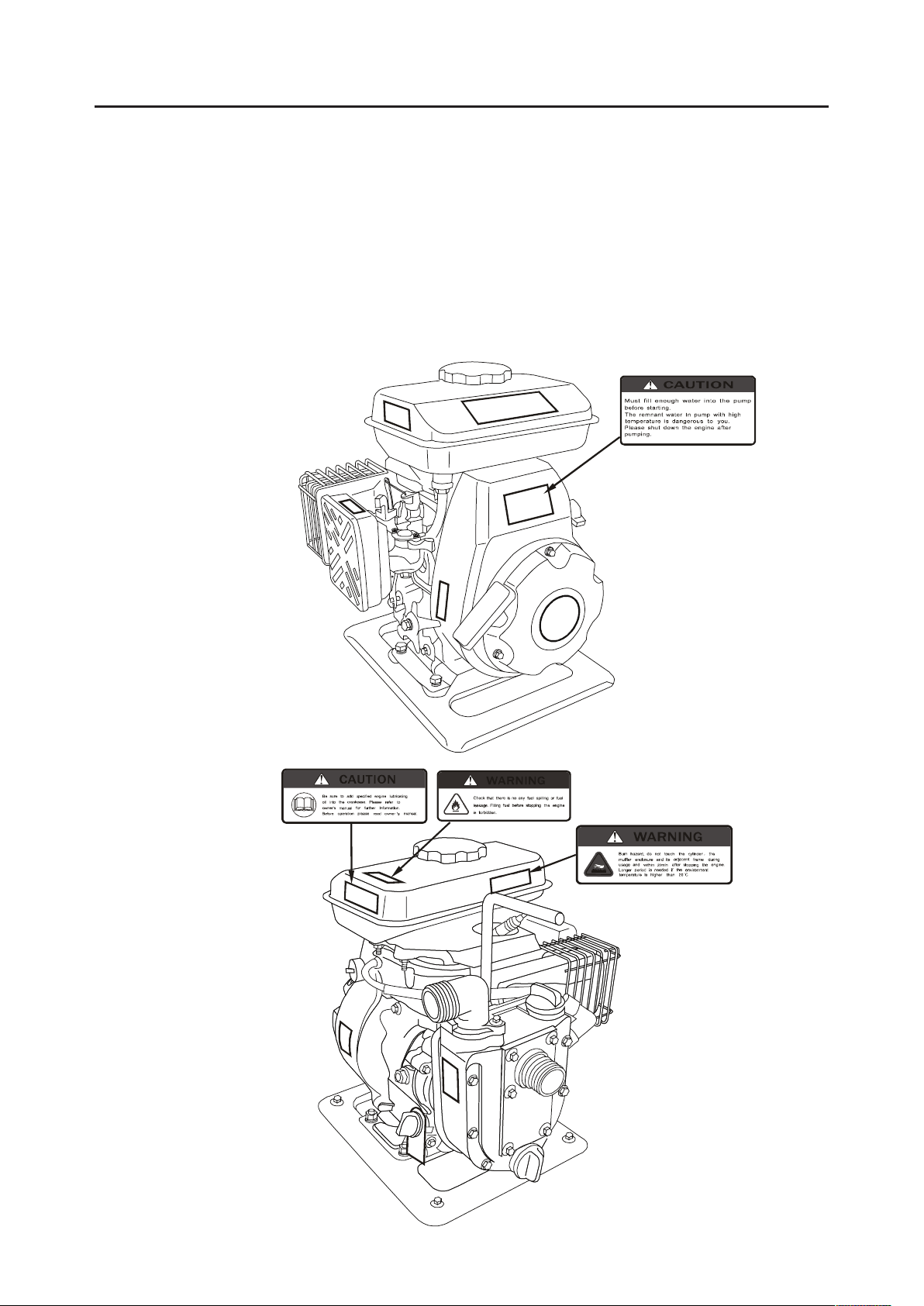

2. COMPONENT IDENTIFICATION

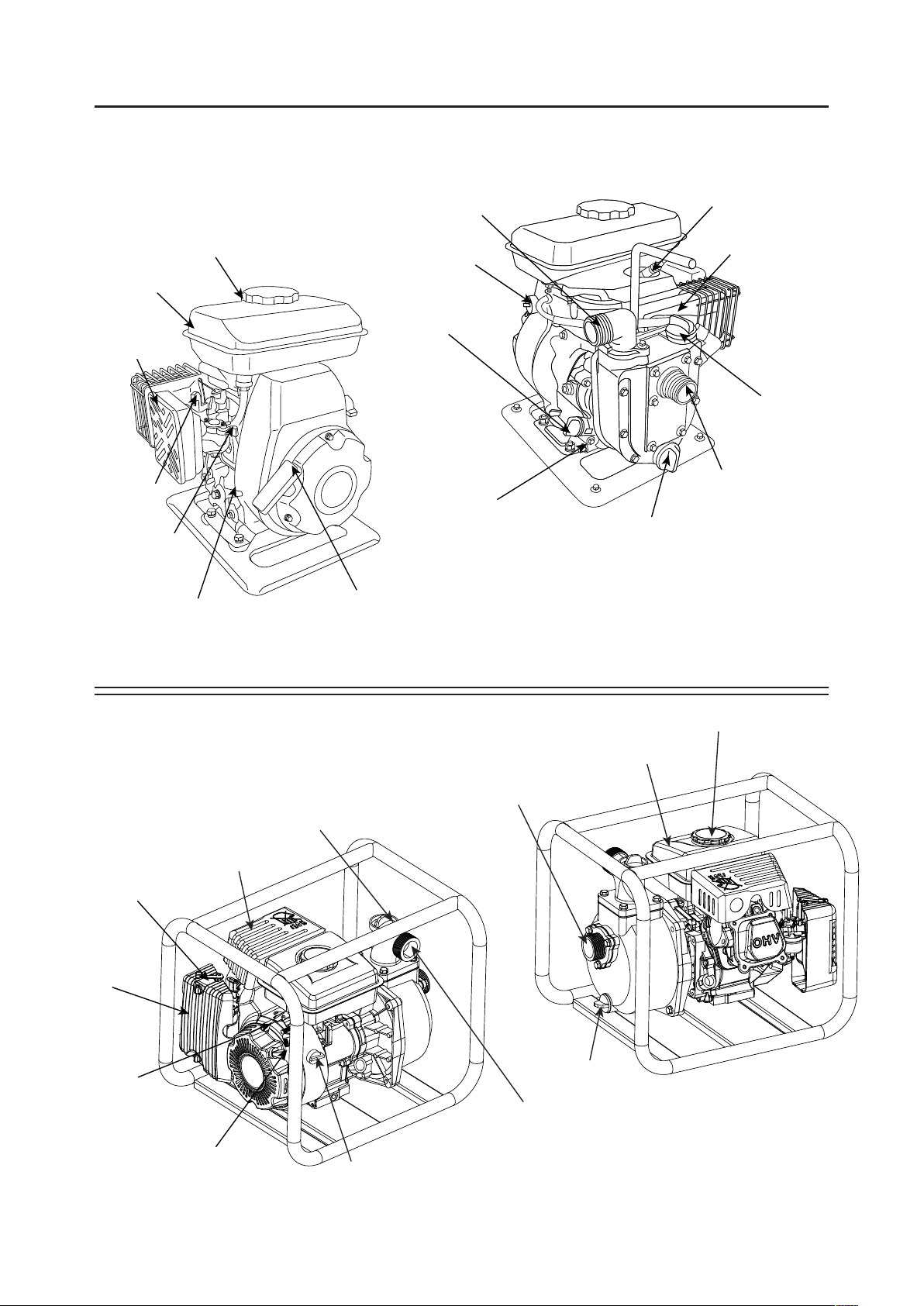

1" CLEAN WATER PUMP

COMPONENT IDENTIFICATION

· 8 ·

COMPONENT IDENTIFICATION

1.5" CLEAN WATER PUMP

AIR

FILTER

RECOIL

STARTER GRIP

CHOKE LEVER

MUFFLER

PRIMING WATER

FILTER CAP

DISCHARGE

PORT

FUEL TANK CAP

FUEL TANK

AIR FILTER

CHOKE

LEVER

FUEL

COCK

RECOIL STARTER GRIP

SPARK PLUG

MUFFLER

ENGINE SWITCH

OIL DIPSTICK

PUMP DRAIN PLUG

PRIMING WATER

FILTER CAP

SUCTION PORT

DISCHARGE PORT

OIL DRAIN PLUG

FUEL TANK

SUCTION PORT

PUMP

DRAIN PLUG

ENGINE SWITCH

FUEL TANK CAP

THROTTLE

LEVER

THROTTLE

LEVER

· 9 ·

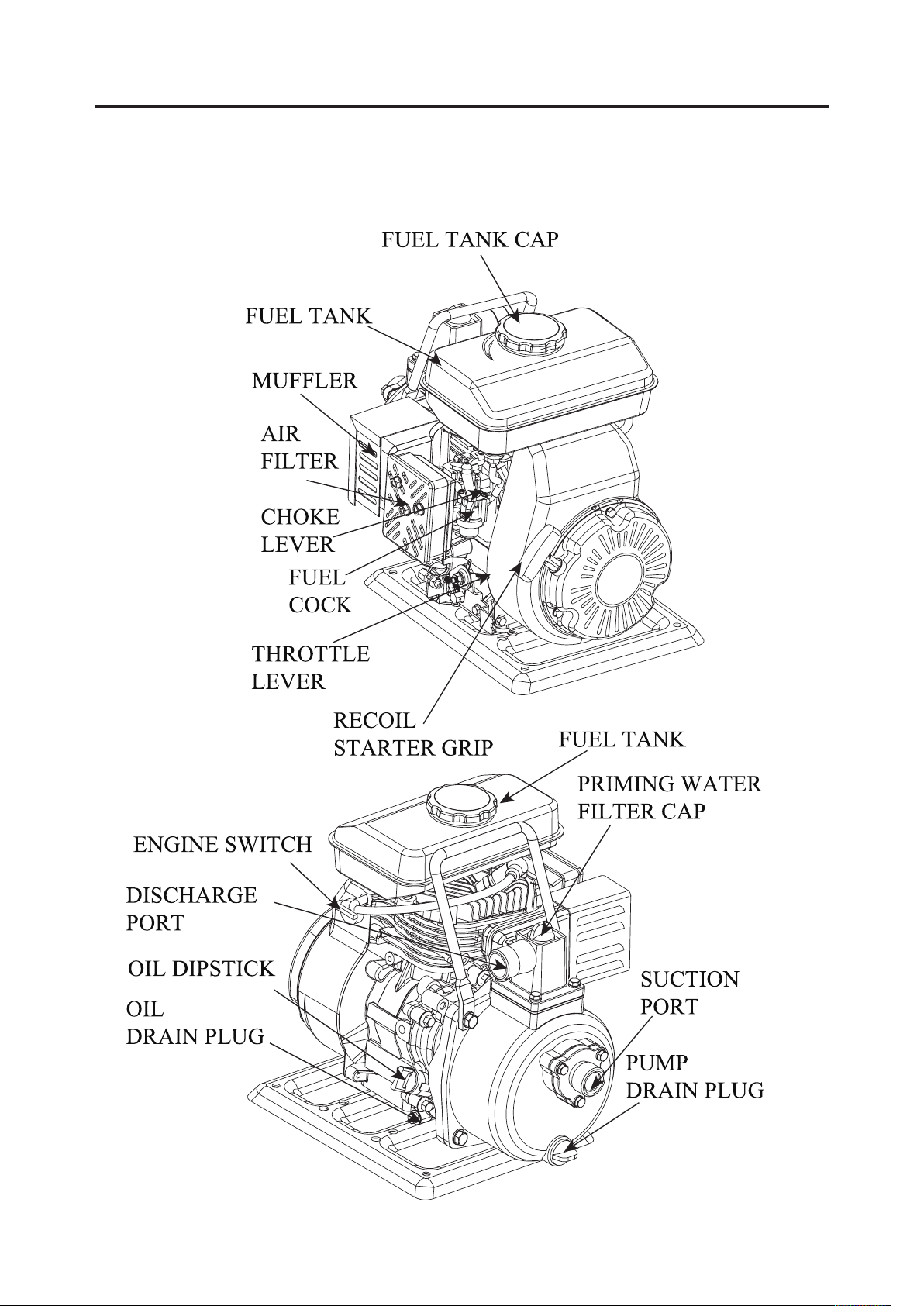

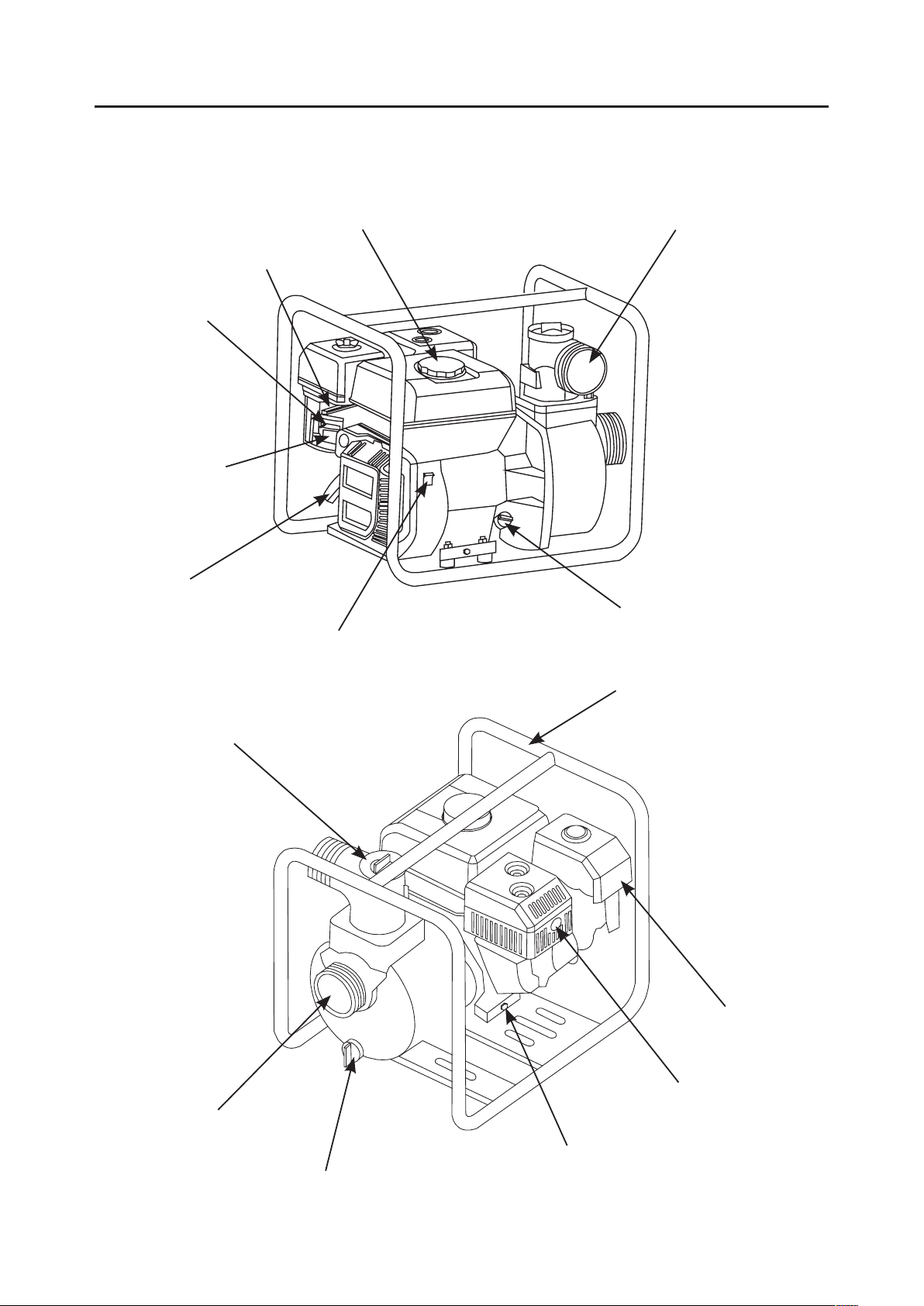

2"/3"/4"/6" CLEAN WATER PUMP

CHOKE LEVER

FUEL TANK CAP

THROTTLE LEVER

DISCHARGE PORT

OIL DIPSTICK

ENGINE SWITCH

RECOIL STARTER GRIP

FUEL COCK

PRIMING WATER FILTER CAP

FRAME

AIR FILTER

MUFFLER

OIL DRAIN PLUG

PUMP DRAIN PLUG

SUCTION PORT

COMPONENT IDENTIFICATION

· 10 ·

CHEMICAL PUMP

CHOKE LEVER

FUEL VALVE

FUEL TANK CAP

THROTTLE

LEVER

DISCHARGE PORT

OIL DIPSTICK

ENGINE SWITCH

RECOIL STARTER

GRIP

PRIMING WATER FILTER CAP

FRAME

AIR FILTER

MUFFLER

OIL DRAIN PLUG

PUMP

DRAIN PLUG

SUCTION PORT

COMPONENT IDENTIFICATION

· 11 ·

HIGH PRESSURE PUMP( The illustrations employ the

2" high pressure pump as the example)

CHOKE

LEVER

FUEL

VALVE

FUEL TANK CAP

THROTTLE

LEVER

DISCHARGE

PORT

OIL DIPSTICK

ENGINE SWITCH

RECOIL STARTER

GRIP

OIL DRAIN PLUG

COMPONENT IDENTIFICATION

PRIMING WATER

FILTER CAP

FRAME

AIR

FILTER

MUFFLER

PUMP

DRAIN PLUG

SUCTION

PORT

CHOKE

LEVER

FUEL

VALVE

FUEL TANK CAP

THROTTLE

LEVER

PRIMING WATER

FILTER CAP

OIL DIPSTICK

ENGINE SWITCH

RECOIL STARTER

GRIP

OIL DRAIN PLUG

DISCHARGE

PORT

FRAME

AIR FILTER

MUFFLER

PUMP

DRAIN PLUG

SUCTION

PORT

· 12 ·

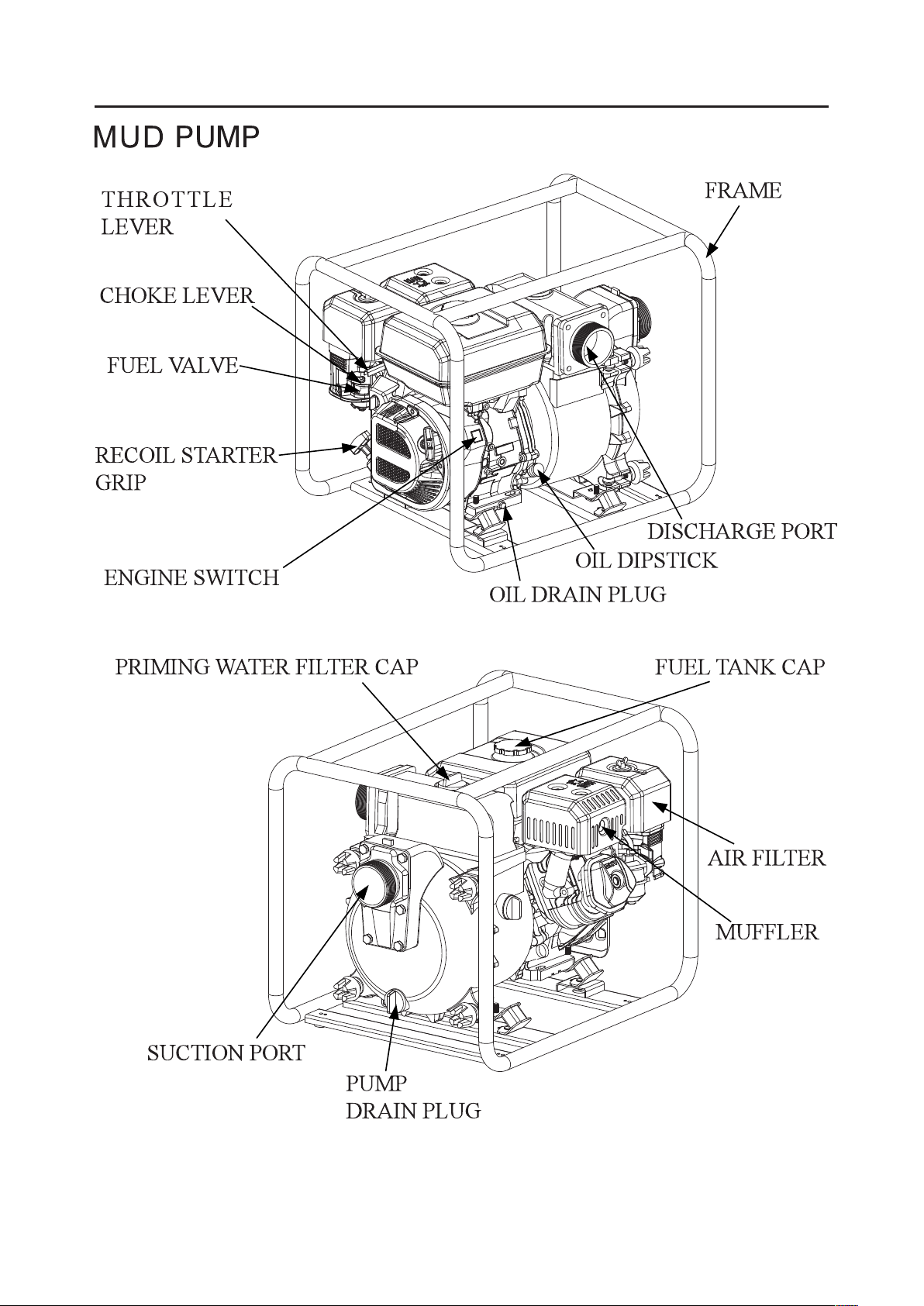

SEWAGE PUMP

CHOKE LEVER

FUEL VALVE

FUEL TANK CAP

THROTTLE

LEVER

DISCHARGE PORT

OIL DIPSTICK

ENGINE SWITCH

RECOIL STARTER

GRIP

PRIMING WATER FILTER CAP

FRAME

AIR FILTER

MUFFLER

OIL DRAIN PLUG

PUMP

DRAIN PLUG

SUCTION PORT

COMPONENT IDENTIFICATION

· 13 ·

COMPONENT IDENTIFICATION

· 14 ·

3. CONTROL SYSTEM

Before operating our company's water pump, carefully read and

understand the owner’s manual and be familiar with each control

function. Know how to operate and how to do in a urgency condition.

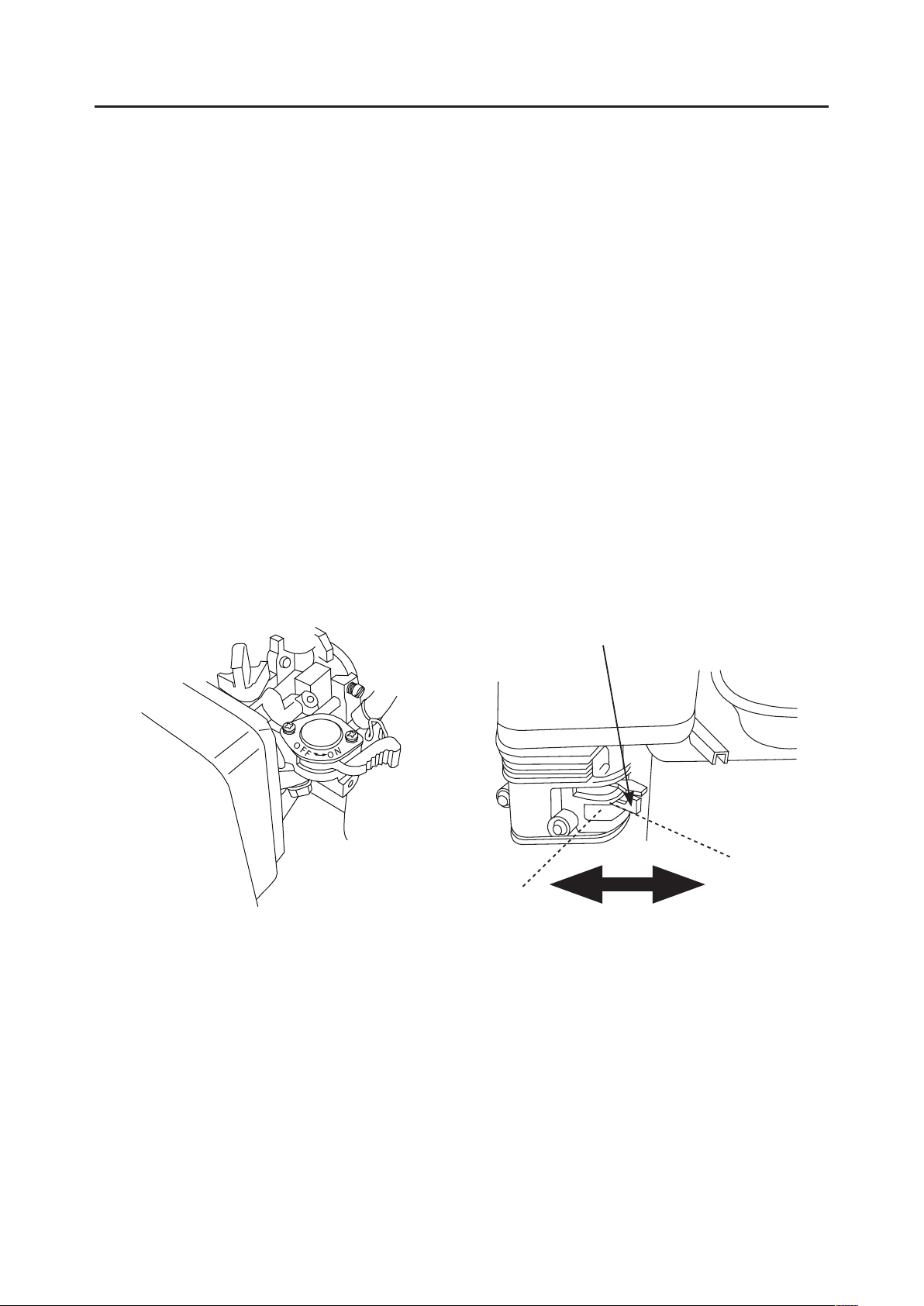

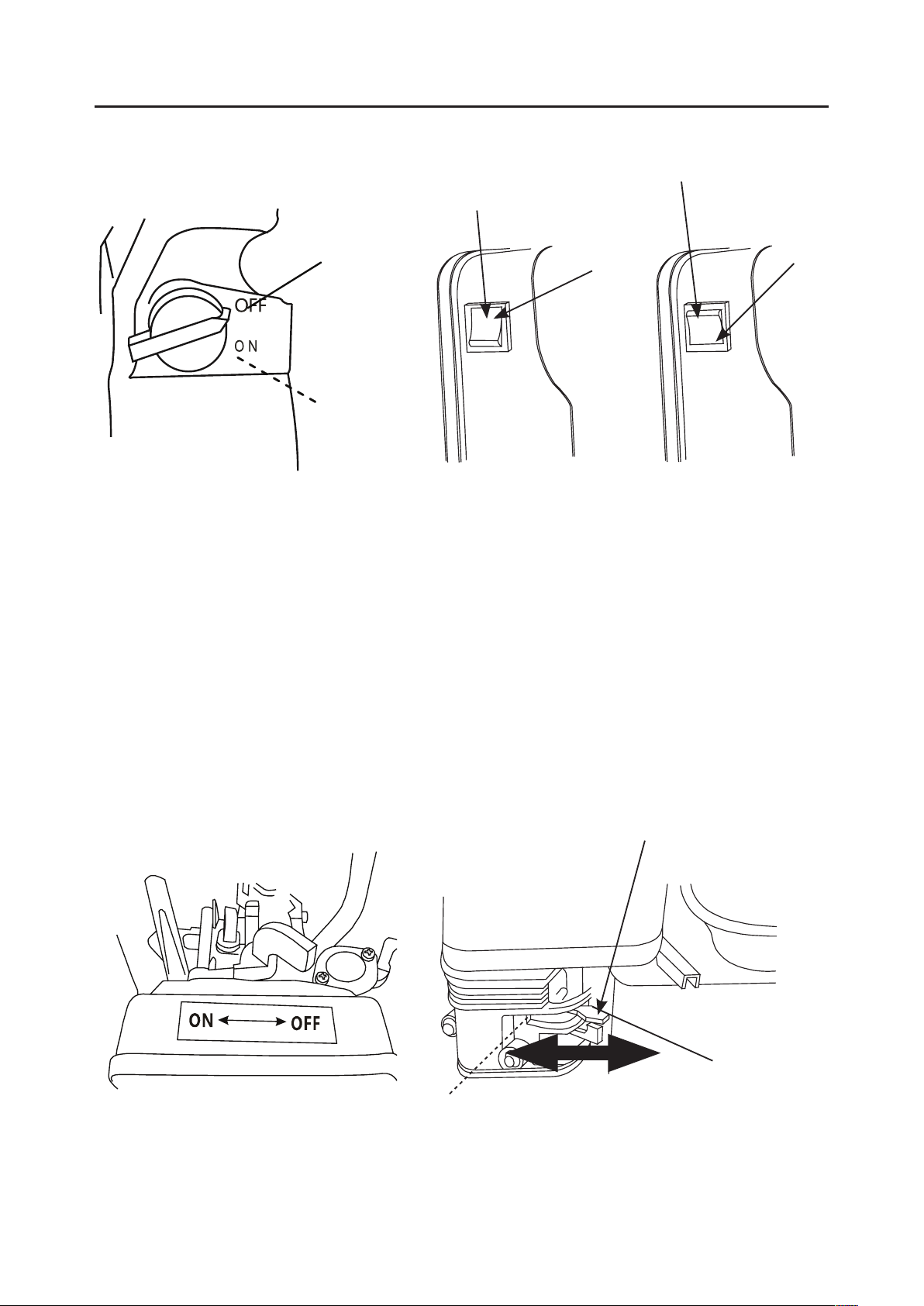

1) Fuel Lever

Set the fuel lever to the “OPEN” position.

When not operating the engine, set the fuel lever to the “CLOSE”

position.

2) Engine Switch

The engine switch is used for opening or closing ignition circuit :

Set the engine switch to the “OPEN” position to run the engine, and set it

to the “CLOSE” position to stop the engine.

FUEL LEVER

CLOSE

OPEN

CONTROL SYSTEM

· 15 ·

3) Choke Lever

The choke lever is used for opening and closing the choke of the

carburetor.

Set the choke lever to the “CLOSE” position for cold starting.

Set the choke lever to the “OPEN” position for normal operation or the

Engine's warm starting.

OPEN

OPEN

CLOSE

CLOSE

ENGINE SWITCH

ENGINE SWITCH

CHOKE LEVER

CLOSE

OPEN

CONTROL SYSTEM

· 16 ·

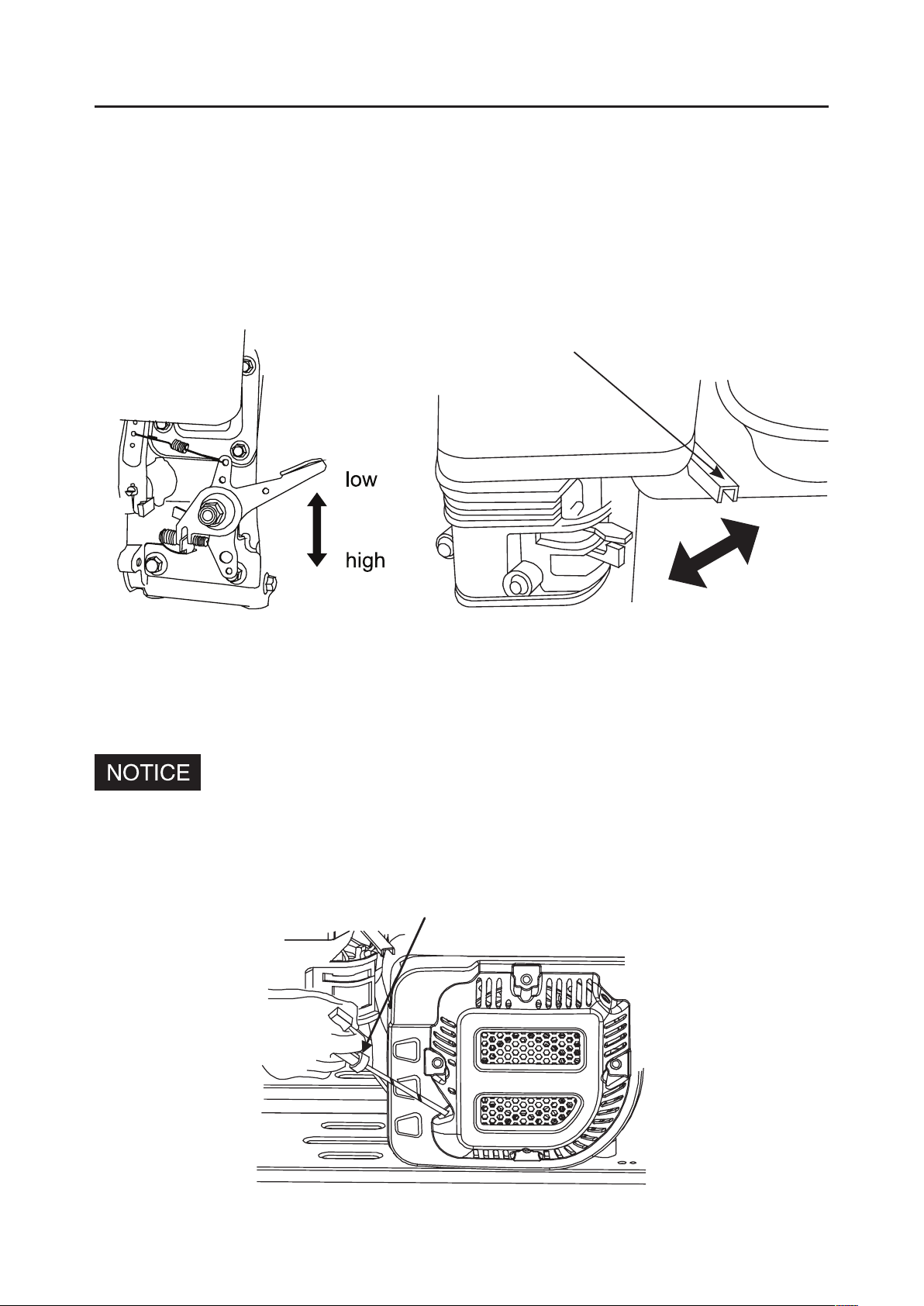

4) Throttle Lever

Adjust the throttle lever to change speed of the engine, thereby adjust the

discharge water. For a bigger water discharge, set the throttle lever to the

HIGH position, for a smaller water discharge, set the throttle lever to the

LOW position.

5) Recoil Starter

Pull the recoil starter to start the engine.

Don’t allow the starter grip to snap back against the engine. Return

it gently to prevent damage to the starter

STARTER GRIP

CONTROL SYSTEM

THROTTLE LEVER

HIGH

LOW

· 17 ·

4. PRE-OPERATION INSPECTION

For your safety and to maximize the service life of your equipment, it is

very important to take a few moments before you operate the pump to

your servicing dealer correct it, before you operate the pump.

Improperly maintaining this pump or failing to correct problems

before operation could cause a malfunction in which you could be

seriously injured.

Exhaust gas contains poisonous carbon monoxide. Avoid inhalation of

exhaust gas. Never run the engine in a closed garage or an enclosed area.

To prevent fire hazards, keep the pump at least 1m away from each of

the building walls and other equipment during operation. Do not place

Before beginning your pre-operation checks, be sure the pump is on a

level surface and the ignition switch is in the OFF position.

1) Routine Check

Look around and underneath the pump for signs of oil or gasoline leaks.

Remove any excessive dirt or debris, especially from around the engine

Look for signs of damage.

are tightened.

PRE-OPERATION INSPECTION

· 18 ·

2) Check The Suction And Discharge Hoses

Check the general condition of the hoses. Be sure the hoses are in

serviceable condition before connecting them to the pump. Remember

that the suction hose must be of a reinforced construction to prevent hose

collapse.

Check to ensure that the sealing washer in the suction hose connector is

in a good condition.

Check to ensure that the hose connectors and clamps are securely

installed.

Check to ensure that the strainer is in a good condition and is installed on

the suction hose.

3) Check Engine Oil

Put the engine on a level place and check the engine oil.

screwing it in.

3) If the level is low, add the recommended oil to the upper mark on the

dipstick.

PRE-OPERATION INSPECTION

This manual suits for next models

4

Table of contents

Popular Water Pump manuals by other brands

Uponor

Uponor CPG Mounting instructions

Grundfos

Grundfos PS.R.05 Installation and operating instructions

Flotec

Flotec FPSC2150A owner's manual

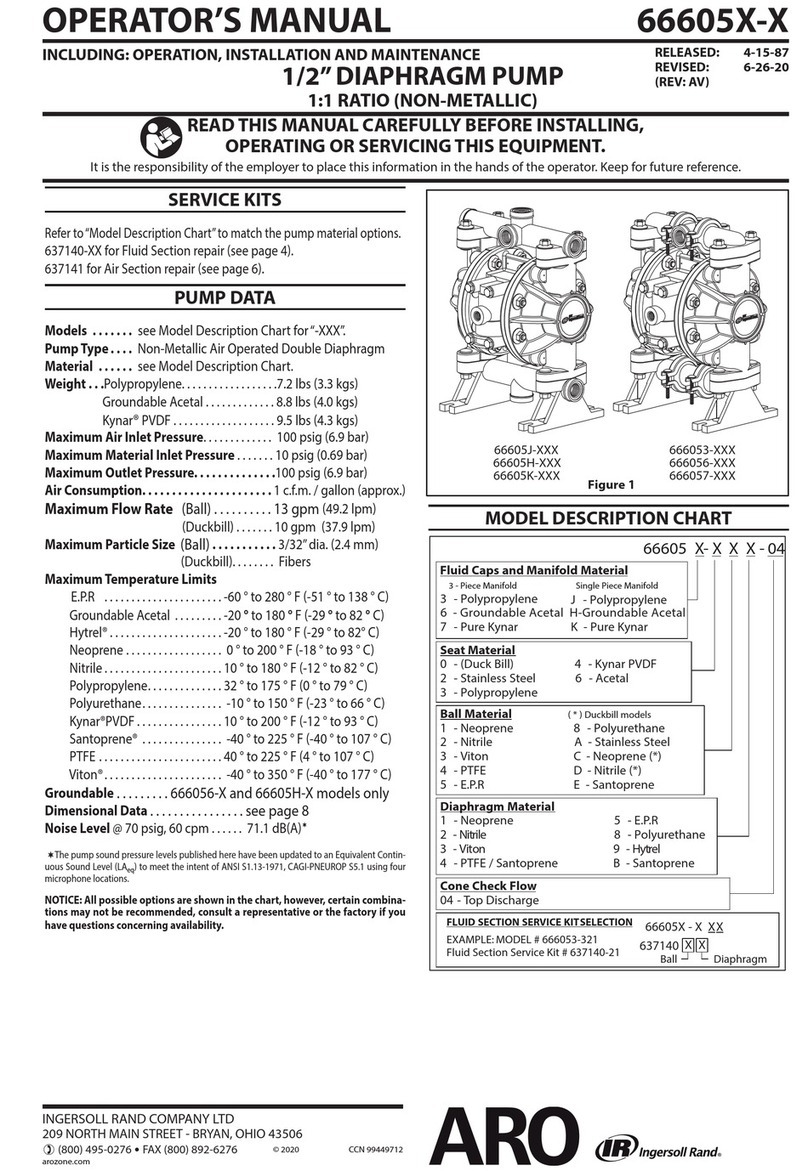

Ingersoll-Rand

Ingersoll-Rand ARO 66605 Series Operator's manual

Pfeiffer Vacuum

Pfeiffer Vacuum HIPACE 2300 I operating instructions

Salamander

Salamander RGP installation guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS D Series Installation, operation, and maintenance manual with parts list

KSB

KSB Delta Macro F Installation & operating manual

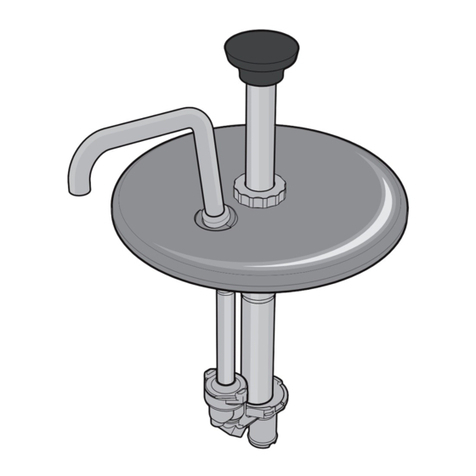

Server

Server CP-MEC3 manual

Wilden

Wilden PS 4 Stallion Metal Engineering, operation & maintenance

IBO

IBO IVO 25-40/180 manual

Barmesa Pumps

Barmesa Pumps BMV Series Installation, operation & maintenance manual