Thorne & Derrick VEGAPULS 67 User manual

Operating Instructions

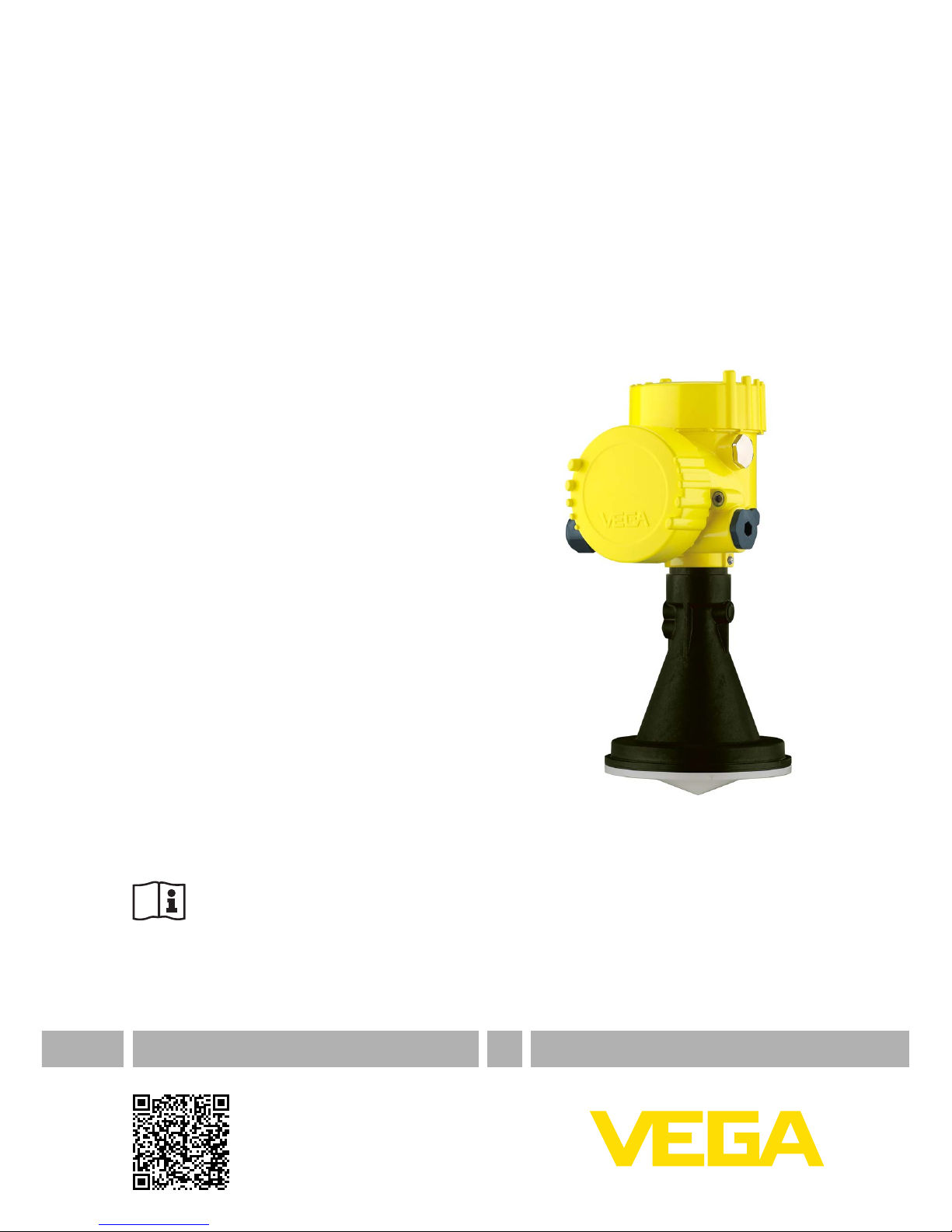

VEGAPULS 67

4 … 20 mA/HART - four-wire

Document ID: 32939

2

Contents

VEGAPULS 67 • 4 … 20 mA/HART - four-wire

32939-EN-150630

Contents

1 About this document

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Safety label on the instrument .......................................................................................... 5

2.6 CE conformity................................................................................................................... 6

2.7 FulllmentofNAMURrecommendations ......................................................................... 6

2.8 FCC/IC conformity (only for USA/Canada) ....................................................................... 6

2.9 Environmental instructions ............................................................................................... 7

3 Product description

3.1 Conguration.................................................................................................................... 8

3.2 Principle of operation........................................................................................................ 9

3.3 Packaging, transport and storage................................................................................... 10

3.4 Accessories and replacement parts ............................................................................... 11

4 Mounting

4.1 General instructions ....................................................................................................... 13

4.2 Mountingpreparation ..................................................................................................... 15

4.3 Mountinginstructions ..................................................................................................... 17

5 Connecting to power supply

5.1 Preparing the connection ............................................................................................... 22

5.2 Connection procedure.................................................................................................... 23

5.3 Wiring plan, double chamber housing ............................................................................ 24

5.4 Switch-on phase............................................................................................................. 26

6 Set up with the display and adjustment module PLICSCOM

6.1 Short description ............................................................................................................ 27

6.2 Insert display and adjustment module............................................................................ 27

6.3 Adjustment system......................................................................................................... 28

6.4 Setup steps .................................................................................................................... 29

6.5 Menuschematic............................................................................................................. 41

6.10 Saving the parameter adjustment data........................................................................... 43

7 Set up with PACTware and other adjustment programs

7.1 Connect the PC via VEGACONNECT ............................................................................ 44

7.2 Parameter adjustment with PACTware............................................................................ 45

7.3 ParameteradjustmentwithAMS™andPDM................................................................. 46

7.4 Saving the parameter adjustment data........................................................................... 47

8 Maintenanceandfaultrectication

8.1 Maintenance,cleaning ................................................................................................... 48

8.2 Rectify faults................................................................................................................... 48

8.3 Exchanging the electronics module................................................................................ 49

8.4 Software update ............................................................................................................. 50

3

Contents

VEGAPULS 67 • 4 … 20 mA/HART - four-wire

32939-EN-150630

8.5 How to proceed if a repair is necessary.......................................................................... 50

9 Dismount

9.1 Dismounting steps.......................................................................................................... 51

9.2 Disposal ......................................................................................................................... 51

10 Supplement

10.1 Technical data ................................................................................................................ 52

10.2 Dimensions .................................................................................................................... 56

Safety instructions for Ex areas

TakenoteoftheExspecicsafetyinstructionsforExapplications.

These instructions are attached as documents to each instrument

with Ex approval and are part of the operating instructions manual.

Editing status: 2015-06-26

4

1 About this document

VEGAPULS 67 • 4 … 20 mA/HART - four-wire

32939-EN-150630

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important instruc-

tionsformaintenanceandfaultrectication.Pleasereadthisinforma-

tion before putting the instrument into operation and keep this manual

accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained specialist

personnel.The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbols used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

SIL applications

This symbol indicates instructions for functional safety which must be

taken into account particularly for safety-relevant applications.

• List

The dot set in front indicates a list with no implied sequence.

→ Action

This arrow indicates a single action.

1 Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of bat-

teries and accumulators.

5

2 For your safety

VEGAPULS 67 • 4 … 20 mA/HART - four-wire

32939-EN-150630

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must

be carried out only by trained specialist personnel authorised by the

plant operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

VEGAPULS 67 is a sensor for continuous level measurement.

Youcannddetailedinformationabouttheareaofapplicationin

chapter "Product description".

Operational reliability is ensured only if the instrument is properly

usedaccordingtothespecicationsintheoperatinginstructions

manual as well as possible supplementary instructions.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbi-

traryconversionsormodicationsareexplicitlyforbidden.

2.3 Warning about incorrect use

Inappropriate or incorrect use of the instrument can give rise to

application-specichazards,e.g.vesseloverllordamagetosystem

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a high-tech instrument requiring the strict observance of stand-

ard regulations and guidelines.The user must take note of the safety

instructionsinthisoperatinginstructionsmanual,thecountry-specic

installation standards as well as all prevailing safety regulations and

accident prevention rules.

Depending on the model, the emitting frequencies of all radar sensors

are either in the C or K band range.The low transmitting power lies far

below the internationally permitted limit values.When the instrument

is used correctly, it presents no danger to human health. It may be

operated without restriction outside of closed metallic vessels.

Theinstrumentmustonlybeoperatedinatechnicallyawlessand

reliable condition.The operator is responsible for trouble-free opera-

tion of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the necessary occupational safety measures with the

current valid rules and regulations and also take note of new regula-

tions.

2.5 Safety label on the instrument

The safety approval markings and safety tips on the device must be

observed.

Table of contents