Throwdown CORE HEALTH & FITNESS ALPHA XTC WR1 User manual

OWNER'S

MANUAL

CORE HEALTH & FITNESS

ALPHA XTC WR1 & WR2

Page 1

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS................................................................................................................2

IMPORTANT LABEL LOCATIONS ........................................................................................................................4

ASSEMBLY ........................................................................................................................6

MAINTENANCE ......................................................................................................................11

TOOLS ................................................................. 11

MAINTENANCE SCHEDULE ................................................................. 12

SUPPORT & SERVICE ......................................................................................................................13

Page 2

Before using this product, it is essential to read the ENTIRE Owner’s Manual and ALL

installation instructions. The Owner’s Manual describes equipment assembly and instructs

members on how to use correctly and safely.

Read all warnings posted on the machine.

Health related injuries may result from incorrect or excessive use of exercise equipment.

Core Health & Fitness strongly recommends you to encourage your members to discuss their

health program or fitness regimen with a health care professional, especially if you or they

have not exercised for several years, are over 35, or have known health conditions.

WARNING!

WARNING: to reduce the risk of serious injury to

persons using this equipment, read and follow all of

these warnings:

24 in (0.6 m)

Fig. 1 Required Clearance (WR1 Shown)

1. Assemble and operate the unit on a solid level

surface. Position the machine with a minimum of

24 inches (0.6 meters) of clearance on one side

to allow for ease of mounting and dismounting.

Leave a minimum of 19.7 inches (0.5 meters)

between two adjacent units. These dimensions

are the recommended minimum distances.

The actual area for access and passage shall be

the responsibility of the facility and should take

into account this training envelope, Americans

with Disabilities Act Accessibility Guidelines

(ADAAG) requirements and any required local

codes or regulations (www.access-board.gov/

ada).

2. This equipment is designed for use in a

commercial gymnasium or health club. To ensure

the proper use of the equipment in a safe manner,

all users of the equipment should read this

manual before using the machine. This machine

should be made a part of your club training

program in order that the equipment is used by

your members in a safe manner as intended. In

addition to instructing the club members in the

proper use of the equipment, the club member

should obtain a complete physical examination

form their health care provider before beginning

any exercise program.

3. The safety and integrity of this machine can only

be maintained when the equipment is regularly

examined for damage and wear and repaired.

It is the sole responsibility of the owner of this

equipment to ensure that regular maintenance

is performed. Worn or damaged parts must be

replaced immediately or the equipment removed

from service until the repair is made.

4. Use only replacement components supplied by

Throwdown. Substitutes are forbidden and will

void all warranties.

5. This machine is not intended to be used by

persons with reduced physical, sensory, or

mental capabilities or lack of experience and

knowledge, unless given instruction and under

the personal supervision concerning use of the

machine by a person responsible for their safety.

6. Keep children away.

7. Wear proper exercise clothing and athletic shoes

during a workout. Avoid wearing loose clothing.

Tie back long hair and keep towels away from the

moving parts.

IMPORTANT SAFETY INSTRUCTIONS

Page 3

8. Do not over exert yourself during exercise. Stop

exercising if you feel pain or tightness in your

chest, become short of breath or feel faint. If you

feel pain or experience any abnormal symptoms,

stop exercising and consult your health care

provider.

9. It is the purchaser’s sole responsibility to properly

instruct its end users and supervising personnel

as to the proper operating procedures of all

Throwdown equipment.

SAVE THESE INSTRUCTIONS

Page 4

This page shows the location of the warning labels and communication stickers placed on the equipment as part of the manufacturing process. It is critical that

owners maintain the integrity and placement of these stickers. If you find any stickers missing or damaged the replacement numbers are shown on the support

site and following pages. See Support and Service to order replacements.

12-00212

81-00016

81-00005

Serial Label

Serial Label

Fig. 2

IMPORTANT LABEL LOCATIONS

SKU: TD-WR1-XXXXX Desc: Weight Room 1 SKU: TD-WR2-XXXXX Desc: Weight Room 2

Unit Weight Width Length Height

642 lbs

291 kg

69.6 in

177 cm

54.6 in

138 cm

105.5 in

268 cm

Unit Weight Width Length Height

595 lbs

270 kg

68.9 in

175 cm

56.7 in

144 cm

105.5 in

268 cm

Page 5

81-00005

THROWDOWN VERTICAL LOGO

81-00016

STICKER,WARNING,LANDMINE

12-00212

STICKER, PINCH POINT

Notice: images are not to scale

Page 6

All equipment MUST be secured

(bolted and tightened) to a solid, level

surface, using all of the anchoring

holes provided, to stabilize and

eliminate rocking or tipping over. Shim

any mounting surface that does not

rest thoroughly on the floor using flat

washers, DO NOT force the foot to

contact the ground with anchors.

Fasteners must have a minimum of 500 lbs. tensile capacity, be a bolt of grade 2 or better and be installed per

the bolt manufacturer’s specifications.

Due to the wide variety of flooring on which equipment may be anchored or installed and differences in

applicable local building codes, Core Health & Fitness is not responsible for any damage to the flooring that

may result due to anchoring or installing equipment to the floor and for compliance with local building codes.

Only licensed contractors or certified installers should be used to insure proper anchoring, installation, and

compliance with local building code.

Required Tools:

• Metric Allen Key Set

• Loctite Blue1

• Torque Wrench

• Metric Open-Ended Wrench Set

• Large Adjustable Crescent Wrench

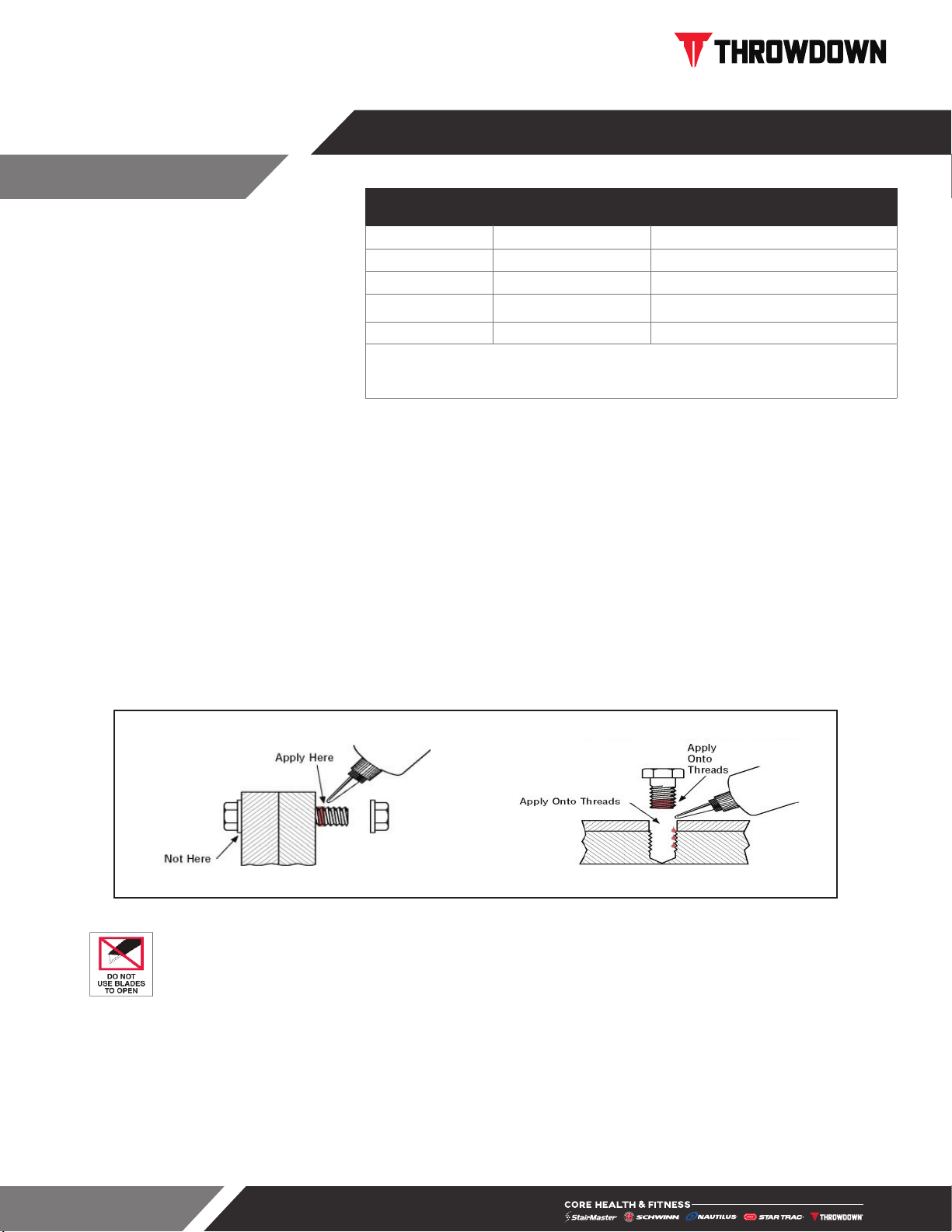

THREAD LOCKER APPLICATION: Clean all threads and holes, apply no more than 3-4 drops per bolt.

Thru Holes Blind Holes

PACKAGING REMOVAL:

Unit is heavy and requires two people for assembly.

Carefully remove all packaging materials that wrap the equipment.

DO NOT USE A KNIFE OR BOX CUTTER AS YOU MAY DAMAGE THE EQUIPMENT.

At this time remove any sub-components from the pallet and set aside for later assembly. Once all packaging

has been removed, lay all parts out in a clean open area to prepare for assembly. Should any component not

be present or if you have any operational questions, please refer to SUPPORT & SERVICE

After assembly, a complete visual inspection, and test of the features and functions of the assembled unit must

be made prior to use.

ASSEMBLY

Metric Steel Bolts Torque Specifications

Bolt Size Thread Pitch Torque, N-m (lbs-ft)

6mm 1.25 10 to13.5 (8 to10)

8mm 1.25 25.5 to 28.5 (19 to 21)

10mm 1.75 55.5 to 58 (41 to 43)

12mm 1.25 61 to 65 (45 to 48)

• Torque all hardware to values as specified above, unless noted otherwise.

• See procedure of this manual for fastener sizing information; for reference only.

Note: All torque values are in N-m unless otherwise stated.

Page 7

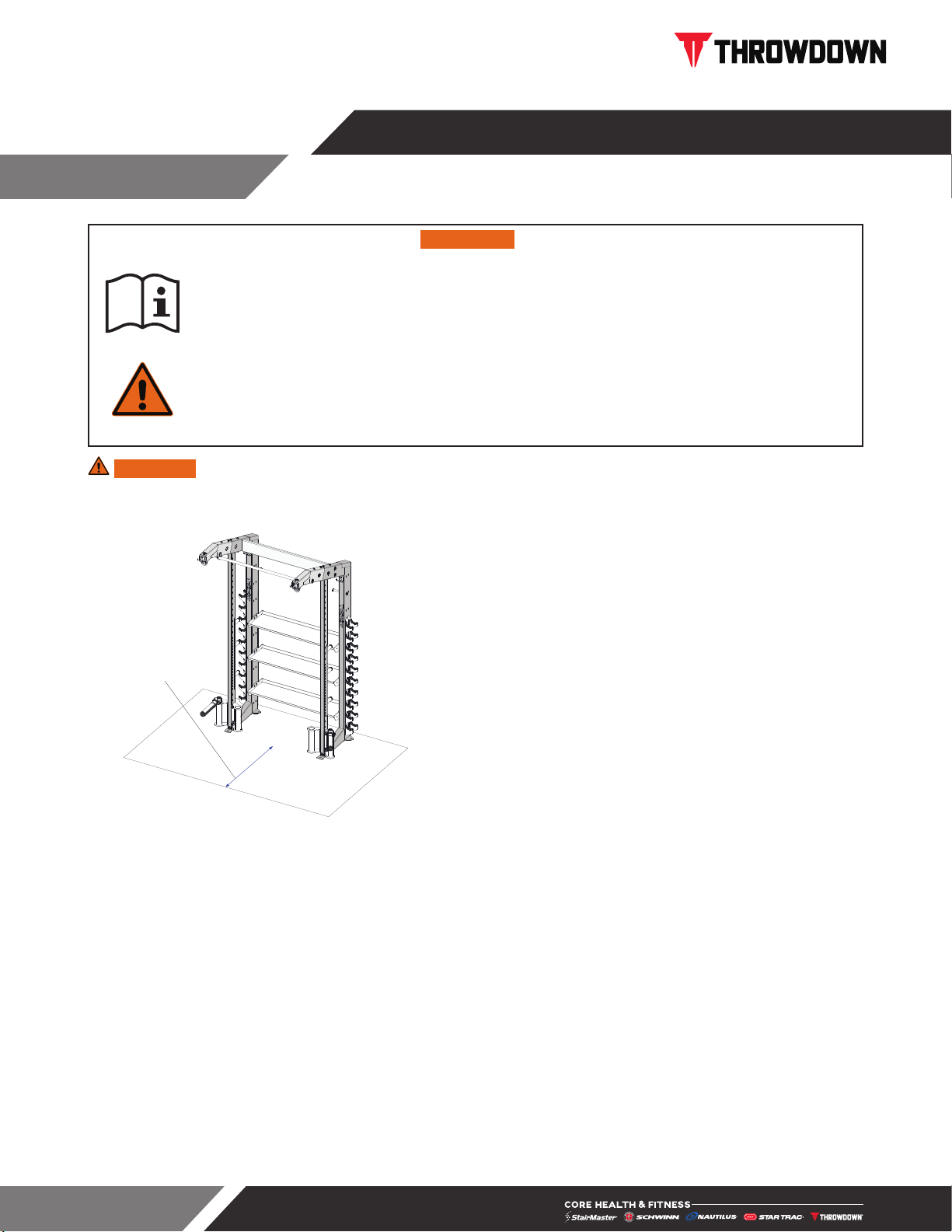

TD-WR1 PROCEDURE

1. Slide the rack side upper hanger

assemblies 73-00161-XX onto the

two side frames then secure with

one bolt set in the side, and two of

the M12x1.75,30mm bolts (31-

00392) and two washers 31-00267

top and bottom.

Note: Many accessories and

supports are attached with large

bolt sets consisting of one each

M12 x 90 Flat Head Bolt (31-

00396), a bolt washer (11-00811)

and a bolt nut (11-00810).

11-00810

11-00811

31-00396

73-00161-XX

31-00267

31-00392

Fig. 3

2. Prior to standing frames up attach

the shelving and the vertical

dumbell racks to the frame in

using six large bolt sets per side.

3. Attach the upper stabilizer to

the frames with two large bolt sets

per side.

4. Stand frame up and fully tighten all

hardware.

Fig. 4

Page 8

71-00267-XX

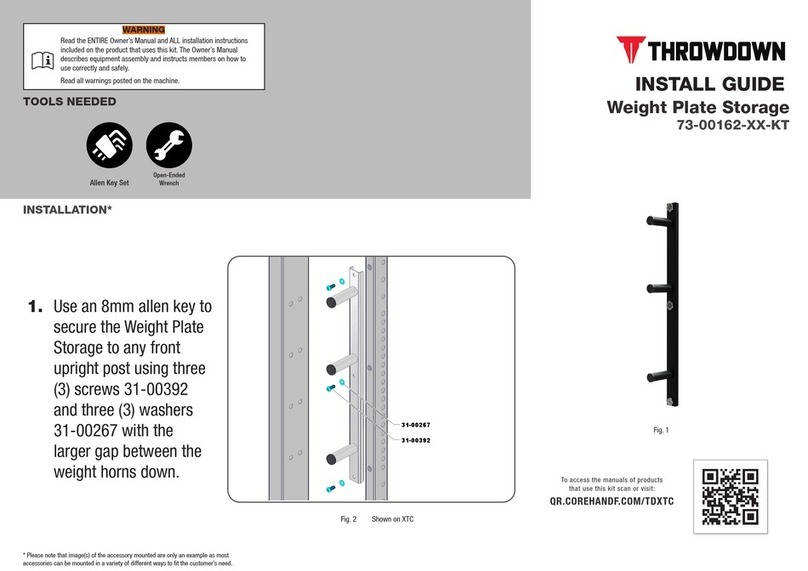

73-00163

73-00162

73-00164-XX

52-00260-XX

52-00261

Fig. 5

5. Attach pull-up bar assembly (52-00260-XX) at top of unit using one large bolt set per side.

6. Attach all 4 Double-J hooks (52-00261) to the frame using two M12x1.75,30mm bolts (31-00392) and

washers 31-00267 each.

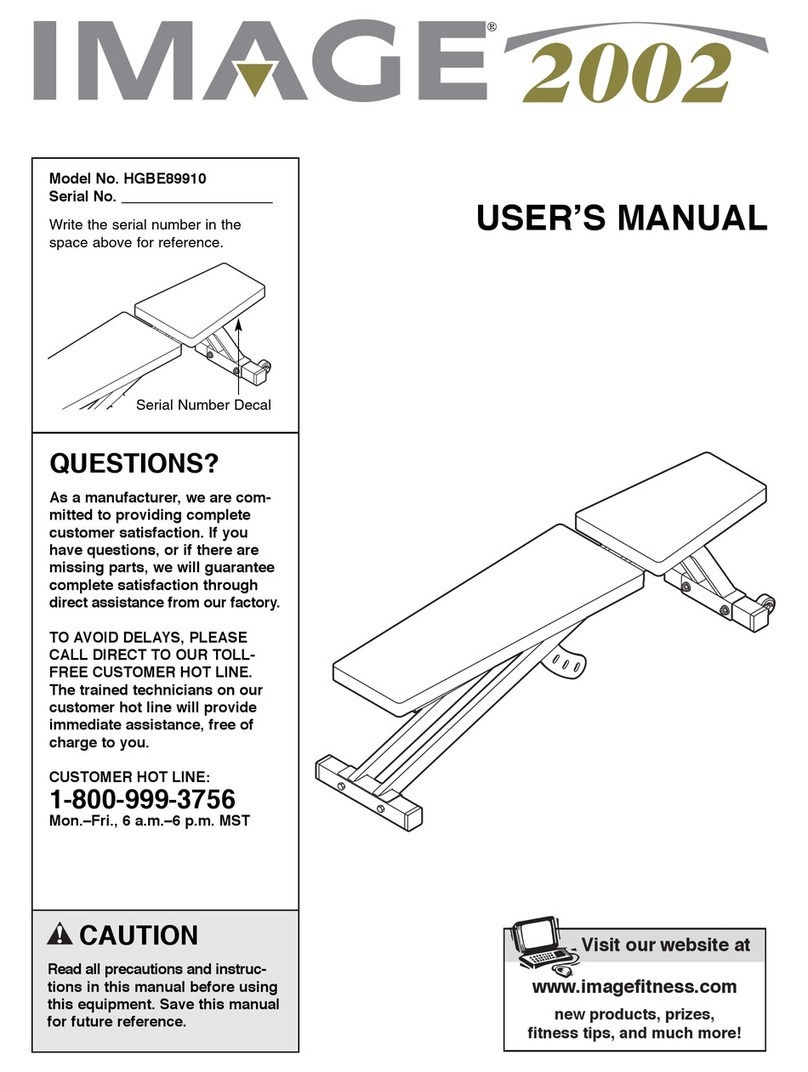

7. Attach the weight plate storage hangars (73-00162) using three M12x1.75,30mm bolts (31-00392) and

washers 31-00267 each.

8. Install the Oly Bar kits (71-00267-XX) at the bottom of the unit with two large bolt sets each. The Landmine

accessory (73-00163) goes into the Oly Bar kits.

9. Fully tighten all hardware.

10. Assembly is complete.

Page 9

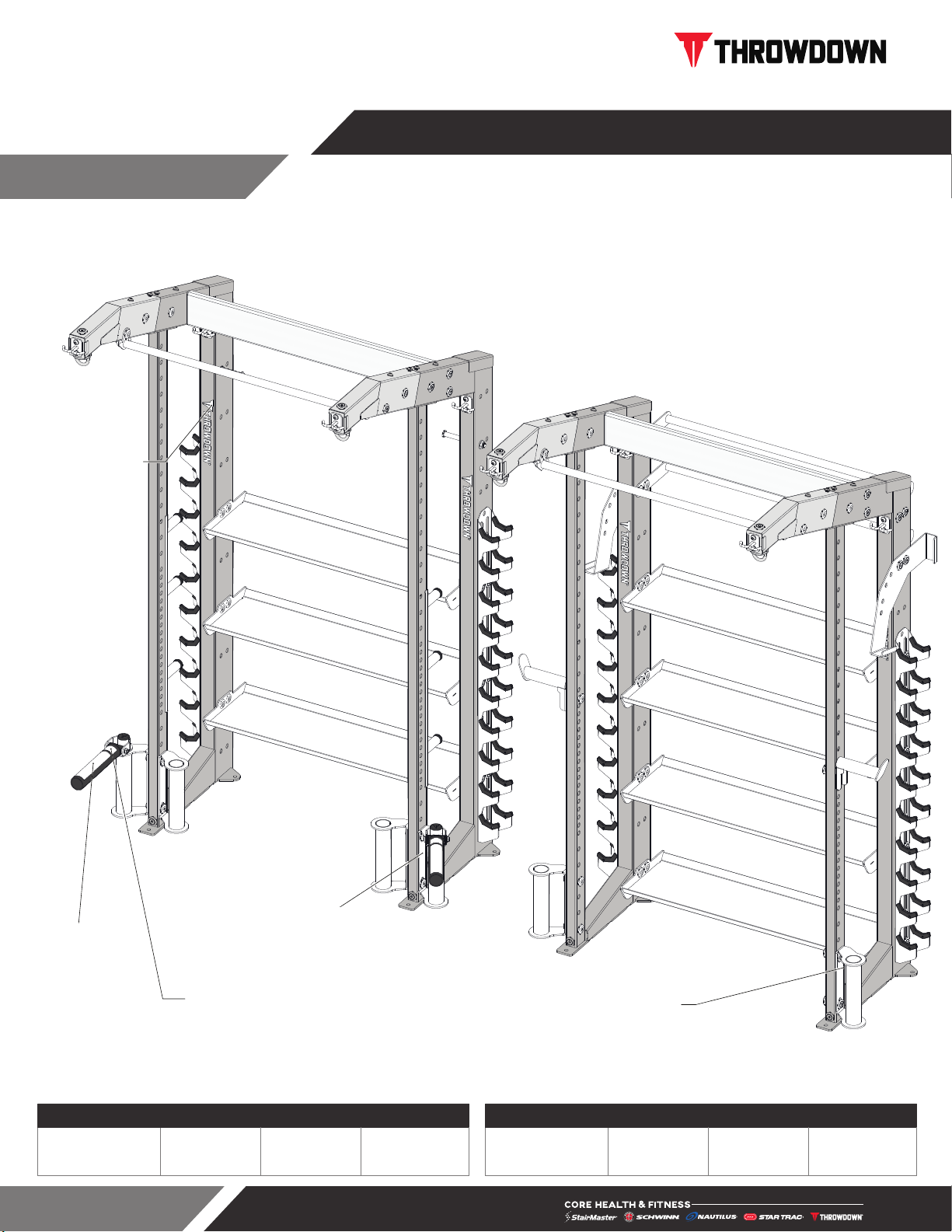

TD-WR2 PROCEDURE

1. Slide the rack side upper hanger

assemblies 73-00161-XX onto the

two side frames then secure with

one bolt set in the side, and two of

the M12x1.75,30mm bolts (31-

00392) and two washers 31-00267

top and bottom.

Note: Many accessories and

supports are attached with large

bolt sets consisting of one each

M12 x 90 Flat Head Bolt (31-

00396), a bolt washer (11-00811)

and a bolt nut (11-00810).

11-00810

11-00811

31-00396

73-00161-XX

31-00267

31-00392

Fig. 6

2. Prior to standing frames up attach

the shelving and the vertical

dumbell racks to the frame

using eight large bolt sets per

side.

3. Attach the upper stabilizer to

the frames with two large bolt sets

per side.

4. Stand frame up and fully tighten all

hardware.

Fig. 7

Page 10

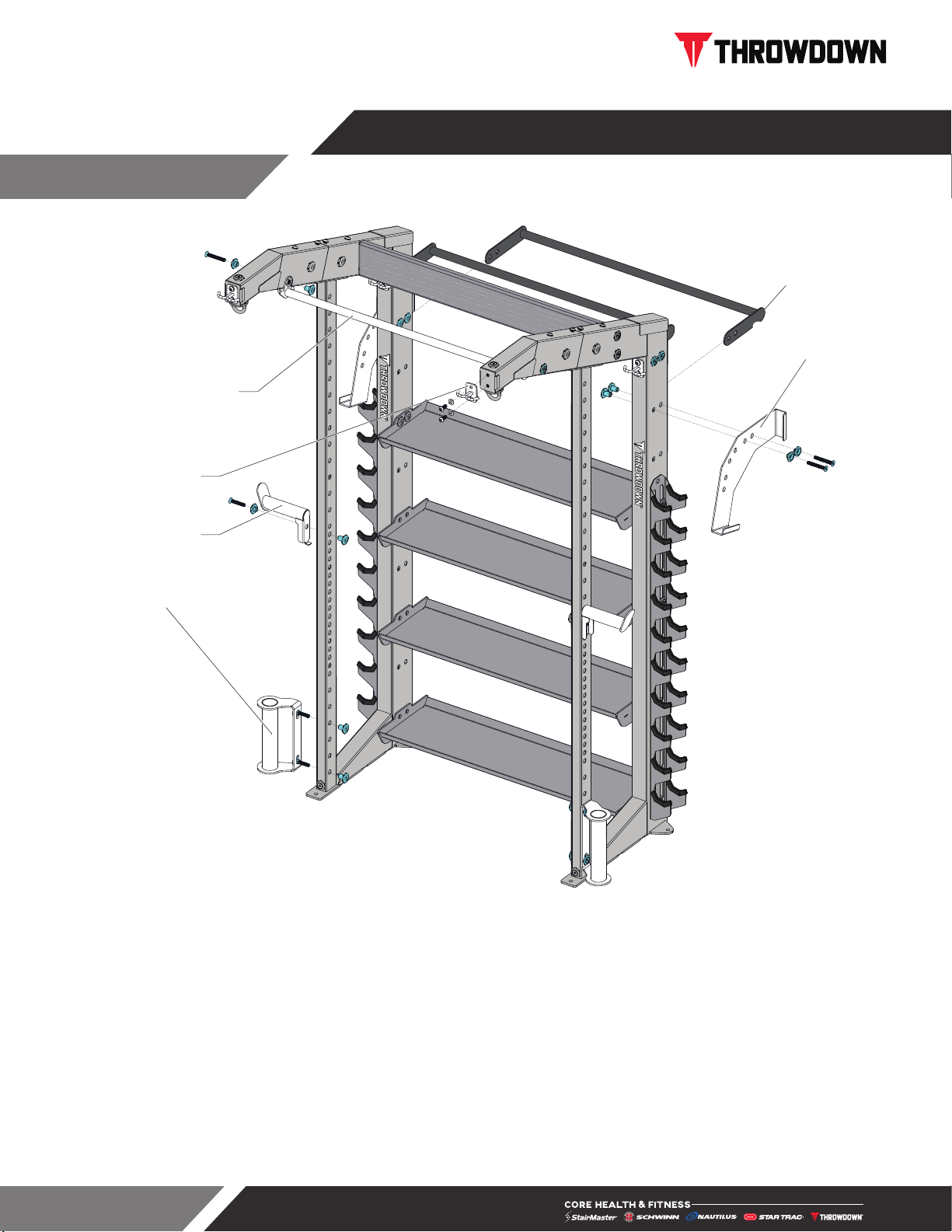

71-00267-XX

52-00267

52-00268-XX

12-00313

52-00260-XX

52-00261

Fig. 8

5. Install the two bars (52-00268-XX) at the top of the unit using two large bolt sets per side. The lower bar is

installed with the balance ball storages (12-00313) on the outside of the frame on either side.

6. Attach pull-up bar assembly (52-00260-XX) at top of unit using a large bolt set on each side.

7. Attach all 4 Double-J hooks (52-00261) to the frame using two M12x1.75,30mm bolts (31-00392) and two

washers 31-00267 each.

8. Install the Oly Bar kits (71-00267-XX) at the bottom of the unit with two large bolt sets each.

9. Attach the Rope Hangar pegs (52-00267) to the left and right of the unit with a large bolt set.

10. Fully tighten all hardware.

11. Assembly is complete.

Page 11

TOOLS

Working on this product will require basic and/or sometimes specialty tools based on the type of service that

will be performed at any time. To assist, we recommend having the tools listed available when performing

maintenance.

Tool

Socket Set, Metric Screwdriver Set, Flat

8mm Hex Bit Rubber Mallet or Dead-Blow Hammer

Socket driver Tape Measure

Open end wrenches, Metric Motorcycle straps, adjustable

Hex Bit Socket Set, SAE Loctite 243

Adjustable Wrench Chalk Line

Torque Wrench

MAINTAIN ALL EQUIPMENT: Preventative maintenance is the key to smooth operating equipment as well

as keeping the product in safe operating condition. Failure to conduct preventative maintenance by the owner

may cause the product to operate in an unsafe manner. Equipment needs to be inspected and maintained at

regular intervals per the preventative maintenance schedule provided in this manual.

Cleaning

Keeping your Strength units clean is an important component of preventative maintenance and the overall

aesthetics of your product. While your clients will appreciate clean equipment free of sweat, dirt and other

contaminants proper care and cleaning will extend the life of your product and reduce premature aging and

wear. See the maintenance schedule for recommended frequency.

Inspection

Visual inspection of your units will insure a safe environment for your clients and alert you to any issues that

may require maintenance prior to equipment failure. Proper, timely visual inspection is a critical component to

the long term care of your product.

• Fasteners, hardware and attachments should be checked monthly for looseness. Tighten as required

using appropriate tools.

• Main frame should be inspected every six months for signs of unusual wear, corrosion or structural

integrity issues.

MAINTENANCE

Page 12

MAINTENANCE SCHEDULE

With durable, high performance components, this equipment is designed for heavy usage with minimal

maintenance required. To keep it in top condition, perform regular daily, weekly and monthly preventive

maintenance routines outlined below.

The safety and integrity of this machine can only be maintained when the equipment is regularly examined for

damage and wear and repaired. It is the sole responsibility of the owner of this equipment to ensure that regular

maintenance is performed. Worn or damaged parts must be replaced immediately or the equipment removed

from service until the repair is made.

Daily Weekly Monthly Bi-Annually

Inspect

Check Safety & Warning Labels X

Check for loose bolts & hardware X

Cleaning

Main Frame1X

1 Clean with a water dampened cloth & wipe dry after cleaning.

Page 13

SUPPORT & SERVICE

For Technical Support, Service, Parts Orders or any Customer Service needs, please contact us direct by phone,

email, or through our 24 hour support site:

To help us support you, please provide the following information when requesting assistance with your equipment:

Facility Name & Address Product Serial Number Description of Issue

Our goal is to provide fast, reliable support to all your product support requests. We strive to answer all support

requests under an average hold time of 3 minutes, all support emails within 1 business day and all field service

requests within 48 hours.

PREVENTATIVE MAINTENANCE

Protect your product & assure it always runs like new with a Core Advantage Preventative Maintenance or Extended

To request access scan or visit:

CONNECT.COREHANDF.COM

• General Inquiries

• Warranty Registration

• Preventative Maintenance

• Service Requests

• Parts Orders

• Automated partner payment

• Product technical library

• Transparency on service performance

• 24-Hour Automated Assistant

• Live Chat

OFFERS 24-HOUR SELF SERVICE ACCESS TO:

Core Connect is your portal to all things service! Whether you need to

order parts or register your warranty, Core Connect is the most effective

way to get what you need fast and keep your facility operating smoothly.

CORE CONNECT

GLOBAL SUPPORT CENTER

4400 NE 77th Avenue, Suite 300 Vancouver, WA 98662

Warranty information: https://corehandf.com/warranty

Core Connect is accessible through our app on mobile devices

Page 14

THIS PAGE INTENTIONALLY BLANK

© 2021 CORE HEALTH & FITNESS LLC PART NUMBER 90-00060, REV A

All rights reserved. Star Trac, the Star Trac logo and StairMaster are registered trademarks of Core Health & Fitness, LLC. Schwinn and Nautilus are registered

trademarks of Nautilus Inc. used under license to Core Health & Fitness LLC. Throwdown is a registered trademark of Throwdown Industries, LLC.

This manual suits for next models

1

Table of contents

Other Throwdown Fitness Equipment manuals