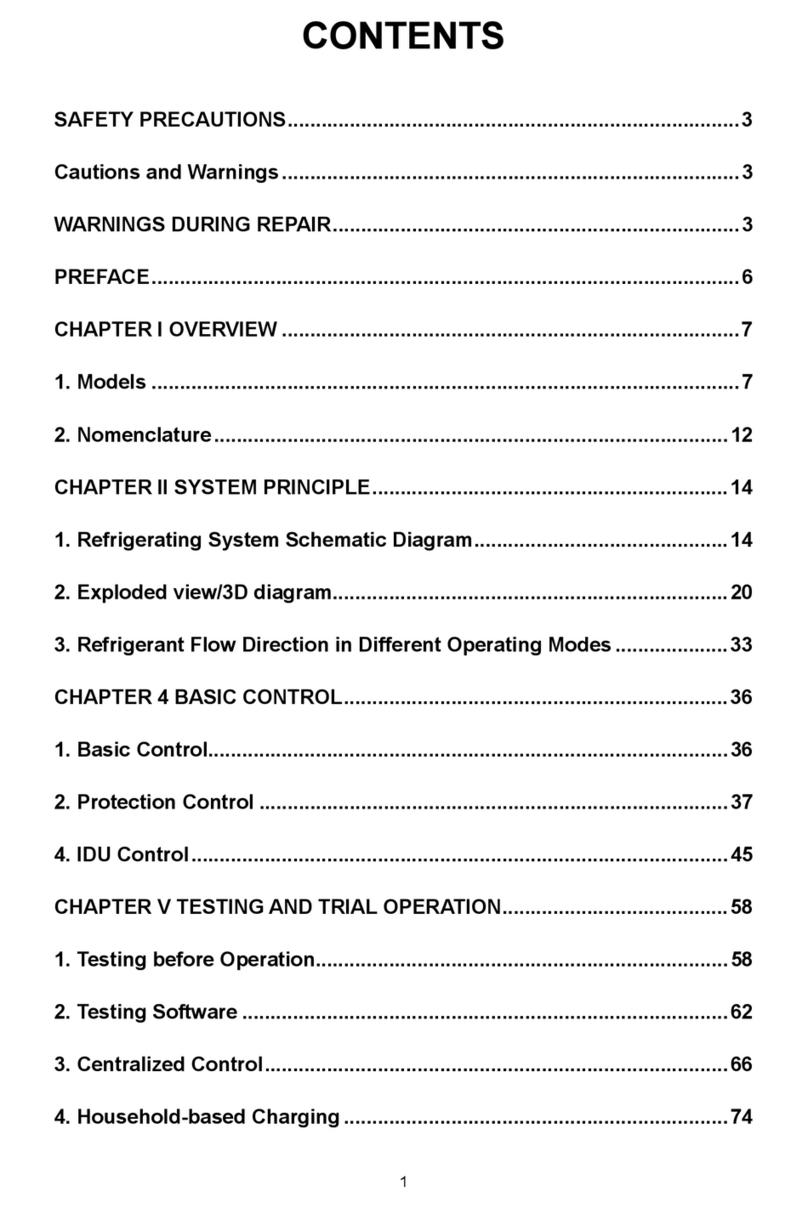

Contents

Safety Precautions .................................................................................................................. 5

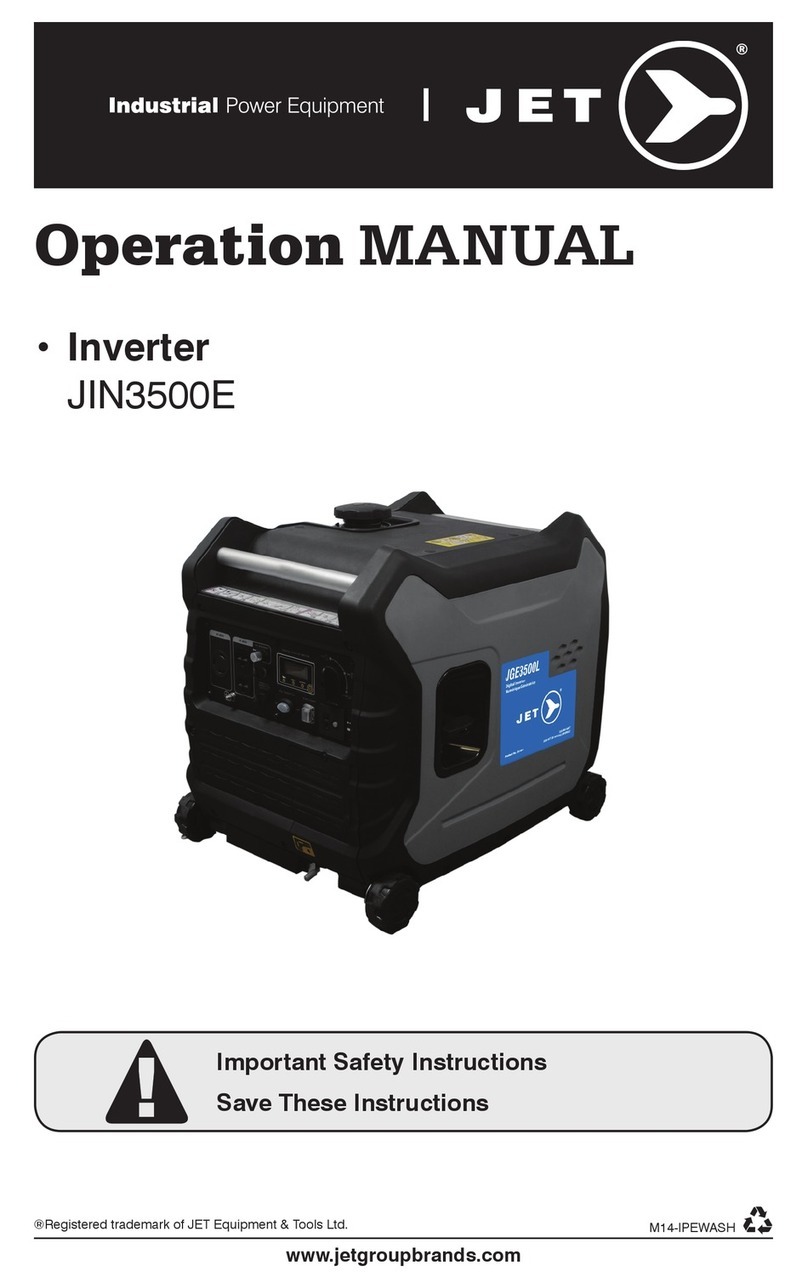

Installation of ODU .................................................................................................................. 6

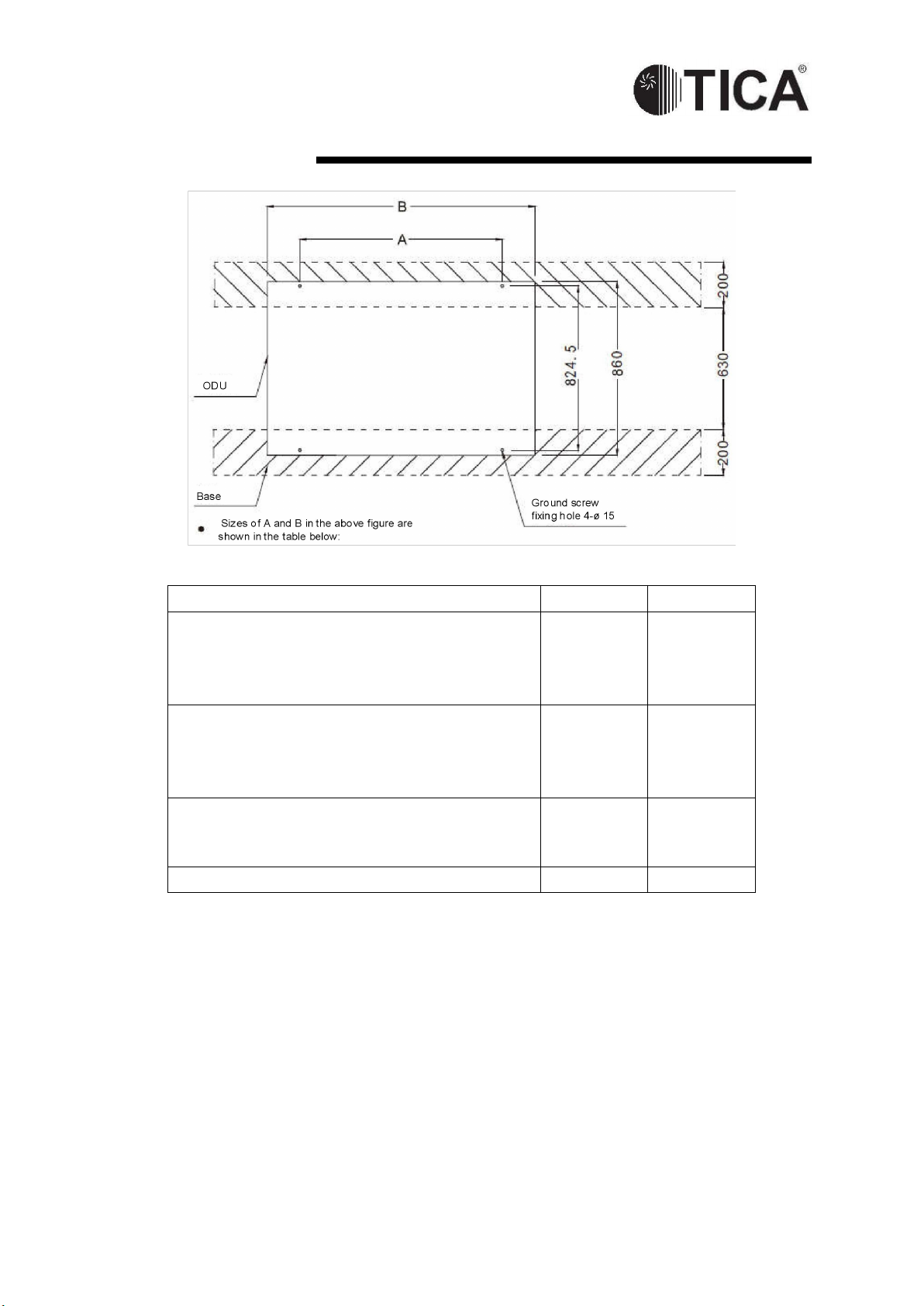

Dimension ....................................................................................................................................... 8

Installation space ..............................................................................................................10

Handling........................................................................................................................................14

Placement ...........................................................................................................................13

Installation of Refrigerant Piping .........................................................................................15

Precautions for the installation of piping: .........................................................................16

The choice of the refrigerant pipe diameter .....................................................................20

Installation of branch pipes .............................................................................................. 21

Refrigerant piping length .................................................................................................. 25

Air Tightness Test, Vacuuming and Supplementing Refrigerant ....................................26

Air tightness test ...............................................................................................................26

Vacuumizing: ....................................................................................................................26

Supplementing refrigerant ................................................................................................28

Electric Control Installation ..................................................................................................29

Wiring cautions .................................................................................................................29

Wiring specifications .........................................................................................................30

Electrical wiring ................................................................................................................ 31

Communication wiring ......................................................................................................31

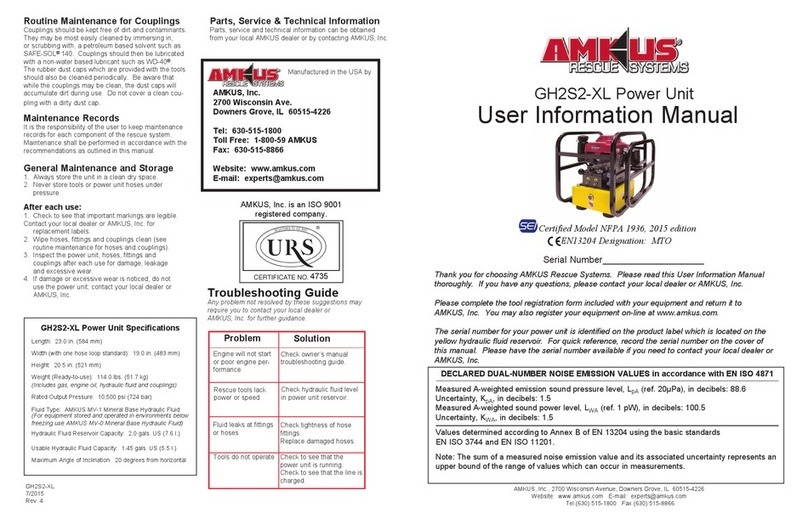

ODU Control Panel ................................................................................................................ 32

Code settings ....................................................................................................................32

Settings of relevant keys .................................................................................................. 35

Digital display ................................................................................................................... 37

Trial Operation ....................................................................................................................... 39

Before trial operation ........................................................................................................39

Trial operation .................................................................................................................. 39

Trial operation check ........................................................................................................40

Description of Hazardous Substances ............................................................................... 41

TICA

PRO LLC Tel: +7(495)127-79-00; +7(969)190-85-85 E-mail: [email protected] www.tica.pro