Elettronica Santerno SINUS K User manual

•15P0095B2 •

SINUS K

FULL DIGITAL INVERTER

USER MANUAL

-Installation Instructions-

Updated 13/04/07

R. 07

Elettronica Santerno S.p.A.

Via G. Di Vittorio, 3 - 40020 Casalfiumanese (Bo) Italy

Tel. +39 0542 668611 - Fax +39 0542 668622

www.elettronicasanterno.it [email protected]

•This manual is integrant and essential to the product. Carefully read the instructions contained herein as they

provide important hints for use and maintenance safety.

•This device is to be used only for the purposes it has been designed to. Other uses should be considered improper

and dangerous. The manufacturer is not responsible for possible damages caused by improper, erroneous and

irrational uses.

•Elettronica Santerno is responsible for the device in its original setting.

•Any changes to the structure or operating cycle of the device must be performed or authorized by the Engineering

Department of Elettronica Santerno.

•Elettronica Santerno assumes no responsibility for the consequences resulting by the use of non-original spare-

parts.

•Elettronica Santerno reserves the right to make any technical changes to this manual and to the device without

prior notice. If printing errors or similar are detected, the corrections will be included in the new releases of the

manual.

•Elettronica Santerno is responsible for the information contained in the original version of the Italian manual.

•The information contained herein is the property of Elettronica Santerno and cannot be reproduced. Elettronica

Santerno enforces its rights on the drawings and catalogues according to the law.

English

INSTALLATION SINUS K

INSTRUCTIONS

2/191

0. TABLE OF CONTENTS

0.1. Chapters

0. TABLE OF CONTENTS .................................................................................................................. 2

0.1. Chapters......................................................................................................................................2

0.2. Figures.........................................................................................................................................5

0.3. Tables..........................................................................................................................................6

1. GENERAL DESCRIPTION............................................................................................................... 7

1.1. FEATURE LIST ...............................................................................................................................8

1.2. EQUIPMENT DESCRIPTION AND INSTALLATION...........................................................................9

1.3. PRODUCTS COVERED IN THIS MANUAL.......................................................................................9

2. CAUTION STATEMENTS ............................................................................................................. 10

3. INSPECTION UPON RECEIPT OF THE GOODS............................................................................ 12

3.1. INVERTER NAMEPLATE................................................................................................................13

4. USING THE DISPLAY/KEYPAD .................................................................................................... 14

4.1. Adjusting the Display Contrast.....................................................................................................15

5. STARTUP PROCEDURES ..............................................................................................................16

5.1. Startup Procedure for IFD Software ..............................................................................................16

5.2. Startup Procedure for VTC Software.............................................................................................17

6. TECHNICAL SPECIFICATIONS .................................................................................................... 18

6.1. Choosing the Product .................................................................................................................20

6.1.1. Technical Sheet for LIGHT Applications: Overload up to 120% .............................................21

6.1.2. Technical Sheet for STANDARD Applications: Overload up to 140%......................................23

6.1.3. Technical Sheet for HEAVY Applications: Overload up to 175% ...........................................25

6.1.4. Technical Sheet for STRONG Applications: Overload up to 200% .........................................27

6.2. Carrier Frequency Setting (IFD SW only) and Peak Currents ..........................................................29

6.3. OPERATING TEMPERATURES BASED ON APPLICATION CLASSES .................................................31

7. INSTALLING THE EQUIPMENT.................................................................................................... 33

7.1. Environmental Requirements for the Equipment Installation, Storage and Transport .......................33

7.2. Air Cooling ................................................................................................................................34

7.3. Size, Weight and Dissipated Power ..............................................................................................35

7.3.1. IP20 and IP00 STAND-ALONE Models (S05-S60) 2T Class ...................................................35

7.3.2. IP20 and IP00 STAND-ALONE Models (S05 – S60) 4T Class.................................................36

7.3.3. Modular IP00 STAND-ALONE Models (S65).........................................................................37

7.3.4. IP54 STAND-ALONE Models (S05-S30) 2T Class .................................................................40

7.3.5. IP54 STAND-ALONE MODELS (S05-S30) 4T Class...............................................................41

7.3.6. IP54 BOX MODELS (S05-S20) 2T Class ...............................................................................42

7.3.7. IP54 BOX MODELS (S05-S20) 4T Class ...............................................................................43

7.3.8. IP24 - IP54 CABINET Models (S15-S65)...............................................................................44

7.4. Standard Mounting and Fixing Points for IP20 and IP00 Stand-Alone Models (S05-S60).................45

7.5. Standard Mounting and Fixing Points for IP00 Modular Stand–Alone Models (S64-S65) .................47

7.5.1. Installation and Wiring of a Modular Inverter (S65) ..............................................................50

7.6. Standard Mounting and Fixing Points for IP54 Stand-Alone Models (S05-S30) ..............................51

7.7. Through-panel Assembly and Fixing Points (Stand-Alone Models S05-S50)...................................52

7.7.1. SINUS K S05......................................................................................................................52

7.7.2. SINUS K S10......................................................................................................................53

7.7.3. SINUS K S12......................................................................................................................54

7.7.4. SINUS K S15-S20-S30........................................................................................................55

7.7.5. SINUS K S40......................................................................................................................56

7.7.6. SINUS K S50......................................................................................................................57

7.8. Connections to Control Terminals and Power Terminals (IP20/IP00)..............................................58

7.9. Connections to Control Terminals and Power Terminals (IP54 Models) ..........................................59

8. WIRING...................................................................................................................................... 60

8.1. Wiring Diagram (S05-S60)..........................................................................................................61

8.2. Wiring Diagram for Modular Models (S65) ..................................................................................62

SINUS K INSTALLATION

INSTRUCTIONS

3/191

8.2.1. Connection of Modular Inverters .........................................................................................62

8.2.2. External Connections for S64 Modular Inverters ...................................................................63

8.2.3. 12-Phase Connection for Modular Inverters .........................................................................64

8.2.4. Internal Connections for Modular Inverters (S65)..................................................................65

8.2.5. Internal Connections for S64 Modular Inverters....................................................................72

8.3. Control Terminals.......................................................................................................................76

8.3.1. Grounding the Shield of Signal Screened Cables .................................................................78

8.4. POWER TERMINALS....................................................................................................................79

8.4.1. Lay-out of the Power terminals for S05 – S50.......................................................................79

8.4.2. Connecting Bars for S60 – S65 ...........................................................................................81

8.4.3. Grounding the Inverter and the Motor .................................................................................83

9. CROSS SECTIONS OF POWER CONNECTION WIRE AND SIZE OF PROTECTION DEVICES ........ 84

9.1. VOLTAGE CLASS: 2T ..................................................................................................................85

9.2. VOLTAGE CLASS: 4T ..................................................................................................................87

9.3. UL-APPROVED FUSES – 2T VOLTAGE CLASS ...............................................................................89

9.4. UL-APPROVED FUSES – 4T VOLTAGE CLASS ...............................................................................90

10. INPUT - OUTPUT FEATURES ................................................................................................... 91

10.1. Digital Input Features (Terminals 6 to 13) ....................................................................................91

10.1.1. Enable (Terminal 6) ............................................................................................................92

10.1.2. Start (Terminal 7)................................................................................................................92

10.1.3. Reset (Terminal 8)...............................................................................................................92

10.1.4. MDI-Multifunction Digital Inputs (Terminals 9 to 13).............................................................93

10.1.5. Motor Thermal Protection (PTC Type) Input (Terminal 13) .....................................................93

10.2.

Analog Input Features (Terminals 2,3,15 and 21)

............................................................................93

10.3. Digital Output Features...............................................................................................................94

10.3.1. Relay Outputs (Terminals 24 to 31) .....................................................................................95

10.4. Analog Output Features (Terminals 17 and 18)............................................................................95

11. SIGNALS AND PROGRAMMING FOR ES778 CONTROL BOARD ............................................. 96

11.1. Indicator Leds.............................................................................................................................97

11.2. Jumpers and Dip-Switches ..........................................................................................................97

12. SERIAL COMMUNICATIONS................................................................................................... 99

12.1. General Features........................................................................................................................99

12.1.1. Direct Connection ............................................................................................................100

12.1.2. Multidrop Network Connection .........................................................................................100

12.1.2.1. Connection ..............................................................................................................100

12.1.2.2. Line Terminators ......................................................................................................102

12.1.3. ES822 Isolated Board (Optional) .......................................................................................102

12.2. The Software ............................................................................................................................102

12.3. Communication Ratings............................................................................................................103

13. ACCESSORIES ...................................................................................................................... 104

13.1. Braking Resistors ......................................................................................................................104

13.1.1. Application Tables............................................................................................................104

13.1.1.1. Braking Resistors for Applications with a Braking Duty Cycle of 10% and 380-500VAC

Supply Voltage .............................................................................................................................105

13.1.1.2. Braking Resistors for Applications with a Braking DUTY CYCLE of 20% and 380-500VAC

Supply Voltage .............................................................................................................................107

13.1.1.3. Braking Resistors for Applications with a Braking DUTY CYCLE of 50% and 380-500VAC

Supply Voltage .............................................................................................................................109

13.1.1.4. Braking Resistors for Applications with a Braking DUTY CYCLE of 10% and 200-240VAC

Supply Voltage .............................................................................................................................111

13.1.1.5. Braking Resistors for Applications with a Braking DUTY CYCLE of 20% and 200-240VAC

Supply Voltage .............................................................................................................................113

13.1.1.6. Braking Resistors for Applications with a Braking DUTY CYCLE of 50% and 200-240VAC

Supply Voltage .............................................................................................................................115

13.1.2. Available Models..............................................................................................................117

13.1.2.1. 56-100 Ohm/350W Model ......................................................................................117

INSTALLATION SINUS K

INSTRUCTIONS

4/191

13.1.2.2. 75 Ohm/1300W Model ...........................................................................................118

13.1.2.3. Models from 1100W to 2200W ................................................................................119

13.1.2.4. 4kW-8kW-12kW Models ..........................................................................................120

13.1.2.5. Models of IP23 Box Resistors, 4kW-64kW ..................................................................121

13.2. Braking Unit BU200 .................................................................................................................123

13.2.1. Inspection upon Receipt of the Goods................................................................................123

13.2.1.1. Nameplate of BU200 ...............................................................................................124

13.2.2. Operation........................................................................................................................125

13.2.2.1. Configuration Jumpers .............................................................................................125

13.2.2.2. Adjusting Trimmers ..................................................................................................126

13.2.2.3. Indicator LEDs..........................................................................................................127

13.2.3. Ratings ............................................................................................................................127

13.2.4. Installation .......................................................................................................................128

13.2.4.1. Mounting.................................................................................................................128

13.2.4.2. Wiring .....................................................................................................................130

13.3. Braking Unit for Modular Inverters (BU720-BU1440)..................................................................135

13.3.1. Inspection upon Receipt of the Goods................................................................................135

13.3.1.1. Nameplate for BU720-960-1440 .............................................................................135

13.3.2. Operation........................................................................................................................136

13.3.3. Ratings ............................................................................................................................136

13.3.4. Installation .......................................................................................................................137

13.3.4.1. Mounting.................................................................................................................137

13.3.4.2. STANDARD MOUNTING ..........................................................................................138

13.3.4.3. Wiring .....................................................................................................................139

13.4. KEYPAD REMOTING KIT ...........................................................................................................145

13.4.1. Remoting the Keypad........................................................................................................145

13.5. OPTIONAL INPUT-OUTPUT REACTORS.....................................................................................148

13.5.1. Input Reactor....................................................................................................................148

13.5.2. 12-phase connection........................................................................................................151

13.5.3. Output Inductance............................................................................................................152

13.5.4. Applying the Inductance to the Inverters.............................................................................154

13.5.4.1. 2T CLASS – AC / DC INDUCTANCE .........................................................................154

13.5.4.2. 4T CLASS – AC / DC INDUCTANCE .........................................................................155

13.5.4.3. 2T-4T Class, Interphase Inductance...........................................................................156

13.5.5. Inductance Ratings ...........................................................................................................156

13.5.5.1. Voltage Class: 2T – 4T..............................................................................................156

13.5.6. AC 3-phase Inductance, 2T and 4T Class in IP54 Cabinet..................................................158

13.6. ES836/2 Encoder board ...........................................................................................................160

13.6.1. Environmental Requirements .............................................................................................160

13.6.2. Electric Specifications........................................................................................................161

13.6.3. Installing the Encoder Board on the Inverter.......................................................................162

13.6.4. Encoder Board Terminals..................................................................................................163

13.6.5. Configuration Dip-switches ...............................................................................................163

13.6.6. Jumper For Encoder Supply...............................................................................................164

13.6.7. Tuning Trimmer................................................................................................................165

13.6.8. Encoder Wiring and Configuration Examples .....................................................................165

13.6.9. Wiring the Encoder Cable.................................................................................................170

13.7. ES822/1 ISOLATED SERIAL BOARD...........................................................................................171

13.7.1. Environmental Requirements .............................................................................................172

13.7.2. Electrical Features.............................................................................................................172

13.7.3. Installing ES822 Board .....................................................................................................173

13.7.4. Configuring ES822 Isolated Board ....................................................................................174

13.7.4.1. Jumper Selecting RS232/RS485 ................................................................................174

13.7.4.2. Dip-Switch Enabling RS485 Terminator .....................................................................175

13.8. “LOC-0-REM” Key Selector Switch and Emergency Push-button for IP54 Models ..........................176

13.8.1. Wiring Inverters with “LOC-0-REM” Key Selector Switch and Emergency Push-button ...........177

SINUS K INSTALLATION

INSTRUCTIONS

5/191

14. NORMATIVE REFERENCES.................................................................................................... 178

14.1. Radiofrequency Disturbance......................................................................................................182

14.1.1. Mains ..............................................................................................................................183

14.1.2. Output Toroid Filters.........................................................................................................184

14.1.3. Cabinet ...........................................................................................................................184

14.1.4. Input and Output Filters....................................................................................................185

15. DECLARATIONS OF CONFORMITY....................................................................................... 186

0.2. Figures

Figure 1: Example of a nameplate placed on a 2T SINUS K inverter. .............................................................13

Figure 2: Example of a nameplate placed on a 4T SINUS K inverter. .............................................................13

Figure 3: Keypad of SINUS K inverters. ........................................................................................................14

Figure 4: Fixing points for STAND-ALONE models from S05 to S50 included.................................................45

Figure 5: Fixing points for stand-alone models (S60).....................................................................................46

Figure 6: Fixing points for modular units. .....................................................................................................48

Figure 7: Fixing points for stand-alone control unit. ......................................................................................48

Figure 8: Installation Example of a SINUS K S64 – S65. ................................................................................49

Figure 9: S65 inverter installed inside an enclosure.......................................................................................50

Figure 10: Fixing points for IP54 SINUS K. ...................................................................................................51

Figure 11: Mounting the accessories for the through-panel assembly of SINUS K S05. ...................................52

Figure 12: Fixing points of the mounting panel for the through-panel assembly of SINUS K S05. ....................52

Figure 13: Mounting the accessories for the through-panel assembly of SINUS K S10. ...................................53

Figure 14: Fixing points of the mounting panel for the through-panel assembly of SINUS K S10. ....................53

Figure 15: Fittings for the through-panel assembly for SINUS K S12. .............................................................54

Figure 16: Piercing template for the through-panel assembly for SINUS K S12...............................................54

Figure 17: Through-panel assembly and fixing points for SINUS K S15, S20, S30. ........................................55

Figure 18: Removing the mounting plate from SINUS K S40 .........................................................................56

Figure 19: Through-panel assembly and fixing points for SINUS K S40..........................................................56

Figure 20: Removing the mounting plate from SINUS K S50 .........................................................................57

Figure 21: Through-panel assembly and fixing points for SINUS K S50..........................................................57

Figure 22: Access to the control terminals and power terminals.....................................................................58

Figure 23: Wiring diagram for S05-S60.......................................................................................................61

Figure 24: External connections for modular inverters. ..................................................................................62

Figure 25: External connections for S64 modular inverters. ...........................................................................63

Figure 26: Lay-out of a 12-phase connection. ..............................................................................................64

Figure 27: Single optical fibre connector. .....................................................................................................65

Figure 28: Double optical fibre connector. ...................................................................................................66

Figure 29: Internal connections for SINUS K S65. .........................................................................................68

Figure 30: ES840 supply control board. .......................................................................................................69

Figure 31: ES841 inverter module gate unit board........................................................................................69

Figure 32: ES843 inverter module. ..............................................................................................................70

Figure 33: ES842 control unit. .....................................................................................................................71

Figure 34: Single optical-fibre connector......................................................................................................72

Figure 35: Double optical-fibre connector. ...................................................................................................73

Figure 36: Internal wiring for S64 inverters...................................................................................................75

Figure 37: Tightening a signal screened cable..............................................................................................78

Figure 38: Connecting bars for S60.............................................................................................................81

Figure 39: Connecting bars for S64 – S65. ..................................................................................................82

Figure 40: Control modes for the digital inputs.............................................................................................91

Figure 41: Connecting a relay to the OPEN COLLECTOR output. ..................................................................94

Figure 42: Location of the jumpers on ES778 control board. .........................................................................96

Figure 43: Location of SW1 dip-switch and RS485 connector for Sinus K S05 to S20. .....................................98

Figure 44: Location of SW1 dip-switch and RS485 connector for Sinus K S30 to S60. .....................................98

Figure 45: Example of multidrop and direct connection. ...............................................................................99

Figure 46: Recommended wiring diagram for “2-wire” MODBUS wiring......................................................101

INSTALLATION SINUS K

INSTRUCTIONS

6/191

Figure 47: Overall dimensions for 56-100Ω/350W resistor. .......................................................................117

Figure 48: Overall dimensions and ratings for 75Ω/1300W braking resistor................................................118

Figure 49: Overall dimensions and mechanical features for braking resistors from 1100W to 2200W. .........119

Figure 50: Overall dimensions for 4kW, 8kW, 12kW braking resistors.........................................................120

Figure 51: Overall dimensions for IP23 box resistors. .................................................................................121

Figure 52: Position of the electrical connections in box resistors...................................................................121

Figure 53: Nameplate of BU200. ..............................................................................................................124

Figure 54: Position of the jumpers on ES839 BU200 control board..............................................................125

Figure 55: Positions of BU200 adjusting trimmers.......................................................................................126

Figure 56: Position of the indicator LEDs. ...................................................................................................127

Figure 57: Dimensions and fixing points of BU200. ....................................................................................129

Figure 58: Connecting one BU200 to the inverter.......................................................................................130

Figure 59: Master – Slave multiple connection............................................................................................131

Figure 60: Terminals in BU200..................................................................................................................132

Figure 61: Max. allowable duty-cycle (depending on Ton) for the connected braking resistor. .......................133

Figure 62: Peak power and average power (depending on Ton) dissipated to the braking resistor.................134

Figure 63: Nameplate of BU720-1440. .....................................................................................................135

Figure 64: Dimensions and fixing points of BU720-1440............................................................................138

Figure 65: External power connections for S65 modular inverters provided with BU770-1440. .....................139

Figure 66: ES841 gate unit board for the braking unit. ...............................................................................142

Figure 67: Wiring points of the optical fibres in ES482 control board...........................................................143

Figure 68: Internal wiring of S65 inverters provided with an integrated braking unit. ....................................144

Figure 69: Removing the display/keypad....................................................................................................146

Figure 70: Front view/rear view of the keypad. ...........................................................................................147

Figure 71: Wiring diagram for optional inductance. ...................................................................................148

Figure 72: Amplitude of harmonic currents (approximate values).................................................................150

Figure 73: Lay-out of a 12-phase connection. ............................................................................................151

Figure 74: Connection of an output inductance. .........................................................................................153

Figure 75: Mechanical features of an AC 3-phase inductance. ....................................................................157

Figure 76: Mechanical features of an AC 3-phase inductance, 2T-4T Class in IP54 cabinet. .........................159

Figure 77: ES836/2 Encoder board. ..........................................................................................................160

Figure 78: Position of the slot for the installation of the encoder board. .......................................................162

Figure 79: Encoder board fastened to its slot..............................................................................................162

Figure 80: Positions and default settings of the configuration dip-switches....................................................163

Figure 81: LINE DRIVER or PUSH-PULL encoder with complementary outputs. ..............................................166

Figure 82: PUSH-PULL encoder with single-ended outputs. .........................................................................167

Figure 83: PNP or NPN encoder with single-ended outputs and load resistors with external wiring. ...............168

Figure 84: PNP or NPN encoder with single-ended outputs and internal load resistors..................................169

Figure 85: Wiring the encoder cable..........................................................................................................170

Figure 86: ES822 isolated board. ..............................................................................................................171

Figure 87: Position of the slot for the installation of the isolated serial board................................................173

Figure 88: Configuration of the jumpers for RS232/RS485..........................................................................174

Figure 89: Configuring the dip-switch for RS485 terminator. .......................................................................175

Figure 90: Wiring inverters with optional “LOC-0-REM” key selector switch and emergency push-button. ......177

Figure 91: Disturbance sources in a power drive system equipped with an inverter.......................................182

Figure 92: Toroid filter connection for Sinus K. ...........................................................................................185

0.3. Tables

Table 1: Max. braking time depending on the duty-cycle and the connected braking resistor. .......................134

Table 2: Max. braking time depending on the duty-cycle and the connected braking resistor. .......................134

SINUS K INSTALLATION

INSTRUCTIONS

7/191

1. GENERAL DESCRIPTION

Inverters are electronic devices capable of driving asynchronous motors at adjustable speed.

The speed of rotation of asynchronous motors depends on the voltage frequency of the motor power supply. To

adjust the motor speed, the voltage frequency of the motor power supply must be adjusted accordingly.

Inverters are voltage generators capable of adjusting both the voltage value and the relevant frequency value at

a time.

To enhance the motor operation at any speed value, the simultaneous variation of voltage and supply frequency

must be obtained with particular criteria in order not to alter the torque characteristics of the torque produced by

the connected motor.

Inverters manufactured by ELETTRONICA SANTERNO fully meet these adjustment and control requirements and

incorporate a wide range of the latest technologies to fit any application requirement.

Available SINUS K models range from 1.3kW to 900kW.

AVAILABLE SINUS K MODELS:

NOTE

It is possible to change some technical features and to customize the inverter

enclosures shown in the picture. The proportion of one enclosure to the other is

shown as an example and is not binding.

INSTALLATION SINUS K

INSTRUCTIONS

8/191

1.1. FEATURE LIST

• One product, three functions:

¾vectorial-modulation IFD software for general-purpose applications (V/f pattern) (*);

¾sensorless, vectorial VTC software for high-torque demanding performance (direct torque control) (*);

¾vectorial-modulation LIFT software for lift applications* (in compliance with EN 81-1 and lift directive) (V/f

pattern) (NOT COVERED IN THIS MANUAL) (*);

(*) Must be specified when ordering the equipment.

• Wide range of supply voltage: 200÷500VAC both for stand-alone models and cabinet models.

Standard DC power supply ranging from 280 to 705Vdc.

• Wide power range: 1 to 900kW.

• Wide range of voltage values and power values for the electrical motor to be connected to any single inverter

size.

MODEL LIGHT

STANDARD HEAVY STRONG

SINUS K 0025 4TBA2X2 22kW 18.5kW 15kW 11kW

• Built-in filters for the whole SINUS K range in compliance with regulation EN61800-3, issue 2 concerning

emission limits.

•No line contactor included. The new hardware configuration is standard supplied with

a safety system including redundant contacts for the inhibition of firing pulses in the

power circuit, in compliance with the latest requirements of the safety regulations in

force. (However, respect the specific rules of the field of application).

•Beyond performance enhancement, the new SINUS K models are more compact than the prior models. The

overall dimensions have been reduced up to 50% in order to install the inverter in small-sized, light-weight

control panels. A compact, book-like structure allows easy side-by-side installation. The SINUS K may be

installed in cabinets and its system design offers a better price/performance ratio.

•Automatic control of the cooling system (up to Size S10). The ventilation system activates only when required

and indicates any failures of the cooling fan. This ensures greater energy saving, lower wear of the cooling fans

and weaker noise. In case of equipment failure, the customer may to adjust the system speed in order not to

stop the equipment and to limit dissipated power.

•Built-in braking unit up to Size S30 included.

•Noiseless operation ensured by high modulation frequency programmable up to 16kHz (IFD SW).

•Integrated motor thermal protection through thermal relay and PTC input.

•Control panel with LCD display showing full words for an easier comprehension of the

operation parameters.

•Managing and programming panel provided with eight function keys.

•Window-structured programming menu for an easy and quick control of each function.

•Preset parameters for the most used applications.

•PC interface for WINDOWS environment with the REMOTE DRIVE software in five foreign languages.

•PC compiled software for the programming of more than 20 application functions.

• RS485 MODBUS RTU serial communications for serial links to PC, PLC and control interfaces.

•Optional field buses of any type (Profibus DP, Can Bus, Device Net, Ethernet, etc.)

SINUS K INSTALLATION

INSTRUCTIONS

9/191

1.2. EQUIPMENT DESCRIPTION AND INSTALLATION

The inverters of the SINUS K series are full digital inverters for the speed regulation of asynchronous motors up

to 900 kW.

The inverters of the SINUS K series are designed and manufactured in Italy by the technicians of Elettronica

Santerno; they incorporate the most advanced features offered by the latest electronic technologies.

SINUS K inverters fit any application thanks to their advanced features, among which: 16-bit multiprocessor

control board; vectorial modulation; power control with the latest IGBTs; high immunity to radio interference;

high overload capability.

Any value of the variables required for the equipment operation may be easily programmed through the

keypad, the alphanumeric display and the parameter menus and submenus.

The inverters of the SINUS K series are provided with the following standard features:

- wide power supply range: 380-500VAC (-15%,+10%) for 4T voltage class;

- two supply voltage classes available: 2T (200-240VAC) and 4T (380-500VAC);

- EMC filters for industrial environment incorporated in any inverter Size;

- EMC filters for domestic environment incorporated in Sizes S05 and S10;

- possibility of AC power supply (standard feature for all sizes);

- built-in braking unit up to Size S30;

- RS485 serial interface with communications protocol according to MODBUS RTU standard;

- IP20 degree of protection up to Size S40;

- possibility of providing IP54 up to Size S30;

- 3 analog inputs 0±10VDC, 0(4)÷20mA;

- 8 optoisolated, configurable digital inputs (NPN/PNP);

- 2 configurable analog outputs, 0÷10V, 4÷20mA, 0÷20mA;

- 1 static, “open collector” digital output (optoisolated);

- 2 relay digital outputs with reverse contacts;

- air-cooling control up to Size S10.

A comprehensive set of diagnostic messages allows a quick fine-tuning of the parameters during the equipment

starting and a quick resolution of any problem during the equipment operation.

The inverters of the SINUS K series have been designed and manufactured in compliance with the requirements

of the “Low Voltage Directive”, the “Machine Directive” and the “Electromagnetic Compatibility Directive”.

1.3. PRODUCTS COVERED IN THIS MANUAL

This manual covers any inverter of the SINUS K, SINUS K BOX, SINUS K CABINET series provided with IFD

software or VTC software.

INSTALLATION SINUS K

INSTRUCTIONS

10/191

2. CAUTION STATEMENTS

This section contains safety statements. The non-observance of these safety instructions may cause serious injury

or death and equipment failure. Carefully read the instructions below before installing, starting and operating

the inverter.

Only competent personnel must carry out the equipment installation.

SYMBOLS:

DANGER Indicates operating procedures that, if not correctly performed, may cause serious

injury or death due to electrical shock.

CAUTION Indicates operating procedures that, if not carried out, may cause serious

equipment failure.

NOTE Indicates important hints concerning the equipment operation.

SAFETY STATEMENTS TO FOLLOW WHEN INSTALLING AND OPERATING THE EQUIPMENT:

Always read this instruction manual before starting the equipment.

NOTE The ground connection of the motor casing should follow a separate path to

avoid possible interferences.

ALWAYS PROVIDE PROPER GROUNDING OF THE MOTOR CASING AND THE

INVERTER FRAME.

The inverter may generate output frequency up to 800Hz (IFD SW); this may

cause a motor rotation speed up to 16 (sixteen) times the motor rated speed:

never use the motor at a higher speed than the max. allowable speed stated on

the motor nameplate.

ELECTRICAL SHOCK HAZARD – Never touch the inverter electrical parts when the

inverter is on; always wait at least 5 minutes after switching off the inverter

because electric energy accumulates within the electrical components.

Never perform any operation on the motor when the inverter is on.

Do not perform electrical connections on the motor or the inverter if the inverter is

on. Electrical shock hazard exists on output terminals (U,V,W) and resistive

braking unit terminals (+, -, B) even when the inverter is disabled. Wait at least 5

minutes after switching off the inverter before operating on the electrical

connection of the motor or the inverter.

MECHANICAL MOTION – The inverter determines mechanical motion. It is the

operator's responsibility to ensure that this does not give rise to any dangerous

situation.

DANGER

EXPLOSION AND FIRE – Explosion and fire hazard exists if the equipment is

installed in presence of flammable fumes. Do not install the inverter in places

exposed to explosion and fire hazard, even if the motor is installed there.

SINUS K INSTALLATION

INSTRUCTIONS

11/191

Do not connect supply voltages exceeding the equipment rated voltage to avoid

damaging the internal circuits.

If the inverter is installed in environments exposed to flammable and/or explosive

substances (zones AD according to standards IEC 64-2), please refer to IEC 64-2,

EN 60079-10 and related standards.

Do not connect the equipment power supply to the output terminals (U,V,W), to

the resistive braking unit terminals (+, -, B) and to the control terminals. The

equipment power supply must be connected only to terminals R,S,T.

Do not short-circuit terminals (+) and (-) and terminals (+) and (B); do not

connect any braking resistors with lower ratings than the required ratings.

Do not start or stop the motor using a contactor over the inverter power supply.

Do not install any contactor between the inverter and the motor. Do not connect

any power factor correction capacitor to the motor.

Do not install any contactor between the inverter and the motor. Do not connect

any power factor correction capacitor to the motor.

Operate the inverter only if a proper grounding is provided.

In case of alarm trip, a comprehensive review of the Diagnostic section in the

Programming Manual is recommended. Restart the equipment only after

removing the cause responsible of the alarm trip.

Do not perform any insulation test between the power terminals or the control

terminals.

Make sure that the fastening screws of the control terminal board and the power

terminal board are properly tightened.

Do not connect single-phase motors.

Always use a motor thermal protection (use the inverter motor thermal model or a

thermoswitch installed in the motor).

Respect the environmental requirements for the equipment installation.

The bearing surface of the inverter must be capable of withstanding high

temperatures (up to 90°C).

CAUTION

The inverter electronic boards contain components which may be affected by

electrostatic discharges. Do not touch them unless it is strictly necessary. Always

be very careful so as to prevent any damage caused by electrostatic discharges.

INSTALLATION SINUS K

INSTRUCTIONS

12/191

3. INSPECTION UPON RECEIPT OF THE GOODS

Make sure the equipment is not damaged and it complies with the equipment you ordered by referring to the nameplate

located on the inverter front part. The inverter nameplate is described below. If the equipment is damaged, contact the

supplier or the insurance company concerned. If the equipment does not comply with the one you ordered, please contact

the supplier as soon as possible.

If the equipment is stored before being started, make sure that the ambient conditions do not exceed the ratings

(mentioned in chapter 7 “Installing the equipment”). The equipment guarantee covers any manufacturing

defect. The manufacturer has no responsibility for possible damages due to the inverter transportation or

unpacking. The manufacturer is not responsible for possible damages or faults caused by improper and

irrational uses; wrong installation; improper conditions of temperature, humidity, or the use of corrosive

substances. The manufacturer is not responsible for possible faults due to the inverter operation at values

exceeding the inverter ratings and is not responsible for consequential and accidental damages. The equipment

is covered by a 3-year guarantee starting from the date of delivery.

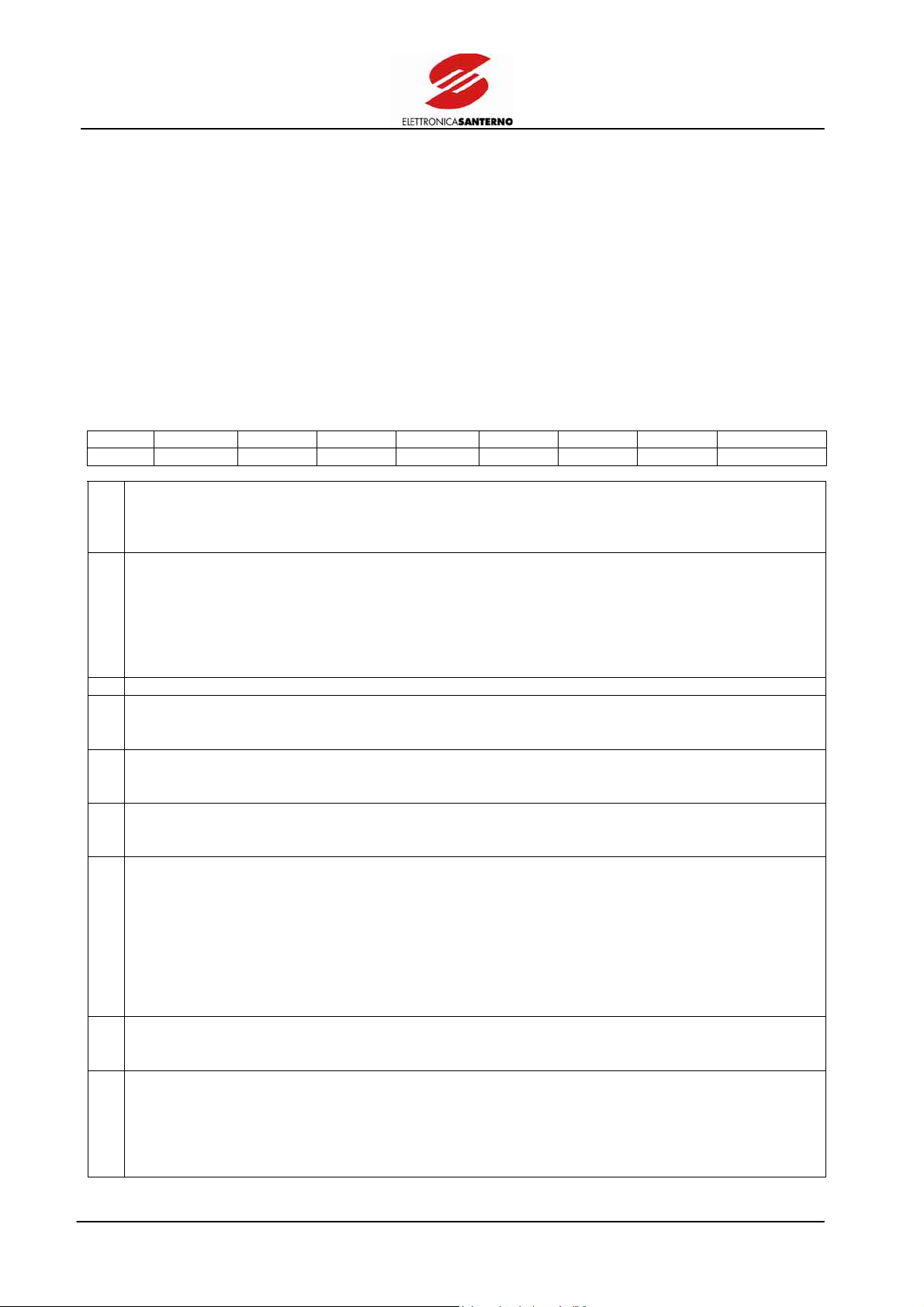

SINUS K 0005 4 T B A2 X 2

1 2 3 4 5 6 7 8 9

1 Product line:

SINUS stand-alone inverter

SINUS BOX inverter contained inside a box

SINUS CABINET inverter contained inside a cabinet

2 "K" type of control with three types of software installed:

IFD = Space vector modulation for general-purpose applications (vectorial modulation PWM with V/f

pattern)

VTC = Vector Torque Control for high torque demanding applications (Sensorless vectorial control with

direct torque control)

LIFT = Space vector modulation with a special software for lift applications

(vectorial modulation PWM with V/f pattern - NOT COVERED IN THIS MANUAL)

3 Inverter Model

4 Supply voltage

2 = power supply 200÷240Vac; 280÷340Vdc.

4 = power supply 380÷500Vac; 530÷705Vdc.

5 Type of power supply

C=Direct current supply T = three-phase

D=12 Impulse Bridge S = single-phase (available by request)

6 Braking unit

X = no braking chopper (optional external braking chopper)

B = built-in braking chopper

7 Type of EMC filter:

I = no filter, EN50082-1, -2.

A1 = integrated filter, EN 61800-3 issue 2 FIRST ENVIRONMENT Category C2, EN55011 gr.1 cl. A for

industrial and domestic users, EN50081-2, EN50082-1, -2, EN61800-3-A11.

A2 = integrated filter, EN 61800-3 issue 2 SECOND ENVIRONMENT Category C3, EN55011 gr.2 cl. A for

industrial users, EN50082-1, -2, EN61800-3-A11.

B = integrated input filter (type A1) plus external, output toroid filter, EN 61800-3 issue 2 FIRST

ENVIRONMENT Category C1, EN55011 gr.1 cl. B for industrial and domestic users, EN50081-1,-2,

EN50082-1, -2, EN61800-3-A11.

8 Control panel

X = no control panel provided

K = control panel provided (back-lit, 16x2 characters LCD display).

9 Degree of protection

0 = IP00

2 = IP20

3 = IP24

4 = IP42

5 = IP54

SINUS K INSTALLATION

INSTRUCTIONS

13/191

3.1. INVERTER NAMEPLATE

Figure 1: Example of a nameplate placed on a 2T SINUS K inverter.

Figure 2: Example of a nameplate placed on a 4T SINUS K inverter.

INSTALLATION SINUS K

INSTRUCTIONS

14/191

4. USING THE DISPLAY/KEYPAD

For the parameter programming and view a display/keypad is located on the front part of SINUS K inverters.

The keypad includes 4 LEDs, an LCD display and 8 function keys. During the inverter operation, the display

shows the parameter values, the alarm messages (if any) and the value of the measures processed by the

inverter.

Figure 3: Keypad of SINUS K inverters.

LED REF: “on” when a frequency/

speed/torque reference is sent.

IFD SW ONLY

REF LED: flashes when run command

active; frequency reference equal to 0.

RUN LED: is on during the

inverter operation

VTC SW ONLY:

RUN LED:

flashes with inverter enabled

(fluxed motor)

IFD SW ONLY:

RUN LED and REF LED:

if both Leds are flashing, the

inverter is performing a

deceleration ramp up to

frequency reference 0.

.

“TRM” LED: if on, commands and

reference are sent from the

terminal board; if flashing, either

one of the commands or the

reference is sent from the terminal

board.

“REM” LED: if on, commands and

reference are sent from serial link; if

flashing, either one of the

commands or the reference is sent

from serial link.

LED “FWD”: frequency/speed/torque

reference > 0

LED “REW”: frequency/speed/torque

reference < 0

SINUS K INSTALLATION

INSTRUCTIONS

15/191

The keypad includes the following keys: PROG, ↓, ↑,SAVE, MENU, RESET, START, STOP. They are detailed

below.

PROG

allows entering and quitting the menus and submenus and enables altering the inverter

parameters (when switching from parameter display to parameter programming, the cursor starts

flashing);

down arrow; scrolls through the menus and submenus, the pages in a submenu or the

parameters in descending order. During programming, it decrements the parameter value;

up arrow; scrolls through the menus and submenus, the pages in a submenu or the parameters

in descending order. During programming, it increments the parameter value;

SAVE

in programming mode, this key saves to non-volatile memory (EEPROM) the value of the

parameter being altered. This prevents any parameter modification from being cleared in case of

mains loss;

MENU if pressed once, allows accessing the main menu; if pressed twice, allows returning to the prior

condition;

RESET resets the alarms tripped;

START if enabled, allows starting the motor;

STOP if enabled, allows stopping the motor;

LOC | REM press once to force commands and reference from keypad; press twice to return to any previous

setting.

FWD/REW pressing the key you reverse the motor direction rotation;

HOME pressing the key, you return to the first page of a sub-menu;

NOTE START/STOP/FWD-REW are active in Keypad mode only.

NOTE

The inverter operation is affected by the active parameter set. The parameter

being altered with ↑and ↓immediately replaces the prior parameter value,

even if the SAVE key is not pressed. The new parameter value will be cleared at

power off.

4.1. Adjusting the Display Contrast

Press the SAVE key for more than 5 seconds; *** TUNING *** is displayed; the indicator Leds come on and

configure as a 5-dot bar extending proportionally to the contrast value set. Press ↓or ↑to adjust the display

contrast. Press SAVE for at least 2 seconds to store the new contrast setting.

INSTALLATION SINUS K

INSTRUCTIONS

16/191

5. STARTUP PROCEDURES

The startup procedures described below relate to commands sent via terminal board (factory setting). For the

configuration of the terminal board, see the Control Terminals section.

DANGER Before changing the equipment connections, shut off the inverter and wait at least

5 minutes to allow for the discharge of the capacitors in the DC-link.

DANGER At startup, if the connected motor rotates in the wrong direction, send a low

frequency reference and check to see if the direction of rotation is correct.

CAUTION When an alarm message is displayed, find the cause responsible for the alarm

trip before restarting the equipment.

5.1. Startup Procedure for IFD Software

1) Connection: Follow the instructions stated in the CAUTION STATEMENTS and WIRING sections.

2) Power on: Link to terminal 6 (ENABLE) is to be open when the inverter is started.

3) Parameter alteration: Use the PROG, ↓, ↑and SAVE keys to access the other parameters. See the

"Submenu Tree" in the Programming Manual.

4) Motor parameters: Access the V/f Pattern submenu and set the following: C05 (Imot) (motor rated

current); C06 (fmot1) (motor rated frequency); C07 (fomax1) (maximum output

frequency desired) and C09 (Vmot1) (motor rated voltage). Press SAVE each time a

new parameter value is set. For loads producing a quadratic pattern of the torque

with respect to rpm (turbo pumps, fans, etc..), set C11 (preboost) to 0%. Press SAVE

to store the new parameter value.

5) Overload: Set parameters C41/C43/C45 in the Limits submenu based on the max. current

desired.

6) Startup: Close terminals 6 (ENABLE) and 7 (START) and send a frequency reference: the

RUN LED and REF LED will come on and the motor will start. Make sure the motor

is rotating in the right direction. If not, operate on terminal 12 (CW/CCW) or open

terminals 6 and 7. Shut off the inverter, wait a few minutes and reverse two of the

motor phases.

7) Possible failures: If no failure occurred, go to step 8. Otherwise, check the inverter connections

paying particular attention to supply voltages, DC link and input reference. Also

check if alarm messages are displayed. In the Measure submenu, check the

reference frequency (M01), the supply voltage to the control section (M05), the DC

link voltage (M06), and the condition of terminals 6, 7, 8, 9, 10, 11, 12, and 13

(M08; a number other than 0 indicates the "activation" of the relevant terminal).

Check to see if these readings match with the measured values.

8) Additional alterations: Note that you can change Cxx parameters in the CONFIGURATION menu only

when the inverter is DISABLED or STOPPED.

You can write down any customized parameter in the table on the last pages of the

Programming Manual.

9) Reset: If an alarm trips, find the cause responsible for the alarm and reset the equipment.

Enable terminal 8 (RESET) for some time, or press the RESET key.

SINUS K INSTALLATION

INSTRUCTIONS

17/191

5.2. Startup Procedure for VTC Software

The startup procedures described below relate to commands sent via terminal board (factory setting). For the

configuration of the terminal board, see the Control Terminals section.

1) Connection: Follow the instructions stated in the CAUTION STATEMENTS and WIRING sections.

2) Power on: Link to terminal 6 (ENABLE) is to be open when the inverter is started.

3) Parameter alteration: Use the PROG, ↓, ↑and SAVE keys to access the other parameters. See the

"Submenu Tree" in the Programming Manual.

4) Motor parameters: Access the VTC Pattern submenu and set the following: C01 (fmot) (motor rated

frequency); C02 (Speedmax) (desired maximum speed); C03 (Vmot) (motor rated

voltage); C04 (Pnom) (motor rated power); C05 (Imot) (motor rated current); and

C06 (Speednom) (motor rated speed). Also set C07 (resistance of one stator phase

for a star connection or one third of one phase resistance for a delta connection),

C08 (resistance of one rotor phase for a star connection or one third of one phase

resistance for a delta connection) and C09 (inductance of stator leakage of one

phase for star connection or one third of the leakage of one phase for a delta

connection). If values to be set in C07, C08, and C09 are not known, either use

parameter C10 to perform the parameter autotuning (see step 5) or go to step 6.

Press SAVE each time a new parameter value is set.

5) Overload: Set parameter C42 (Limits submenu) depending on the maximum torque that can

be generated.

6) Vectorial control

autotuning:

Set C10 to [YES]: close the ENABLE contact (terminal 6) and wait approx. 30 sec.

The inverter will compute the motor parameters. Open terminal 6.

7) Startup: Close terminals 6 (ENABLE) and 7 (START) and send a speed reference. The RUN

LED and REF LED will come on and the motor will start. Make sure the motor is

rotating in the right direction. If not, operate on terminal 12 (CW/CCW) or open

terminals 6 and 7. Shut off the inverter, wait a few minutes and reverse two of the

motor phases.

8) Speed regulator

adjustment:

If an overdisplacement occurs when the speed setpoint is reached or if a system

instability is detected (irregular motor operation) adjust the parameters relating to

the speed loop (“Speed loop” submenu; P100 Speed prop. Gain and P101 Speed

integr. time). Set low values for P100 and high values for P101, then increase

P100 until an overdisplacement takes place when the setpoint is reached. Decrease

P100 by approx. 30%, then decrease P101 until an acceptable setpoint response is

reached. Check that the motor runs smoothly at constant speed.

9) Possible failures: If no failure occurred, go to step 10. Otherwise, check the inverter connections

paying particular attention to supply voltages, DC link and input reference. Also

check if alarm messages are displayed. In the Measure submenu, check the speed

reference(M01), the supply voltage of the control voltage (M08), the DC link voltage

(M09), the condition of terminals 6,7,8,9,10,11,12, and 13 (M11; if a number

other than 0 appears, this indicates the “activation” of the relevant terminal).

Check to see if these readings match with the measured values.

10) Additional

alterations:

Note that you can change Cxx parameters in the CONFIGURATION menu only

when the inverter is DISABLED.

You can write down any customized parameter in the table on the last pages of the

Programming Manual.

11) Reset: If an alarm trips, find the cause responsible for the alarm and reset the equipment.

Enable terminal 8 (RESET) for some time, or press the RESET key.

INSTALLATION SINUS K

INSTRUCTIONS

18/191

6. TECHNICAL SPECIFICATIONS

Power Range

• kW connected motor/voltage range

0.55~400kW 200÷240Vac, 3phase

1~710kW 380÷415Vac, 3phase

1~800kW 440÷460Vac, 3phase

1~900kW 480÷500Vac, 3phase

• Degree of protection/size

STAND ALONE: IP20 from Size S05 to Size S40, IP00

Size S50-S60, IP54 from Size S05 to Size S30

BOX: IP54

CABINET: IP24 and IP54.

Mains

• VAC supply voltage/tolerance

200÷240Vac, 3phase, -15% +10%

380÷500Vac, 3phase, -15% +10%

• Supply frequency (Hz)/tolerance

50÷60Hz, +/-20%

• VDC supply voltage/tolerance

280÷360Vdc, -15% +10%

530÷705Vdc, -15% +10%

Motor Specifications

• Motor voltage range/precision

0÷Vmains, +/-2%

Current/torque to motor/time

105÷200% for 2min. every 20min. up to S30.

105÷200% for 1min. every 10min. from S40.

• Starting torque/max. time

240% for a short time

• Output frequency/resolution

0÷800Hz (120Hz for VTC SW), resolution 0.01Hz

• Braking torque

DC braking 30%*Cn

Braking while decelerating up to 20%*Cn (with no

braking resistor)

Braking while decelerating up to 150%*Cn (with

braking resistors)

• Adjustable carrier frequency with silent random

modulation.

IFD SW:

S05÷S15 = 0.8÷16kHz

S20 = 0.8÷12.8kHz

S30 = 0.8÷10kHz (5kHz for 0150 and 0162)

≥S40 = 0.8÷4kHz

VTC SW:

5kHz

Environmental Requirements

• Ambient temperature

0÷40°C no derating; 40°÷50° with derating

(see the OPERATING TEMPERATURES BASED ON

APPLICATION CLASSES section)

• Storage temperature

-25÷+70°C

• Humidity

5÷95% (non condensing)

• Altitude

Up to 1000m a.s.l.

For higher altitudes, derate the output current of 1%

every 100m beyond 1000m (max. 4000m)

• Vibrations

Lower than 5.9m/sec2(=0.6G)

• Installation environment

Do not install in direct sunlight and in places exposed

to conductive dust, corrosive gases, vibrations, water

sprinkling or dripping (if not protected by an adequate

degree of protection). Do not install in salty

environments.

• Operating atmospheric pressure

86÷106kPa

• Cooling system:

Forced air-cooling

NOTE For DC supply of S60 and S65 SINUS K inverters, please contact Elettronica

Santerno.

SINUS K INSTALLATION

INSTRUCTIONS

19/191

Control method IFD – LIFT = Space vector modulation (vectorial modulation PWM with V/f curve)

VTC = Vector Torque Control (Sensorless vectorial, direct torque control)

Frequency/speed setting

resolution

Digital reference: 0.1Hz (IFD SW); 1 rpm (VTC SW)

Analog reference 10bit: 0.01% resolution of maximum output

frequency/speed with respect to max. speed

Speed precision Open loop: 0.5% of max. speed (2% for IFD SW and LIFT)

Closed loop (with encoder): < 0.5% of max. speed

Overload capacity Up to 2 times rated current for 120sec.

Starting torque Up to 200% Cn for 120sec and 240% Cn for a short duration

CONTROL

Torque boost Programmable for a rated torque increase

Operation method Operation through terminals, keypad, serial communication

Analog inputs

4 analog inputs:

2 voltage sum inputs, resolution 10bits

1 current input, resolution 10bits

1 voltage input, resolution 10bits

Analog: 0÷10VDC, +/-10VDC, 0 (4) ÷20mA.

Digital: from keypad, serial communication

Digital inputs 8 NPN/PNP digital inputs: 3 fixed inputs (ENABLE, START, RESET) and 5

programmable inputs

Multi frequency/

Multispeed

IFD: 15 programmable frequency sets +/-800Hz

VTC: 7 programmable speed sets +/-9000rpm

LIFT: 4 programmable speed sets 0÷2.5m/sec

Input signals

Ramps 4 + 4 accel./decel. ramps, 0 to 6500sec; possibility to set user-defined curves.

Digital outputs

3 configurable digital outputs with setting of internal timers for

activation/deactivation delay:

2 relay outputs with reverse contacts 250VCA, 30VDC, 3A

1 open collector output, NPN/PNP 5÷48VDC, 50mA max

Auxiliary voltage 24VDC +/-5%, 100mA

Potentiometer voltage +10Vdc –0% + 2%, 10mA

OPERATION

Output signals

Analog outputs 2 configurable analog outputs, 0÷10VDC and 0(4)÷20mA, 8bits resolution

Alarms

Inverter thermal protection, motor thermal protection, mains failure,

overvoltage, undervoltage, overcurrent at constant speed or ground failure,

overcurrent while accelerating, overcurrent while decelerating, overcurrent

during speed search (IFD SW only), auxiliary trip from digital input, serial

communication failure, Eeprom failure, control board failure, precharge

circuit failure, inverter overload conditions for long duration, unconnected

motor, encoder failure (VTC SW only), overspeed (VTC SW only).

PROTECTIONS

Warnings

INVERTER OK, INVERTER ALARM, acceleration – constant rpm -deceleration,

current/torque limiting, POWER DOWN, SPEED SEARCHING (IFD SW only),

DC braking, autotuning (VTC SW only).

Operating data

Frequency/torque/speed reference, output frequency, motor speed, required

torque, generated torque, current to motor, voltage to motor, bus DC

voltage, motor-absorbed power, digital input condition, digital output

condition, trip log (last 5 alarms), operating time, auxiliary analog input

value, PID reference, PID feedback, PID error value, PID regulator output, PID

feedback with programmable multiplying factor, (cage speed reference, cage

speed, cage acceleration time, length covered by the cage while accelerating,

cage deceleration time, length covered by the cage while accelerating) (*).

(*)LIFT SW only

Serial communication Standard incorporated RS485 multidrop, up to 247 devices

MODBUS RTU communication protocol

COMMUNICATION DISPLAY

Field bus

AB Communicator: optional MODBUS/field bus converter (Profibus DP; Can

Bus; Device Net; Ethernet; etc.).

Each device may control up to 4 inverters.

SAFETY EN 61800-5-1, EN50178, EN60204-1, IEC 22G/109/NP

MARK

INSTALLATION SINUS K

INSTRUCTIONS

20/191

6.1. Choosing the Product

Inverters of the SINUS K series are dimensioned based on allowable current and overload.

SINUS K series is characterized by two different current values:

-Inom: continuous current that can be produced.

-Imax: max. allowable current that can be produced when the inverter is overloaded, for a time of

120sec every 20min up to S30 and for a time of 60 sec every 10min from S40 to S65.

Each inverter model may be connected to 4 different motor power sizes depending on load performance.

Typical applications have been divided into 4 overload categories to help choosing the most suitable inverter

size.

LIGHT overload up to 120%; may be connected to light loads with constant/quadratic torque

(pumps, fans, etc.);

STANDARD overload up to 140%; may be connected to standard loads with constant torque (conveyors,

mixers, extruders, etc.);

HEAVY overload up to 175%; may be connected to heavy loads with constant torque (lifts, injection

presses, mechanical presses, translation and lifting of cranes, bridge cranes, mills, etc.);

STRONG overload up to 200%; may be applied to very heavy loads with constant torque (mandrels,

axis control, etc.).

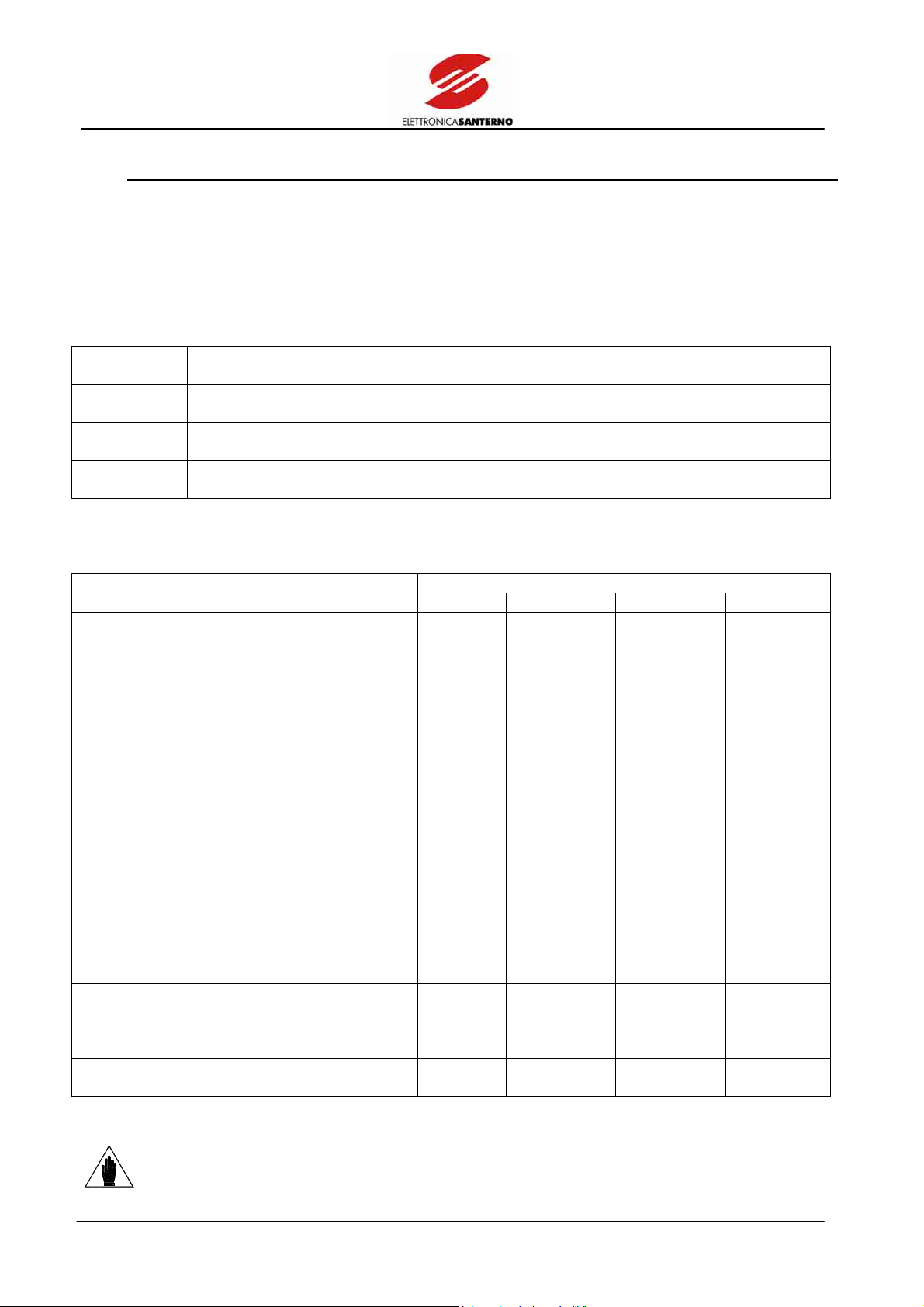

The table below indicates the overload class typically required for each application.

Dimensioning is not binding; the torque model required by the duty cycle of the connected machine should be

known.

OVERLOAD

Application

LIGHT STANDARD HEAVY STRONG

Atomizer, bottle washer, screw compressor (no-

load), damped axial fan, undamped axial fan,

centrifugal damped fan, undamped centrifugal

fan, high-pressure fan, bore pumps, centrifugal

pumps, positive displacement pumps, dust

collector, grinder, etc.

*

Slurry pump * *

Agitator, centrifuge, piston compressor (no-load),

screw compressor (loaded), roller conveyor, cone

crusher, rotary crusher, vertical impact crusher,

debarker, edger, hydraulic power pack, mixer,

rotary table, sanding machine, bandsaw, disk

saw, separator, shredder, chopper,

twister/spinner, industrial washer, palletizer,

extruder, etc.

*

Conveyor belt, drier, slicer, tumbler, mechanical

press, forming machine, shears,

winding/unwinding machine, drawplate,

calender, screw injection moulding machine, etc.

* *

Piston compressor (loaded), conveyor screw,

crusher jaw, mill, ball mill, hammer mill, roller

mill, planer, pulper, vibrating screen, hoist and

crane displacement, loom, etc.

*

Mandrel, axis control, lifting application,

hydraulic power pack injection press, etc. * *

The tables contained in the following pages state the power of the motors to be connected to SINUS K inverters

based on their overload classes.

NOTE The data items contained in the tables below apply to standard 4-pole motors.

Table of contents

Other Elettronica Santerno Inverter manuals

Popular Inverter manuals by other brands

CHAFFOTEAUX

CHAFFOTEAUX Zelios CF 2.0-1 RF Instruction manual for authorized service personnel

CPS

CPS SCA Series Installation and operation manual

Sigineer Power

Sigineer Power M6048D user manual

LETRIKA

LETRIKA 260 user manual

Schletter

Schletter ALUTILE Mounting instructions

SMA

SMA SUNNY BOY 3000TL Single Tracker user manual