TICA TIMS080AS User manual

1

CONTENTS

SAFETY PRECAUTIONS................................................................................3

Cautions and Warnings .................................................................................3

WARNINGS DURING REPAIR........................................................................3

PREFACE........................................................................................................6

CHAPTER I OVERVIEW .................................................................................7

1. Models ........................................................................................................7

2. Nomenclature ...........................................................................................12

CHAPTER II SYSTEM PRINCIPLE...............................................................14

1. Refrigerating System Schematic Diagram.............................................14

2. Exploded view/3D diagram......................................................................20

3. Refrigerant Flow Direction in Different Operating Modes ....................33

CHAPTER 4 BASIC CONTROL....................................................................36

1. Basic Control............................................................................................36

2. Protection Control ...................................................................................37

4. IDU Control ...............................................................................................45

CHAPTER V TESTING AND TRIAL OPERATION........................................58

1. Testing before Operation.........................................................................58

2. Testing Software ......................................................................................62

3. Centralized Control..................................................................................66

4. Household-based Charging ....................................................................74

2

CHAPTER VI TROUBLESHOOTING............................................................92

1. Fault Code List .........................................................................................92

2. Common fault handling and analysis ..................................................102

CHAPTER VII ELECTRICAL CONCEPTUAL DIAGRAM AND

DESCRIPTION OF DIP SWITCH ................................................................152

1. IDU and ODU DIP Switch Table.............................................................152

2. Electric control system .........................................................................159

CHAPTER VIII APPENDIXES .....................................................................169

3

Safety Precautions

Cautions and Warnings

Read these precautions carefully before repair.

This manual classifies the precautions into Warning and Caution. Warning is very

important as failure to observe it may lead to deaths or serious injuries. Caution is also

important as in some cases failure to observe it may also lead to grave accidents. Hence,

be sure to follow the safety precautions below.

After completing repair, test the unit to ensure it runs properly. In addition, give the

user adequate instructions concerning the precautions when using this unit.

Warnings During Repair

Before dismantling the unit for repair, be sure to remove the power plug, as operating

a device that is powered on may result in electric shock. If repair must be carried out

with power on, do not touch any active part.

Keep away from the refrigerant gas that leaks during repair, because exposure to this

gas may result in frostbite.

When dismantling compressor intake or discharge pipes at welding part, first empty

refrigerant gas in a well-ventilated place, as the trapped refrigerant gas or refrigerator

oil may flow out and cause injuries.

If any refrigerant gas leaks during repair, ventilate the place immediately. Refrigerant

gas may produce a toxic gas if it comes in contact with fire.

Boost capacitor is a component that provides high voltage electricity for ODU

electrical parts. Make sure it is fully discharged before repair; otherwise, it may cause

electric shock.

Do not attempt to turn on or off the unit by inserting or removing the power plug, as

this may result in electric shock or fire.

Precautions During Repair

Do not attempt to touch electrical parts with wet hands, as it may cause electric shock.

Do not clean the air conditioner by spraying water on it, as it may cause electric

shock.

To prevent an electric shock, make sure that the unit is grounded when repair is

carried out in a damp place.

Cut off the power supply and remove the power plug before cleaning.

The fan running at high speed may hurt people.

When relocating the unit, do not tilt it; otherwise, the water inside the unit may splash

on floor and furniture.

4

Before repair, check to make sure that the refrigeration and circulation system is fully

cooled. Otherwise, it may result in burns.

Make sure to use the gas welding machine in a well-ventilated place, as use of it in a

sealed room may cause hypoxia.

Warnings after Repair

Use components listed in the Maintenance Parts List and appropriate tools of the

corresponding model. Do not attempt to modify the unit, as improper use of

components or tools may cause electric shock, overheating or fire.

When installing the unit in a new place, make sure that the place of installation is

strong enough to support the unit’s weight. If the place cannot provide enough

support or the installation is not secure enough, the unit may fall and cause injuries.

Make sure to use a standard mounting rack to install the unit. Improper use of

mounting rack or operations may result in unit dropping and personal injuries.

Fasten the unit securely to the mounting rack that is fixed on the sash frame.

Improper installations may cause unit falling and personal injuries.

When wiring, make sure to use a dedicated power supply and observe the relevant

technical standards, internal wiring rules and installation manual on electrical equipment.

Insufficient power capacity and improper electrical wiring may cause electric shock or fire.

Be sure to use dedicated cables to connect IDU and ODU. Fasten and arrange the

wires in a way that the wires at the joint are not too tight. Improper wiring may result in

overheating or fire.

When connecting IDU and ODU, make sure that the terminal cover doesn't fall off

because cables extend out of the cover. If the covers are improperly fixed, the

terminal connection part may cause electric shock, overheating or fire.

Do not damage or change power cords, as damaged or changed power cords may

result in electric shock or fire.

Do not put heavy objects on power cords. Heating or stretching power cords will

cause damages to power cords.

Use designated refrigerants (R-410A) in the refrigerating system. Do not let air or

other gases in refrigerating system, as it may generate high pressure and hence

damage the unit.

If refrigerant gas leaks, make sure to find the leaking points and repair them before

refrigerant can be added. If leaking points cannot be determined, stop repair work

immediately and perform evacuation. Close service valves to prevent refrigerant gas

from entering the room. Refrigerant gas is nontoxic in itself. However, when it comes

in contact with fire, or fans, other heaters, furnaces, it may generate toxic gases.

5

Make sure to dispose of the old batteries after removing them from the remote

controller. Keep these batteries away from children.

Precautions after Repair

Residual current device may be provided depending on circumstances to prevent

electric shock.

Do not install the unit where flammable gases are present, as it may cause fire.

Install sealing parts and pads to mounting rack correctly, as improper installations

may let water in room and wet furniture and floor.

Check after Repair

Check to make sure that power plug is clean and fastened securely, and then insert

the power plug into power socket. If power plug is dirty or loosened, electric shock or

fire may occur.

If cables and wires are scratched or damaged, make sure to replace them with new

ones, as broken cables or wires may cause electric shock, overheating or fire.

Do not use cables in tandem or stretched cables. Use a separate socket. Otherwise,

it may cause electric shock, overheating or fire.

Check whether all parts are fastened reliably, wires connected correctly and welding

part or crimping part connected securely. Improper installation or wiring may result in

electric shock, overheating or fire.

Replace the corroded mounting stand or rack with a new one, as the old ones may fall

off and cause personal injuries.

Check grounding. If the unit is grounded improperly, repair it immediately, as improper

grounding may cause electric shock.

After repair, measure insulation resistance to make sure that the value is at least

1 MΩ, as improper insulation may cause electric shock.

After repair, check IDU drainage status, as improper drainage may allow water enter

the room and wet the floor or furniture in it.

6

Preface

Thank you for purchasing TICA products.

This is the Maintenance Manual for TICA cooling and heating type air conditioners (TIMS).

TICA offers a broad spectrum of models to meet different air conditioning needs in

buildings and offices. We believe that there is a model for everyone.

This Maintenance Manual contains information on repairing R-410A cooling and heating

type air conditioner (TIMS).

December 2016

TICA Technology Center

7

Chapter I Overview

1. Models

1. Models and Codes of VRF ODUs

Product series Product model Batch No. Remarks

Individual

VRF ODU

TIMS**AS

TIMS080AS P70432000000

8-16HP Single

compressor Full inverter

18-32HP Dual

compressor Full inverter

TIMS100AS P70433000000

TIMS120AS P70389000000

TIMS140AS P70350000000

TIMS160AS P70351000000

TIMS180AS P70379000000

TIMS200AS P70272000000

TIMS220AS P70380000000

TIMS240AS P70381000000

TIMS260AS P70440000000

TIMS280AS P70536000000

TIMS300AS P70537000000

TIMS320AS P70538000000

Full inverter

VRF ODU

TIMS**AX

TIMS080AX P70526000000

Full inverter 3 modules in

parallel allowable

TIMS100AX P70527000000

TIMS120AX P70528000000

TIMS140AX P70515000000

TIMS160AX P70444000000

TIMS180AX P70524000000

TIMS200AX P70525000000

TIMS220AX P70505000000

Strong-heat

individual

VRF ODU

TIMS**AST

TIMS080AST P70849000000

8-18HP Single

compressor Full inverter

EVI

TIMS100AST P70850000000

TIMS120AST P70851000000

TIMS140AST P70852000000

TIMS160AST P70853000000

TIMS180AST P70854000000

8

2. Models and Codes of VRF IDUs

Product

series Product model Batch No. Remarks

All-way

embedded

IDU

TMCF028AB P70245000000

TMCF036AB P70246000000

TMCF045AB P70363000000

TMCF050AB P70547000000

TMCF056AB P70247000000

TMCF063AB P70548000000

TMCF071AB P70377000000

TMCF080AB P70248000000

TMCF090AB P70361000000

TMCF100AB P70249000000

TMCF112AB P70362000000

TMCF125AB P70250000000

TMCF140AB P70360000000

TMCF160AB P70549000000

Two-way

embedded

IDU

TMCD028A P70131000000

TMCD036A P70132000000

TMCD045A P70133000000

TMCD056A P70134000000

TMCD071A P70135000000

TMCD080A P70136000000

TMCD090A P70137000000

TMCD100A P70138000000

TMCD112A P70139000000

TMCD125A P70140000000

TMCD140A P70141000000

One-way

embedded

IDU

TMCS028A P70142000000

TMCS036A P70143000000

TMCS045A P70144000000

TMCS056A P70145000000

TMCS071A P70146000000

Ultra-thin

silent duct

type IDU

TMDN022AC P70517000000

TMDN025AC P70518000000

TMDN028AC P70481000000

TMDN032AC P70519000000

TMDN036AC P70445000000

TMDN040AC P70520000000

TMDN045AC P70521000000

TMDN050AC P70466000000

TMDN056AC P70522000000

TMDN063AC P70523000000

9

Product

series Product model Batch No. Remarks

TMDN071AC P70478000000

TMDN022AC-NS P70770000000

TMDN025AC-NS P70771000000

TMDN028AC-NS P70772000000

TMDN032AC-NS P70773000000

TMDN036AC-NS P70774000000

TMDN040AC-NS P70775000000

TMDN045AC-NS P70776000000

TMDN050AC-NS P70777000000

TMDN056AC-NS P70778000000

TMDN063AC-NS P70779000000

TMDN071AC-NS P70780000000

Standard duct

type IDU

TMDN022AB P70276000000

TMDN025AB P70277000000

TMDN028AB P70278000000

TMDN032AB P70279000000

TMDN036AB P70280000000

TMDN040AB P70281000000

TMDN045AB P70282000000

TMDN050AB P70283000000

TMDN056AB P70284000000

TMDN063AB P70285000000

TMDN071AB P70286000000

TMDN080AB P70287000000

TMDN090AB P70288000000

TMDN100AB P70289000000

TMDN112AB P70290000000

TMDN125AB P70343000000

TMDN140AB P70342000000

TMDN160AB P70800000000

TMDN080AB-NS P70764000000

TMDN090AB-NS P70765000000

TMDN100AB-NS P70766000000

TMDN112AB-NS P70767000000

TMDN125AB-NS P70768000000

TMDN140AB-NS P70769000000

High static

pressure duct

type IDU

TMDH100A P70170000000

TMDH112A P70171000000

TMDH125A P70172000000

TMDH140A P70173000000

10

High-capacity

duct type IDU

TMDH195AI P70669000000

TMDH255AI P70670000000

TMDH410AI P70685000000

TMDH520AI P70846000000

TMDH620AI P70847000000

TMDH790AI P70848000000

Ceiling

exposed/floor

type IDU

TMVX028A P70162000000

TMVX036A P70163000000

TMVX056A P70164000000

TMVX071A P70165000000

TMVX090A P70166000000

TMVX112A P70167000000

TMVX125A P70168000000

TMVX140A P70169000000

Wall mounted

IDU

TMVW028A P70158000000

TMVW036A P70159000000

TMVW040A P70550000000

TMVW056A P70160000000

TMVW063A P70551000000

TMVW071A P70161000000

Full-fresh air

handling unit

TMDF175A-022 P70174000000

TMDF210A-020 P70175000000

TMDF250A-015 P70176000000

TMDF250A-020 P70177000000

TMDF250A-030 P70178000000

TMDF300A-020 P70179000000

TMDF400A-020 P70180000000

TMDF400A-030 P70181000000

TMDF500A-020 P70182000000

TMDF500A-030 P70183000000

TMDF600A-020 P70184000000

TMDF600A-030 P70185000000

Series E

ultra-thin duct

type IDU

TMDS022AE P70492000000

TMDS025AE P70493000000

TMDS028AE P70494000000

TMDS032AE P70495000000

TMDS036AE P70496000000

TMDS040AE P70497000000

TMDS046AE P70498000000

TMDS050AE P70499000000

TMDS056AE P70500000000

TMDS063AE P70501000000

11

TMDS071AE P70502000000

Series D DC

ultra-thin duct

type IDU

TMDS022AD P70579000000

TMDS025AD P70580000000

TMDS028AD P70581000000

TMDS032AD P70582000000

TMDS036AD P70583000000

TMDS040AD P70584000000

TMDS046AD P70585000000

TMDS050AD P70586000000

TMDS056AD P70587000000

TMDS063AD P70588000000

Series E

four-way

embedded

IDU

TMCF036AE P70594000000

TMCF040AE P70595000000

TMCF046AE P70596000000

TMCF050AE P70597000000

TMCF056AE P70598000000

Mini quiet

series

ventilators

TRD015ACA V4A14D000000

TRD020ACA V4A14F000000

TRD030ACA V4A14H000000

TRD040ACA V4A14K000000

TRD060ACA V4A14M000000

TRD080ACA V4A14P000000

TRD015ACC V4A14E000000

TRD020ACC V4A14G000000

TRD030ACC V4A14J000000

TRD040ACC V4A14L000000

TRD060ACC V4A14N000000

TRD080ACC V4A14Q000000

Medium

high-end

series fresh

air ventilators

TRD100ACB V4A0XF000000

TRD150ACB V4A0ZZ000000

TRD200ACB V4A0YM000000

TRD250ACB V4A0YL000000

TRD300ACB V4A0ZE000000

TRD400ACB V4A10G000000

TRD500ACB V4A10H000000

TRD600ACB V4A10J000000

Notes: The foregoing models are expected to go on the market in 2016. However, they

are subject to change over time; please refer to listing or change notice for specific models

and their functions.

12

2. Nomenclature

2.1 ODUs

TIMS 080 A A

1~4 5~7 8 9

Digits 1-4: TICA inverter VRF air conditioning unit (ODU)

Digits 5-7: Specifications

For example: 080 = 8HP

Digit 8: Design S/N

A

The 9: Structure

S: Individual X: Full inverter ST: Strong-heat individual

2.2 IDUs

TM C S 028 A A

1~2 3 4 5~7 8 9

Digits 1-2: TICA inverter VRF air conditioning unit (IDU)

Digit 3: IDU type

C: Embedded type D: Duct type V: Exposed type

Digit 4: Classification of types

S: Ceiling embedded (C type) S: Ultra-thin duct type (D type)

D: Two-way embedded (C type) N: Standard duct type (D type)

F: Four-way embedded (C type) H: High static pressure duct type (D type)

W: Wall-mounted (V type) F: All fresh air duct type (D type)

X: Ceiling exposed/floor type (V type)

Digits 5-7: Specifications

028: 2.8 kW

175: 1750CMH (only applied to TMDF)

Digit 8: Design S/N

A

Digit 9: Product code Standard configuration May be omitted

2.3 Branch pipes

TVB 16 A 2

1-3 4-5 6 7

Digits 1-3

TICA flow control box

13

Digits 4-5

Specifications

16 applied to 2.2kW~3.6kW

18 applied to 4.0kW~5.6kW

20 applied to 6.3kW~9.0kW

25 applied to 10.0kW~14.0kW

Digit 6

Design S/N

A

Digit 7

Pipe diameter

2=1/4"

3=3/8"

2.4 AHU kits

TBP 4022T A

1-3 4-8 9

Digits 1-3

TICA branch pipes

Digits 4-8

Specifications

4022T

R410a: IDU total capacity < 22.5 kW

4033T

R410a: 22.5 kW ≤IDU total capacity < 35.0 kW

4072T

R410a: 35.0 kW ≤IDU total capacity < 71.0 kW

4073T

R410a: IDU total capacity > 71.0 kW

4073P

Used together with 4073T

4090T

R410a: Dual module connection pipe

4135T

R410a: Triple module connection pipe

Digit 9

Design S/N

14

Chapter II System Principle

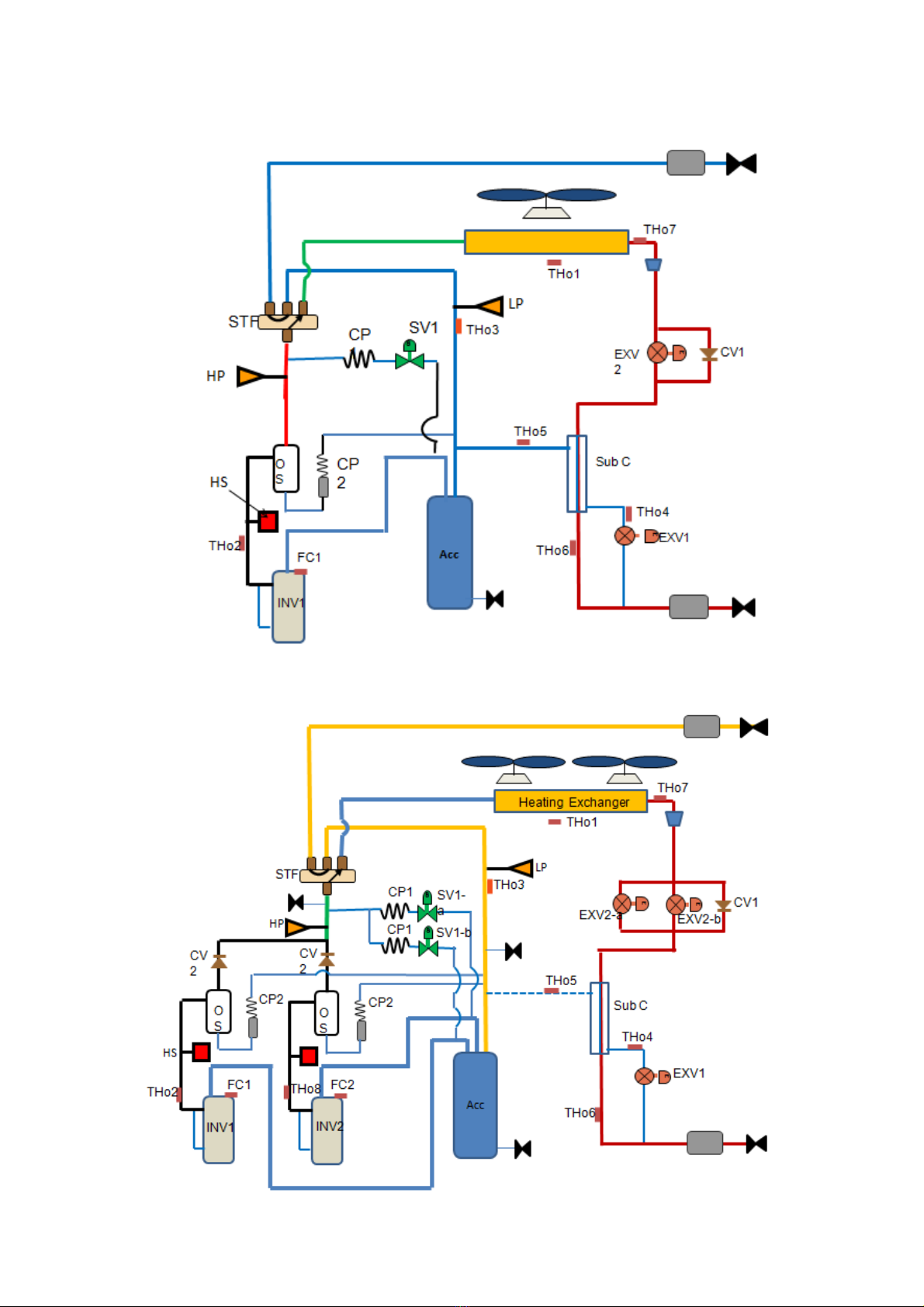

1. Refrigerating System Schematic Diagram

1.1 TIMS080/100/120/140/160AS

4-way valve

Hot air bypass valve

Hot air

bypass

valve

Compressor

Air/liquid separator

Heating expansion

valve

Subcooler

Subcooling expansion

valve

1.2 TIMS180/200/220/240/260/280/300/320AS

4-way valve

Heating expansion

valve

Subcooling expansion valve

15

1.3 TIMS080/100/120/140/160AX

1.4 TIMS180/200/220AX

16

1.5 TIMS080/100/120AST

Copper

silencer

1.6 TIMS140/160/180AST

Copper

silencer

Refrigerant cooling loop

17

1.7 Key ODU Components

①Compressor

Air inlet

Air jetting port

Air outlet

The inverter compressor adopts the low-

temperature and strong heating scroll compressor

that is equipped with the advanced permanent

magnet synchronous motor. Speed: 20-100RPS;

generally, compressor coil has a resistance value

of 2~4 Ωand insulation resistance ≥1 MΩ.

Features of scroll compressor:

1. Highest efficiency

2. Small rotation torque changes, stable

performance with less vibration and low noises

3. Least components used, simple structure,

compact, low weight and high reliability

4. High requirements for machining precision and

high costs

Model Compressor Item No.

TIMS080-100AS/X E655DHD-65D2YG B7020226

TIMS120AS/X E705DHD-72D2YG B7020796

TIMS140-160AS/X E856DHD-80D2YG B7020743

TITIMS180-240AS

TIMS180-220AX

E655DHD-65D2YG*2 B7020226

TIMS260AS E705DHD-72D2YG*2 B7020796

TIMS280-320AS E856DHD-80D2YG*2 B7020743

TIMS080-120AST DS4GK5052FVS B7020977

TIMS140-180AST AMB78FZDMT B7021045

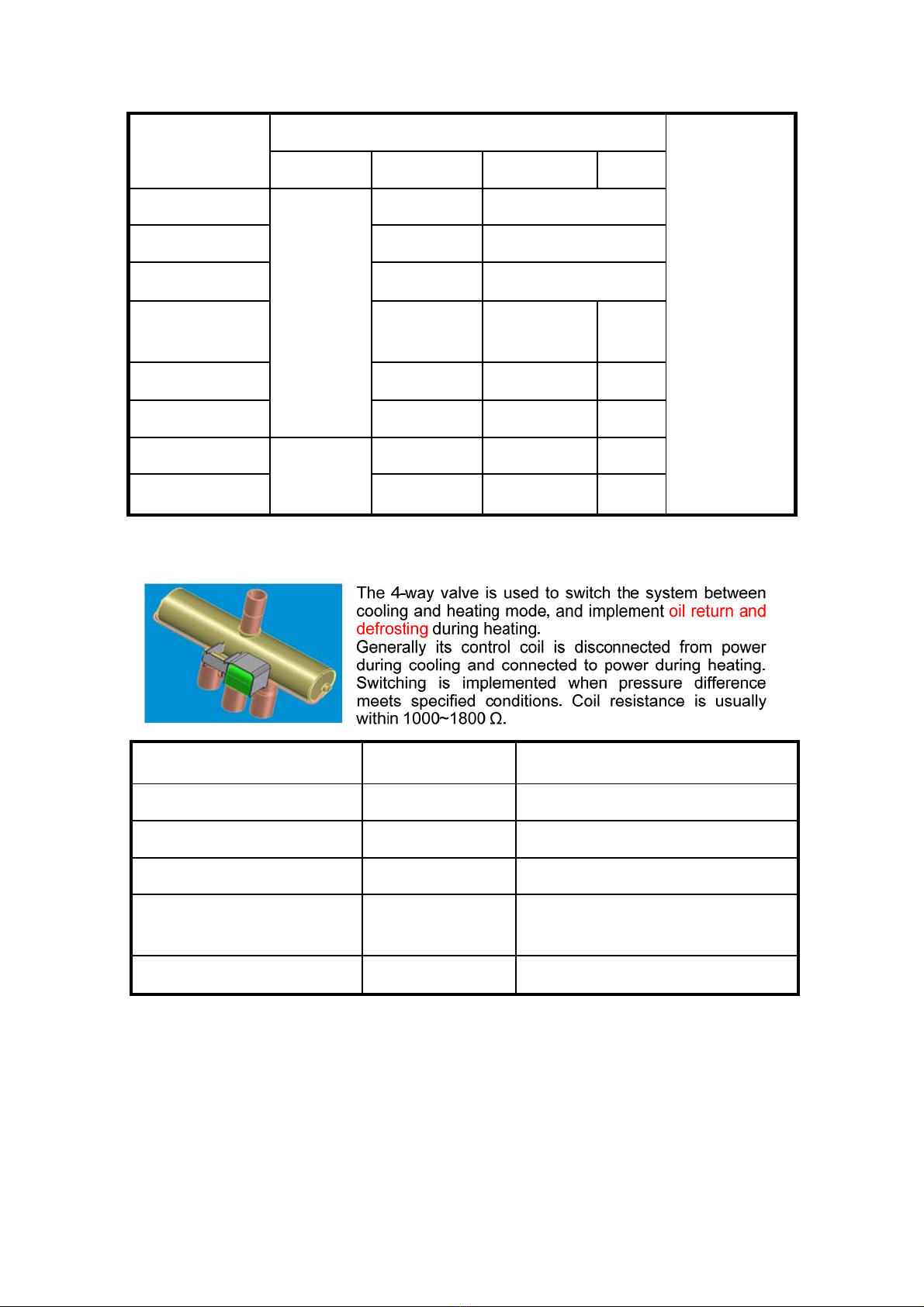

②Electronic expansion valve

18

Model Electronic expansion valve Item No.

UKV18D202

B4040079

UKV-30D209

B4040083

UKV-32D210

B4040147

UKV-40D305

B4040107

DPF(TS1)

1.65C-03

B4040283

EXV1 EXV2 EXV3 EXV4

TIMS080-100AS/X

UKV18D202

UKV30D209 /

TIMS120AS/X UKV32D210 /

TIMS140-160AS/X UKV-40D305 /

TIMS180-240AS

TIMS180-220AX UKV-40D305 UKV-40D305 /

TIMS260AS UKV-40D305 UKV-40D305 /

TIMS280-320AS UKV-40D305 UKV-40D305 /

TIMS080-120AST DPF(TS1)

1.65C-03

UKV30D209 / /

TIMS140-180AST UKV-40D305 / /

③4-way valve

Model 4-way valve Item No.

TIMS080-100AA STF-H0712 B4050052

TIMS120-180AA STF-2011G B4050061

TIMS080-120AS/X STF-H0712 B4050052

TIMS140-260AS

TIMS140-220AX

STF-2011G B4050061

TIMS280-320AS STF-2501G B4050013

19

④Air/liquid separator

Model Air/liquid separator capacity L Item No.

TIMS080-160AS

TIMS180-260AS

TIMS080-160AX

TIMS180-220AX

TIMS080-180AST

24 B7010147

B7010148

B7010145

B7010166

B7010147

TIMS280-320AS 30 B7010152

⑤Oil separator

Model Oil separator capacity L Item No.

TIMS080-160AS

TIMS180-260AS

TIMS080-160AX

TIMS180-220AX

TIMS280-320AS

TIMS080-180AS T

1.5

B7010167

20

⑥Pressure sensor

The pressure sensor converts the system pressure value into voltage signal, and then

sends the signal to main board, thereby ensuring system operation and pressure

protection. Falling into two categories (low pressure and high pressure), the pressure

sensor has 3 lead-out wires.

High pressure sensor (red) Vout=0.87*Pg+0.5

Low pressure sensor (blue) Vout=2*Pg+0.5

Pg=Mpa (gage pressure)

Model High/low pressure sensor Item No.

TIMS080-160AS

TIMS180-260AS

TIMS080-160AX

TIMS180-220AX

TIMS280-320AS

TIMS080-180AST

2HMP6-1 (red)/2HMP6-2 (black) B5180406/B5180361

2. Exploded view/3D diagram

2.1 TIMS080/100/120AS/AX

This manual suits for next models

369

Table of contents

Other TICA Inverter manuals

Popular Inverter manuals by other brands

SolaX Power

SolaX Power X3-Fit-G4 installation manual

Fuji Electric

Fuji Electric Frenic-Mini instruction manual

Briggs & Stratton

Briggs & Stratton P4500 Operator's manual

Fuji Electric

Fuji Electric frenic 5000g11s instruction manual

Phocos

Phocos SI700-12110 user manual

Eversolar

Eversolar Eversol-TL2100 installation instructions