Tiger Aircraft AG-5B Series User manual

T/QEK

AIKCKAff

AG-5B

SERIES

N.UUNTENANCE~AL

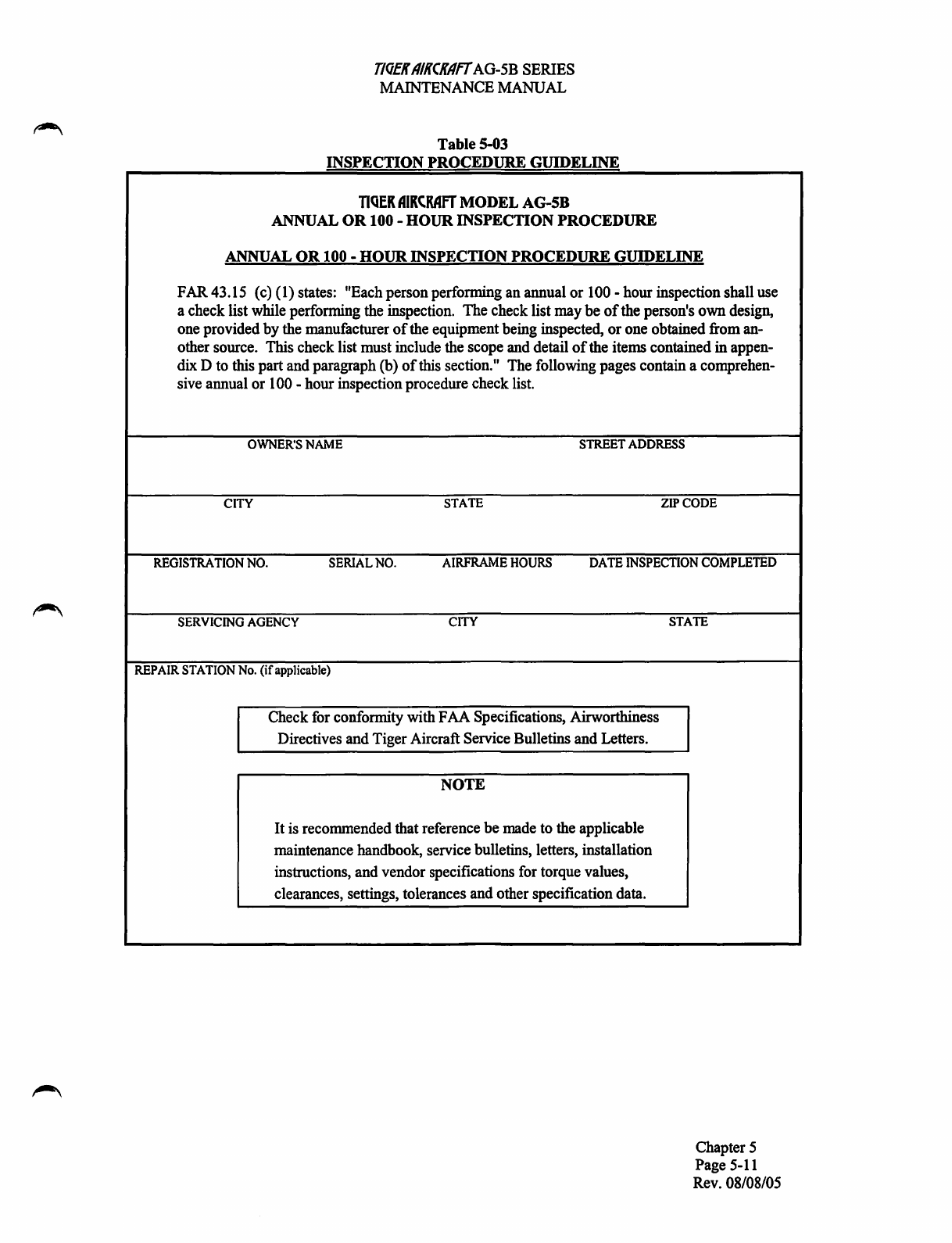

Table S-03

INSPECTION PROCEDURE GUIDELINE

TIQEK

~IKtKAfT

MODEL

AG-SB

ANNUAL

OR

100-

HOUR

INSPECTION

PROCEDURE

ANNUAL

OR

100-

HOUR

INSPECTION

PROCEDURE

GUIDELINE

FAR

43.15

(c)

(1)

states: "Each person performing

an

annual or 100-hour inspection shall

use

a check list

while

performing

the

inspection. The check list

may

be

of

the

person's

own

design,

one

provided

by

the

manufacturer

of

the

equipment being inspected, or

one

obtained

from

an-

other source.

This

check list must include

the

scope

and

detail

of

the

items contained in

appen-

dix

D

to

this

part

and

paragraph (b)

of

this

section."

The

following

pages contain a comprehen-

sive

annual or

100

-hour inspection procedure check

list.

OWNER'S

NAME

STREET

ADDRESS

CITY

STATE

ZIP

CODE

REGISTRATION

NO.

SERIAL

NO.

AIRFRAME

HOURS

DATE

INSPECTION

COMPLETED

SERVICING

AGENCY

CITY

REPAIR

STATION

No.

(if

applicable)

Check

for

conformity with FAASpecifications, Airworthiness

Directives

and

Tiger Aircraft Service Bulletins

and

Letters.

NOTE

It

is

recommended that reference

be

made

to

the

applicable

maintenance handbook, service bulletins, letters, installation

instructions,

and

vendor specifications

for

torque values,

clearances, settings, tolerances

and

other specification

data.

STATE

Chapter 5

Page

5-11

Rev.

08/08/05

T/QER

AIKCKAff

AG-5B SERIES

MAINTENANCE MANUAL

Table 5-03 (continued)

MODELAG-5B

ANNUAL

OR

100-

HOUR

INSPECTION PROCEDURE

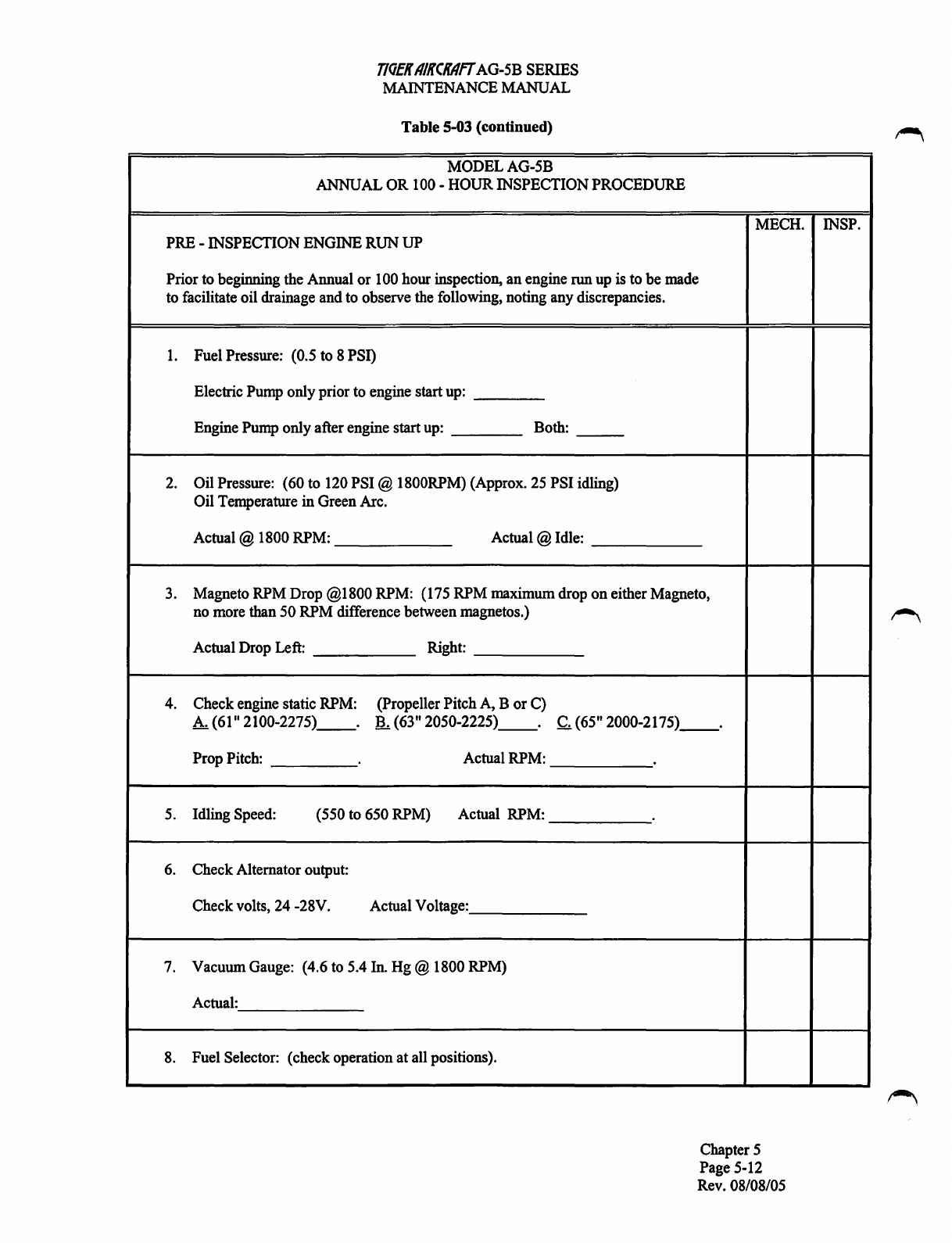

PRE -INSPECTION ENGINE

RUN

UP

Prior to beginning the Annual

or

100 hour inspection,

an

engine run

up

is to

be

made

to facilitate oil drainage and to observe the following, noting any discrepancies.

1.

Fuel Pressure: (0.5 to 8 PSQ

Electric Pump onlyprior to engine start up:

__

_

Engine Pump only after engine start up:

__

_ Both:

2. Oil Pressure: (60 to 120 PSI @ 1800RPM) (Approx. 25 PSI idling)

Oil Temperature

in

Green Arc.

Actual@

1800 RPM:

____

_

Actual@

Idle:

____

_

3. Magneto RPM Drop @1800 RPM: (175 RPM maximum drop

on

either Magneto,

no more than

50

RPM difference between magnetos.)

Actual Drop Left:

____

_ Right:

-----

4. Check engine static RPM: (Propeller PitchA, B

or

C)

A. (61" 2100-2275)

__

. B. (63" 2050-2225)

__

. C. (65" 2000-2175)

__

.

Prop Pitch:

___

_ Actual RPM:

-----

5.

Idling Speed: (550 to 650 RPM) Actual

RPM:-----

6. Check Alternator output:

Check volts, 24 -28V. Actual Voltage:

_____

_

7. Vacuum Gauge: (4.6 to 5.4 In.

Hg@

1800 RPM)

Actual:

_____

_

8. Fuel Selector: (check operation

at

all positions).

MECH. INSP.

Chapter 5

Page 5-12

Rev. 08/08/05

T/QEK

AIKCKAFT

AG-5B

SERIES

MAINTENANCE MANUAL

Table 5-03 (continued)

MODELAG-5B

ANNUAL

OR

100-HOUR INSPECTION PROCEDURE

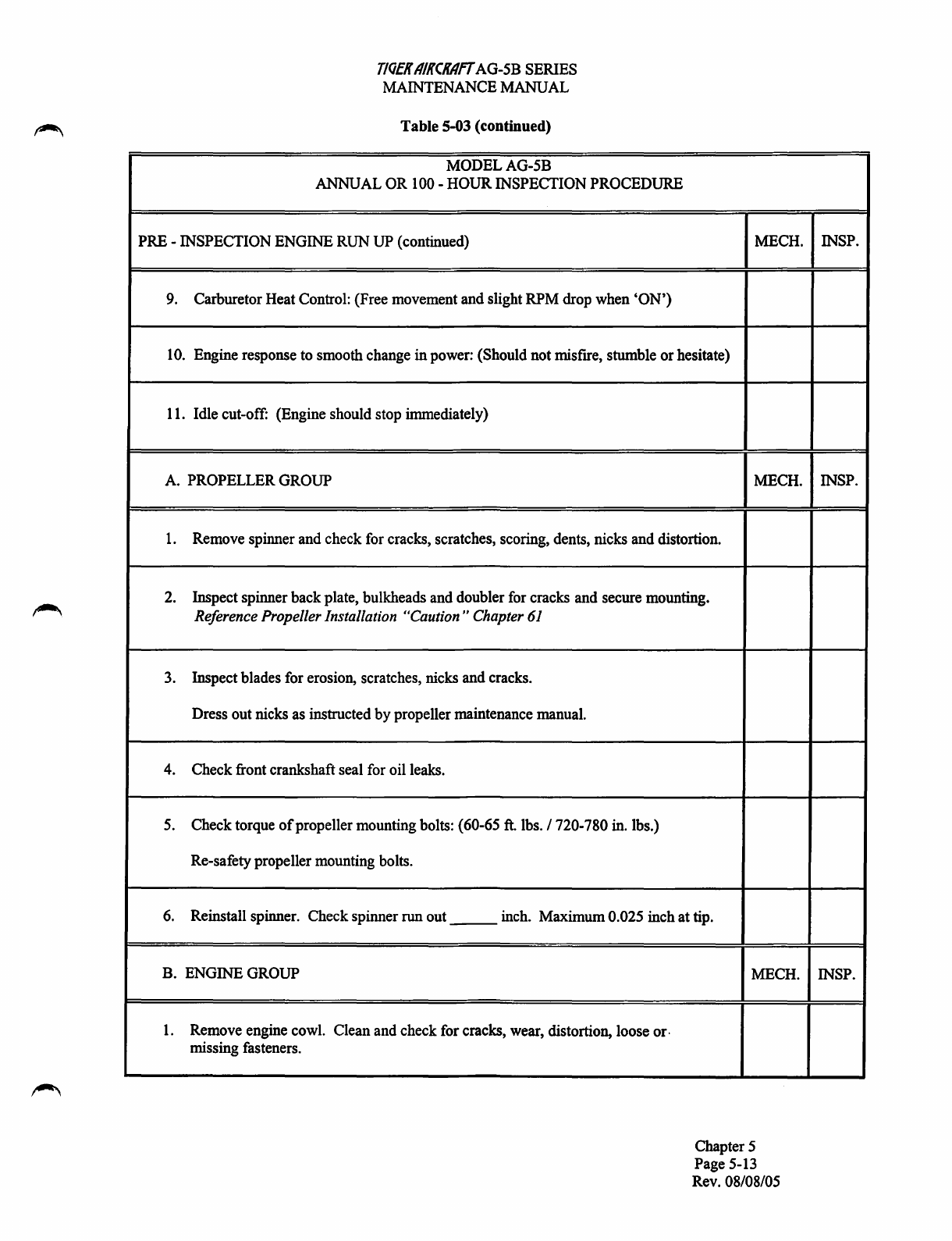

PRE -INSPECTION ENGINE

RUN

UP

(continued)

9.

Carburetor Heat Control: (Free movement and slight

RPM

drop when 'ON')

10.

Engine response

to

smooth change in power: (Should not misfrre, stumble or hesitate)

11.

Idle cut-off: (Engine should stop immediately)

A.

PROPELLER

GROUP

1.

Remove spinner and check

for

cracks, scratches, scoring, dents, nicks and distortion.

2.

Inspect spinner back plate, bulkheads and doubler

for

cracks and secure mounting.

Reference Propeller Installation "Caution" Chapter

61

3.

Inspect blades for erosion, scratches, nicks and cracks.

Dress out nicks

as

instructed

by

propeller maintenance manual.

4.

Check front crankshaft seal

for

oil leaks.

5.

Check torque

of

propeller mounting bolts: (60-65

ft.

lbs.

I 720-780

in.

lbs.)

Re-safety propeller mounting bolts.

6.

Reinstall spinner. Check spinner

run

out

___

inch.

Maximum 0.025 inch at tip.

B.

ENGINE

GROUP

1.

Remove engine cowl. Clean and check for cracks, wear, distortion, loose or.

missing fasteners.

MECH.

MECH.

MECH.

Chapter 5

Page

5-13

Rev.

08/08/05

INSP.

INSP.

INSP.

T/QER

AIRCRAfT

AG-5B SERIES

MAINTENANCE MANUAL

Table

5-03 (continued)

MODELAG-5B

ANNUAL OR

100-

HOURINSPECTION PROCEDURE

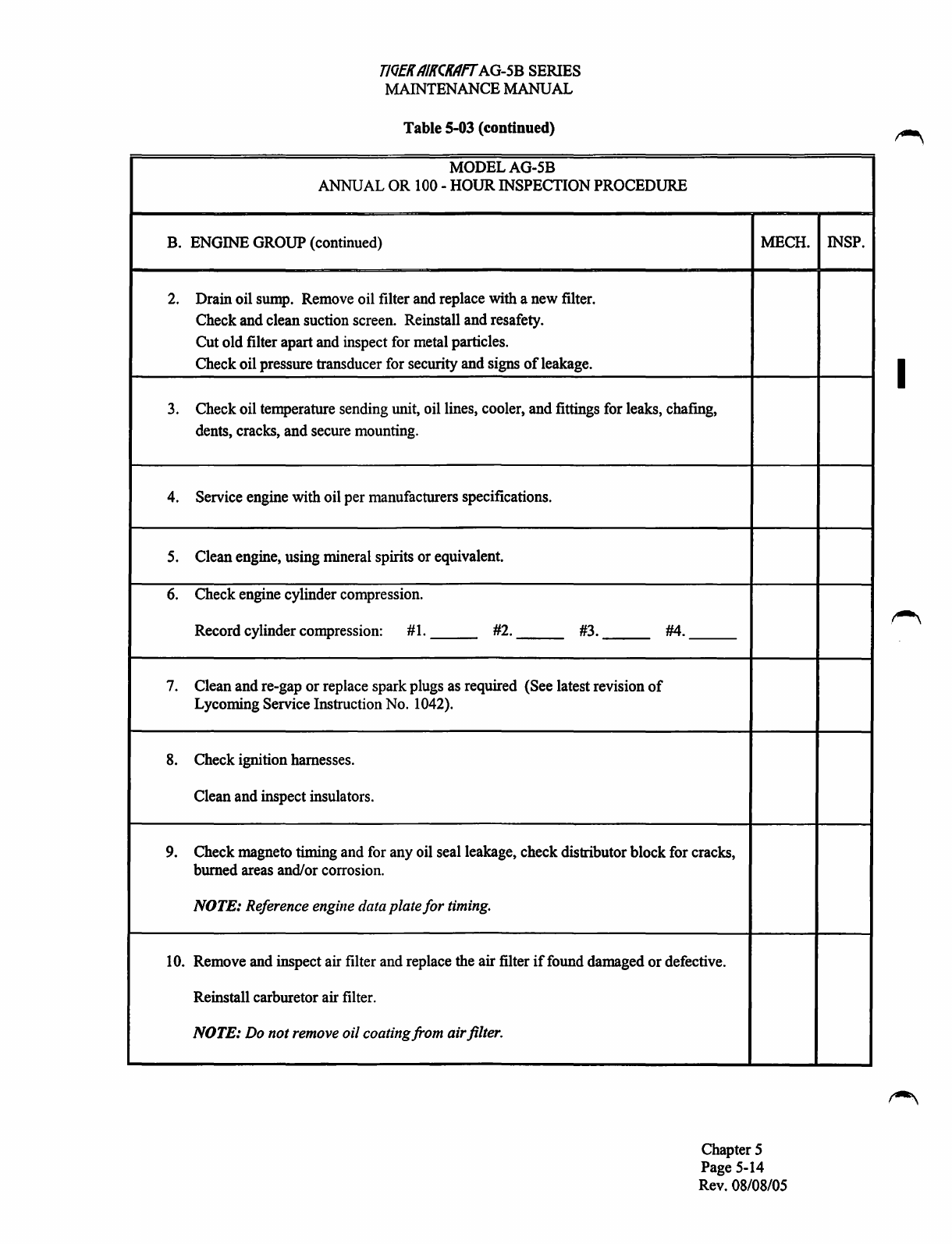

B. ENGINE GROUP (continued)

2. Drain oil sump. Remove oil filter and replace with a new filter.

Check and clean suction screen. Reinstall and resafety.

Cut old filter apart and inspect for metal particles.

Check oil pressure transducer for security and signs

of

leakage.

3. Check oil temperature sending unit, oil lines, cooler, and fittings for leaks, chafmg,

dents, cracks, and secure mounting.

4. Service engine with oil per manufacturers specifications.

5. Clean engine, using mineral spirits or equivalent.

6. Check engine cylinder compression.

Record cylinder compression: #1.

__

#2.

__

#3.

__

7. Clean and re-gap

or

replace sparkplugs as required (See latest revision

of

Lycoming Service Instruction No. 1042).

8. Check ignition harnesses.

Clean and inspect insulators.

#4.

9. Check magneto timing and for any oil seal leakage, check distributor block for cracks,

burned areas and/or corrosion.

NOTE:

Reference engine data plate

for

timing.

10. Remove and inspect air filter and replace the air filter

if

found damaged

or

defective.

Reinstall carburetor air filter.

NOTE:

Do notremove oil coatingfrom airfilter.

MECH. INSP.

Chapter 5

Page 5-14

Rev. 08/08/05

I

T/QER

AIRCRAFT

AG-SB SERIES

MAINTENANCE MANUAL

Table 5-03 (continued)

MODELAG-5B

ANNUAL OR

100-

HOUR INSPECTION PROCEDURE

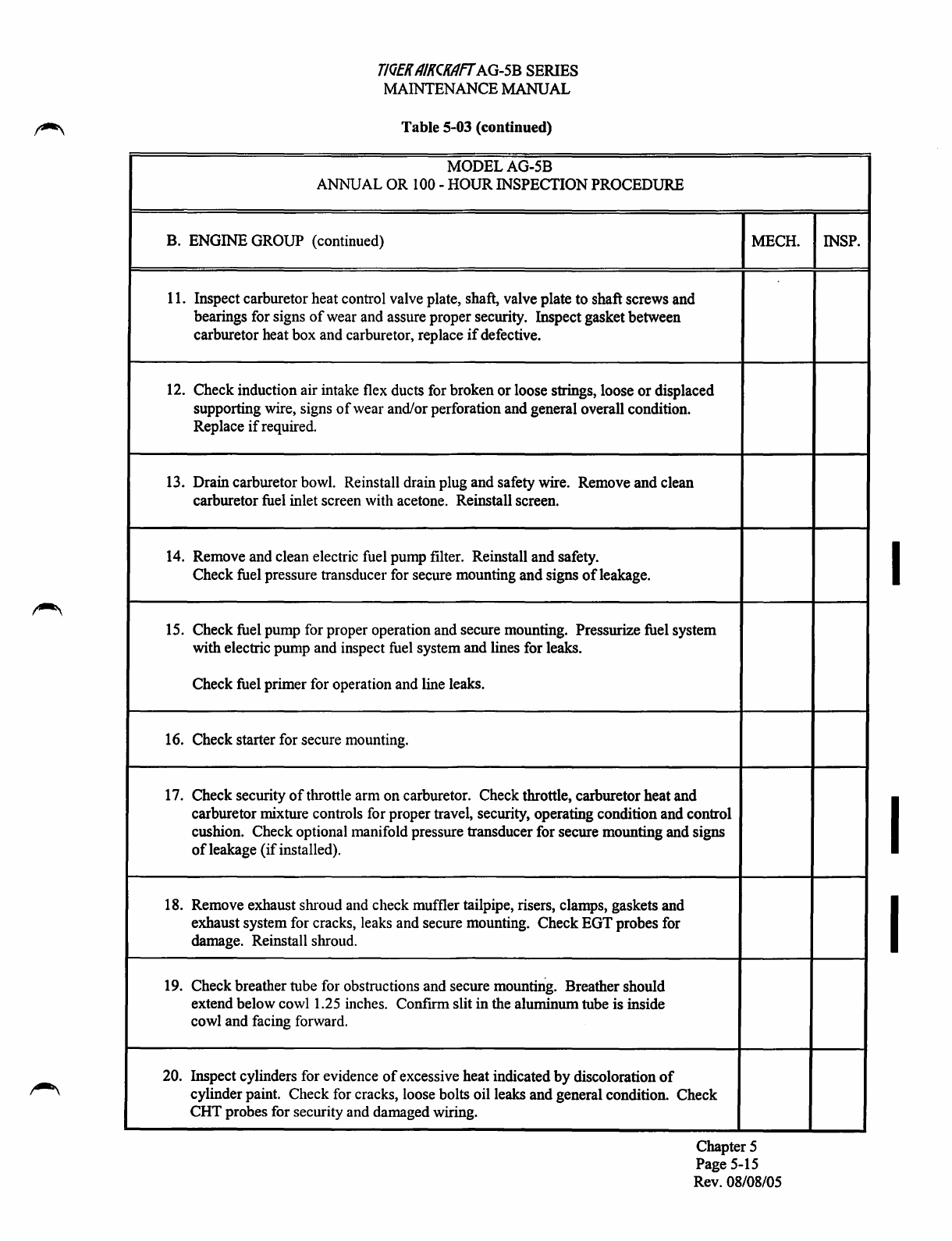

B. ENGINE GROUP (continued)

11. Inspect carburetor heat control valve plate, shaft, valve plate to shaft screws and

bearings for signs

of

wear and assure proper security. Inspect gasket between

carburetor heat box and carburetor, replace

if

defective.

12. Check induction air intake flex ducts for broken

or

loose strings, loose or displaced

supporting wire, signs

of

wear and/or perforation and general overall condition.

Replace

if

required.

13. Drain carburetor bowl. Reinstall drain plug and safety wire. Remove and clean

carburetor fuel inlet screen with acetone. Reinstall screen.

14. Remove and clean electric fuel pump filter. Reinstall and safety.

Check fuel pressure transducer for secure mounting and signs

of

leakage.

15. Check fuel pump for proper operation and secure mounting. Pressurize fuel system

with electric pump and inspect fuel system and lines for leaks.

Check fuel primer for operation and line leaks.

16. Check starter for secure mounting.

17. Check security

of

throttle arm on carburetor. Check throttle, carburetor heat and

carburetor mixture controls for proper travel, security, operating condition and control

cushion. Check optional manifold pressure transducer for secure mounting and signs

ofleakage

(if

installed).

18. Remove exhaust shroud and check muffler tailpipe, risers, clamps, gaskets and

exhaust system for cracks, leaks and secure mounting. Check EGT probes for

damage. Reinstall shroud.

19. Check breather tube for obstructions and secure mountiiig. Breather should

extend below cowl 1.25 inches. Confrrm slit in the aluminum tube is inside

cowl and facing forward.

20. Inspect cylinders for evidence

of

excessive heat indicated

by

discoloration

of

cylinder paint. Check for cracks, loose bolts oil leaks and general condition. Check

CHT probes for security and damaged wiring.

MECH.

Chapter 5

Page 5-15

Rev. 08/08/05

INSP.

I

I

I

T/QEK

AIKCKAfT

AG-5B SERIES

N.UUNTENANCE~AL

Table

5-03 (continued)

MODELAG-5B

ANNUAL OR

100-

HOUR INSPECTION PROCEDURE

B. ENGINE GROUP (continued)

21. Inspect engine mount for cracks and secure mounting. Checkrubber vibration

dampeners for signs

of

deterioration. Replace

if

required.

22. Check all baffles for cracks, loose

or

missing screws and deteriorated seal material.

23. Check alternator for secure mounting and lugs and brackets for cracks. Check

condition and tension

of

alternator drive belt. Replace

if

required. Adjust the

Alternator Belt as follows:

Apply a torque wrench

to

the nut that attaches the pulley to the alternator and apply

force in a clockwise direction, note the torque when the pulley slips. Adjust belt to

the following tension:

Belt Size Condition

Torgue

Slippage

3/8" New 11-13

ft.

lbs.

3/8" Old 7-9 ft.lbs.

Yl"

New 13-15

ft.

lbs.

Yz"

Old 9-10 ft. lbs.

24. Check battery electrolyte level and specific gravity. Clean and tighten battery

terminals. Check battery drain for condition and assure drainage is clear

of

the

aircraft structure.

Note:

GlOOO

equipped

aircraft

have two batteries (check both).

The

Back-Up

Battery

must be replaced every 24 months. See

Chapter

24A

25. Inspect vacuum system components for secure mounting. Check vacuumpump

drive for evidence

of

seal leakage. Replace seal and pump

if

required. Check all

interconnecting lines and fittings for leaks, deterioration and damage.

Replace

if

required.

26. Check ground straps for condition and secure attachment.

27. Check electrical wiring for condition and secure connections including shielded

cable ground connection.

28. Check Alternator Control Unit, Starter Relay and Master SwitchRelay for condition,

operation and installation.

MECH.

Chapter 5

Page 5-16

Rev. 08/08/05

INSP.

I

T/QER

11/RCRflfT

AG-5B SERIES

MAINTENANCE MANUAL

Table

5-03 (continued)

MODELAG-5B

ANNUAL

OR

I

00-

HOUR

INSPECTION PROCEDURE

B. ENGINE GROUP (continued)

29. Check fuses for condition and installation.

30. Install cowl, checking for proper engagement

of

air intake duct and cowl latches.

C. CABIN GROUP

1.

Remove front seats, aft. console, rear seat back cushions and fold rear seatbottom

forward, remove cover from rear seat support and remove console side panels.

To

gain access for following inspections and checks.

2. Check windshield, windows and canopy for cracks and secure mounting. Clean

and lubricate canopy rails. Check canopy operation and locking devices.

3. Check seat belts and shoulder harnesses for condition

and

secure mounting.

4. Check elevator trim control for condition, secure mounting, proper operation

and indication.

5. Check rudder pedal and brake system for proper operation

and

condition.

Check brake fluid level. Replace rudder pedal springs at 1000 hours.

6. Check control "T" column for secure mounting and adequate clearance from

other equipment.

7. Check pitot static system lines and the alternate air source valve. Drain

any

accumulated moisture from system drain. ("T" Fitting under the L/H side

of

rear

seat).

NOTE:

Opening

the

alternate

air

source

valve will

drain

static

lines

behind

the

panel.

MECH.

MECH.

Chapter 5

Page 5-17

Rev. 08/08/05

INSP.

INSP.

TIOEK

11/:TCK/IFT

AG-5B SERIES

MAINT!::\A1\CE MANUAL

TabL.· 5-03 (continued)

- - -

7\'IODEL

AG-5B

ANNUAL OR lOll- IlOUR INSPECTION PROCEDURE

C. CABIN GROUP (continued) MECH.

8. Check chains, cables, pulleys,

turnbtt~.:klcs

and cable ends for condition, secure

attachment and safeties. Specificall:. check cables at pulleys for fraying while

actuating controls through full travc

l.

9. Check all cable tensions.

10. Check all controls for clearance and i)ropcr operation.

11. Check all interior bond lines for any indication

of

damage, peeling and/or

cracking.

12. Check nose gear torque

tubes,

mom:~ing

brackets and bondjoints for cracks

and secure mounting. Check torque

')

rmounting bolts -center bearing bracket

bolts 185-195 in. lb. and end plate b•lts

~00-350

in.

lb.

13. Check flap actuator, push rods, limit ;witches and indicator for proper operation

and secure mounting.

14. Lubricate

per

lubrication chart. (Ch<:ptcr

12).

-

15. Check all plumbing in cabin for leak,; and condition.

16. Actuate fuel selector through its

full

:angl',

check for smooth operation and

position detents.

-

17. Check gyro system filters, replace irnecessary.

18. Check instruments for condition.

se(

trc

mounting and legible markings.

19. Inspect Transorb Fuse.

If

fuse

is

bl(

vn. replace ihse and Transorb.

See Chapter 24A.

{GlOOO

equipped

,tirnan

only)

Chapter 5

Page 5-18

Rev. 08/08/05

INSP.

'~

T/QEK

AIKCKAfT

AG-5B SERIES

N.UUNTENANCE~AL

Table 5-03 (continued)

MODELAG-5B

ANNUAL OR

100-

HOUR INSPECTION PROCEDURE

C. CABIN GROUP (continued) MECH.

20. Check electrical wiring, switches, lights and electronic equipment for condition

and security. Test the Emergency Buss Dual Diode. (Reference Chapter 24A,

01000

equipped aircraft only.)

21. Inspectbaggage compartment, baggage door and cargo tie downs.

22. Inspect all placards in cabin for condition and legibility.

23. Inspect the emergency locator transmitter (ELT) for security, operation and

battery expiration date.

24. Reinstall items removed in item 1

of

this section.

25. Check fresh air vents for proper operation.

D. FUSELAGE AND EMPENNAGE GROUP MECH.

1.

Remove tailcone (stinger) and empennage inspection covers.

2. Inspect exterior surfaces for condition and damage. Assure all drain holes in

bottom

of

fuselage are unobstructed.

3. Inspect bond lines for any indication

of

damage, peeling separation and/or cracks.

Chapter 5

Page 5-19

Rev. 08/08/05

INSP.

I

INSP.

T/QEK

AIKCKAff

AG-5B

SERIES

~NANCE

MANUAL

Table

5-03

{continued)

MODELAG-5B

ANNUAL

OR

100-HOUR INSPECTION

PROCEDURE

D.

FUSELAGE

AND

EMPENNAGE

GROUP

(continued)

4.

Check,

horizontal and vertical stabilizers

for

damage

and

secure mounting. Inspect

mounting structure carefully for

any

buckling or cracks (see Chapter

55

for

details).

Assure

the

horizontal stabilizer

and

elevator drain

holes

are

unobstructed.

5.

Check elevator, elevator bearings

and

stops, rudder, rudder bearings

and

stops,

tab

hinges

and

bellcranks

for

damage,

travel and proper operation. Maximum

allowable torque tube wear limit at rudder bearing supports

is

0.030

in.

reduction in

wall

thickness. Wear beyond 0.030 in. requires replacement

of

the

control surface.

Wear

from

0.005

in.

up

to

and

including 0.030

in.

require

the

installation

of

Tiger

Aircraft Service Kit

121.

6.

Check elevator trimmechanism

for

damage,

secure mounting (safety

wire

and

cotter pins)

and

proper operation.

7.

Check rudder

and

elevator cables

and

pulleys

for

damage,

proper operation

and

safeties. Check bellcrank attaching bolts

for

wear.

8.

Lubricate per lubrication chart. (Chapter

12)

9.

Inspect antenna mountings, wiring

and

connectors.

10.

Check position

and

anti-collision light(s)

for

secure mounting.

11.

Check static system lines in the tailcone

for

security

and

chafmg.

12.

Reinstall inspection covers.

MECH.

Chapter 5

Page

5-20

Rev.

08/08/05

INSP.

T/QEK

AIKCKAff

AG-5B

SERIES

MAThnENANCEMANUAL

Table 5-03 (continued)

MODELAG-5B

ANNUAL

OR

100-HOUR

INSPECTION

PROCEDURE

E.

WING

GROUP

MECH.

1.

Remove

wing

tips

and

access

panels, except

fuel

cell area. Inspect all surfaces,

skins

ribs

and

tips

for

damage.

Check position/strobe

and

landing lights for secure

mounting.

Insure that all drain holes

are

open.

CAUTION: DO NOT USE A MAGNETIC SCREWDRIVER

TO

REMOVE

THE

OUTBOARD, FORWARD INSPECTION PANEL ON THE

RIGHT

WING

OF

GlOOO

EQUIPPED AIRCRAFT. (MAGNETOMETER LOCATION)

2.

Visually inspect interior

and

exterior bond

lines

for

any

indication

of

damage,

peeling, separation and/or cracks.

3.

Check ailerons, aileron bearings and

stops,

flaps,

and

flap

bearings

for

secure

mounting,

damage,

proper travel and

wear.

Assure that aileron

and

flap

drain

holes

are

clear. Maximum allowable aileron torque

tube

wear

limit at bearing supports

is

0.030

in.

reduction in wall thickness. Wear beyond 0.030

in.

requires replacement

of

the torque

tube

or control surface. Wear

from

0.005

in.

up

to

and

including 0.030

in.

requires

the

installation

of

Tiger Aircraft Service Kit

121.

4.

Check

fuel

vents

and

connecting lines

for

damage

and/or restrictions.

5.

Check

fuel

tanks,

sump

tanks

and

lines

for

evidence

of

leakage.

Check

sump

tanks

and

lines

for

secure

mounting.

6.

Check

fuel

cap

sealing condition.

7.

Check

wing

and

outboard

wing

section attaching bolts. Torque

to

60-85

in.

lb.

8.

Inspect

fuel

tank placards.

9.

Check pitot

tube

opening

and

lines

for

obstruction

and

condition

and

heat element

for

proper operation.

10.

Check

for

interior corrosion

of

skin indicated by a

white

flaking material.

Chapter 5

Page

5-21

Rev.

08/08/05

INSP.

I

T/QEK

A/KCKAff

AG-5B

SERIES

MAINTENANCE

MANUAL

Table

5-03 (continued)

MODELAG-5B

ANNUAL

OR

100-HOUR INSPECTION

PROCEDURE

F.

MAIN

LANDING

GEAR

GROUP

MECH.

1.

Remove

wheels

and

check

for

cracks. Check condition

of

brake linings, wheel

cylinders, torque plates

and

mounting pins. Pack wheel bearings, reinstall wheels

and

key

axle

nuts at

frrst

100

hours

and

each 500

hours

thereafter. Inspect

wheel

bearing grease

for

contamination

and

solidification at each annual or

100

hour

inspection. For operation in dusty areas or areas

of

high humidity, repack every

100

hours. Perform a complete wheel inspection at each tire replacement.

2.

Check tires

for

approved

type,

acceptable condition

and

proper inflation.

3.

Check brake lines

for

leaks

and secure attachment.

4.

Check struts

for

secure mounting. Inspect

for

cracks, delamination and/or

nicks.

5.

Inspect

the

upper

main

mounting brackets

and

spar attaching supports (center spar

to

fuselage)

for

wear,

cracks and/or

loose

bolts.

6.

Inspect

wheel

and

strut fairings

for

damage

and

secure mounting.

G.

NOSE

GEAR

GROUP

MECH.

1.

2.

3.

Check nose gear strut

for

secure mounting, deformation,

damage

and/or cracks.

Remove

nose

gear strut

from

torque

yoke

and

inspect

for

corrosion

of

the

surfaces

every

12

calendar

months.

Remove

corrosion

if

present and apply McLube

1708

dryfilm lubricant or equivalent

to

the

mating

end

of

the strut

and

the

inside

of

the

yoke.

Allow lubricant

to

dryand reassemble.

Seal

strut

to

yoke

connection with

PIS

870

by

PRC

DeSoto, or equivalent.

Remove

and

check

nose

gear

fork

for

deformation, wear and/or cracks. Maximum

fork

to strut bearing clearance

is

0.035

in.

Chapter 5

Page

5-22

Rev.

08/08/05

INSP.

INSP.

T/QfR

AIRCRAfT

AG-5B SERIES

N.UUNTENANCE~AL

Table S-03 (continued)

MODELAG-5B

ANNUAL OR 100 -HOUR INSPECTION PROCEDURE

G. NOSE GEAR GROUP (continued) MECH.

4.

Grease fork and friction dampener, assemble to strut and tighten to 10-22 lb. drag

to axle. (Reference Chapter 32)

5. Remove nose wheel, clean, check for cracks, inspect and repackbearings,

reinstall wheel and safety axle at frrst 100 hours and each 500 hours thereafter.

Inspect wheel bearing grease for contamination and solidification at each annual

or

100 hour inspection. For operation in dusty areas

or

areas

of

high humidity,

repack every 100 hours. Perform a complete wheel inspection at tire replacement.

6.

Inspect nose wheel for cracks, corrosion and/or loose

or

broken bolts.

7.

Check tire for approved type, acceptable condition and proper inflation.

8. Check wheel fairing for damage and secure mounting.

H. OPERATIONAL INSPECTION MECH.

1.

2.

3.

4.

5.

Check brake and parking brake operation.

Check fuel primer operation and lines for leaks.

Check electric pump operation.

Check fuel pressure.

Check starter for proper operation.

Chapter 5

Page 5-23

Rev. 08/08/05

INSP.

INSP.

H.

T/QEK

AIKCKAfT

AG-5B

SERIES

MAINTENANCE

MANUAL

Table 5-03 (continued)

MODELAG-5B

ANNUAL

OR

100

-HOUR INSPECTION

PROCEDURE

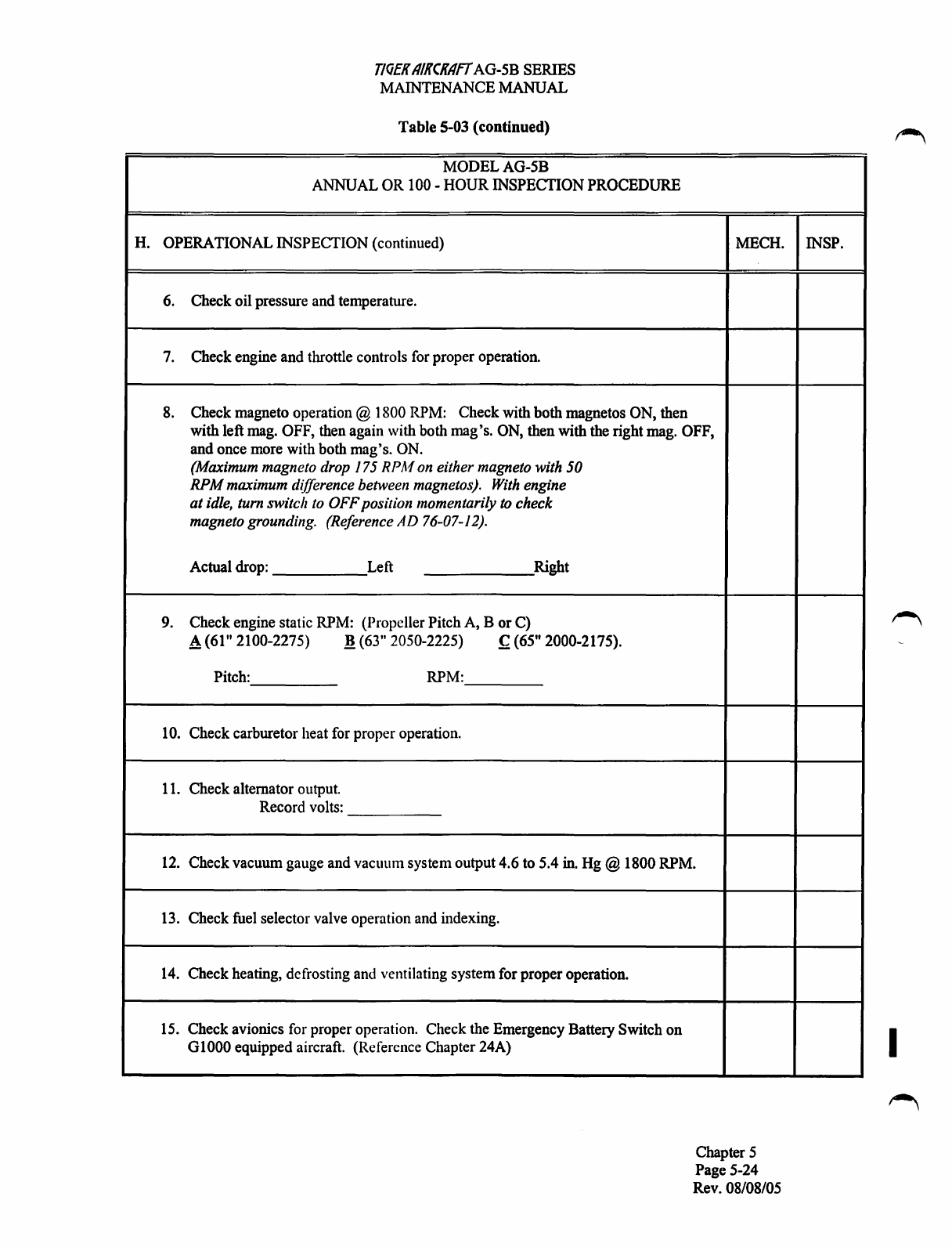

OPERATIONAL INSPECTION (continued)

6.

Check oil pressure and temperature.

7.

Check engine and throttle controls

for

proper operation.

8.

Check magneto operation @

1800

RPM:

Check with both magnetos

ON,

then

MECH.

with left

mag.

OFF,

then

again with both mag's.

ON,

then with

the

right

mag.

OFF,

and once

more

with both mag's.

ON.

(Maximum magneto drop 175

RP/11

on either magneto with

50

RPM

maximum difference between magnetos).

With

engine

at

idle, turn switch to OFFposition momentarily

to

check

magneto grounding. (Reference

AD

76-07-12).

Actual

drop:

Left Right

9. Check engine static

RPM:

(Propeller Pitch

A,

B or

C)

A(61" 2100-2275)

.!!

(63"

2050-2225)

~

(65"

2000-2175).

Pitch:

RPM:

10.

Check carburetor heat

for

proper operation.

11.

Check alternator

output.

Record

volts:

12.

Check vacuum gauge and vacuum system output 4.6

to

5.4

in.

Hg@

1800

RPM.

13.

Check

fuel

selector valve operation

and

indexing.

14.

Check heating, defrosting

and

ventilating system

for

proper operation.

15.

Check avionics

for

proper operation. Check

the

Emergency Battery Switch on

G

1000

equipped aircraft. (Reference Chapter

24A)

Chapter 5

Page

5-24

Rev.

08/08/05

INSP.

I

TJQEK

AIKCKAff

AG-5B SERIES

MAThiTENANCEMANUAL

Table 5-03 (continued)

MODELAG-5B

ANNUAL OR

100-

HOUR INSPECTION PROCEDURE

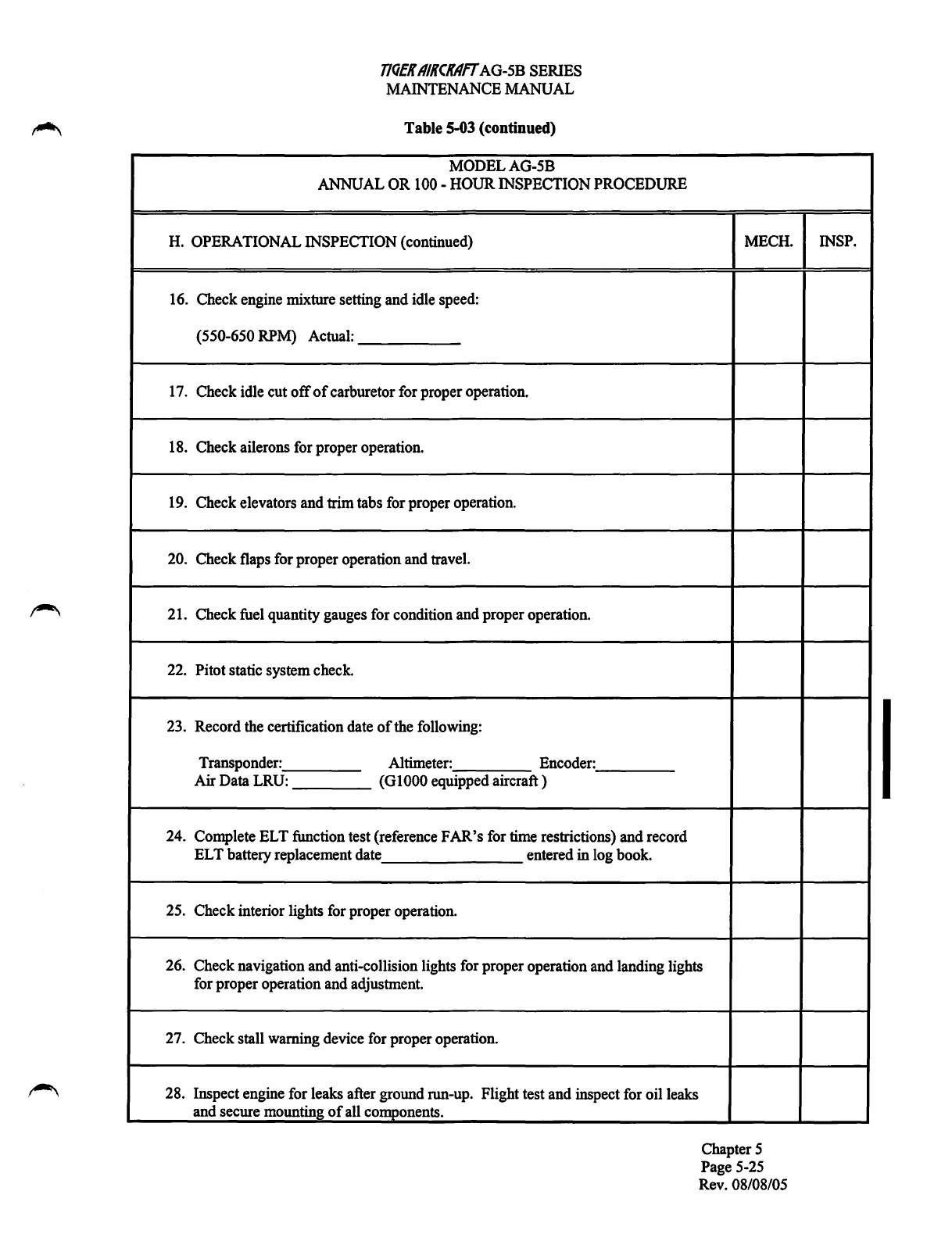

H. OPERATIONAL INSPECTION (continued)

16. Check engine mixture setting and idle speed:

(550-650 RPM) Actual:

17. Check idle cut

off

of

carburetor for proper operation.

18. Check ailerons for proper operation.

19. Check elevators and trim tabs for proper operation.

20. Check flaps for proper operation and travel.

21. Check fuel quantity gauges for condition and proper operation.

22. Pitot static systemcheck.

23. Record the certification date

of

the following:

Transponder: Altimeter: Encoder:

Air Data LRU: (G1000 equipped aircraft)

24. Complete ELT function test (reference

FAR's

for time restrictions) and record

ELT battery replacement date entered inlog book.

25. Check interior lights for proper operation.

MECH.

26. Check navigation and anti-collision lights for proper operation and landing lights

for proper operation and adjustment.

27. Check stall warning device for properoperation.

28. Inspect engine for leaks after ground run-up. Flight test and inspect for oil leaks

and secure mounting

of

all components.

Chapter 5

Page 5-25

Rev. 08/08/05

INSP.

I.

1.

2.

3.

4.

5.

6.

T/QfK

AIKCKAff

AG-5B SERIES

N.UUNTENANCE~AL

Table

5-03 (continued)

MODELAG-5B

ANNUAL

OR

100-

HOURINSPECTION PROCEDURE

GENERAL

Aircraft cleaned and serviced.

Aircraft conforms to

TC

Data

Sheet

All FAA Airworthiness Directives complied with.

All Service Letters and Bulletins complied with.

Checked for proper and complete Pilots Operating Handbook (with AFM).

Aircraftpapers in proper order. Make log book entry.

Minimum required documents:

a. Registration

b.Airworthiness Certification

c. POH with AFM (including weight and balance records and equipment list.)

d. Log Books for Aircraft, Engine and Propeller

MECH.

Chapter 5

Page 5-26

Rev. 08/08/05

INSP.

Table of contents

Other Tiger Aircraft Aircraft manuals

Popular Aircraft manuals by other brands

Cessna

Cessna 172 Skyhawk SERIES Ownersmanual

Pipistrel

Pipistrel Sinus 503 Flight and maintenance manual

Aerospool

Aerospool WT-9 Dynamic Technical description and operating instructions

Ozone

Ozone Swift 2 Pilot's manual

HPH

HPH Glasflugel 304S Technical Description, Operating, Maintenance and Repair Manual

iKarus

iKarus C42 Pilot operating handbook