Tiger Aircraft AA-5 TRAVELER User manual

ST

I

I

TIGER

AIRCRAFT

LLC

MAINTENANCE

MANUAL

FOR

Gulfstream

Aerospace

Corporation*

MODELS:

AA-5

TRAVELER

AA-5A

CHEETAH

AA-5B

TIGER

ISSUED:

NOVEMBER

15,1976

REVISION

5:

MARCH

1,

2004

*REVISION 5

-CONTENT

REVIEWED

AND

APPROVED BYTYPE DESIGN HOLDER

TIGER

AIRCRAFT

LLC

226

PILOT

WAY

MARTINSBURG,

WV

JfpN

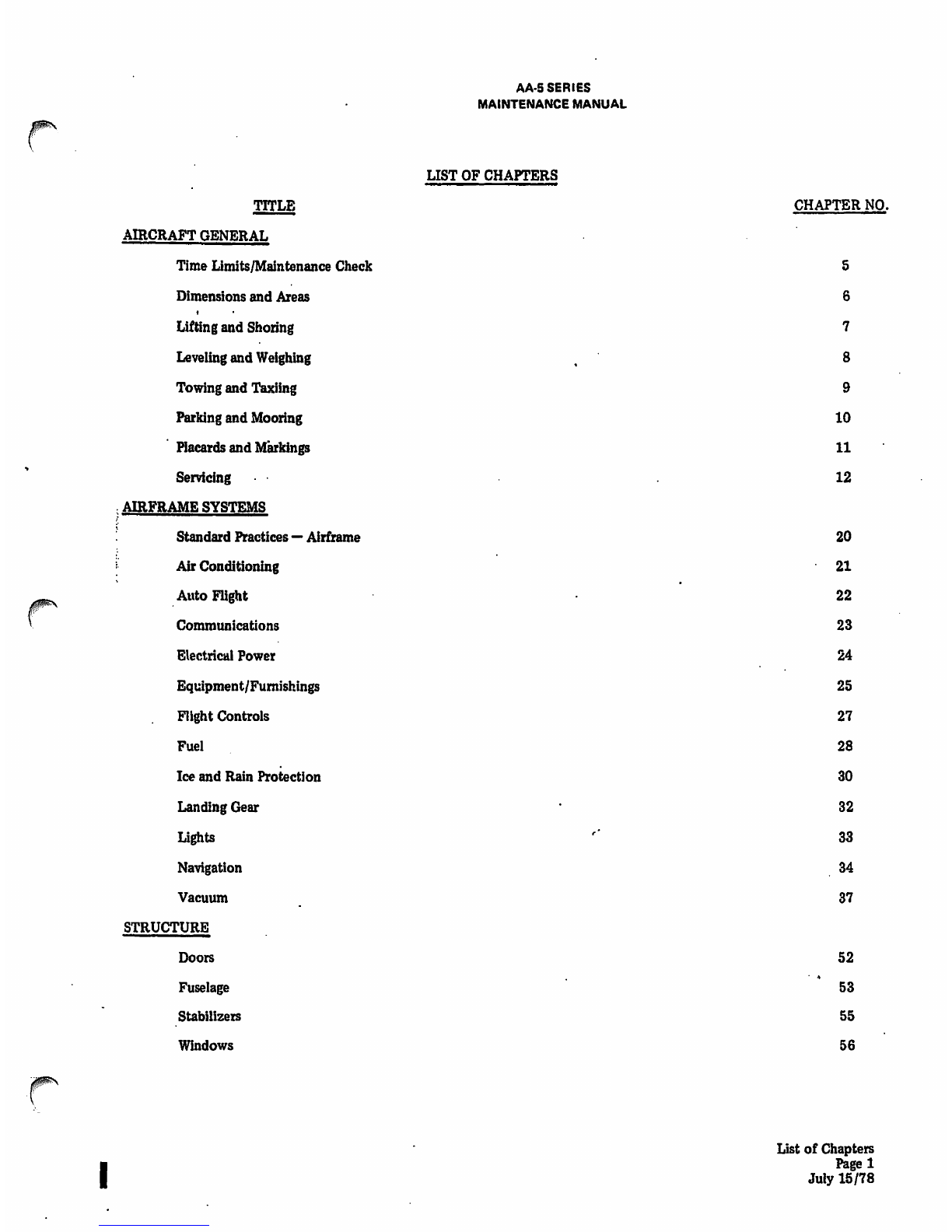

TITLE

AIRCRAFT

GENERAL

Time

Limits/Maintenance

Check

Dimensions

and

Areas

Lifting and Shoring

Leveling and Weighing

Towing

and Taxiing

Parking and Mooring

Placards and Markings

Servicing

AIRFRAME

SYSTEMS

Standard

Practices

—

Airframe

Air

Conditioning

Auto

Flight

Communications

Electrical

Power

Equipment/Furnishings

Flight Controls

Fuel

Ice

and

Rain

Protection

Landing Gear

Lights

Navigation

Vacuum

STRUCTURE

Doors

Fuselage

Stabilizers

Windows

A

A-5

SERIES

MAINTENANCE

MANUAL

LIST

OF

CHAPTERS

CHAPTER

NO.

5

6

7

8

9

10

11

12

20

21

22

23

24

25

27

28

30

32

33

34

37

52

53

55

56

List

of

Chapters

Page 1

July

15/78

TITLE

Wings

PROPELLER

Propellers

POWER

PLANT

Power

Plant

General

Engine Fuel

and

Control

Ignition

Engine Indicating

Exhaust

* 0iI

$Starting

chajJts

Charts

A

A-5

SERIES

MAINTENANCE

MANUAL

UST

OF

CHAPTERS

CHAPTER

NO.

57

61

71

73

74

77

78

79

80

91

List

of

Chapters

Page 2

July

15/78

AA-5

SERIES

MAINTENANCE

MANUAL

INTRODUCTION

GENERAL

The function of this Maintenance

Manual

Is to acquaint maintenance personnel with the systems andtheir

components of the

AA-5,

AA-5A

and

AA-5B

aircraft and to

direct

them

in the proper procedures for

maintaining

the

aircraft

In an

airworthy

condition.

This manual contains Information on installations made in the aircraft during manufacture and optional

equipmentonly. However, information derived from applicable Single Engine Aircraft Service Kits,

Service Bulletins, and Service Letters will be included in the manual as soon as possible after the

issuance of these documents. Changes or installations made by the operator are not Included In this

manual.

The ability of maintenance personnel is recognized, and those procedures which are considered common

to

all

aircraft

have

been

either

briefly

referenced

or

omitted.

FORMAT

The

chapter

identification

in this

manual

has

been

prepared

In

accordance

withAir Transport Associa

tion

(ATA)

Specification

No.

100.

A

functional

breakdown

is

employed

whereby

all

data

pertaining

to a

given

system,

or component of a

system,

may be

found

In one chapter with a minimum of

cross-refer

encing

to

other

chapters.

The Electrical

Power

Chapter

in this

manual

covers only the

power

sources anddistribution equipment

- for the electrical system. There is not a chapter in this

manual

specifically designated for instruments.

Details

of

individual

branch

electrical or instrument systems will be

found

in the

applicable

chapter.

IDENTIFICATION

OF

SUBJECT

MATTER

Athree-dash number

system

is employed to Identify subject matter. The

first

dash number Identifies

the chapter, the second dash number the section, and the third dash number the component or sub

section of the section. The following example illustrates how the numbering

system

is used in the

NAVIGATION

Chapter.

34 - l — i

•Identifies

NAVIGATION

Chapter.

•

Identifies

that

section

(group

of

related

subjects)

which

provides

coverage

for

the

Flight

Environment

Data

portion

of the

NAVIGATION

Chapter.

•Identifies a

specific

subject

(component) of

the

Flight

Environment Data. In this manual It

is

assigned

to

the

Pitot

and

Static

Pressure

Systems.

The

dash

0

(-0)

is

provided

as a

means

for

covering

a

complete

system or sub-system. The

chapter

number

followed

by a zero

(34-0)

will segregate that material covering the complete system; the chapter

section numbers

followed

by a zero (34-1-0) is used for further details covering the sub-system or com

ponent.

PAGE

NUMBER

IDENTIFICATION

Page number blocks are used to separate the subject matter into the following categories:

General Coverage andUnit Description Pages 1 through

1Q0

Troubleshooting Pages

101

through

200

Maintenance

Practices

(See

Below)

Introduction

Pagel

Nov

15/76

AA-5

SERIES

MAINTENANCE

MANUAL

Maintenance

Practices

include as applicable the following sub-topics: Servicing, Removal/Installation.

Adjustment/Test, Inspection/Check, Cleaning/Painting, and

Approved

Repairs.

If

all

sub-topics, under Maintenance Practices

are

brief, they

are

combined into one topic. All such com

bined topics are numbered withinpage number

block

201-300.

Whenever

individualsub-topics are so

lengthy

thata

combination

requires

several

pages,

each

sub-topic

is

treated

as

an

individual

topic.

Page

number blocks for this sub-topic

arrangement

are

as follows:

Servicing

301

- 400

Removal/Installation

401 -

500

Adjustment/Test

501 - 600

Inspection/Check

601 - 700

Cleaning/Painting 701 - 800

Approved

Repairs

801 - 900

Each

new

subject starts

with

page 1,

101,

201,

etc.,

and

continues

through

the page

block

assignment to the

extent necessary. The first page of each block is placed on a right-hand page.

I

-FIGURE

IDENTIFICATION

Figures (illustrations) are

numbered

consecutively

within

eachtopic

(subject)

as

follows:

Figures in Description - 1, 2, 3, 4, 5, etc.

Figures in Troubleshooting - 101, 102, 103, etc.

Figures

in

Maintenance

Practices

-

When not sub-divided - 201, 202, 203, etc.

When

sub-divided

-

Servicing-

301, 302, 303,

etc.

Removal/Installation - 401, 402, 403, etc.

Adjustment/Test - 501, 502, 503, etc.

Cleaning/Painting- 701, 702, 703, etc.

Approved

Reoairs

- 801,

802,

803,

etc.

INDEXING

Each

chapter

is prefaced

with

a

table

of

contents

identifying

the subject matter

within

the chapter in the

order

of presentation. The table of contents is arranged with the

following

headings:

DESCRIPTION:

TROUBLESHOOTING;

and

MAINTENANCE

PRACTICES.

PART

NUMBERS

This manual

must

not be used for identifying

spare

parts

by number. Consult the

Illustrated

Parts

Catalog for this information.

Part

numbers

are

used in this manual only as a means of identification

when

nomenclature

alone

is

inadequate.

Introduction

Page

2

Nov

15/76

This manual suits for next models

2

Table of contents

Other Tiger Aircraft Aircraft manuals