Tigersheds Flex Apex User manual

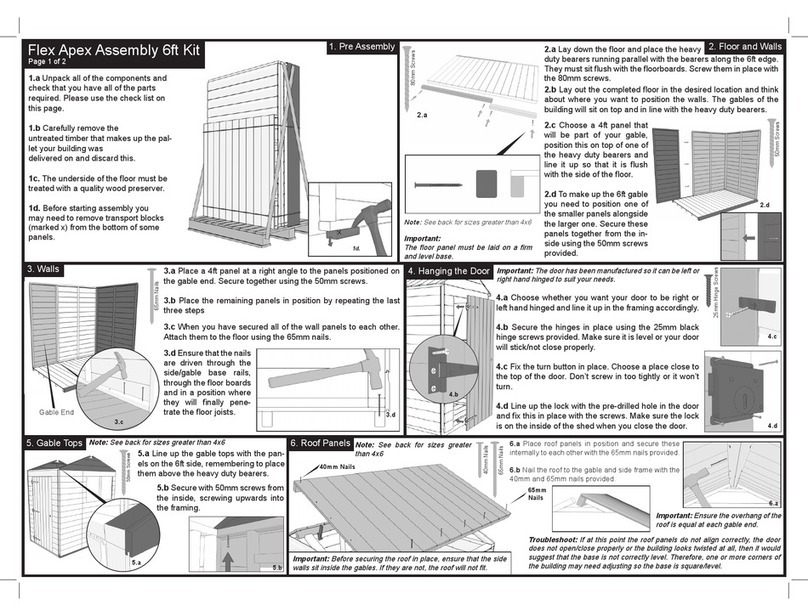

1. Pre Assembly 2. Floor and Walls

2.a Lay down the oor and place the heavy

duty bearers running parallel with the oor

boards and ush with the oor. Screw them in

place with the 80mm screws .

2.b Lay out the completed oor in the desired

location and think about where you want to

position the walls. The gables of the building

will sit on top and in line with the heavy duty

bearers.

Important:

The oor panel must be laid on a rm and

level base.

Gable End 3.a

50mm Screws

65mm Nails

2.d

3.b

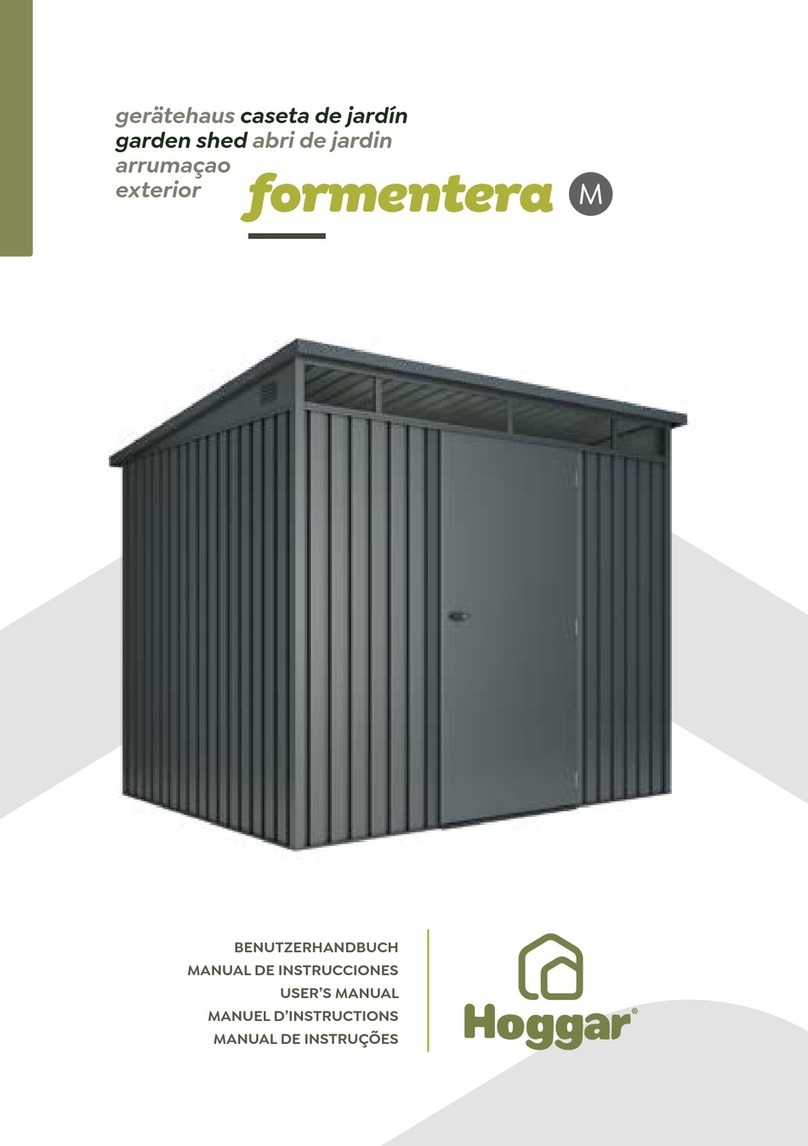

4. Hanging the Door

Important: The door has been manufactured so it can be left or

right hand hinged to suit your needs.

4.a Choose whether you want your door to be right or

left hand hinged and line it up in the framing accordingly.

4.b Secure the hinges in place using the 25mm black

hinge screws provided. Make sure it is level or your door

will stick/not close properly.

4.c Fix the turn button in place. Chose a place close to

the top of the door. Don’t screw in too tightly or it won’t

turn.

4.d Line up the lock with the pre-drilled hole in the door

and x this in place with the screws. Make sure the lock

is on the inside of the shed when you close the door.

25mm Hinge Screws

4.b

4.c

4.d

5.a Line up the gable tops with the

panel, remembering to place them

above the heavy duty bearers.

5.b Secure with 50mm screws

from the inside, screwing upwards

into the framing.

50mm Screws

5. Gable Tops

5.a

5.b

65mm Nails

40mm Nails

6.a Place roof panels in position and secure

these internally to each other with the 65mm nails

provided.

6.b Nail the roof to the gable and side frame with

the 40mm and 65mm nails provided.

Important: Ensure the overhang

of the roof is equal at each gable

end.

Troubleshoot: If at this point the roof panels do not align correctly, the door does not

open/close properly or the building looks twisted at all, then it would suggest that the

base is not correctly level. Therefore, one or more corners of the building may need

adjusting so the base is square/level.

6.a

Note: See back for sizes greater

than 4x4

Note: See back for sizes greater than 4x4

Note: See back for sizes greater than 4x4

40mm Nails

65mm

Nails

6. Roof Panels

Flex Apex Assembly 4ft Kit

3.a When you have secured all of the wall

panels to each other. Attach them to the oor

using the 65mm nails.

3.b Ensure that the nails are driven through

the side/gable base rails, through the oor

boards and in a position where they will nally

penetrate the oor joist.

2.c Place a side panel at a right angle to the panel positioned on

the gable end. Secure the panels together from the inside, using the

50mm screws provided.

2.d Place the next side wall in position and secure this to one of the

other side panels, again using the 50mm screws provided.

3. Walls

Page 1 of 2

80mm Screws

2.a

Important: Before securing the roof in place, ensure that the side

walls sit inside the gables. If they are not, the roof will not t.

1.a Unpack all of the components and

check that you have all of the parts

required. Please use the check list on

this page.

1.b Carefully remove the

untreated timber that makes up the

pallet your building was

delivered on and discard this.

1c. The underside of the oor must be

treated with a quality wood preserver.

1d. Before starting assembly you

may need to remove transport blocks

(marked x) from the bottom of some

panels. 1d.

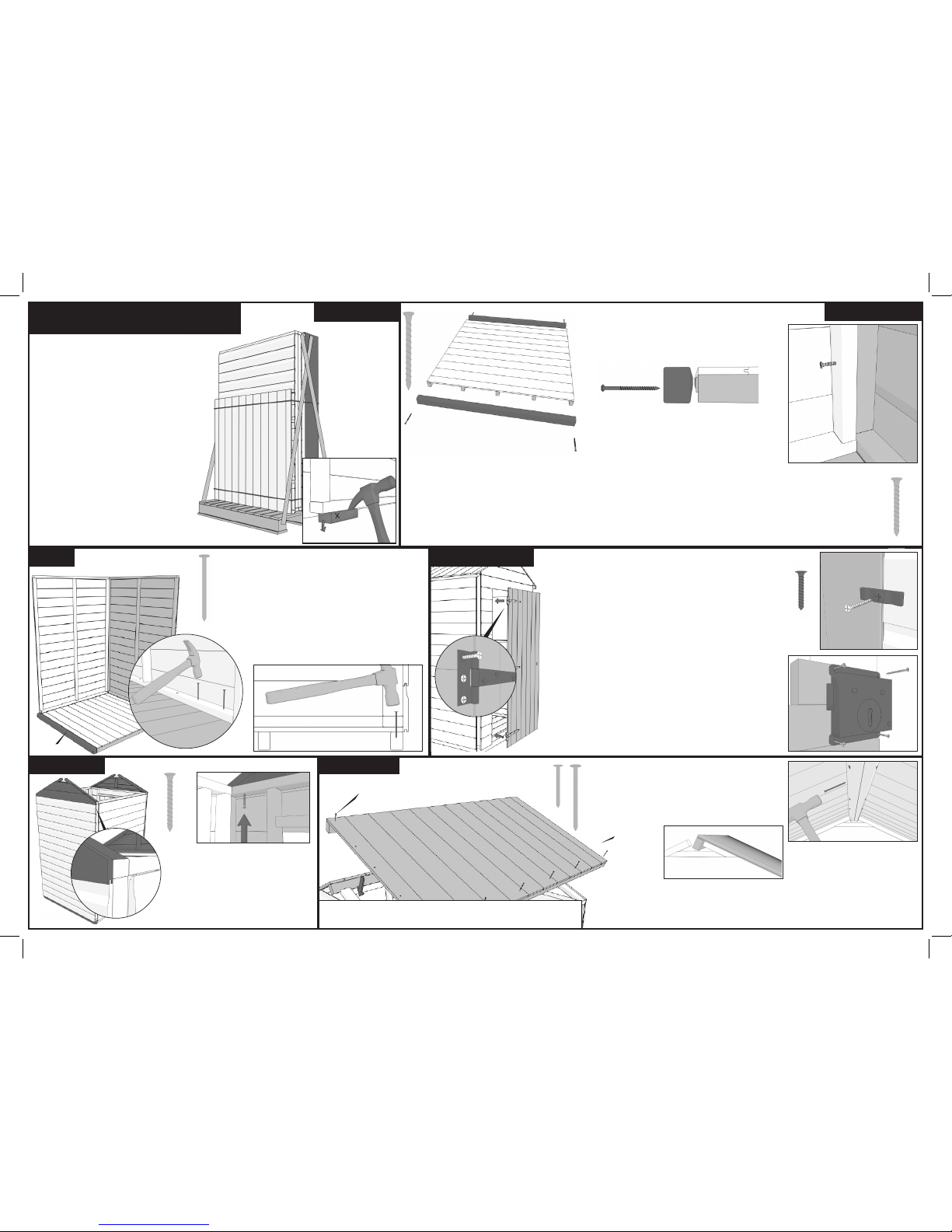

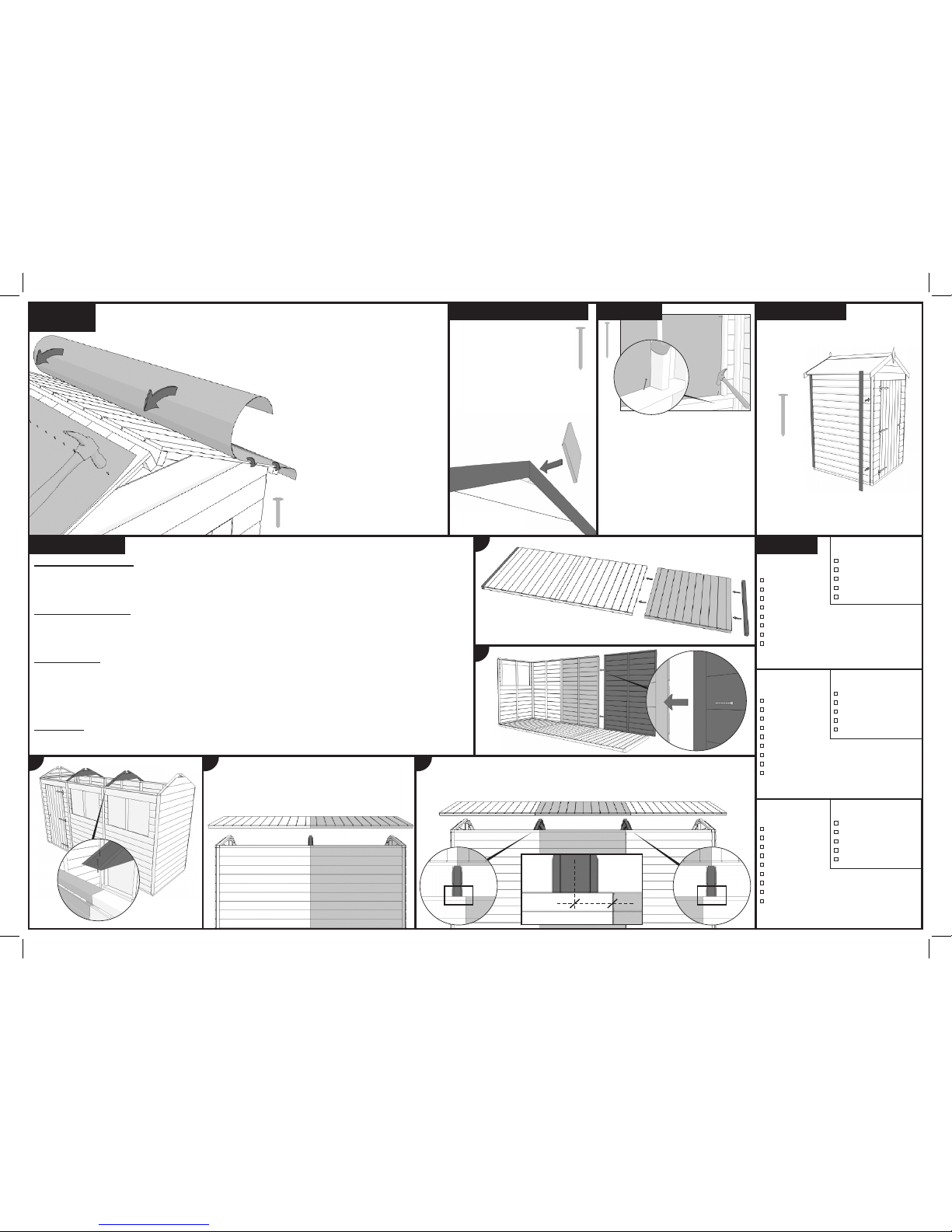

7. Roof Felt 7.a Roll out the mineral roong felt along the lower part of one side of the roof.

Allow sucient overhang to fold down onto the roof framing (but not the under-

side of the roof).

Clout Nails

8. Bargeboards and Finials

40mm Nails

8.a Fit the bargeboards to

the roof panels, trapping

the overhanging end of the

felt in between to provide a

weatherproof seal.

8.b Secure the diamond

nials over the top of the

bargeboards. 9.a Glaze the windows by securing

the glass or perspex from the inside

with the panel pins supplied.

Important: All windows must be

sealed inside and out with silicone or

any other watertight solution of your

choice (not supplied).

Panel Pins

9. Windows

Important: Please do not confuse these

corner strips as window beading. Also

please be aware that the strips may need

cutting to length.

10.a Secure the corner strips at each

corner of the shed with the 40mm

nails provided.

10. Corner Strips

40mm Nails

Check List

4x4 Pack

x1 Floor

x2 Gable Tops

x2 Blank Panels

x1 Window Panel

x1 Door Panel

x1 Door

x2 Roof Panels

x2 Heavy Duty Bearers

(found in polytube pack)

x4 Bargeboards

x2 Diamond Finials

x4 Corner Strips

Fixing Kit

Instructions

8x4 Pack

x2 Floor

x2 Gable Tops

x3 Blank Panels

x2 Window Panels

x1 Door Panel

x1 Door

x4 Roof Panels

x2 Heavy Duty Bearers

x1 Truss

(found in polytube pack)

x4 Bargeboards

x2 Diamond Finials

x6 Corner Strips

Fixing Kit

Instructions

12x4 Pack

x3 Floor

x2 Gable Tops

x4 Blank Panels

x3 Window Panels

x1 Door Panel

x1 Door

x6 Roof Panels

x2 Heavy Duty Bearers

x2 Trusses

(found in polytube pack)

x4 Bargeboards

x2 Diamond Finials

x8 Corner Strips

Fixing Kit

Instructions

11. Larger Models A.

B.

E.

D.

C.

8x4: The truss should be centered over the top of

the join of the two side panels and xed in place.

The roof can then be tted in the same way, again

centering the join of the two panels over the mid-

dle of the truss.

12x4: Each truss should be positioned to the outside of the join between each side

panel, to make this more accurate measure 56mm out from the join and use this

as the centre point for your truss. You should then attach the centre roof panel rst.

Again make sure the roof panel join is centered over the truss.

56mm

Joining the Floor Panels

These are simply butted up against each other. There is no need for any xings as the shed, which is built on top,

will hold them together. Don’t forget to attach the heavy duty bearers to the panels, one on each end of the complete

oor. See Image A.

Joining the Side Panels

These are attached using the 50mm screws provided, through the internal framework. You are supplied extra cover

strips to cover the external join. These can be tted at the end of the build as you would with smaller models. See

Image B.

Internal Trusses (8ft and 12ft Models Only)

Not to confuse with the gable tops, they can be identied by cladding xed to both sides of the framing. The truss

should be xed by nailing down through the framing in to the side panels using 65mm nails (Image C). The larger

models come with 1 or 2 trusses to support the weight and the joins of the roof, because of the way the Flex Apex is

manufactured, assembly of the the roof/trusses varies with each size, please See Image D and E below for instruc-

tions on 8x4 and 12x4 roofs.

Roof Panels

These are tted in much the same way as the smaller model, just make sure on the larger models that the join of

the panels is centered over the truss. See Image D and E

If you have the 8x4 or 12x4 model, there are a few extra steps you will need to take to

complete your building.

Tip: Leaving the backing lm on whilst

installing will prevent scratches on

your perspex or glass.

7.c Fold the overhanging felt at the

gable ends under the roof boards

and tack in place, you could cut the

felt at the corners to make it t if you

wish.

7.b Use clout nails to tack along top edge of felt in to framing.

Repeat this process on the other side of the roof.

7.d As these sheds are only 4ft

wide, there will be adequate felt

to cover the ridge, by folding the

pieces over the ridgeline. You

must make sure you don’t set

the pieces too low so that you

have enough to do this.

Page 2 of 2

Other Tigersheds Outdoor Storage manuals

Popular Outdoor Storage manuals by other brands

Hoggar

Hoggar Formentera user manual

Duratuf

Duratuf MK4 Assembly instructions

Gardiun

Gardiun Coventry instruction manual

Karibu

Karibu 71753 Building instructions

Riverlea

Riverlea Duratuf Guardian SHED SGS73 Assembly instructions

Mercia Garden Products

Mercia Garden Products 03DTSHPN0406DSHSA-V1 General instructions

Playcore

Playcore ultra site CH-R32AU manual

USP

USP DuraMax 8 Ft x 8 Ft DuraPlus owner's manual

Keter

Keter Marvel Plus Assembly instructions

Duratuf

Duratuf Glenburn Assembly instructions

Riverlea

Riverlea Duratuf Garrison Sheds PL46 Assembly instructions

Backyard Products

Backyard Products HEARTLAND CORONADO 12x8 Assembly manual