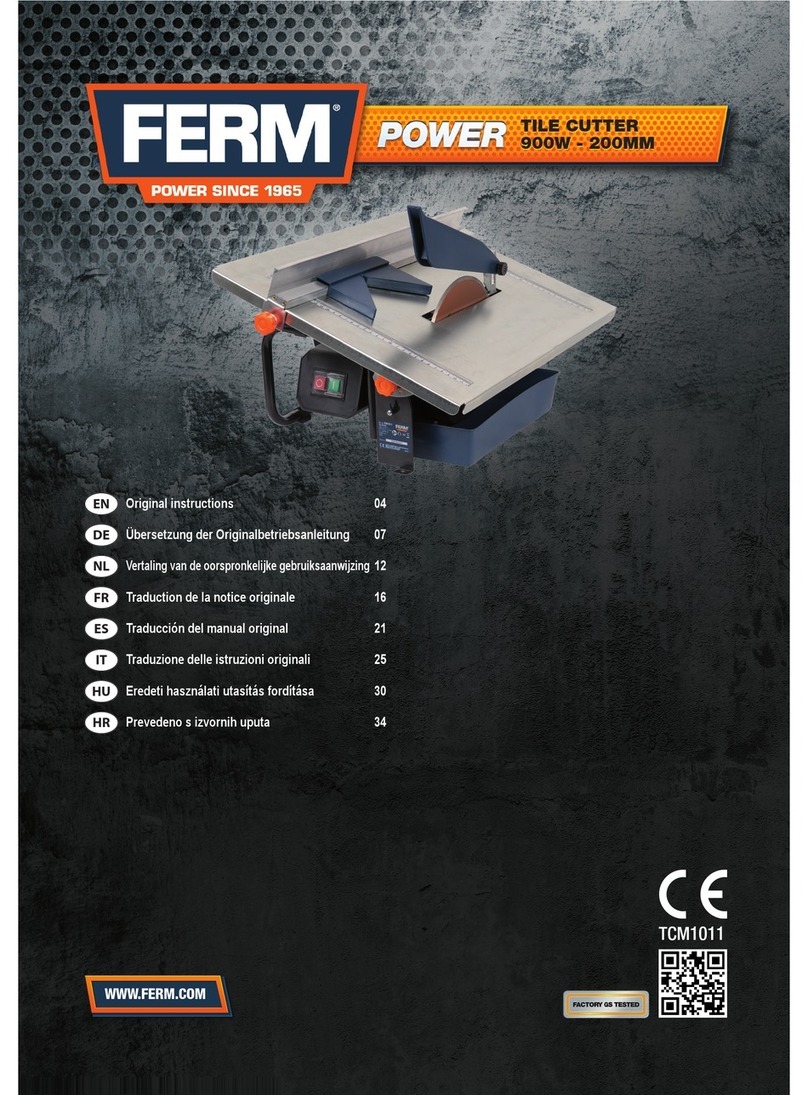

Tile Rite TRP 438 User manual

450 WATT DIAMOND TILE CUTTER

MODEL NO. TRP 438

Please read these instructions BEFORE using your tile cutter

450 Watt Diamond Tile Cutter

WARNING! PLEASE READ THESE INSTRUCTIONS CAREFULLY

BEFORE USING THIS TILE CUTTER

General Safety Rules

Failure to follow all instructions listed below may result in electric shock, fire and/or serious

personal injury, please read and save these instructions.

Work area

Keep work area clean and well lit. Cluttered and dark areas invite accidents. Do not operate

power tools in explosive atmosphere, such as in the presence of flammable liquids, gases or

dust. Tools create sparks that may ignite such substance. Keep bystanders, children and

visitors away while operating a power tool. Distractions can cause loss of control.

Electrical safety

Avoid body contact with grounded surfaces such as pipes, radiators and refrigerators. There is

an increased risk of electric shock if your body contacts with such grounded surfaces.

Do not expose tools to rain or wet conditions. Water entering a tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords

immediately to avoid the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a tool. Do not

use tool while tired or under the influence of drugs, alcohol or medication. A moment of

inattention while operating tools may result in serious personal injury.

Dress properly, Do not wear loose clothing or jewellery. Tie back long hair. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be

2

caught in moving parts.

Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your

finger on the switch or plugging-in tools that have the switch on invites accidents.

Remove adjusting wrenches or switches before turning the tool on. A wrench or a key that is

left attached to a rotating part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enables better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard

hat, or hearing protection must be used for appropriate conditions.

Tool use and care

Do not force the tool. Use the correct tool for your application. The correct tool will do the job

better and safer at the rate for which it is designed.

Do not use the tool if the switch does not turn it on and off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tools. Such preventive safety measures reduce the risk of staring

the tool accidentally.

Store idle tools out of reach of children and other untrained person. Tools are dangerous in the

hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools with

sharp cutting edges are less likely to bind and are easier to control.

Check for misalignment or binding of moving parts, breakage of parts and any other condition

that may affect the tools operation. If damaged, have the tools serviced before using. Poorly

maintained tools cause many accidents.

Use only accessories that are recommended by the manufacturer for your model. Accessories

that may be suitable for one tool may become hazardous when used on another tool.

3

Service

Have your power tool serviced by a qualified repair person using only identical replacement

parts. This will ensure that the safety of the power tool is maintained.

Specific Safety Rules

Always connect to an electrical power point using an approved RCD circuit breaker. This is an

essential safety precaution.

For safety and to prolong the motor life only switch the tile cutter on before cutting a tile and

switch off immediately after use.

Only ever cut one tile one time.

Keep water clear off the electrical parts of the tool and away from persons in the working area.

Always use blades correct in size and arbor shapes. Blades that do not match the mounting

hardware of the saw will run eccentrically causing loss of control.

Never use damaged or incorrect blade washers or bolts. The blade washers and bolts are

specially designed for your saw to ensure optimal performance and safety of operation.

Tool Precaution

Make sure the tool is connected to the voltage marked on its name plate.

Always wear hearing protection, safety glasses and dust mask.

Never touch the moving parts or the blades during use.

Never start the tool when its rotating components are in contact with the work piece.

Check the blade carefully to see if cracked or damaged before use. If cracked or damaged,

replace it immediately.

Keep the cord away from the cutting area and position it so that it will not be caught on the

work piece.

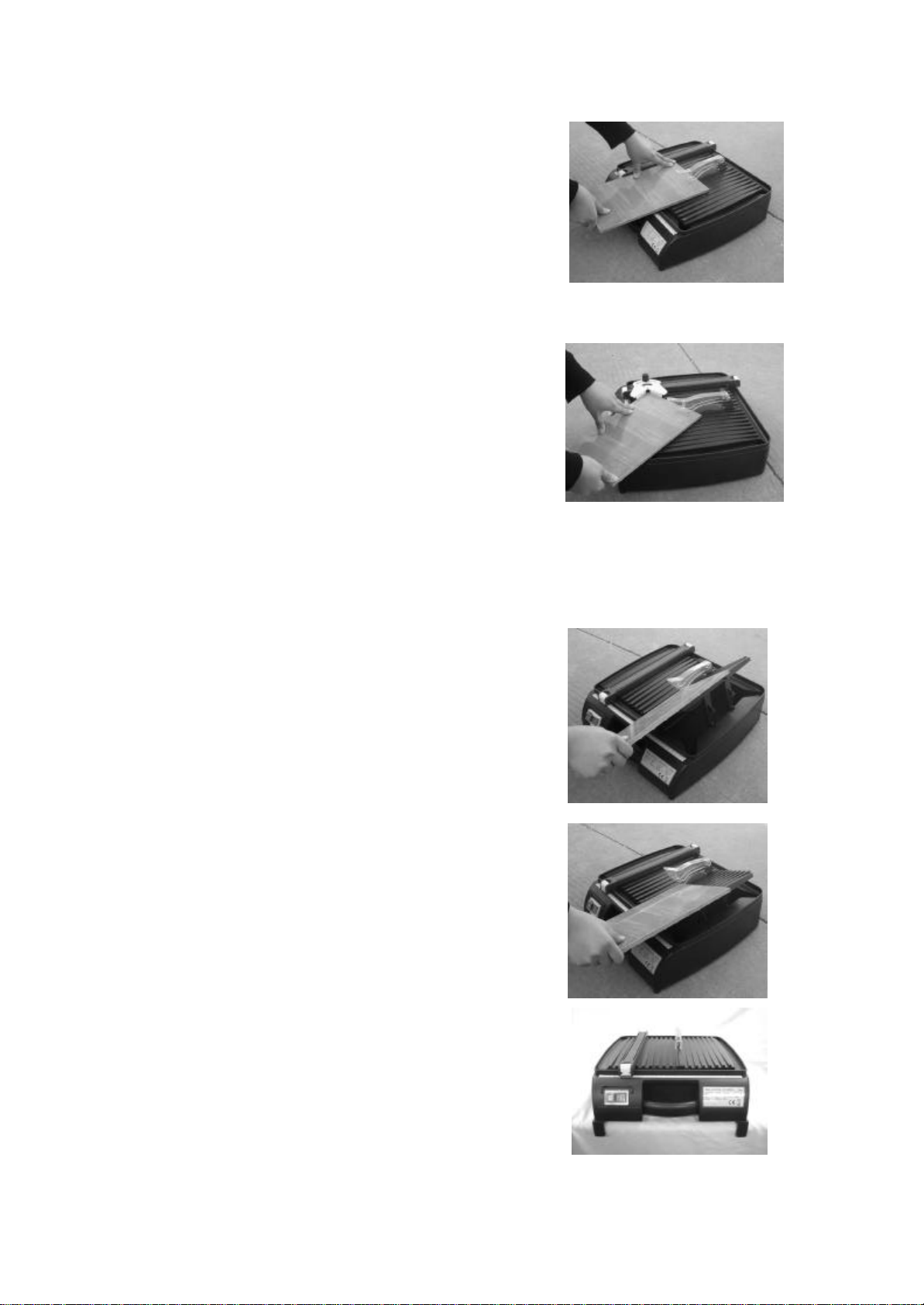

Unpacking

The tile cutter comes partially assembled for packaging purposes. Lay the parts on the bench

and check against the parts list.

-1Pc x Cutting guide

-1Pc x Angle cutting guide

-1Set x Splash guard assembly

(1Pc x Splash guard, 1Pc x Metal plate, 1Pc x Locking bolt, 1Pc x Nut)

-1Pc x Diamond wheel

-2Pcs x Spanners (holding spanner and tightening spanner)

-2Pcs x Bench stops

Once it has been established that all parts are correct proceed assembling as below.

4

Assembly Instructions

Fitting the Diamond Wheel

A. Cutting guide

B. Angle guide

C. Splash guard

D. Water reservoir lid

E. On/Off switch

F. Carry handle

G. Extension table

R. Bench stops

H. Diamond wheel

I. Outer flange

J. Tightening nut

K. Water tank splash guard

L. Lid supports

S. Tightening spanner

T. Holding spanner

lDisconnect the machine.

lLift the water reservoir lid (D) up to remove by pulling the two

pivot tabs upward at the front and back.

l

Remove the water tank splash guard (K) by unscrewing

the screw and the washer.

lLoose the tightening nut (J) using the tightening spanner

(S) while holding the spindle in place with the holding

spanner (T).

lRemove the tightening nut (J) and the outer flange (I).

lFit the diamond wheel (H) onto the inner flange noting the

rotation direction on the diamond wheel. The direction arrows

on the diamond wheel (H) must be in the same direction as

that marked on the splash guard (C), or as that indicated

around the spindle.

lEnsure that the diamond wheel (H) is fully located and centred.

lReplace the outer flange (I) and lock the tightening nut (J) firmly

using spanners (S&T).

lRe-fit the water tank splash guard (K) and the water reservoir

lid (D).

5

Fitting the Wheel Guard

M. Locking bolt

N. Nut

O. Metal plate

P. Screw

C. Splash guard

lLocate the metal plate of the splash guard (C)

into the recess behind the diamond wheel (H) on the cutting blade.

lEnsure the vertical part of metal plateis fitted so it is in line with the diamond wheel (H).

lSecure the metal plate to the cutting table using the screw supplied by screwing down from

the top of the cutting table.

lFit the splash guard (C) by using locking bolt (M) and nut (N) through metal plate (O).

Note: The splash guard has been designed to be loose so that it always rests on the tile or tile

cutting table. This has been necessary to conform to the latest CE safety requirements.

Fitting the Cutting Guide

Q. Cutting guide clasps

lLocate the cutting guide (A) to seat over the

table.

lFirmly clasps the cutting guide at both ends.

Operating Instructions

Starting up

lLift the water reservoir lid (D) up to remove by pulling the two pivot tabs upward at the front

and back.

lFill the water reservoir with water to the recommend level. Do not overfill.

lConnect the machine to the mains by using a RCD circuit breaker.

lStart by means of the On/Off switch (E). To start the machine, press the green On (1)

button.To stop the machine, press the red Off (0) button.

NOTE. In the event of a power failure while the machine is operating the motor will not

restart when the power is restored until the green button is pressed.

6

Straight cuts

lLoosen the cutting guide clasps (Q) at both ends of the

cutting guide (A).

lSet the cutting guide (A).

lRelock cutting guide clasps (Q).

lPlace the piece of tile against the cutting guide (A) then

push the work piece towards the diamond wheel (H).

Diagonal cuts

lLoosen the cutting guide clasps (Q) at both ends

of the cutting guide (A).

lSet the cutting guide (A) to the distance required.

lRelock the cutting guide clasps (Q).

lHook the angle guide (B) onto the cutting guide (A).

lChoose the angle desired and tighten the bolt to secure

the angle guide (B) in conjunction with the cutting

guide (A).

lPush the angle guide (B) together with the tile to be cut towards the diamond wheel (H).

Mitre Cuts (22.5°and 45°)

lLift up the water reservoir lid (D).

lPull out the two lid supports (L) located on the back

of the water reservoir lid (D).

lTo cut 22.5°angles, place the two upper 22.5°mitre

stays on the lid supports (L) into the two slots located

inside the water reservoir.

lTo cut 45°angles, place the two lower 45°mitre stays

on the lid supports (L) into the two slots located inside

the water reservoir.

lPlace the piece of tile facing down onto the water

reservoir lid (D) then push the work piece towards the

diamond wheel (H).

Using the Bench stops

lLocate and place both of the bench stops (R)

underneath the front bottom legs on both left and right

ends.

7

Using the Extension Table

lSlide outwards the extension table (G) to get the

maximum working table length this tile cutter can

provide.

Maintenance

WARNING!

When servicing, use only identical replacement parts. Use of any other parts may create

a hazard or cause product damage.

Always ensure that the machine is disconnected from the power supply before any

maintenance or adjustments are carried out.

Cleaning:

lKeep the ventilation slot of the machine clean to prevent overheating of the motor.

Regularly clean the machine housing with a soft cloth, preferable after each use. Keep the

ventilation slot free from dust and dirt. If the dirt does not come off use a soft cloth

moistened with soapy water.

lNever use solvents such as petrol, alcohol, ammonia water, etc. these solvents my

damage the plastic parts.

8

Technical Specifications

Voltage/Frequency 230-240V~ 50Hz

Motor Power 450W

Duty Cycle S2:30min

No-Load Speed 5400/min

Blade size ø110mm (D) -Bore ø22.23mm

Max. Cutting Thickness To 90°:23mm –to 45°:16mm

Ingress Protection (IP) IP23

Sound pressure level 92.6 dB(A)

Sound power level 105.6 dB(A)

Symbols

This symbol is known as the 'Crossed-out Wheelie Bin Symbol'. When

this symbol is marked on a product or battery, it means that it should not

be disposed of with your general household waste. Some chemicals

contained within electrical/electronic products or batteries can be

harmful to health and the environment.

Only dispose of electrical/electronic/battery items in separate collection

schemes, which cater for the recovery and recycling of materials

contained within. Your co-operation is vital to ensure the success of

these schemes and for the protection of the environment.

9

10

Wear eye protection.

Wear respiratory protection.

Wear protection gloves

Wear hearing protection.

Read the instruction manual

Wear foot protection.

Warning.

Use correct size of blades.

Wet cut only.

Do not use segmented blade.

Attention! Risk of injury! Do

not hold hands into the

rotating disc!

Conforms to relevant safety

standard.

Table of contents