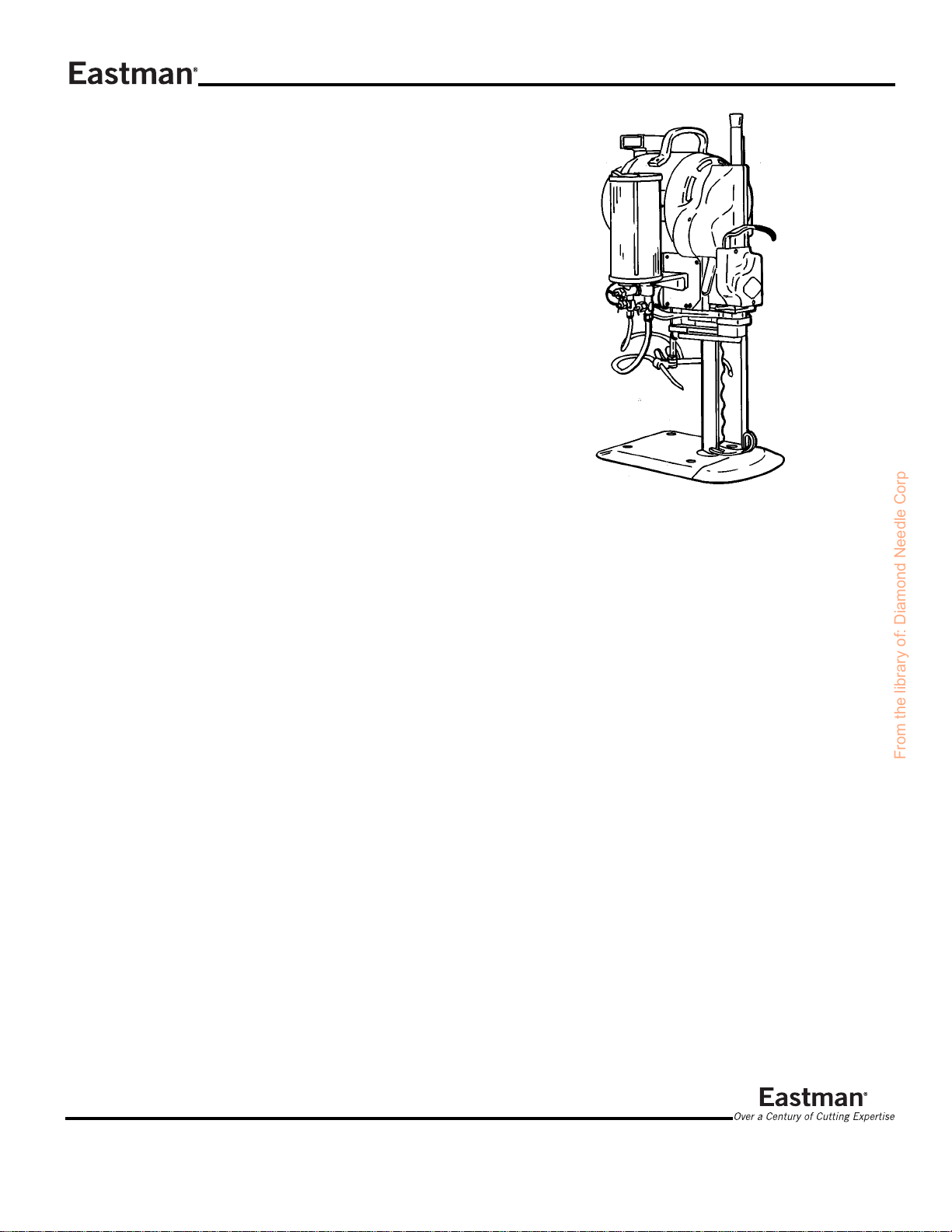

Plastic Master

Model 627PM/629PM

Maintenance, Instruction and

Parts List

OPERATINGINSTRUCTIONS

Before turning machine on, swing felt pads into operating

position with felt pads bearing exactly on knife. Turn valve

(23) counterclockwise to allow EASTMAN lubricant to flow

freely without restriction. Open left and right valve (25) by

turningcounterclockwiseequalamountstoinsureequalflow

fordesirelubrication.

SHARPENING

Takethemachineoutofthelay.Swingfeltholdersoutofthe

way by pressing levers 36 and 46 together. Drop KNIFE

GUARD/PRESSUREFOOTbymeansofpressurefootlever

located next to machine operating handle. Press lever

downwardwithaslow,firmpressuretoengagesharpening

mechanism.Toofastleveractionmaycauselevertolock,if

thisoccurs,liftleverandstartover. Afterafewtriesyouwill

feelcorrectoperatingpressure. ForbestresultsuseGENU-

INEEASTMANWaterproofBeltsandGENUINEEASTMAN

HighSpeedWaveKnives.

CAUTION: Toavoidextensivedamagetomachine,

swing felt holders out of the way by

pressinglevers36and46together

BEFOREoperatingsharpener.

LUBRICATION

With electrical cord disconnected, fill water can assembly

with diluted EASTMAN Concentrated PLASTIC MASTER

FLUID. Fluidmustbedilutedwithplainwaterbeforeanyuse.

Addtwoouncesoffluidwithonegallonofwater.Shakeorstir

thoroughly.

NOTICE: TheEastman MachineCo. doesnot warrantthis

PlasticCuttingFluidanddisclaimsallliabilityfor

any damage that may occur through its use.

All reference numbers shown herewith refer to the partlist

andillustrationon the followingtwopages.

SupplementtoEastmanBlueStreakIIInstructionBookand

PartsList. AllInstructionsandSafetyWarningscontained

intheBlueStreakIImanualmustbereadandfollowed. Only

instructions and parts special to the Eastman Plastic

Master Option are contained in this booklet and referral to

the Blue Streak II Book must be made.

FELTHOLDERADJUSTMENT

If felt holders do not bear exactly on knife, adjustment is

required. Loosensetscrews(37),adjustandtightenscrews.

To adjust for height, loosen thumb nut (29), adjust and

tighten.

FELTREPLACEMENT

With electrical cord disconnected, remove moistening de-

vicefrommachinebyremovingthumbnut(29)androdscrew

(34).Removewornfelts(43)andreplacewithEASTMANpart

191C1-14. Replacemoisteningdevice, thumb nutandrod

screw.

FormC-1498

779 Washington St., Buffalo, N.Y. 14203-1396 U.S.A. • (716)856-2200 • Fax (716)856-1140 or (716)856-2068

ManufacturersofEastman Cloth Cuttingand Cloth SpreadingMachines

Website: www.EastmanCuts.com

From the library of: Diamond Needle Corp