TILLOTSON HS Series User manual

+6

6(5,(6

SERVICE MANUAL

TILLOTSON LTD., CLASH INDUSTRIAL ESTATE,

TRALEE, CO. KERRY, IRELAND

PHONE: +353 66 7121911 FAX: +353 66 7124503

e-mail: sales@tillotson.ie

2

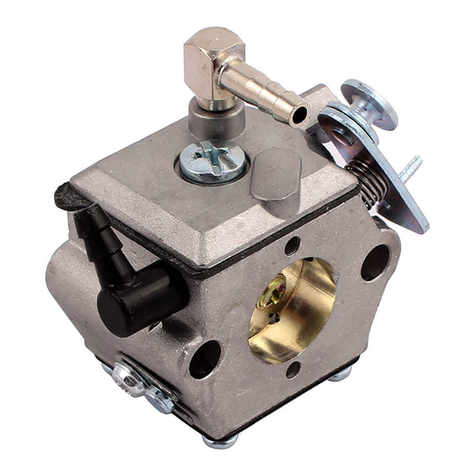

The demand for a miniature all position diaphragm

carburetor prompted Tillotson to design and develop

the “HS” series. This small compact unit, only a 1-1/2

inch cube, is versatile in application because of its

lightweight and compact size. Even though the

carburetor is extremely minute, it still comprises a

self-contained fuel pump and filtering screen.

The “HS” series carburetor is die-cast aluminium,

consisting of three basic parts: metering body, pump

cover plate and main diaphragm cover plate. This

carburetor incorporates many of the components

found in float type carburetors: choke, throttle, idle

and high speed mixture screw and inlet needle.

Information contained in the following pages is

presented as an aid to understanding construction,

operation and servicing of the “HS” series carburetor.

Complete carburetors, repair kits and service parts

are available through our dealers.

Idle and high speed mixture screws are spring friction

type and require no packing. These mixture screws

are located on the right side looking toward air horn.

A rubber tipped needle seats directly on a machined

orifice in the body casting. An inlet tension spring

CONSTRUCTION DATA AND CHART

HS SCHEMATIC

1. Filtering Screen

2. Venturi

3. Pulse Chamber

4. Fuel Chamber

5. Fuel Pump Diaphragm

5A. Diaphragm Pump Inlet Valve

5B. Diaphragm Pump Outlet Valve

6. Fuel Pump Body

7. Fuel Pump Gasket

8. Fuel Inlet

9. Impulse Channel

10. Throttle Shutter

11A Primary Idle Discharge Port

11B Secondary Idle Discharge Port

12. High Speed Mix. Screw Orifice

13. Idle Mixture Screw

14. Body

15. Metering Chamber

16. Idle Mixture Screw Orifice

17. Diaphragm

18. Atmospheric Chamber

19. Atmospheric Vent

20. Diaphragm Cover

21. Inlet Tension spring

22. Fulcrum Pin

23. Diaphragm Gasket

24. Inlet Control Lever

25. Inlet Needle

26. High Speed Mixture Screw

27. Choke Shutter

28. Fuel Inlet Supply Channel

29. Main Nozzle Discharge Port

INTRODUCTION

3

exerts a pre-determined force on the inlet control

lever, which holds the needle on its seat.

A metering diaphragm is subjected to engine suction

on the metering chamber side and atmospheric

pressure on the vented side. Atmospheric pressure

on the vented side pushes the diaphragm toward the

inlet control lever opening the inlet needle to allow

fuel to enter the metering chamber, from which it is

then delivered into the mixing passages.

The inlet control lever hooks on the center of the

metering diaphragm and a self tapping screw holds

the fulcrum pin place.

Movement of the pump diaphragm is caused by

pulsation’s from the engines, acting on it through an

impulse channel. This movement draws fuel into the

fuel chamber and a reverse movement forces fuel out

of the fuel chamber through the inlet needle into the

metering chamber.

An easily accessible fine mesh-filtering screen is

located under the fuel pump cover and diaphragm.

Before disassembling carburetor it is imperative to

blush it clean of sawdust and dirt by pouring gasoline

over it and tools.

1. Remove pump diaphragm cover screws and

cover.

2. Remove pump gasket and pump diaphragm.

3. Remote filtering screen.

4. Remove main diaphragm cover screws and

cover.

5. Remove main diaphragm and gasket (slide

diaphragm towards mixture screws approximately

1/16

th

of an inch and pull up to unhook from the

control lever).

6. Remove fulcrum pin screw, pin, control lever and

spring….

7. Remove inlet needle.

8.

Remove idle and high speed mixture screws and

springs.

Commercial carburetor cleaner can be used on all

parts except diaphragms and gaskets. Before

reassembling, rinse all parts in clean gasoline and

blow off with compressed air. Do not use cloth, as

tiny particles of lint adhering to carburetor parts will

cause malfunction. Channels in the metering body

can be cleaned by blowing through idle and high

speed mixture screw orifices. Do not use wires or

drills to clean orifices.

23(5$7,21$/'$7$

ADJUSTMENT INSTRUCTIONS

Open high speed mixture screw one and one quarter (1¼) turns.

Open idle mixture screw one (1) turn.

SERVICE DATA

HOW TO DISASSEMBLE FOR CLEANING AND REPAIR

4

Starting an engine with the “HS” Carburetor involves

the same methods used in a conventional float feed

carburetor.

When starting a cold engine, place the choke shutter

in the closed position and throttle shutter in a cracked

or open position. As the engine is cranked, engine

suction will be transmitted to the diaphragm fuel

chamber through both primary and secondary idle

discharge ports as well as the main fuel discharge

port, creating a low pressure area on the fuel side of

the main diaphragm. Atmosphere air pressure on the

opposite side will force the main diaphragm upward

causing the diaphragm button to depress the inlet

control lever, overcoming inlet tension spring

pressure, permitting fuel to enter through the inlet

seat, then into the fuel chamber side of main

diaphragm, up through the idle and high speed fuel

supply orifices and channels, and out the discharge

ports to the engine.

When engine is idling, throttle shutter is partially

cracked. Engine suction is transmitted through the

primary idle fuel discharge port to the fuel chamber

side of main diaphragm via the idle fuel supply

channel. Again, the main diaphragm is forced upward

by atmospheric pressure, depressing the inlet control

lever overcoming inlet tension spring pressure and

permitting fuel to enter through inlet seat, and filling

the fuel chamber. Fuel is then drawn up through idle

mixture screw orifice and delivered to the engine

through primary idle discharge port.

OPERATIONAL DATA

STARTING (CHOKE) OPERATION

IDLING OPERATION

5

Fuel is delivered into and through the carburetor in

the same manner as when the engine is idling.

However, as the throttle opens and the engine speed

increases, more fuel is supplied to the engine by

valving in the secondary idle discharge port located

immediately behind the throttle shutter.

As the throttle shutter continues to open and engine

Speed increases, the velocity of air through the

venturi creates a low pressure area at the venturi

throat and diminishes the suction on engine side of

the throttle shutter. When the pressure at the venturi

throat is less than that existing within main diaphragm

fuel chamber, fuel is drawn up through high speed

mixture orifice and out main fuel discharge port into

the air stream entering engine intake.

As the throttle shutter progressively opens from

intermediate position to full open position, the air

velocity through the venturi increases and fuel is

metered up through high speed mixture orifice and

main fuel discharge port in accordance with the power

requirements of the engine. The action of the main

diaphragm is the same as previously described with

suction required to operate the diaphragm being

transmitted through the main fuel discharge port.

INTERMEDIATE OPERATION

HIGH SPEED OPERATION

6

SERVICE HINTS

Be certain both diaphragms are installed correctly -

the

pump diaphragm next to the metering body, then the

gasket – the main diaphragm gasket, then the main

diaphragm. Evenly tighten all screws to insure

complete

seal.

When reassembling the inlet control lever and spring,

care should be taken to see that the spring rests in

the well of the metering body and locates on the

dimple of the inlet control lever (as illustrated above).

CAUTION: Do not stretch spring. Inlet control lever is

properly set when flush with the floor of the

diaphragm chamber. If diaphragm end of control

lever is low, pry up. If lever is high, depress

diaphragm end and push on needle for proper

adjustment. (See illustration). On some models the

inlet control lever is hooked to both the inlet needle at

one end and the metering diaphragm at the other. On

other models the inlet lever is hooked to the inlet

needle while the opposite end of the lever merely

rests against the metering diaphragm. Special care is

required when reassembling these parts to insure

proper operation.

CAUTION:

Under extreme conditions of

clogged idle fuel channel and discharge ports, it may

be necessary to remove the channel welch plug. If

so, it must be done very carefully in the following

manner:

Drill a 1/8 “ diameter hole through the

11/32” diameter welch plug. This hole

should just break through the welch plug.

Deeper drilling will seriously damage the

body casting and render the carburetor

non-serviceable.

Carefully pry out the welch plug and

clean discharge ports and cross

channels. To reinstall, place welch

plug in well, convex side up, and flatten

with a flat end tool slightly larger than

the welch plug. Nozzle welch plug can

be removed in the same manner by

using a 1/16” drill.

SERVICE DATA

2

1

7

CARBURETOR

FLOODS

ENGINE

WILL NOT

ACCELERATE

ENGINE WILL

NOT IDLE

ENGINE RUNS

OUT LEAN

CARBURETOR

RUNS RICH

WITH HIGH

SPEED MIXTURE

SCREW SHUT

OFF

Dirt or foreign particles preventing

inlet needle from seating.

Diaphragm lever spring not seated

on lever dimple

Diaphragm improperly installed in

carburetor

Idle mixture too lean.

Incorrect setting on diaphragm lever.

Diaphragm cover plate loose.

Diaphragm gasket leaking

Main fuel orifice plugged

Incorrect idle adjustment

Idle discharge ports or channels

clogged.

Diaphragm lever set incorrectly.

Throttle shutter cocked in the throttle

bore causing fast idle.

Dirty nozzle check valve or outlet

screen.

Welch plug covering the idle discharge

ports does not seal. This causes the

engine to idle with idle mixture shut off.

Tank vent not operating correctly.

Leak in fuel system from tank to

pump

Ruptured fuel pump diaphragm

Main fuel orifice plugged

The 7/32 “ diameter nozzle welch

plug, or nozzle check valve cage, is

not sealing.

Remove, clean and replace

Remove lever and reinstall

Replace diaphragm or correct

installation.

Readjust

Reset

Tighten

Replace

Remove diaphragm cover,

diaphragm, diaphragm lever and

high speed mixture screw. Clean out

orifice by blowing through high

speed mixture screw threaded hole.

Reset to best idle

Blow out with compressed air, or, if

compressed air is not available,

clean and flush with gasoline.

Reset diaphragm lever so it is flush

with the floor of the diaphragm

chamber.

Reset

Clean or replace.

Replace welch plug, following

instructions outlined in service hints.

Clean, if possible, or replace

Tighten or replace fittings or line

Replace

Clean

Install new plug or

new cage

Note: IN MAKING CARBURETOR ADJUSTMENTS TURN ADJUSTMENTS

CAREFULLY AND GENTLY – DO NOT RAM ADJUSTMENTS INTO SEATS.

Set engine idling speed in accordance with engine manufacturer’s recommendation.

TROUBLE DATA

TROUBLE PROBLEM REMEDY

8

Table of contents

Other TILLOTSON Engine manuals

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton 190000 Series Operator's manual

Generac Power Systems

Generac Power Systems GN-220 owner's manual

MOTO GUZZI

MOTO GUZZI V750 IE Service station manual

hager

hager HXE04.H User instructions

Kohler

Kohler KD83V16 Service and repair manual

SOMFY

SOMFY sonesse 30 rts instructions